Carpentry work and its types and characteristics. Templates for carpentry: tips for a novice carpenter, instructions, guides. Execution of glass works

Wooden structures for construction are supplied in the form of ready-made elements - arches, half-trusses, trusses, purlins, beams, partition panels, window and door blocks. Wooden structures and products for construction are accepted according to the passport, specifications and through external inspection. Upon acceptance, they check compliance with the requirements of the project, the accuracy of parts, connections, assembly units, etc. Mostly ready-made window and door units are supplied for construction, but carpenters sometimes perform the following work: assemble window and door units from elements, install built-in cabinets, install window sill boards, partitions, vestibules, lay parquet of various designs, assemble trusses, roof and ceiling elements.

Wooden structures are accepted by external inspection and checking dimensions. The dimensions of the structures must correspond to the dimensions given in the working drawings, taking into account permissible deviations. When accepting window and door units, they check the correctness of their installation, caulking, the correctness of the hinges, door panels and the installation of platbands.

When accepting parquet coverings, check the strength of their attachment to the base, horizontality, and the tightness of the connection of the covering elements.

At construction sites, carpenters assemble prefabricated houses, floors, roofs, carpenters install windows, doors, built-in furniture and other elements, parquet workers lay parquet floors.

Control questions. 1.Tell us about the purpose of the buildings, their number of storeys.

2. Tell us about the durability and fire resistance of buildings and structures.

3. What structural elements do buildings consist of? 4. What is the purpose of load-bearing and enclosing structures? 5. What kind of work do carpenters, construction joiners, and parquet workers do at construction sites? 6. List the general construction work performed at construction sites.

X2

Chapter IV

CONSTRUCTIONSBASIC JOINERY- CONSTRUCTIONPRODUCTS

§ 16. Types, purpose and methods of manufacturing formwork and inventory scaffolding

Formwork. When constructing buildings and structures made of monolithic concrete and reinforced concrete, formwork is used. Formwork is a form in which reinforcement and concrete mixture or one concrete mixture are placed in order to obtain the required building structures. The shapes and internal dimensions of the formwork must correspond to the dimensions and shape of reinforced concrete and concrete structures specified in the project.

The formwork must have exact dimensions in accordance with the working drawings, be strong and rigid. It should not deform under the influence of technological loads and interfere with the ease of installation of reinforcement and compaction of the concrete mixture. According to its design, the formwork must ensure compliance with the geometric dimensions of the elements being concreted, the speed of its installation and dismantling, the ease of repair and replacement of unusable elements, and minimal adhesion to concrete. Heating (thermosetting) formwork must ensure uniform temperature on the shield deck, and temperature differences should not exceed 5 °C. It is used mainly in winter and to speed up the setting of concrete in summer.

The formwork should not have holes or cracks and allow cement laitance to pass through (when filled with concrete mixture).

Wooden formwork can be used for concreting up to 30 times. Reusing formwork is called recycling. It is recommended to use inventory formwork, which is easy to assemble and disassemble. The formwork must be dismantled carefully so as not to break or damage the boards and panels.

The use of inventory formwork in the form of panels increases its turnover. Inventory formwork has standardized dimensions, so it can be used for concreting various building structures with dimensions that correspond to the main module.

Tightening bolts, tie rods and other fastening elements must be in stock and easy to install and remove.

To increase the turnover of inventory formwork, as well as to obtain a smoother surface after concreting, the formwork is covered with plastic film.

Depending on the structures of the buildings being erected, various types of formwork. Collapsible small-panel inventory unified formwork is used for concreting various types of monolithic structures, including curved 6" . 83

Rice. 56. Unified panels of wooden collapsible formwork:

A- for foundations, walls, columns, slabs, floors, b- for strip foundations, beams, purlins and frame crossbars; / - deck, 2 - stitching strip

linear outline. Collapsible large-panel formwork is used in the construction of large-sized massive structures and walls; horizontally sliding (rolling) - for the construction of tunnels, collectors, water conduits, etc.; volumetric-adjustable - during the construction of residential and public buildings.

The most often used is wooden collapsible formwork, consisting of individual panels (Fig. 56) and supporting ribs, screeds, and ties. In some cases, the formwork is supported by scaffolding consisting of posts, braces, etc.

There are certain requirements for materials used for the manufacture of formwork. The moisture content of wood for supporting elements (stands, etc.) should be no more than 22 %, and for the deck - no more than 18%. For the manufacture of supporting elements of the formwork, it is allowed to use round timber and lumber of coniferous species of at least 2nd grade, for the manufacture of decks - lumber of 2nd class of coniferous and deciduous species.

Panels can be made from fiberboards (GOST 4598-86), bakelized plywood (GOST 11539-83) and FSF plywood (GOST 3916.1-89), protected with a waterproof coating.

Formwork boards directly adjacent to the concrete must have a milled surface and a width of up to 150 mm, and horizontal sliding formwork boards must have a width of no more than 120 mm. Wider boards are not used as they warp.

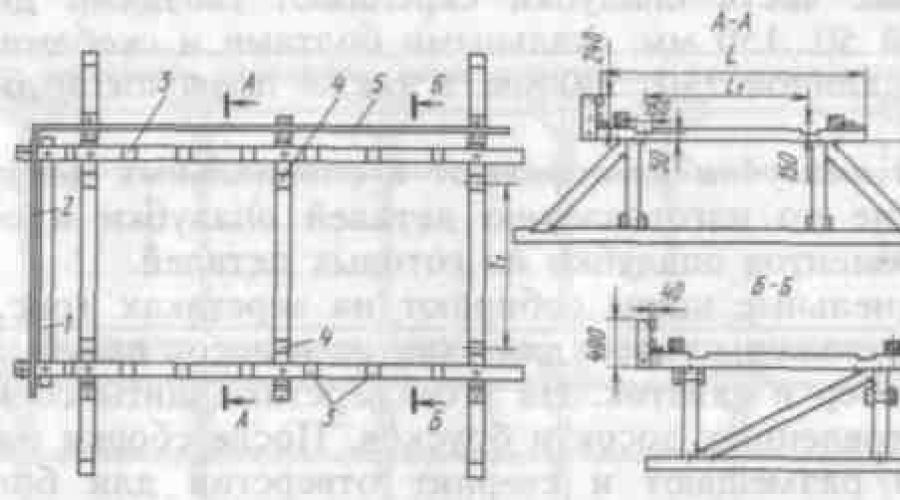

Rice. 57. Workbench for making large-panel panels:

/ - emphasis for contractions, 2 - support for deck boards, 3 - sockets for ribs,

4 - sockets for fights, 5 - stop for ribs and deck boards (£ - length

shield, L]- distance between contraction axes)

Rotten, rotten, tobacco knots and wormholes on the boards are unacceptable, since their presence reduces strength. Falling out knots are sealed with plugs using waterproof glue.

Rice. 58. Workbench for the manufacture of small panels of collapsible formwork:

"workbench diagram, b- method of driving nails, c - removable socket designed by N. P. Ga-khov; / - a thrust block for the ends of the boards, 2 - steel strip for bending nails, 3 - a stop ruler (rail) for stitching strips, 4 - workbench cover, 5 - slats forming a nest for the stitching strips of the shield, b - a thrust block for the shield boards, 7 - nails, S- shield boards, 9 - stitching strip

The wooden parts of the formwork are fastened with nails with a diameter of 2...6 and a length of 50...150 mm, steel bolts and staples with a diameter of 12...19 and a length of 250...300 mm, as well as with wire with a diameter of 3...4 mm.

Formwork elements are produced in special workshops that have a department for the production of formwork parts and a department for the assembly of formwork elements from finished parts.

Large-panel panels are assembled on workbenches (Fig. 57), on which stops for screeds and deck boards are located, as well as sockets for ribs and screeds. On this workbench, shields are assembled from pre-prepared boards and bars. After assembly, holes for bolts are placed and drilled on the surface of the shields.

Small shields are assembled on the workbenches shown in Fig. 58, in templates. The shields need to be held together firmly. The front side of the boards adjacent to the concrete must be processed and not have pins. The stitching strips are nailed to the boards, and the nails must be well bent and sunk into the wood.

