Building a brick smokehouse with your own hands. Two in one - oven with barbecue and smokehouse made of brick DIY cold smoked smokehouse made of brick

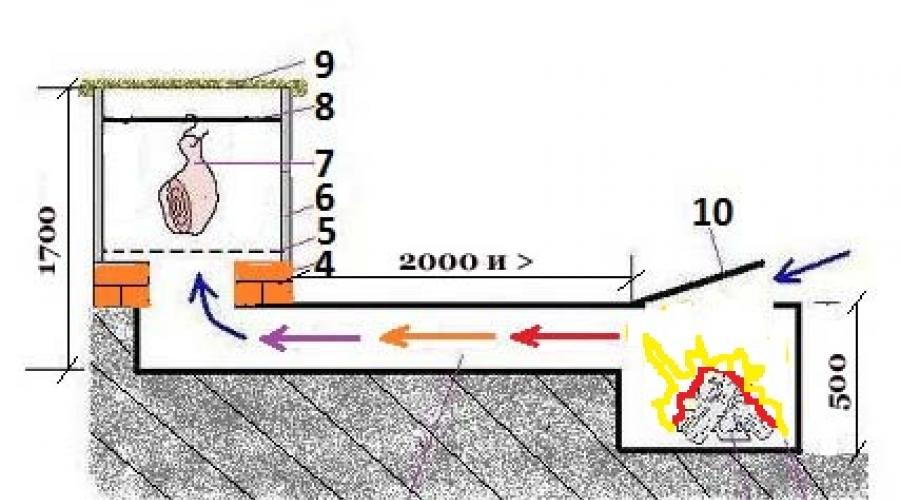

The cold smoking process is different in that the products are exposed to cold smoke, the temperature of which does not exceed twenty-five degrees. Therefore, all drawings of a cold smoked smokehouse take into account the location of the firebox at some distance. While the smoke goes through the pipe and rises in the smoking chamber, it cools and is freed from soot and harmful impurities.

Do-it-yourself cold smoked brick smokehouse. Step-by-step instruction

Before starting construction directly, you need to do drawing cold smoked smokehouse and mark the location of all its components on the site. The combustion chamber must be no less than two and a half meters. It is better to choose a place with a slope, so that the smoking chamber itself is located on a hill, and the firebox is located on a slope.

Cold smoked smokehouse. Operating principle

The most thorough and reliable design is a cold smoked brick smokehouse. To build it correctly, you need to take several points into account. The step-by-step instructions for building a cold smoked smokehouse cover all the details of the process.

. Stage one - laying the foundation

At the place where it will be located smoking chamber, soil is selected. The depth of the pit should be sixty centimeters. Formwork is installed in it, rising twenty-five centimeters above the edges. The space is reinforced, placed in the center ten liter bucket to create a recess after pouring concrete mortar. At this point, smoke will come out of the chimney. Before pouring, it is necessary to lay a pipe that will supply smoke. When all necessary elements will be placed, the foundation space is filled with concrete mortar.

. Stage two - erection of walls

For the walls of such a smokehouse it is used building brick or concrete blocks

. The specific design of a cold smoked smokehouse depends on the personal wishes of the owner. She may be quite small for minimum quantity products or spacious. You can install a window in it, but it should be small. Because the Sun rays harmful to smoked products, it should go to north side or be positioned so that light does not fall on the area where smoked meats are placed.

. Stage three - roof arrangement

The most economical, easy to install and convenient option is soft roof

. To create it, a small section of timber is used to construct rafter system. Lay on the rafters sheet material, for example, moisture-resistant plywood or OSB boards. The elements of flexible tiles are already mounted on a flat base.

. Stage four - arrangement of the firebox

The firebox can be made of brick or used as such metal stove

. If brick is used, then you need to take fireproof fireclay. You also need a fireproof pipe that will remove smoke from the firebox to the smoking chamber. The diameter of the pipe must be large enough so that the smoke flows slowly, cools and is freed from soot particles.

. Stage five - interior arrangement

The interior of the smokehouse is very simple. Installed above the smoke exit hole gratings and are hung hooks.

After this, the cold smoked brick smokehouse can be used.

DIY cold smoked smokehouse. Photo

The terrain of the site with slopes and terraces simplifies the installation of a cold smoked smokehouse. The presence of a terrace allows you not to deepen the firebox into the ground. It can simply be placed on the lower tier, and a smoking chamber can be installed on the upper tier. As a result, the amount of work is reduced, the smokehouse is built faster, with less labor and time.

Step-by-step instruction for the construction of a cold smoked smokehouse. Video

DIY cold smoked wood smokehouse. Step by step photos

To make a cold smoked smokehouse with your own hands, it is not at all necessary to use brick. Wood is also excellent for this purpose. Step-by-step instructions for building a cold-smoked smokehouse from natural wood will help in construction.

1. They dig up the site trench for pipes, smoking and combustion chambers. The depth of the trench should be from one and a half to two spade bayonets. The part intended for the pipe is located slightly higher than the smokehouse pit.

DIY cold smoked smokehouse. Photo

2. Pit for smoking chamber dig two or three shovels deep. When it gets into it, the smoke is slightly delayed. At this time, large particles of soot fall out of it, i.e. the smoke clears. After this, it rises into the smoking chamber.

3. The fire pit is filled cement to create a reliable floor. This level base It is necessary that the combustion chamber made of brick does not subsequently collapse due to natural soil movements.

4. Place in the chimney trench pipe. Its diameter should be sufficient for the smoke to pass freely to the smoking chamber, cooling along the way.

5. Posted combustion chamber

. To do this, take refractory bricks, from which the walls of the firebox and its upper part are made.

6. Attach a cast iron door to the firebox, which closes securely. This will force the smoke to take a longer path through the chimney and prevent it from being lost.

Step-by-step instructions for building a cold smoked smokehouse. Photo

7. For a cold-smoked smokehouse made of wood, set up base. For this building bricks lay out the walls of the recess under it and bring them to a certain height above the ground. For this brick base then the wooden part of the structure will be installed directly.

8. The trench with the chimney pipe is covered with earth and thoroughly compacted. Earth is needed for better cooling of the chimney and smoke. Wet soil conducts heat better than air.

9. Create a wooden smoking chamber:

To make a cold smoked smokehouse from wood, use wooden blocks. It is advisable to take material from hardwood. The base of the future chamber is assembled from the bars.

DIY cold smoked smokehouse. Photo

Smooth planks are placed on the base. They should fit as tightly as possible to each other so that smoke does not escape through the cracks.

The roof is made single or gable. The door is attached to the front so that it fits tightly and opens easily. A latch will help prevent spontaneous opening.

A hole is left in the roof for the pipe and it is installed there. The pipe should be of small diameter so that the smoke does not escape too quickly.

The first kindling will help check the correct operation of all parts.

Smokehouse from a barrel

If all previous options seem complicated and expensive, then you should pay attention to a cold smoked smokehouse from a barrel. The basis of the slipper design will be a barrel made of wood or other material. The only exception is plastic. The bottom of the container is removed so that the smoke can pass through.

To make a cold smoked smokehouse with your own hands, you need to dig two holes in the ground for the firebox and smoking chamber, as well as a trench connecting them. The firebox should be about fifty centimeters in diameter and about forty centimeters deep. The bottom is covered with a sheet gland. The walls can be reinforced with brick, but the firebox will function even without it.

Pit under smoking chamber They dig out of the barrel at a distance of about three meters. The diameter should be slightly smaller than the diameter of the base of the barrel, and the depth should be about forty centimeters.

The pits connect trench, which will be used to hold the smoke. The depth of the trench should be about thirty centimeters. The finished trench is closed metal sheets, covered with earth and compacted. It is not necessary to use a pipe, but it is better to compact the walls of the trench so that they do not crumble over time.

Attached to the bottom of the barrel metal grate. It will be covered with smoke filtering material, such as straw or burlap. Filter materials are moistened so that they better clean the smoke from large particles of combustion products. This layer makes the smoke lighter, thinner, and free of soot. In addition, the grate will not allow food to fall into the depths of the pit.

Install at the top of the barrel rods, on which the meat hooks will be attached. You can install and grille for product placement.

The resulting cold smoked smokehouse from the barrel is covered with burlap, wooden shield or similar material. The smokehouse is ready and can be used for its intended purpose.

To prevent smoke from getting lost and coming out from underneath the barrel, its base is covered with earth. This soil around the base is carefully compacted.

Cold smoked smokehouse from an old refrigerator

In almost every household you can find old refrigerator, which has long been broken. In order not to increase the amount of garbage, it, or rather the body, can be used to make a smokehouse.

Building a cold smoked smokehouse from an old refrigerator is not at all difficult. To do this you will need to take refrigerator body(the insides are dismantled), a pipe about four meters long, heat-resistant bricks for arranging the firebox and an iron lid for it.