Clamps for column formwork and frames for column formwork are assembled from pre-fabricated parts. Permissible deviations from the design dimensions of the formwork should not exceed the values given in table. 7. Table 7. Permissible deviations from the design dimensions of the formwork, mm

|

Types of deviations |

Wooden |

Wood-metal- |

|

and plywood |

personal |

|

|

Deviations of collapsible formwork panels and frames | ||

|

for them with length and width, m: | ||

|

Diagonal deviations of shields | ||

|

Deviations of the edges of the boards from a straight line, forming | ||

|

surface of the structure | ||

|

Deviations of the panels are volumetric, horizontally sliding | ||

|

formwork: | ||

|

from the design dimensions of the boards | ||

|

difference in length of diagonals in plan | ||

|

difference between adjacent panels when joining | ||

|

Displacements from the design position of the holes for | ||

|

connecting elements (bolts, hooks, etc.) | ||

|

Local unevenness of surfaces in contact | ||

|

with concrete: | ||

|

one-piece | ||

|

detachable and reconfigurable |

Scaffolding for supporting formwork. To support the formwork of reinforced concrete floors and other building structures, floor-by-floor (up to 6 m high) and rack (more than 6 m high) scaffolding is used.

Floor scaffolding(Fig. 59) are a structure assembled from racks and braces. The racks are installed on logs,

Rice. 59. Floor scaffolding for supporting formwork:

1 - concrete floor, 2 - racks, 3 - braces (spreads), 4 - logs under the racks, 5 - concreted floor, 6 - lining to transfer the load to the racks of the floor below

laid on a base (concrete floor). For greater stability, the racks are secured with braces. On different floors, the racks are located on the same vertical axis. This is necessary so that loads from the upper floor are evenly transferred to the racks of the lower floor. The logs under the racks must be positioned strictly horizontally.

Floor scaffolding is usually assembled from racks of constant height, made of beams or round timber. It is not allowed to replace beams with boards, even nailed ones. The racks, having a height of 3 to 6 m, are braced one against the other in two mutually perpendicular directions, with the lower braces performed at a distance of at least 1.8 m from the floor, and the upper braces at a distance of 1.6 m from the bottom of the formwork. The upper braces are usually used in the form of supports for scaffolding during stripping. In addition, diagonal braces are made through one and two rows of racks.

For making stands post scaffolding use round timber with a diameter of up to 160 mm or beams with a cross-section of 130X130 mm. The length of the round timber is increased by cutting into half a tree and fastened with twisted wire or a steel clamp. When installing the racks in place, it is necessary to ensure that the joints of the rack joints are spaced apart in height.

Rack scaffolding is secured in two mutually perpendicular directions with braces, which give stability to the scaffolding and at the same time serve as support for scaffolding during formwork and concrete work. Braces designed for

for supporting the scaffolding, they are made from boards with a section of 40X 120 or 40X 150 mm, cut into the rack and secured with nails (3 pcs.) or bolts. Diagonal braces are made from boards 25X 120... 150 mm and installed along the entire perimeter of the building.

Solid wood itself is obtained from a tree cut down and cleared of branches and bark. The value of a particular wood depends on the type of tree and the structure of its trunk.

Solid wood is used in carpentry in the form of boards of different lengths, beams, beams, beams, and various kinds of figured elements.

You should first consider the structure of wood itself in Figure 1.

1. Main cuts of the trunk.

Here the main technological

the cuts are:

- transverse (in Fig. 1 this is plane B),

- radial (plane B),

- tangential (plane A is a section tangential to the growth rings).

The most visual representation of the structural texture of wood is provided by a tangential cut. In the central part of the tree trunk

core 1 is located (the core is usually the loosest tissue).

2. Tree rings.

Tree rings radiate from the core in concentric circles around the circumference, forming sapwood; each ring represents annual growth, which allows us to determine the age of the trunk.

Rice. 1

A - tangential cut;

B - radial cut;

B - cross section

1 - core;

2 - core;

3 - sapwood;

4 - bark;

5 - medullary rays;

b - annual rays

3. Tree species.

Wood species are divided into those with a core and those without a core. They are also called core and coreless.

Coreless species have only core 1 and sapwood 3. The quality of sapwood is significantly inferior to the core, and therefore, for example, oak wood itself varies in quality. The oak core is valuable (for cabinetry), and the sapwood of this valuable species is not used at all in carpentry.

Class carpentryIt is unthinkable without the ability to distinguish wood species from one another and recognize them in a workpiece or product. For white-wood work, coniferous species are usually used - pine, spruce and deciduous species - birch, linden, poplar. Coniferous species are also used as a base when gluing parts with plywood made from valuable wood species. Solid wood products use hardwood for a clear finish. When carving wood, which will then be painted dark, hardwoods are used - aspen, linden, birch, rowan, and willow. If the carved parts have a natural color, it is best to take pear, maple, walnut, and chestnut.

Brief characteristics of the main tree species and their application

1. Hardwood.

Hardwoods are of the greatest importance in carpentry, of which oak should be given primacy in our territory.

Oak(hardwood) - used in furniture production, construction (milled wooden parts, parquet), carriage building, shipbuilding, hydraulic engineering; oak wood is durable, strong, hard, resistant to rotting, has a beautiful texture, and bends well.Oak has clearly visible pores when cut tangentially, and core rays when cut radially; very durable, easily stained black. Real bog oak that has lain in water has a color ranging from brown-green to black. In combination with a radial cut, the texture of such an oak board is very beautiful.

Beech(hardwood) - used in furniture production (parquet, veneer, carpentry tools, containers), in shoe production (lasts), and mechanical engineering. Acetic acid and creosote are obtained from beech wood by dry distillation. Beech wood is durable, but susceptible to rotting, good

processed, impregnated, bends well. It warps a lot when it dries out.

Beech in its pure form is not expressive. In a radial section of the beech, shiny plates appear, visible from the end as dark lines. This type of cutting gives beech wood the most decorative qualities. But in terms of strength, beech has almost no equal.

Elm has a dark core and clearly visible annual layers. In a radial section, they form an interesting pockmarked appearance. By the nature of processing, hardness and other properties, elm is close to oak. The wood texture is especially beautiful in the butt part.

Hornbeam(hard rock) - used in turning, mechanical engineering, and textile production. The bodies of carpentry tools are made from hornbeam. Hornbeam wood is distinguished by its hardness, heaviness, difficult to process, and very resistant to abrasion. Like beech, hornbeam wood warps greatly when it dries out.

Ash(strong and tough rock) - widely used in the manufacture of sports equipment, furniture production, aircraft manufacturing, carriage building, shipbuilding, and housing construction.

Ash resembles oak wood, it is somewhat lighter, and has no core rays. When stained and dyed, it acquires an unpleasant gray color, so it is usually used in its natural color.

Carpentry tools are made from ash. The wood is strong and tough, has a beautiful texture, durable, and resistant to decay. Ash wood bends well, warps a little, but is poorly saturated with antiseptics. Elm, elm, elm (dense, durable species) - these species, due to their beautiful texture, are widely used in furniture and plywood production. Having great strength, they are used in mechanical engineering and carriage building. The wood of elm, elm, and elm is distinguished by its strength, viscosity, and density. It resists wear well and bends well.

Nut(hardwood) - scope of use - furniture and plywood production, housing construction (interior wood finishing). Walnut wood is heavy, durable and hard with a beautiful texture. The wood is well processed and polished well. Linden (soft wood) - pencils, toys, musical instruments, and other products are made from it. Linden is also widely used in furniture and plywood production. Linden wood is soft, light, and easy to process. When drying, linden shrinks significantly, but warps and cracks to a small extent.

Walnut and Manchurian walnut have red-brown wood, sometimes with dark veins, are difficult to plan, and lend themselves well to polishing and painting. Walnut burls have a particularly beautiful pattern; Burls are cut into planks, which are assembled into shields on a coniferous base. Hornbeam has hard wood of white-yellow color, very heavy, suitable for imitation of ebony. Mainly used on the soles of carpentry tools. Works well, polishes poorly. The pear has wood of a beautiful pink color with delicate lines of annual layers. The wood is dense, heavy, and can be easily polished and painted. Suitable for small-profile carved items, drawing tools. Little warping and cracking when drying. Thanks to the developed central trunk, the pear produces long, straight pieces.