The firebox is installed below the level of the smoking chamber. It is better to use a site that has a slope for convenient placement. For the firebox, a hole is dug and laid out heat-resistant brick. If the farm has a metal container of sufficient volume, then you can dig it in. It is closed on top with a metal lid so that the smoke goes into the chimney.

The next element of a cold smoked smokehouse from an old refrigerator is pipe for smoke removal. She must be pretty long length so that the smoke, passing through it, has time to cool. In addition, it is recommended to bury the pipe underground. Surrounded by damp earth, it will cool down better and cool the smoke to the desired temperature.

The pipe entry into the refrigerator body can be done in two ways. In the first case, the connection is made to existing holes, which served to accommodate the main working parts of the refrigerator. In this case, the entrance can be either at the top or at the bottom. The specific option depends on the refrigerator model.

Second way - pipe insertion V bottom part housings. It requires extra work, but it provides the most optimal smoke supply. It will run from the bottom up and provide best result, since more smoke will pass through the product.

Inside the refrigerator body is equipped with all necessary equipment for product placement. Lattice shelves or hooks are used to allow meat or fish to be hung.

Finally, the homemade smokehouse should be equipped chimney for smoke outflow. But it will only be needed if the seal on the door is still quite effective and does not create cracks. In most cases, the seal on an old refrigerator leaves small gaps through which smoke escapes.

This option for disposing of an old refrigerator can be considered the most optimal, because... it will still serve usefully.

Home cold smoked smokehouse "Dym Dymych"

If you look at the drawings of a cold smoked smokehouse, you realize that they are not suitable for a small personal plot, then you should pay attention to home smokehouse Smoke Dymych.

This household smokehouse is made from cold-rolled steel sheet

, the thickness of which is eight tenths of a millimeter. The smoking container has a volume of thirty-two liters. The kit includes a smoke generator and compressor. Smoke enters the smoking chamber through a flexible hose.

IN smoke generator The smokehouse is filled with wood chips. There smoke is released, which is sent to the smoking container. The smoke supply is regulated using an electric compressor. Through a hose, the length of which is seventy-four centimeters, the smoke passes to the stored products. Smoking times depend on several factors. Firstly, they depend on the weight and volume of the products, and secondly, on the activity of the smoke treatment. The result is time frames ranging from five hours to fifteen.

This smokehouse has several advantages. It is compact and can be stored anywhere when not in use. The device can be used not only in conditions suburban area, but also in the city, for example, on a balcony or near the house. Smokehouse Dym Dymych is sold in a form that is completely ready for use. It does not require pre-assembly or manufacturing in-house.

With the help of a smokehouse, delicious smoked products can be easily and relatively quickly produced. Prolonged treatment with cold smoke creates an environment unfavorable for bacteria. As a result, the product not only gets a unique taste, but is also stored much longer.

From the presented variety of devices for cold smoking, everyone can choose the best option for themselves. If you don’t want to build a smokehouse yourself, and the cooking volumes are small, then last option. If you want to make a special, your own smokehouse or save money, then you can choose any of the options, made by yourself.

It is also worth mentioning that products must be prepared before smoking. They are pre-salted according to a certain scheme. If this is not done, then real smoked meats will not turn out from them.

A good solution for your own yard would be a brick smokehouse. Available on the market wide choose models, it is possible to purchase a ready-made small structure, but make stationary device you can do it yourself. Installation work does not require large material investments and excessive physical effort; it is enough to select the material and create a project.

Types of smokehouses and drawings

You can make your own device that would perform the function of saturating food with smoke from different materials, but the advantages similar design made of brick are undeniable:

- practicality;

- strength;

- Beautiful appearance;

- possibility of repair work.

Due to the fact that all meat and fish preparations can be smoked, there are several types of devices that differ in the following characteristics:

- by size - small, medium, large;

- by type of device - cold or hot smoking;

- according to the function performed - only smoking, grilling, etc.

Each variety involves separate drawing, where all elements of the smokehouse are indicated. The accuracy of the design and sizing depends on correct work devices. Plan - important stage installation process that will help you build a smokehouse, organize and facilitate construction works. Drawings can be ordered from an architect or drawn up yourself. The only thing that is necessary is to adjust the diagram to the selected type of device and take into account the nuances of a separate building.

Cold smoking devices require longer cooking.