Birch(moderately hard wood) - widely used in the manufacture of skis, gun stocks, parquet, laminated plastics, particle boards and fiberboards, cellulose. Housing construction, furniture and plywood production are also areas of application for birch. Where there is high humidity, birch wood is not used. Birch is uniform in density, moderately hard, and easy to process. Birch material is often imitated to resemble valuable species, is well polished, painted, and can be impregnated well. But birch is not resistant to decay and warps, which narrows its scope of application.

Maple(hardwood) - area of application - mechanical engineering, plywood, music and furniture production. In shoemaking, lasts are made from maple, and in carpentry, lasts for planes are made. Maple wood is characterized by strength, density and hardness, and has an impressive glossy surface. Amenable to painting and polishing. The drying rate is insignificant.

Russian maple, sycamore, black maple have dense gray-pink wood with a delicate pattern. The radial cut is especially beautiful. Maple is easily polished and accepts mordants; it can imitate most rare trees with wood of an even structure. American maple, or ash-leaf, has a wood texture similar to ash, but with smaller pores and denser wood; it is difficult to process and polish.

Aspen(softwood) - this type of wood is widely used in the match industry, construction, and in the viscose industry for the production of rayon. Aspen, like poplar, is successfully used for various crafts and for making toys. Roofing tiles are also made from aspen. The wood is soft, has few knots, is light, can be processed well, is well impregnated and glued together. Of particular note is the strength of aspen in the aquatic environment and its resistance to woodworms. Aspen warps little and is resistant to cracking.

Poplar- used as a good ornamental material (dishes, troughs, spoons, toys, etc.), used in the production of pulp and in construction. Poplar wood is soft, dries out quite strongly, bends poorly, and is susceptible to rotting. The material of this breed is mossy. Alder (soft wood) - the area of application of alder is quite extensive - this includes carpentry and furniture production, plywood production, and lumber production. Alder has proven itself well in underwater construction, in particular, it is used to construct log houses for wells. Alder is used in the manufacture of souvenirs; it is a good material for artistic processing (wood carving). Considering that alder does not give off any odor, it is indispensable in container production.

Elm- Southern tree with brown wood. Burls often form on elm trunks. The sawn boards made from them are exceptionally beautiful. Sycamore, plane tree (eastern plane tree), growing in the south of the country, have a brownish-brown core. The oblique direction of the wavy lines in the annual rings gives the texture of the plane tree, especially in a radial section, a grain-like appearance. Edible chestnut has a gray-brown core, the wood is similar to oak, but in a radial section it does not have shiny core rays. Horse chestnut is usually cross-laminated, the wood is evenly colored, grayish in color (reminiscent of pine), and is suitable for carvings and mordants. Strength is high. Amur velvet (Amur cork) has wood similar to ash wood, but slightly darker.

Rare hardwoods.

Rare hardwood species include pear, cherry, white acacia, apple tree. The density of the wood of these species exceeds that of oak and beech, has a beautiful color, and is well processed and polished. The wood of the listed species is mainly used in ornamental work.

White acaciahas a wide black-gray or green-brown core, very durable wood with matted fibers, difficult to process in a dry state. Wet - prone to brittleness. But the work is rewarded by the beautiful appearance of the product. Mulberry (mulberry) has red-brown wood (narrow sapwood); Wood darkens when exposed to light. Wood from fruit trees - cherries, cherries, plums, apple trees, apricots- an excellent ornamental material for a wide variety of products. As a rule, it is a very hard, fine-grained wood of various shades - from white-pink to black-blue and purple in the core parts. With the exception of cherries, pieces of wood from these species are not long due to the branching structure of the trees. Birch- The most common hardwood, suitable for a variety of stains.

2. Conifers.

Pine(softwood) is a good building material in various fields; it is widely used in furniture production, including various artistic crafts. Pine wood is quite strong, light, and soft. When it dries, it warps a little, is well processed, impregnated and painted.

Spruce(soft rock) - main application - pulp and paper production and construction. A good material for the furniture industry, for the manufacture of musical instruments, and is used in the manufacture of tannins. Spruce, as a material, is inferior to pine. Although spruce wood has a similar structure to pine, it is more knotty, is processed worse, and is poorly impregnated with antiseptics. However, spruce, due to its low resin content, holds glue better and dries faster. Spruce has white wood with barely noticeable annual layers. It has black, chaotically scattered knots, unlike pine, in which the knots are located in whorls (groups at the same level).

It has a very beautiful texture juniper- coniferous shrub with trunks up to 10 cm thick. The end cuts of juniper, suitable for inlay, are amazingly beautiful. The pleasant smell of wood lasts for a very long time and carpentry made from it can be compared with similar products made from camphor laurel, so beloved in Europe in the last century.

Cypress, thujaThey are similar in properties to juniper, but their wood is grayer and wider-grained. Cypress does not crack or warp, which is why it was previously used for icon boards. Cypress, thuja and juniper lend themselves well to fine carving. Other conifers are less suitable for small carvings.

Fir(soft rock) - used in the pulp and paper industry, construction, furniture industry, and in the manufacture of musical instruments. Fir is also used in medicine to make fir oil. Fir wood is close in its characteristics to spruce. Soft and light, it is difficult to impregnate with antiseptics. The scope of application of fir is narrowing due to its instability against decay.

Cedar, Siberian pine(softwood) - the area of application is the same as that of pine (construction, furniture industry, carpentry, pencil making, etc.). In terms of physical and mechanical properties, it is between spruce and fir, but is more resistant to rotting. Well processed.

Larch - beautiful The wood is a beautiful creamy brown color.

3. Imported wood.

Eucalyptus(hard rock) - is used in bridge construction, hydraulic structures, underwater technologies and, of course, in residential and industrial construction. Eucalyptus wood is strong, hard and heavy. Very resistant to rotting. But it is difficult to process; the core of the tree is poorly saturated with antiseptics. Grows in Georgia, Australia, Indonesia, and the Philippines.

Mahogany (mahogany). The wood of this tree is used to make high-quality furniture, panels, various crafts and accessories. Carpentry tools made from mahogany are highly valued. Veneer from this tree is used to decorate prestigious products. The wood is hard, durable, does not crack or warp. Very beautiful texture. Mahogany is a low-density species that can be processed well industrially, but is difficult to process manually. Grows in Mexico and Central America.

Balsa wood- in carpentry work it is used for internal layers of laminated laminated wood. Good heat and sound insulator, filler for life-saving equipment. Balsa wood is the lightest, fastest growing and softest of all tree species. Grows in Mexico, Central America and South America (Ecuador). There is balsa in Georgia (Colchis).

Before reaching the construction site as building structures, wood goes through several stages of processing: logging, sawmilling, woodworking. Logging involves felling, limbing, and bucking. Sawmilling – sawing round wood (sawlogs) into various types of lumber, drying. Wood processing – production of carpentry and joinery products from lumber.

All construction work involving the use of wood is divided into carpentry and joinery. Carpentry work includes processing logs, beams and boards; connecting elements using notches, dowels, bolts and nails; production and installation of foundation elements and wall frames; cutting wooden walls; laying purlins and floor beams; installation of rafters and trusses; ceiling filing; production of formwork, scaffolding, scaffolding, plank floors and partitions for plaster. Carpentry work is characterized by the production of smaller parts compared to carpentry work. This includes installing parquet floors, clean partitions, filling window and door openings and installing built-in furniture.

9. 1. Wood-based building materials

The main wood-based building materials include round timber, lumber, laminated products and structures, particle boards, wood-cement and fiberboards, wood concrete, fiberboard, xylolite, etc.

Round timber is pieces of a tree trunk of different species and sizes, cleared of bark and branches. In general, round timber is used in construction as wall material, supports and poles for overhead communication lines and power lines and decking in the construction of bridges, roads, for fencing areas, etc.

Manufactured from round materials that have preserved the natural structure of wood, sawn timber, split timber (staves for barrels), planed and peeled veneer and others belong to the processed group.

Lumber– products obtained by cutting logs, having standard sizes and quality, used in their entirety or for the production of blanks, parts and wood products. In lumber, the longitudinal and wide sides are called layers, longitudinal narrow – edges, and perpendicular to them – ends. The intersection lines of the faces and edges of sawn products are called ribs. The part of the log surface remaining on the lumber is called wane.

Based on the type of wood, lumber is divided into two main groups: coniferous and deciduous. According to cross-sectional dimensions, they are divided into beams, bars and boards (Fig. 9.1.)

Bars– lumber with a thickness and width of 100 mm or more. Based on the number of sawn layers, two-, three- and four-edged beams are distinguished. Bruschi– lumber up to 100 m thick and no more than double thickness. Boards– lumber up to 100 m thick and more than double thickness.

Lumber can be edged and unedged. For edged lumber, the faces and edges are sawn along the entire length; unedged faces are sawn, but the edges are not sawn or partially sawn, and the size of the unedged part exceeds the permissible dimensions for edged lumber. During the production of lumber, by-products are formed in the form of both sexes Obapol is a lumber product obtained from the side of a log and having one sawn surface and the other unsawn or partially sawn.

Various products and structures are made from lumber for construction needs: sleepers, checkers for road and bridge coverings, semi-finished products, blanks and products (boards and beams cut to specified sizes, floor beams, tongue and groove boards, plinths, fillets, platbands, laminated veneer lumber structures , particle boards, fibreboards, plywood, etc.)

It would seem that in the conditions of the existence of modern technological methods and synthetic materials, in the era of silicone and plastic, the profession of a carpenter should sink into oblivion. Not at all. When furnishing their home, owners increasingly began to purchase products made from natural raw materials. Natural materials are becoming increasingly popular and recognized in interior decoration. Wood and products made from it are almost universally used for repair and finishing work.

Replacement of doors and windows

Doors and windows are used for finishing glazing, so it is recommended to assemble them before finishing and finishing the walls. For a perfect finish, we recommend finishing your glavets using plasterboard systems such as gypsum boards and aluminum joints.

Formation of condensation on the inner surface of the thermopan window. Condensation may occur on the inner surface of the insulated glass or frames. This also applies to the formation of dried water or condensation water. This phenomenon should not be confused with condensation in the interstitial space of thermopan windows, which is a very rare case of defective workmanship.

Carpenter is now a very honorable and significant construction profession. Specialists of this profile of the MosMasterGroup company professionally master modern technologies for processing wood, manufacturing various parts, elements and building structures from it.

Our company offers qualified carpentry work to create a unique interior design, because wood finishing is a creation with unsurpassed style, aroma, carefully preserving natural warmth and comfort, creating a special, calm atmosphere of home. We will diligently and responsibly approach the carpentry work and help you achieve the ideal in the implementation of the interior design project of your home.

Domestic water vapor is constantly released. Human respiration: daily amount of 1-2 liters of cooking: up to 2 liters in a household with 4 household chores, up to 3 liters in a household of 4 people. Condensation can be prevented by following certain rules.

Household users who have new thermal heaters should be mindful of adapting to the new ventilation conditions. In the case of a new, more airtight one, uncontrolled air exchange is no longer supported, so residents must ensure the room is ventilated to avoid condensation. Rooms located in the northern part of houses are cold longer in winter. Make sure that these rooms are better heated than in the south, or supplement their insulation. Additionally, the temperature in your home does not vary from one room to another.

What is carpentry work?

Carpentry work is work on finishing the ceiling, floor, walls with wood and materials made from wood; installation of floor coverings, dismantling of old and installation of new windows, window sills, doors, ducts for heating radiators, installation of wooden stairs, ceilings, etc.

In the morning, it is recommended to ventilate the rooms for about 20 minutes, and after opening the windows, heating is uniform even at moderate temperatures. Why does condensation appear on glass? How can we limit or remove condensation? Condensation occurs when the surface of the building is not well insulated and the water vapor that passes through the cool suddenly appears the so-called dew point, which, when the third internal wall thickness is formed, causes condensation and thus: moisture, mold, etc. Also, the use of washable wallpaper or acrylic paints are not solutions that significantly reduce the permeability of the walls, and spontaneous natural air exchange is no longer produced.

To perform their work perfectly, our craftsmen use only high-quality tools from well-known manufacturers and various auxiliary mechanisms.

What carpentry work can we offer you?

The range of carpentry work we perform is much wider than the standard range of services of the average construction company. Here is our list:

In the context of the above, condensation may form on the inner surface of the glass, namely the frames. this phenomenon should not be confused with condensation of water in the space between glass insulators. in this case, extremely rarely, it is an erroneous performance, for which the company has serious guarantees for five years. Installation in a living space always produces water vapor for the following reasons: in the air that people breathe, cooking, bathing, washing clothes; Flowers in the apartment, etc. adding water continuously to the air in the form of steam.

The maximum amount of water vapor is closely related to the ambient temperature. When the air is saturated and the temperature drops a few degrees, such as during the night, some of the existing vapor will occur on cold surfaces in the room. Other situations that may lead to condensation.

- installation of wooden entrance doors and door frames of any complexity;

- installation of interior doors of various modifications (hinged, sliding, folding);

- insertion of door locks;

- installation of skirting boards;

- installation of a kitchen hood;

- installation of suspended ceilings;

- heating screen equipment;

- laying different types of flooring (laminate, parquet boards, linoleum, carpet, carpet tiles);

- covering the walls of the facade of the house, balconies, loggias with wooden and plastic lining;

- dismantling and installation of built-in furniture, mezzanines;

- dismantling and installation of partitions made of plasterboard, plywood, wood;

- installation of decorative fireplaces.

In addition, you can use the services of our carpenters to repair door locks, secure shelves and slatted ceilings, minor furniture repairs, install ventilation grilles, hang mirrors and carpets.

If the indoor humidity is high and the temperature inside the insulated glass is low; If hot air is prevented by circulation heaters, go to the window; If the premises are not well ventilated; If the windows are installed in the outer part of the wall; If the outline is not sealed properly. Reducing the risk of condensation can be achieved by:

Adequate ventilation, followed by uniform heating to moderate temperatures; Changing the circulation of hot air, so that warm air flows along the window to obtain large heat transfer coefficients; Where there are interior window sills, covering the surface of radiant heating elements to reveal practical purposes is to allow the flow of hot air to the window; Rooms facing north or the dominant wind direction are better heated and insulated. Control sources of moisture content so that the air is not saturated in terms of moisture.

About wood as a material

Wood is a very attractive material, but specific and expensive, and its processing and use in finishing work requires special skills and knowledge of carpentry. It would be better to entrust finishing carpentry work to professionals.

Tightness, in addition to the obvious advantages, but eliminates the possibility of exchange of uncontrolled air width they are returned to users. Lack of ventilation in the room inevitably leads, under certain conditions of temperature and humidity, to condensation on the insulating window, starting from the bottom of the bottle. With increasing condensation of moisture at the top of it and ultimately, if not interfered with, the transformation of condensate droplets. Condensation occurs on a glass sheet when the air is saturated with vapor on the inside, that is, when there is high humidity in the chamber and the inner surface of the glass is cold.

Drywall along with wood

If previously wood was used in the form of solid wood or timber, now the range of wood products has been replenished with a new, but already beloved product - plasterboard. This building material is successfully used in the installation of suspended multi-level ceilings, all kinds of curved architectural decorative structures, shelves, arches, columns. Most designers love to work with drywall, as it makes it possible to realize many creative ideas regarding both the functionality of interior items and simply decorating it with original decorative elements.

Often, when it comes to heating installations, there is a problem with the placement of the radiator and the pipes that bring heat to the radiator. Some argue that they should always be installed on glass walls, while others believe, on the contrary, that they should be mounted on the wall opposite the window. The explanation or argument why a radiator should be placed under a window is that due to the cold glass which will cause condensation on the glass and over time we will destroy the windows, we will grow mushrooms on the joinery and on the insulating rubber.