Components of a brick smokehouse

A brick smokehouse consists of several parts that are interconnected, and the functions of each of them provide the effect produced by the smokehouse as a whole. Construction projects include the following elements:

The structure is made up of several important components.

The structure is made up of several important components.

- stove;

- blower;

- chimney;

- smoking compartment;

- door;

- overlap;

- metal grille and horizontal rods with hooks;

- compartment for collecting fat.

The essence of the work brick structures next: they put it in the firebox thin logs When burned, they emit thick smoke. Rising up the chimney, the substance enters the smoking chamber. The substance that remains after the fire goes out remains in the ash pit, which is located above the firebox. During the smoking process, products release fat, which accumulates through the grate in the grease trap.

Where is the best location?

You can determine where to build a smokehouse based on the following characteristics:

Before starting work, you need to make sure that groundwater go deep enough.

Before starting work, you need to make sure that groundwater go deep enough. - distance from residential premises;

- lack of plants and animal enclosures at close range;

- The size of the hot smoking device depends on the type of smoker chosen;

- place the structure on a flat surface;

- make sure the groundwater is deep.

After choosing a location, you need to make preparations before you start building your smoking oven. Trees, bushes and thickets are removed from the territory. After this it is removed upper layer grass cover and a pit is dug out. Sometimes the place where the device will be installed is sprinkled with pebbles, crushed stone or dry sand.

Required materials and tools

A brick smokehouse requires a careful approach to the selection of raw materials and consumables. Before construction, you must prepare the following:

- masonry bricks with which the layout will be carried out;

- clay;

- cement and sand;

- metal bars and lid;

- doors made of wood;

- metal grid for laying out products;

- corner;

- covering material;

- level and plumb;

- trowel, hammer, spatula;

- container for mixing the solution.

Step-by-step instruction

First you need to build a solid foundation.

First you need to build a solid foundation. Even the simplest smokehouse, which has small sizes, requires strict order and adherence to rules during the installation process. Before installing the grill and grates, it is important to properly build the foundation and walls, since the durability and proper operation of the structure depend on these elements. Step-by-step instructions are developed before starting installation work. In this case, the risk of error is minimal.

Construction of the foundation

Before laying the foundation for the future structure, they carry out accurate measurements. To mark the location, you need to install in extreme points wooden pegs and stretch a rope between them. The depth of the foundation is calculated depending on the size of the smokehouse: for a small building 40 cm is enough, while for large structures it is necessary reinforced foundation with greater depth. To construct the base, a mixture of sand and cement is used. For greater strength, crushed stone or gravel is added to the components.

Sometimes the trench under the foundation is filled with construction waste.

After laying out the bottom of the trench with material, the foundation is poured and left until completely dry. To provide additional reliability to the device, it is recommended to cover the base with a layer of roofing felt. Additional strengthening can be achieved by laying out the base. To do this, formwork is installed around the foundation and bricks are laid out in a simple order.

Smoking is not only tasty, but also one from universal methods preservation of meat products and fish for a long time. Most commercially available portable smokers allow you to cook meat or fish only by hot smoking. It’s quick, but such products are stored without refrigeration for 2–3 days.

In order to be able to enjoy smoked ham or delicious muksun at any time, you need to prepare them using the cold smoking method. And this is only possible in a stationary smokehouse or a very expensive imported one, which simulates the smoking process using electronic hardware.

What is this article about?

Examples of designs

Build a stationary brick smokehouse on garden plot It is advisable if you have a subsidiary farm or you produce a significant amount of fish or meat.

Simple outdoor smokehouse for hot smoking

To do this, you can build a simple, free-standing structure that will perform only one function - smoking.

With a hob in the house for hot smoking

More often, in order not to waste time heating the stove and smokehouse separately, they build a stove with hob, in the chimney of which they arrange smoking cabinet. The benefit of such a structure is obvious - at the same time, on one stack of firewood, during the cooking process, the process of hot smoking occurs.

Scheme Appearance

Large universal ovens with hot smokers

Lovers big companies and noisy feasts, not thinking about rest in nature, without barbecues or barbecues, entire furnace combines are built: stove-fireplace-barbecue-smokehouse.

From economic points of view, this design is advantageous because it is combined common walls and has one chimney.

Despite the massiveness of the structure, such oven with barbecue and smokehouse does not require large quantity firewood The structure is located outdoors, so it does not require heating of the walls.

The grill, cooking area and smokehouse are heated separately. Essentially, they all represent independent ovens connected together, and can be rearranged or supplemented at will.