When installing a radiator under a window, a warm air curtain is created to dry the glass and prevent condensation. There are many different people who argue that by placing a radiator on a window, you create a large potential difference between the outside and inside, which leads to high energy losses. This is very true, but it is not an argument.

Repair of balconies cannot be done without carpentry work. Installing frames, covering walls with panels, installing floors and ceilings will transform the look of your balcony, turning it into a full-fledged zone of comfort and relaxation.

Advantages of the material

For a more durable carpentry service, we will make sure that the wood finishing is carried out in accordance with all the rules, taking into account all the parameters and conditions of the design project. Wood in the interior can truly show miracles of adaptation. It is difficult to imagine a more favorable material with its environmental friendliness and beneficial properties for home decoration.

And this means that the inert gas between the glass sheets is released indoors or outdoors, and the window begins to float even inside, but also inside the inside of the document. These things still happen with thermal windows, and when they do, it is advisable to replenish the cavity between the Argon spaces. And the relationship between placing a radiator under a window and lowering the window insulation is that the heat or heat it generates can stop condensation at the front of the house.

It can be noted that when using thermopane windows we may experience condensation when there is no hot air curtain emitted by the radiator. in this case, another possible reason could even be the large distance between the warm air curtain and the glass pane.

Wood is still the most common building material, suitable for any structure of a small house, from the foundation to the roof. Therefore, carpentry and joinery work occupy a leading place in low-rise housing construction. The main disadvantage of wooden structures is their fragility, flammability and rather high cost, so the use of wood, especially for walls, must be completely limited, replacing it, where possible, with cheaper and more durable materials.

Another problem that a window can have when placing a radiator under a window is the radiator mask or the placement of the radiator too far from the window or, rarely, if the wall is very thick or oddly shaped, the warm air curtain radiator is too far from the surface of the window. and there is condensation along the way.

This way, visitors will know what a quality window means, what its components are, and what steps to take to obtain it. The site is structured into two main sections: “Creating a window” and “Installing a window.” The first part presents the basic operations performed in the factory, their correct implementation depending on good use and the aesthetics of carpentry.

Wood is used in the production of both carpentry and joinery, and in construction it is difficult to draw a clear line between them. The tools for both types of work are for the most part common to both the joiner and the carpenter. Therefore, a description of carpentry and joinery tools and devices that facilitate work is given in one section.

How to Install a Window Properly provides some installation examples and shows the technical aspects required for a window to function correctly. Prepare the gap All sides of the internal void should be flat and straight at right angles; any breaks in the wall must be repaired by removing old joinery. Installing a window on a renovated wall is safer and faster. Window installation can be done at any time of the year. However, in cold weather, special materials suitable for low temperatures will be used to repair the wall.

Before starting carpentry and joinery work, it is necessary to arrange a workbench for planing and assembling individual parts, devices for processing logs, and tool points. Practice has shown that it is more profitable to spend an extra day preparing a workplace than to make adjustments and rearrangements during the work process.

Before starting work, the installer must ensure that the profiles are provided with drainage and ventilation holes and that they are not covered, and if the window is provided with a bottom wall, ensure that it exists. Positioning the frame inside the hole is done using locating pins and, of course, a level. Their use guarantees flat installation.

Measurements are taken, the wall is drilled according to the specified distances, and then the fixed frame is installed using brackets or screws on the wall. Subsequently, the feathers are removed from three sides. It is recommended not to remove the feathers from the bottom of the frame.

A carpenter's workbench is a plank flooring made of 40-50 mm boards. The usual width of a workbench is about 1 m, length - 6 m. The flooring is laid on trestles about 80 cm high.

A very convenient carpenter's and joiner's workbench, made as shown in the figure.

The end board of the workbench is taken to be at least 5 cm thick and 25 cm wide. Two stops (velcro) are nailed onto it; one is on the top of the board for planing the boards flat, and the other is on the edge for sharpening the boards from the edge. The top stop must be made of fairly hard wood - oak or birch, at least 2 cm thick.

And in the case of a sash, it is necessary to check the presence of drainage and ventilation holes and, if they are not closed. Sealing the frame-wall connection. Sealing the joint between the frame and the wall, in the case of using pre-compressed strips or special sealing sheets, is carried out before fixing the frames in the window gap. A perimeter is applied to the outside of the fixed frame, its thickness or contact area with the wall, pre-compressed sealing tape or special mounting foil for external use.

A stop with a drilled hole in the top of the cutout clamps better and is less clogged. Its front edge is sawed off somewhat obliquely. When using a side stop, especially during significant work on planing the edges of boards, various devices are installed: a clamp-bracket, “fingers” for supporting the board, nailed to the bottom plane of the workbench, etc. Side cutouts with a width of 5 to 15 cm are used for strengthening with wedges boards and bars when sawing, an inclined cutout - for sawing long bars that are inconvenient to process in a vertical position. The length of the workbench must correspond to the size of the material being processed. The height is such that the worker can place his palms on the board of the workbench without bending his elbows. A long workbench is mounted on three trestles for stability.

When using mounting foil, they should be folded along the corner of the window so that they can be easily applied to the wall. The foam is injected and after a short time any excess foam is cleared and the inner sealant film is bonded to the wall surface. This will provide a very good seal around the inside of the window. Subsequently, these films can be plastered, painted, etc. Please note that the exclusive use of polyurethane foam is not enough. Cause. It's not very durable unless it's protected.

It is recommended to simultaneously contact specialists from a window and construction company who will finish the holes after installation. In practice, various installation situations occur, and to ensure the tightness of the structure it is necessary to correctly evaluate them.

For chopping and hewing with an ax, it is advisable to have a log with a diameter of 30 and a height of 45 cm. You should not chop on a workbench or on the ground. For chopping logs, a stop is installed that prevents the movement of the log from the blows of the ax, and a clamp that prevents the log from spinning when chips are broken off. A convenient stop is obtained from a piece of log buried in the ground to a depth of 60-70 cm, in front of which you need to place a lining with a cutout so that the log does not roll down. To prevent the log from rotating, it can be secured with staples or wedges in the cutout of the front lining. When strengthening with wedges, the end of the log is cut into two edges, and the cutout in the lining is made at least two-thirds the thickness of the log.

Seal it with silicone along its entire length in the area of contact with the window frame. The inner glaze can be made from various materials: wood, plastic, composite materials, marble. The outer strips are installed by cutting under the frame and onto the saltbank, and then secured to it using self-tapping screws. The caps will be installed on the ends. Silicone seals the contact surface between the carpenter and the head if the solbank profile is not used. Avoid drainage holes on the outside.

It is recommended to use Solbank. Insulated glass is installed in the sash or frame for fixed windows. The assembly consists of the work of winding glass using tracks and paths of varying thicknesses. The glass assembly process ends with fixing the perimeter strips on the sash or frame using sticks corresponding to the thickness of the insulating glass, which are cut to size at the factory. The baton is installed as follows: first insert the ends into the predetermined groove, and then secure the rest of the stick by lightly tapping with a rubber mallet.

Before talking about the design of carpentry and joinery tools, it is necessary to talk about the general rules that must be followed when purchasing, setting up and storing them.

A novice master believes that a universal tool is preferable. But that's not true. A specialized “(separate) tool is much more convenient than a universal one, since working with the latter requires greater physical effort and gives worse results. For example, it is better to have an axe, a claw puller and a hammer, rather than a universal hatchet with an inconvenient claw handle, a small blade and a hammer-shaped butt. Cutting boards lengthwise with a saw designed for mixed sawing is twice as difficult as with a special rip saw.

The tool must be adjusted to the hand and height of the worker (for example, an ax handle). For example, the diameter of the handle of any hand tool must be at least 25 mm. It is better to make the handles round, as this creates ease of use in any position of the tool. A good handle allows you to transfer maximum force to the tool.

A large tool is preferable so that it can be used to do any job, with the exception of very small work, for which an appropriate tool is required. An average tool does not make it possible to process a large object well, and for very small work it is just as unsuitable as a large one.

You need to purchase a good quality tool, despite its higher price.