The simplest cold smoked smokehouse

Such a smokehouse is actually made from scrap materials; its structure is completely clear from the drawing.

Smokehouse for hot and cold smoking

If desired, you can build a smokehouse out of brick, which will simultaneously prepare hot and cold smoked products.

The principle of such a smokehouse is extremely simple. It contains one smoking chamber; in the photo it has the largest door. One of the fireboxes is located directly under the smokehouse and from it the smoke flows over a short distance into the smoking chamber, thereby creating conditions for hot smoking. The second firebox is located at some distance - from 1.5 to 3 meters. The smoke from it travels a long distance before entering the smoking chamber, has time to cool down and exposes the products to cold smoking.

Construction of a smokehouse

The combination stove is a rather heavy structure, so a foundation is required.

Foundation

Generally this type stoves are no different from stoves without a smokehouse and are described in a separate article.

You will definitely need two types of bricks - ordinary ceramic (red) and fireclay (fireproof) for laying out the combustion chamber.

Masonry mortar: clay with sand and the addition of salt or cement. You can use local clay. But it’s better not to risk it and buy at hardware store packaged oven clay and fireclay for heating.

Project selection

We will describe in more detail the following combination oven with hob and a smokehouse for hot smoking.

Masonry

When preparing the solution, be guided by:

Each row of bricks is first laid out dry. IN necessary places trimmed with a grinder. After this, 1-2 bricks are removed from the row and lowered into a bath of water for a few minutes. Wait until air bubbles stop escaping from the brick, and only then apply masonry mortar and install the brick in place. It is recommended to do the jointing immediately after laying the next row, otherwise it will be difficult to achieve a beautiful, natural look masonry

Masonry arched structures: barbecue fireboxes, woodshed under the stove, made according to a pre-made template made of wood and plywood.

Installation of accessories

Special attention pay attention to installing the doors of the firebox, blower, and smoking chamber.

To do this, use annealed steel wire d 3–4 mm, 1–2 m long, which is folded in half, passed through an eyelet in the oven door frame, and twisted. The ends are bent at an angle of 90%. After installing the door frame in place, the wire is placed along the masonry of the side walls of the furnace and laid with bricks. This fastening system does not allow the doors to become loose during operation.

The service life of such a smokehouse stove can be 25 years or more. If desired, you can attach a barbecue to it, cutting table and other elements.

Do with my own hands smokehouse, smoke fish or meat, try it and feel how tasty ordinary food can be after smoking!

Products during the smoking process will receive an amazing aroma and taste, and this taste will not be similar to the taste of smoked products purchased in a store. However, first you need to understand the intricacies, and only then decide how to make a smokehouse with your own hands for hot and cold smoking.

We study the features of the smoking process

The man began to smoke food out of necessity. It was noticed that after smoking they can be stored without spoiling for a longer time. To ancient man this made it possible to take some of the food with you in smoked form, rather than relying on luck while hunting or fishing during long trips.

We smoke products at home mainly to give them a different, unique taste. To do this, you can use hot or cold smoking. And the smokehouses themselves come in two types. Their design is almost no different. It is necessary to equip a fireplace, a chamber with hooks where the products will be hung and smoked, and a device for collecting fat that will be released during the smoking process. The smoking chamber must be located in a hermetically sealed housing.

What is the difference between hot and cold smoking? After all, both processes involve the presence of products located in a limited space, in smoke from smoldering sawdust or shavings. The main difference is the distance separating the chamber in which the food is smoked from the hearth. For hot smoking, the smoke temperature should be high enough, for cold smoking - 35°C. Mandatory requirement- smoking cannot be carried out over an open fire.

Cold smoking

Cold smoking takes significantly longer than hot smoking. With this method, products retain their appearance and acquire amazing taste and aroma. The cold smoking process takes place at a temperature of approximately 30°C and lasts several days. You should not rush, because at this temperature bacteria multiply well and, without completing the process, you risk instead delicious dish get seriously poisoned. Typically, cold smoking lasts 5-7 days, but can last several weeks.

Important ! Particular attention should be paid to the sawdust or wood chips that you will use. We forget about sawdust from coniferous species, you should not use aspen sawdust. Best choice will be:

- alder (you must first remove the bark, it produces bitterness);

- juniper;

- bird cherry and birch (should also be cleared of bark);

- maple;

- shavings and sawdust fruit trees(cherry, apple tree, sea buckthorn).