For example, a plane with a double welded iron and a hornbeam sole costs twice as much as a beech plane with an all-steel iron that requires adjustment. The labor and time spent on the second point is twice as much. A good bow saw costs twice as much as a saw assembled from individual elements (machine, blade), but the latter works much worse: it requires more frequent sharpening and additional wiring. The same can be said about the brace, drill, vice. Good craftsmen believe that saving on tools does not bring any benefit.

Carpenter's workbench, stops, clamps: 1 - general view of the workbench; 2 - horizontal stop device; 3 - clamping the board in the cutout with wedges for sawing types; 4 - securing the board using clamps and wedges when sharpening the edge

The tool must always be sharp and pointed. This is the basis of quality work. Therefore, files, whetstones, and whetstones are an integral part of a set of carpentry tools. They must be embedded in wooden blocks so that they can be strengthened when pointing. It is necessary to have three types of whetstones: coarse-grained for primary roughing (dry), medium-grained for point (wet) and whetstone for straightening (wet). It is impossible to sharpen carpentry and carpentry tools on rapidly rotating electric sharpeners - the steel is tempered.

Carpenter's axe: 1 - general view of the axe: 2 - reliable fastening of the ax to the handle; 3 - position of the butt hole and blade: a - correct; b - incorrect; 4 - cut a slot for a wedge; 5 - wedge shape: c - regular; b - incorrect; 6 - shapes of the ax blade chamfers: a and b - irregular; c - correct

Tools with open blades should not be stored in bulk together with hammers, screwdrivers, and pliers. Bow saws must be loosened after work, and the plane irons must be put into blocks.

The main carpentry tool is the axe. Since it is inexpensive, it is recommended to have two axes for work: one, heavy, for two-handed work - cutting logs, and the other, lighter, for small work - a carpenter's ax. Axes are forged and cast. Cast ones are usually made heavier and thicker. Forged ones have a thinner blade, a wider spine and less weight. When purchasing, you need to check whether the direction of the hole for the ax matches the blade, otherwise the correct attachment of the ax will be difficult. Cast axes are more accurate in this regard. It is also necessary to check the uniformity of the blade thickness to ensure an even bevel.

The ax handle is best made from birch, placing the annual layers of wood in the direction of the blade. This arrangement of layers is also mandatory for ax handles made from coniferous trees. Axes made of beech or oak are hard and, as they say, “dry your hands.” The ax handle must have a slight expansion at the end: this allows you to compress it with less force, which makes work easier.

In order for the wedge to fit smoothly into the ax handle and not warp the axe, the slot for it must be sawed through. The wedge should have parallel edges and a slight point at the end. Such wedges cannot be squeezed back out. When driving a wedge into an ax handle without a cut, it often results in a skew, and it is inconvenient to work with such an ax. The best spells are made of 3-6 mm steel. You can also wedge it with a piece of strong, dry sole leather, hammered into the cut instead of a wooden wedge, or with a strip of 4-5 mm steel from the back of the head, the top of which is bent over the butt, and the lower part is screwed with screws to the ax handle. This reinforcement reliably protects the ax from jumping off.

You need to sharpen the ax with small-diameter sanding wheels to get a slightly concave chamfer. A straight chamfer after sharpening very soon becomes convex, and the ax, even being sharp enough, begins to bounce, especially from dry wood. The most important part of the ax is its corners: good craftsmen use them to gouge out and clean out nests, grooves, tenons and quarters when arranging boxes and joining logs and beams, so the corners should always be sharp.

Saws: 1 - transverse two-handed; 2 - arched; 3 - hacksaw; 4 - trigger; 5 - abutment carpentry; 6 - alignment of saw teeth with a file before sharpening; 7 - section of a “planed” saw blade; c - plywood saw; 9 - shapes of saw teeth: a - for transverse cutting; b - for longitudinal; c, d - for mixed

The second most important carpentry tool is the saw. The most convenient for work is a large hacksaw with large isosceles teeth, which equally easily cuts both boards and logs. its length should be about 60 cm. Shorter hacksaws are more likely to tire the worker.

Saws are available for longitudinal, transverse and mixed sawing; They differ in the shape of the teeth. Saws are divided according to their design.

The most common two-handed saw (for cross-cutting logs and firewood) should have the following qualities. The surfaces of its blade must be completely flat and even, without bulges or deflections. Convexities rub against the walls of the cut and make work difficult.

To reduce the friction of these convexities, it is necessary to make a wider spread, which increases the difficulty of working with the saw. The spread should not exceed two thicknesses of the canvas. It is better to make the handles of such a saw slightly curved, with the upper end facing the center of the saw. With such handles, your hands become less tired and your sawing range increases.

In addition to the carpenter's large hacksaw, other one-handed saws with a rigid blade for special purposes are used. Narrow hacksaws - triggers - are used for sawing curved cuts; trigger thickness 1-1.5 mm, inclined tooth. Hacksaws are used for sawing tenons and accurately cutting boards. The riveted backing gives the canvas additional rigidity. These files usually have a rectangular tooth no more than 3 mm high. Rewards and plywood saws are made from scraps of old canvases. The first is used for cutting grooves in panels when installing rack keys in them, the second are used for cutting large sheets of plywood along a ruler. The reward is awarded to themselves.

In addition to hacksaws of various types, bow saws are used in carpentry and carpentry, the blade of which is tensioned in the machine using a string and twist. According to the nature of their work, bow saws are also divided into transverse saws with an isosceles tooth 5-6 mm high, opening saws, designed for sawing boards lengthwise (these saws have a wide blade with a large oblique tooth, blade length up to 850 mm), fine-tooth saws - short saws with machine length 600 mm with a thin blade and a rectangular tooth. For figure sawing, circular saws with a blade width of up to 12 mm and also a rectangular tooth are used. The quality of the bow cloth is checked by bending it into a ring in a vice, where it should take the shape of a regular circle.

The canvas hung by the eye should not have any curvature or skew. A good quality canvas produces a clear sound when struck with a fingernail. The steel of the blades is checked for elasticity: the blade bent by 120° should not have any visible distortions.

Under the file, the steel of the teeth should be fed with noticeable resistance; if the file slides along the steel, then the blade is cemented and made of bad steel. Such blades are difficult to sharpen, they quickly become dull and their teeth crumble.

Handles for hacksaws are made of dense wood (beech, hornbeam) or thick multi-layer plywood and are attached to the blade inserted into the precise cut using countersunk bolts. Rivets are less convenient, as over time they become loose and tear the wood of the handle. The lower end of the hacksaw handle should be 2-4 cm above the teeth line.

To prevent the shaped part of the handle, cut from solid wood, from accidentally breaking off, it is recommended to insert a dowel into it before sawing it out of the board, perpendicular to the grain of the wood.

When setting up a bow saw machine, it is better to make the spacer with through holes into which the posts are passed, and not with forked ends, as is usually the case in machines that go on sale. The holes must be drilled accurately, and their direction must be strictly parallel to the saw blade, otherwise the racks will become skewed. It is recommended to tightly wrap the spacer in the places where it abuts the posts with thin twine or cover it with tin (to prevent splitting). The wrapped area should be varnished. The bowstring is also wrapped, which is made from twisted fishing line of 16-20 threads. Rip saws are not set apart.

Good craftsmen perform the so-called “planing” of the saw blade. This is done in this way: having laid the new canvas on a smooth board, clean its surfaces closer to the butt with coarse sandpaper or a corundum stone, after which it is touched with a sharpened plane. As a result of this operation, repeated several times on both sides, the fabric becomes thinner towards the spine. Such a saw (hacksaw or bow saw) never gets clamped in the cut and makes it very accurate.

Depending on the type of saw, the teeth are set and sharpened differently. Saws intended only for rip sawing are usually not set, and the tooth has a straight edge - the file moves at right angles to the blade. Cross-cut saws have an oblique sharpening, or, as they say, a different point - the file, when sharpening them, moves at an angle of 70′ to the blade. In fine-toothed saws, the angle of the file at the point should be within 80-85°.

Before the point, the saw teeth must be aligned with a file embedded in a block, since if the teeth are uneven, the saw will be pulled to the side and the cut will be jagged.

For the saw point, it is recommended to use two files: first a personal file, then a velvet file, which plays the role of a touchstone. The setting of the saws is done after straightening the teeth in front of the point and is done with a special setting or a wide screwdriver. You can do the wiring yourself by using a hacksaw to cut a hole in a steel plate to the depth of a tooth. For strength, the wiring is quenched in oil.

The saw blade is checked by eye. Excessively spread teeth are driven back with a hammer. If a tooth is broken during setting, then the order of setting should not be violated and the next tooth should be set in the same way as the broken one was set. Some masters recommend making the spread wider in the middle of the canvas; such a saw never clamps.

The width of the spread is made no more than half the thickness of the canvas on each side. Usually its width is equal to 1.5 times the thickness of the canvas. If, when sharpening saws intended for longitudinal sawing, you sharpen on both sides through the tooth, then burrs are formed, which act as a small mark.

Longitudinal sawing of logs is sometimes done with swing saws. After a short training, two men are able to cut boards for a 50 m2 house in three days. For the point of fly saws, you need to have two files: round with a diameter of 8 mm and flat or triangular with a width of 20 mm. Fly saws do not set apart. Sawing of logs is carried out on sawhorses or in a saw pit. It starts from the thick end of the log along the lines marked with a chalked cord. The cut is not completed by 15-20 mm. To prevent the log from pinching, a wedge is inserted into the cut.

Carpenter's and joiner's hammers have square, flat heads. A round-faced machinist's hammer is inconvenient due to the small size of the hammer and the convex head, which leaves dents on the wooden surface. The back of a carpenter's hammer has the shape of a flat, wide blade, designed for grinding plywood when gluing panels with it.

To protect against splitting by nail heads if they miss, a carpenter's hammer must have a handle encased in metal. The hammer is securely secured, while simultaneously protecting the handle, by a metal strip that is folded onto the hammer from above. Do not wedge hammer handles with nails. The best material for the handles of any hammers is dry acacia wood. Wooden hammers (mallets) are made from the very strong butt-curled part of birch. They can be round (carpentry) or rectangular (carpentry).

When chiseling thick wooden parts (logs, beams), use a carpenter's chisel that can withstand high-power blows. This chisel has a glass-shaped handle into which a wooden part surrounded by a metal ring is inserted.

The handle for carpentry chisels and chisels is best made from beech or silver birch. Its length should be at least 16 cm to make it more convenient to work with two hands.

The tails of carpentry chisels and chisels are hammered into precisely drilled holes so that the axes of the handle and the tool coincide. Instead of drilling holes, they can be burned with the hot tail of the tool itself. Such a burnt hole (4/5 of the length of the tail) tightly compresses all the irregularities of the tail and more evenly transfers the blow from the handle to the cutting part.

It is recommended to stuff a piece of thick sole leather on top of the handle, which protects the wood from cracking. The top of the handle must be beveled, and a metal washer must be placed on the tail, increasing the support area. The most popular set of chisels and chisels includes chisels with a width of 8-, 12- and 25-30 mm, chisels with a width of 6-8- and 1.4 mm and a carpenter's chisel with a width of 18 mm.

Chisels are sharpened at an angle of 25°, chisels - from 10° to 25°.

In order for the tenon joint to be tight, it is necessary to cut out a hole, leaving the marking marks visible along the entire contour. You only need to cut out holes with chisels. Chisels are used to chisel only in very fine details, performing finishing work. In all other cases, when working with a chisel, pressure on it (or impact on it) must be done by hand. The chisel must be held perpendicular to the surface of the product. You cannot break out chips by tilting the chisel to the side, as the edges of the hole will inevitably become crushed, and the work will turn out sloppy. Marking is done using a surface planer and a square.

In carpentry, markings are made with an awl. In order for the hole to be accurate, chiselling must begin by retreating from the mark by 1-1.5 mm. The first blow should not be strong so that the tool does not cut deeply and forms a small supporting plane that does not allow the fibers to be crushed when cutting deeply. If you hit hard at once, the chisel will crush the fibers and go beyond the mark; however, the work will not be clean. It is advisable to cut through holes on both sides.

Chiselling holes and sockets with a chisel can be successfully replaced by drilling. It requires significantly less effort and time and in inexperienced hands gives better results. To create right angles, the drilled hole is cleared with a chisel. It is recommended to make holes in wood with a diameter of up to 12 mm using metal-cutting drills sharpened at an angle of 60″. Holes from 12 to 20 mm must be drilled with spiral rotary drills, and over 20 mm - with special flat drills (perks), shaped like a spatula.

Drills must be purchased with a double-threaded end and a single-threaded shaft. Such drills are less clogged with chips. Double-threaded drills enter the wood with great difficulty and become clogged with shavings (especially if the wood is dry or twisted). When buying perks, you need to pay attention to the distance from the edges of the perk to the center. If the cutting feather (road worker) is closer to the center than the other edge of the feather, then the tool will not work, no matter how sharply it is sharpened. The distance from the center to the road runner should be 1 mm greater than the distance to the edge of the opener, and the feather of the road runner should be at least 3 mm below the opener. When drilling hard wood, the thick center does not allow the drill to move, which is why you have to press hard on the brace. In this case, the center needs to be sharpened.

The drills are sharpened with small files - needle files, and the sharpening is done with corundum. To make drilling easier, the wood is moistened - water is poured into the hole, and the work goes easier. Wide axes are very convenient for selecting grooves in logs when making pick-ups - with an ax all that remains is to remove parts of the log between the drilled holes. It is not recommended to drill boards with so-called spoon or “Russian” drills: they can easily be split. Drills are drilled along the fibers, into the end.

The most convenient are rotators with a ratchet and a central chuck, which allows you to clamp drills with any tail. They are built on ball bearings, are easy to move and allow you to work in corners and against walls where circular movements cannot be made.

Tools for planing (planes or planes) can be metal or wood. Metal ones glide worse on wood, but wear out little, have good clamping and mechanical supply of pieces of iron. This makes them very convenient to use. Metal planes are especially good when working with used materials. Steel planes are better than duralumin ones, but many craftsmen prefer only wooden ones.

For planing logs, a plane with a single piece of iron 65 mm wide and a block length of 450-500 mm is used (bearer). The bear is planed by two people, for which two handles are attached to it - crossbars. One pulls the plane towards himself, the other pushes.

Rough planing of the sawn surface of the boards is done with sherhebel (preferably steel), since the surfaces of the boards are often covered with dust, sand, and cement. The narrower the gap between the blade and the block, the more difficult it is to plan raw or roughly sawn wood, so the bear and sherhebel intended for rough planing should have a gap of 5-6 mm.

Sherhebel is used to plan at an angle to the direction of the grain. The remaining planes are used along the grain. For chipping twisted areas and places near knots, short planes with a double piece of iron and a narrow tap hole (sanders) are used. When gluing plywood onto panels, their surfaces are planed with a tsinubel - a plane with a toothed piece of iron set very steeply to the base. If you insert an ordinary double piece of iron into the tsinubel, you can plan with it in the same way as with a sander, removing very thin shavings. The ends are processed with a plane in such a position that its piece of iron is at an angle to the direction of planing.

For clean work (smoothing planes or edges), planes with single and double iron are used, as well as a jointer designed for particularly precise work.

Planing of folds and quarters, for example, in door and window frames, as well as in bindings, for inserting glass, is done with a zenzubel and a folding tool, which is often called a selector or a quadruple. It is recommended to have a zenzubel with a straight piece of iron placed perpendicular to the direction of the sole, since a straight zenzubel can plan in both directions, but with an obliquely set piece of iron - only in one direction.

Obtaining shaped edges and curved surfaces refers to purely carpentry work, which is rarely encountered in the practice of an amateur builder. They are planed with special planes: moldings, fillets with figured pieces of iron.

When choosing new pads, you must be guided by the following rules: the best pads are maple, hornbeam or beech, glued lengthwise. Solid red beech pads sometimes warp from humid air, so after adjustment and adjustment they need to be painted with oil varnish. When purchasing a pad, you need to check that its sliding plane (sole) is correct so that there is no “screw”. You should also check the squareness of the side walls to the bottom plane, especially for jointers. In order for the piece of iron to be moved sideways with precise adjustment of the cutting edge and the sole of the plane, it must be 1-1.5 mm narrower than the groove.