DIY cold smoked smokehouse

It should be remembered that the hearth must be located away from the cold smoking chamber. A good option There will be a dug hole in the far corner of the site; you cannot use the natural height difference. A fireplace is installed in the pit, which should be connected to the chamber with a chimney. There is no need to line the fireplace with bricks; it is enough to line the walls of the fireplace.

Very important ! The length of the chimney is usually 2.5-3.0 meters. To do this, it is enough to dig a trench no more than 0.5 meters wide and 0.25-0.3 meters deep, line the walls and bottom with bricks held together with clay mortar, cover the top with a sheet of metal or slate, and sprinkle with earth. Instead of brick chimney, you can lay a chimney pipe in the trench. Provide a damper at the top of the fireplace to regulate the flow of air, the intensity of combustion and the removal of excess smoke. The flap can be cut from sheet metal. Make the junction of the chimney and the chamber (diameter 200 mm required) airtight using available means. You can use the same clay solution. The chimney has been built.

Another solution could be to install a “potbelly stove”, a chimney made of chimney and installing a smoking chamber above the level of the chimney.

We make a chamber for cold smoking from a barrel

The easiest way to make a simple smokehouse with your own hands is from a barrel. You need a barrel of 100-200 liters. The top cover is cut off, the barrel must be cleaned and washed before use. A hole for the chimney is cut in the bottom of the barrel. The barrel will be mounted on bricks or blocks, so there will be no problems with their articulation. A tray is made from a cut-off lid or other available material to collect fat that will flow out of the product during smoking. The diameter of the pan must be smaller than the diameter of the barrel to ensure the passage of smoke.

We need to make at least one grate on which the food will be smoked. This is one of the options for placing products when smoking. Or secure scraps of reinforcement to the top of the barrel. We will attach hooks to the reinforcement, and products to the hooks.

We make the grate from scrap materials. It can be willow twigs that are woven into shape the right size. It is advisable to secure the cells with thin wire. Can be used thin wire and weave them into a lattice, and make the rim from thicker wire. To do this, a thick wire is wrapped around the barrel to determine the desired size, slightly compressed and the rim is secured.

One grating is used or several gratings are installed at different levels. In this case, the distance between the gratings should be about 15 cm.

To install the pallet, pieces of reinforcement are welded to the walls of the barrel, which form a cross in the center of the barrel. Tip: Provide a loop on the tray so that it can be easily removed for cleaning.

To attach the grates, you can make loops and weld them to the walls of the barrel. Or screw self-tapping screws into the walls of the barrel.

The camera cover is made from hardwood trees. It should not be massive and several small holes should be provided in it for moisture to escape. You can limit yourself to a jute bag, which is simply thrown over the barrel during smoking. Remember that the bag must be moistened with water.

We make a chamber for cold smoking from brick

The smoking chamber can be made of brick. It will be the best solution, but it makes sense to build such a chamber only when you are constantly engaged in smoking products and have achieved the necessary skill in this matter. Otherwise, a rarely used structure of unknown purpose will appear on your site.

A brick smoking chamber is equipped in the same way as a barrel. The bottom of the brick chamber can be made from the lid of a barrel or from scrap materials. Sand-clay mortar is used for laying bricks.

We make a chamber for cold smoking from sheet iron

To make a chamber, a sheet of iron is cut, bent in the shape of a cube without one side (the top), and the seams are welded.

The smoking chamber can be built from a variety of materials and items: a bucket (this is a small barrel), an old pressure cooker or a refrigerator.

Craftsmen even make it to speed up cold smoking. In such a smokehouse, the thermal effect of the electric heater on the wood chips produces smoke. The heating element is periodically switched off, thereby achieving the desired temperature of the smoke upon entering the smoking chamber. The smoke rises through the holes, passes through the mesh of the explosive block and becomes positively charged. When smoke enters the chamber, it interacts with the products that are suspended on hooks. The hooks are connected to the negative pole of the BB block. Products attract positively charged smoke particles and these particles settle on them.

DIY hot smoked smokehouse

Hot smoking takes significantly less time because the process takes place at smoke temperatures ranging from 50°C for meat to 120°C for fish. Reduce the temperature - increase the smoking time.

Schematically, such a smokehouse looks like this: a container with sawdust or shavings is installed above an open fire or on a source high temperature(preheated oven). The temperature at which the sawdust will slowly smolder is important, not the fire source itself. Smoke from sawdust penetrates into the smoking chamber where the products are placed. A tray is installed under the products to collect the fat released during smoking. Excess smoke is discharged through the chimney or holes in the chamber lid.

We make a smokehouse for hot smoking from a barrel

The difference from a cold smoking chamber will be the need to equip a firebox. The firebox can be placed directly in the barrel:

- Several holes are cut in the bottom of the barrel through which ash will be removed and which will serve as an ash pit for the firebox.

- A piece of the wall is cut out from the bottom of the barrel, from which the firebox door is made. A piece measuring 200x300 mm will be enough. Hinges and a latch handle are welded to the door.

- About a third of the barrel's volume is allocated for the firebox, the rest will be the smoking chamber. The firebox and chamber are separated by a sheet of metal 4 mm thick. This sheet will serve as the bottom of the chamber. It is welded to the walls.

- A hole is cut in the bottom of the chamber for the chimney. The diameter of this pipe must match the diameter of the chimney at the top of the chamber. Do not get carried away by the length of the chimney; excessive draft in the firebox is not needed. Chimney welded to the wall of the barrel.

For more rational use the volume of the barrel, the firebox can be placed directly under it. In this case, it is better to make the firebox out of refractory bricks, with holes for inserting sawdust and removing excess smoke. The barrel is installed on the firebox, and the freed volume is used to place additional grates.

Advice . To control, attach a mechanical thermometer with remote sensor. Such a thermometer can save you from many mistakes while you gain experience. You can use the old-fashioned method and splash a few drops of water on the surface. If it doesn't hiss, there's nothing to worry about.

A mini-smokehouse can be easily equipped in an ordinary metal bucket. Sawdust and shavings are poured into the bottom of the bucket, and a grate is installed on top. At the very top of the bucket, holes are made in the walls for the rods. Hooks are hung on the rods. We get two options for placing products in a small volume. In the lid of such a “smoking chamber” it is necessary to provide holes for the smoke to escape. The bucket is placed on the fire. A big fire is not needed, the sawdust should only smolder. As soon as the smoldering process begins, you can lay out and hang the products for smoking and close the lid. Smoking will take from 30 minutes to an hour.

Another option for a mini smokehouse is metal box with a perforated lid that can be placed on the grate over the burnt coals in the barbecue. We fried kebabs, sat down at the table and put the smokehouse on the grill. Good option for hiking or fishing.

Having understood the principle of operation of a hot smoker and after a series of experiments with a barrel, you can think about a more presentable design. You can cook a beautiful smokehouse from of stainless steel or lay it out of brick.

An excellent option for a summer residence would be to combine a smokehouse and a barbecue on one site and in one volume.

DIY smokehouse and barbecue made of brick

The work will require time and effort, but it is worth it - the result will delight you for many years.

First select appropriate place on site, remember fire safety. For convenience, you can bring water and sewerage to this place. Develop a sketch of your structure and be sure to draw up a drawing for laying each row of bricks. You will see, such a drawing will make your work much easier.

You can do without a concrete mixer and mix the solution manually, but a little mechanization will speed up the work several times. Prepare everything necessary materials and tools.

The work begins with clearing and planning the selected site and making a foundation. A brick smokehouse with a barbecue is already considered a permanent structure and strip foundation not enough. Installed in a dug pit wooden formwork, which must be upholstered with roofing felt. A layer of rubble stone is laid, filled with crushed stone and filled with mortar.

Important ! A day later, after the first layer has dried, the next one is done and so on. The number of layers depends on the size and weight of the structure.

The last layer is checked by level, leveled, waterproofed and left for several days until completely dry.

Instead of a rubble foundation, you can build a concrete one. Such a foundation needs to be reinforced.

Use red for masonry kiln brick. Start by laying out the first row of bricks without using mortar. This will help you make markings and determine where to install the grilles.

Start laying by kneading sand-cement mortar with the addition of lime. The usual ratio is 3:1:1. Water is added in volume so that the solution looks like thick sour cream. The second and subsequent rows are laid staggered, laying bricks starting from the corners. Constantly check the horizontality of the laid out rows. The corners must be reinforced with wire.

To install the brazier, corners and fittings are installed between the walls of the oven. The firebox must be made of heat-resistant metal or cast iron.

It is easier to install the lattice if several bricks are laid protruding into the structure.

Space for firewood and various household appliances can be provided in the overall volume of the structure.

The smokehouse is made of two volumes located one above the other. This will give you a hot smoker. It can be easily converted into a smokehouse for cold smoking by placing a portable stove or hearth at the required distance and connecting it to the chamber with a chimney. So you can make a smokehouse with your own hands for hot and cold smoking.