A block with a jammed piece of iron must have a gap in the tap hole from the cutter to the tree: in single planes - 4, in double planes and jointers - 2, in zenzubels and molds - 3 mm. The wedge should come to nothing so that chips do not rest against its lower edge.

In most of the new blocks of saws, selectors and molds, the ejection hole is only marked, and you have to finish it yourself. In such blocks you need to make a special cutout with a drill. To avoid spalling, you need to drill from both sides. From such a hole the chips easily come out on their own or are pushed out with your finger.

It is recommended to buy thin pieces of iron, since thick ones, hardened to the full thickness, are more difficult to sharpen. Welded irons are the most convenient: they have a thinner steel cutting plate welded onto a soft iron base.

The convenience of working with a plane largely depends on the correct sharpening of the piece of iron. In inexperienced hands, the chamfer of the piece of iron usually turns out to be humpbacked and this quickly becomes dull. For proper sharpening, it is not difficult to make a special device. By pulling out or pushing in the piece of iron, you can get the required sharpening angle. After stripping the piece of iron on coarse corundum and a wet point, it must be sent on a whetstone. This grinding of the tip doubles the working life between points.

The sharpening angle varies depending on the humidity and hardness of the wood being processed. For damp and soft wood, the sharpening angle is 30-35°, for dry and hard wood -40-45°. The quality of the metal of a piece of iron can be determined in the following way: if the cloudy spot that appears when breathing on the piece of iron quickly disappears, then the quality of the steel is good. The good quality of the steel is also indicated by scale falling off the cutting part.

In addition to the listed devices and tools for carpentry and joinery work, you need to have a 10 m long cord for marking logs, a plumb line, a square, a folding meter and a tape measure. Marking devices: scribers, drawbar, bracket - you can make it yourself.

In carpentry work, obligatory marking tools are a surface planer and a rhombic awl with a sharp end. In addition to marking, this awl is used to make holes for screwing in screws.

Types of planes, checking the pads: 1 - plane; a - side view (the dotted line shows the location of the incisor); b - block glued horizontally; c - block glued vertically; 2 - checking the correctness of the pad

square; 3 - jointer (the triangle shows the places where the mallet is used to knock out the piece of iron); 4 - selector (quadruple); 5 - zenzubel; 6 - kalevka

Glands (incisors) and devices for the point: 1 - Scherhebel gland; 2 - piece of double plane (jointer): a - rear view; b - side view; 3 - selector piece (quadruple); 4 - piece of zenzubel: a - straight; b - oblique; 5 and 6 - kalevka pieces of iron; 7 - iron fillet; 8 - device for the correct point of the piece of iron; 5 - embedding the bars into the board; 10 - sharpening angles of pieces of iron: a - for hard wood; b - for damp and soft wood

In carpentry and joinery work, you also have to use some general-purpose metalworking tools - pliers, wire cutters, screwdrivers of various types and sizes, pliers, files.

“When buying files, you need to check the strength of the steel. This is done with a piece of hacksaw blade; If, after running the blade with slight pressure along the plane of the file, a strong shine appears, the steel is soft and the file will not work for a long time.

Sanding, sharpening and hewing of logs: 1 - sharpening logs under a staple with a bearer: a - staples; b - bracket; c - taking a sharpener; g - mole cricket; 2 - strengthening the log in the clamp at the stop, beating the cutting line using a cord; 3 - strengthening the log with staples; 4 - direction of the ax when hewing: a - correct; b - incorrect; 5 - drawing the most advantageous section of the beam from the thin end of the log

JOINERY WORKS JOINERY WORKS- work on the manufacture and repair of wooden (carpentry) products (window frames, doors, furniture, etc.). From carpentry work(see) are distinguished by more careful processing of wood and a more precise fit of parts of products, connected mainly with glue. Carpentry work performed from coniferous or soft hardwood wood is called whitewood, and from hardwood (oak, beech) or when veneered - cabinetry.

Carpentry work includes the following operations: sawing, planing, drilling, chiselling, scraping, assembling and fastening parts of products, finishing products and workpieces (sanding, polishing). The processing and assembly of parts is carried out on a workbench, which is a durable elongated table with devices for securing parts. Basic hand tools for carpentry work: bow saws and hacksaws - for longitudinal and transverse sawing; sherhebel plane - for primary (rough) planing; plane - for cleaner planing; jointer (extended planer) - for final, finishing sharpening; scraper - for thoroughly cleaning the surface of the product; drills and braces with drills - for drilling holes; chisels - for roughing and chisels - for final chiselling and cleaning of nests, eyes and tenons. Auxiliary tools: hammer, pliers, screwdrivers, pliers, files, whetstones and whetstones - for pointing and straightening cutting tools; meter, compass, gauge - for drawing parallel lines; square, ruler, clamping devices (collars, clamps, etc.) - for temporary fastening of parts when gluing. see also

.

Parts of joinery products are usually connected to each other by means of tenons, which are cut out on one part and inserted with glue into the corresponding slots, slots, eyes in the adjacent part. Spikes are often made insertable. In addition to glue, metal fasteners are sometimes used to connect parts: screws, pads, squares. Connections made with metal fasteners without glue require less labor than those made with glue, but they are less durable.

Carpentry products are mostly produced by skilled workers at woodworking plants, furniture factories, etc. Manual production of carpentry products also requires professional skills and craftsmanship. However, many simple-in-design products and their repairs are often carried out by carpentry enthusiasts. The simplest carpentry work, especially repair work, can be done “with your own hands” and without special skills.

Below are some examples of simple carpentry repairs around the house.

If the window frame gets stuck in the narthex, you need to clean the narthex with a chisel or plan it with a plane. Places that require cleaning or trimming can be determined by passing tissue paper into the slit of the narthex; The stitching of bindings swollen from dampness should be done only when the bindings are thoroughly dry.

If a too large gap forms in the vestibule, for example due to the binding drying out, then a strip should be placed on its edge, preferably from the hinge side (Fig. 1). The thickness of the planks must be at least 10 mm at the thinnest point; if a thinner strip is required, it is better to trim part of the binding binding and insert a strip of sufficient thickness.

The skewed binding can be straightened; To do this, you have to first remove the glass and place metal squares on screws in the corners (Fig. 1); If the wood is not destroyed, you should cut the squares flush with the binding and then paint the binding.

The rotted flashing, installed on the outside of the summer casements and windows, can be replaced with a new sewn one. On the lower side of the ebb you need to select a drip groove (Fig. 2). It is advisable to embed the ebb into the bottom bar of the binding at 5 mm.

To replace a rotten window frame, you need to: remove the sash from its hinges; take out the glass; drill wooden dowels in the corners where the bar being replaced is adjacent; Using a wooden hammer (mallet), carefully, placing a wooden spacer, knock out the unusable block; place a new block on the glue, processed according to the shape and size of the old one, with holes drilled in the corners for dowels (the block is driven into the eyes of the binding tenons using a mallet); after checking the correctness of the angles, secure the binding in clamping devices (clamps, clamps) and hammer dowels lubricated with glue into the holes (the squareness of the binding is determined by using a square or measuring the diagonals from corner to corner); prick the ends of the through tenons and drive wedges coated with glue into the prick spots; After the glue has dried, cut off the protruding ends of the dowels and spikes and clean the joints with emery cloth. If the lower ends of the vertical bars are also rotten, they can be partially replaced with precisely made extensions on tenons and glue with dowels installed (Fig. 3). Here you should pay special attention to the careful fit of the tenons and the tightness of the parts. When replacing binding bars, metal squares are usually required.

The gaps in the window sill board can be sealed with a strip inserted into the gap using glue.

Small distortions of the door leaf can be corrected by tightening or wedging the hinges and trimming the strapping beam in the vestibule.

In case of large distortions, it is necessary to remove the canvas from the hinges, adjust it and hang it again on the hinges; It is better to put the hinges in new places, and seal the places where there were hinges with strips. If there are large gaps in the narthex, strips should be filled, just like in window sashes (see above).