You choose the design style of the building and its decoration according to your taste.

These are not all the ways to make a smokehouse with your own hands for hot and cold smoking. Among them there are very cheap (option with a bucket) and quite expensive (grill-smokehouse made of bricks). It's up to you to decide, but in any case, there will now always be a place for delicious smoked products on your table.

What could be tastier than homemade smoked meats? Many craftsmen are interested in a description of the principle of creating homemade products that are useful in the household.

The finished products are shown in the photo; cold smoked smokehouses can be made with your own hands. Products homemade is a welcome treat.

Self-made design

Cold smoking is the process of processing food using smoke at a temperature of 32 degrees. The process must be organized correctly, so the master will need to figure out how to make a cold smoked smokehouse correctly. It is important not to make a mistake with the construction scheme.

It is necessary for the hot smoke to become cold. To do this, use a tunnel that connects the firebox to the compartment where the products are placed. The length of the tunnel can vary between 2-7 m. This distance is taken into account to calculate the length of the chimney.

If the firebox is located at a distance of more than 7 m from the smokehouse, draft problems, as a rule, cannot be avoided.

How does the device work?

Principle of operation homemade smokehouse can be represented as follows. Food processing can last from 3 days. The process may continue for several weeks.

The main thing is to ensure that the smoking process occurs evenly. Do not mix in the smoking chamber different kinds food.

You need to prepare food in one go. It is important to sort products by size.

More about the design of the smokehouse

To make a firebox, you need to dig a trench with dimensions of 50x50. These values may be higher. Often the width and depth of the pit are made to be meter wide.

The bottom of the firebox can be made of brick, then cover it tin sheet. Prepare cement mortar not necessary. It is enough to compact the bricks close to each other. The sides are also finished with brick. Here you will need a clay mortar for masonry.

When creating a drawing of a cold smoked smokehouse, you need to take into account both the distance of individual parts of the structure and the dimensions of the materials.

A trench is specially dug under a chimney with a diameter of 25 cm. The top needs to be covered with a sheet of iron. To prevent smoke from escaping, the sheet material is covered with earth.

A filter is installed at the junction of the smokehouse and the chimney. The main element is a metal mesh with small cells. Dense material is placed on the mesh. The filter protects finished products from soot.

It is important to make the smokehouse durable and reliable. In this case, the structure will stand stable and will not fall if someone accidentally touches it. At the top, the smokehouse is equipped with stainless steel rods.

Their thickness varies from 8 to 10 mm. They are durable and are used to hang food prepared for smoking. Usually food is hung on special hooks. An alternative replacement is a regular grill.

The simplest scheme

A smokehouse is considered a budget option, allowing the master to save building materials and time spent on construction.

The chamber with the products is 2 m away from the firebox. The basis for the smokehouse can be a metal barrel.

Note!

Stages of work

Having determined the dimensions of the smokehouse for yourself, you can begin construction. First you will need to dig a hole under the firebox. Its bottom is covered with a tin sheet. Thanks to this, it is possible to ensure more uniform smoldering of chips and sawdust.

The next stage of work is the installation of a chimney. The dug trench needs to be covered from above. Only non-combustible materials are suitable for this purpose.

The pit can be covered with a sheet of slate. The top of the chimney is covered with soil to ensure tightness.

The smoking chamber is installed in a barrel with the bottom cut off. A metal mesh is mounted below, on which burlap is placed. By combining these materials, the problem of filtering out soot particles is effectively solved.

A metal grate is bolted to the top of the barrel, 20 cm away from the edge. It is not necessary to use this option; you can limit yourself to rods with hooks.

Note!

To fully understand all the nuances, you need to watch the corresponding video clip.

When cold smoking, food loses moisture gradually. During the drying process, smoke penetrates deeper into the food. The result is meat and fish delicacies with a delicious taste.

When the carcass of an old animal is smoked, its meat will remain somewhat tough. In order not to be disappointed, you need to be guided at first by recipes that have already been tested by many. It is better to leave experiments with shades of taste for later.

The finished factory-made smokehouse has several grates and a tray. It is better to choose a product with a large capacity so that smoking is carried out more evenly.

For lovers of long hikes, you need a smokehouse made of metal with a thickness of 0.8 mm. At the dacha, you can install heavier options, where the thickness of the steel body is 2 mm.

Photo of a cold smoked smokehouse with your own hands

Note!