Fiberglass reinforcement for foundations: reviews. Fiberglass reinforcement - how to choose and where it can be used Composite reinforcement is made from

Read also

Strict competition requirements in the field modern construction forced to look for ways to reduce costs, including the use of new materials. New formulations of building stone, special grades of concrete, foundation compositions, facing and thermal insulation materials are appearing. In parallel, in a market previously traditional for metal fittings and special designs, manufacturers of various composite products are actively trying to win their “place in the sun.” Most often these are non-metallic strength elements and fiberglass reinforcement.

Why did fiberglass reinforcement appear on the construction market?

Composite materials, including fiberglass reinforcement, are manufactured in a relatively simple manner technological principle impregnation of glass or basalt fibers epoxy or polyester matrix resin. Next, the bundle is formed on a machine into a rod of composite reinforcement calibrated in diameter, and baked at low temperatures. high temperature in a special drying oven. Typically, the length of one piece of reinforcement does not exceed 100 m.

Fiberglass reinforcement does not require the operation of complex and expensive equipment, so the production costs themselves are relatively low, most of the cost is the price of the resin for the matrix and the fiberglass tow. And yet, if you compare the cost of fiberglass and steel rods of the same diameter, metal reinforcement has a warehouse price that is 10-20% less, and this is a very big difference for such an area as construction.

Nevertheless, fiberglass material has quite strongly replaced rolled metal products, not least because of a number of specific properties, but the main factors were slightly different reasons:

- Fiberglass reinforcement has increasingly begun to be used in private low-rise construction. It is more accessible to use, it is easier and much cheaper to transport, store, and cut. It does not need to be straightened and leveled before use, as is the case with the steel version. You can buy the material in a whole bay and cut it into pieces yourself. non-standard length. Whereas a standard 11-meter steel rod would require a lot of waste if your foundation, for example, has reinforcement 8 m long;

- The availability of equipment for the production of reinforcing strands has allowed many small enterprises - manufacturers of building materials - to establish continuous production of fiberglass reinforcement in the most various options performance of the rod surface. A huge number of offers, a competent sales policy and Hiden advertisment allow you to diversify the market;

- The desire of contractors to save money construction work ah on a more advantageous material for reinforcement, for which a formal, “blind” recalculation of the strength equivalent of composite materials and steel reinforcement is often used.

Reviews from experts, advantages and disadvantages of composite thread

If you wish, you can find the most complex calculations and quite simple primitive arguments about why fiberglass reinforcement is good or bad. As a rule, serious research and reviews from specialists in most cases do not give specific recommendations, in fact, the “hot” problem of the foundation; in many ways, the capabilities of fiberglass-based reinforcement must be assessed at your own peril and risk.

Attention! Among the numerous reviews of specialists, there are practically no real professional experts in the field of structural mechanics of composite materials. Their opinion and feedback, as a rule, are reflected in the assessments and custom calculations of specific construction projects, cost a lot of money and are not presented to the public.

An approach can be called professional if the reviews of certain experts are evaluated specific situation using, for example, fiberglass rods in the foundation of a house using practical results and analyzing the reasons. Otherwise, such expert reviews can be called, at best, advertising or anti-advertising.

Using fiberglass rods in the foundation

The use of reinforcing mesh based on fiberglass load-bearing elements began in the 60s of the last century. In addition, a fairly large number of buildings and technological structures made of stone and concrete have been built and are in operation, in the foundations and walls of which fiberglass-based reinforcement is used. Feedback on the condition of buildings with elements of steel and fiberglass reinforcement and many years of operating experience will give more than all the theoretical calculations of “experts” combined.

Almost everyone who makes videos or posts their opinion about the shortcomings of fiberglass reinforcement is either sales managers of competing steel products, or amateurs who confuse the causes and consequences of the basic principles of strength and rigidity of structures. For the most part, such discussions about the disadvantages of fiberglass reinforcement are accompanied by formulas and data on the strength of steel and composites. But there are no clear reasons or processes why fiberglass reinforcement cannot be used. If a person who undertakes to comment on the advantages and disadvantages of fiberglass reinforcement has not demonstrated in practice a fragment of destroyed concrete or a piece of foundation with fiberglass reinforcement, all his reasoning remains fantasies on an arbitrary topic.

Fiberglass reinforcement is used in construction, mechanical engineering, special projects for more than 40 years. If this issue is of fundamental importance to you, refer to old Soviet textbooks from the 70s of the last century, magazines on construction topics; these sources reveal the physics and mechanics of foundation destruction processes and provide numerous examples of errors.

Possessing high specific strength, fiberglass reinforcement can work perfectly in the most difficult conditions, but at the same time it has a number of disadvantages that limit its use in construction:

- The fiberglass nature of composite reinforcement has almost zero ductility of the material. In human terms, a frame for a highly loaded foundation or walls made of such a rod will not be able to plastically adapt to the redistribution of load in a loaded concrete stone. As a result, in selected places the foundation of the building will be overloaded, which may cause cracks;

- The fiberglass base takes tensile axial loads very well, but compressive loads much worse, and tolerates shear forces catastrophically poorly. This means that any transverse shearing force, of which there are many in “fresh” foundations due to sedimentary processes, will lead to destruction of the integrity of the reinforcement;

- Unfortunately, during the time that the foundation concrete gains strength, the fiberglass frame behaves somewhat differently, and it is at this stage that everyone specific case in the arrangement of fittings requires very careful and careful analysis.

Therefore, in those units where it is permissible to replace metal with a composite material, instead of a traditional eight-millimeter rod, a six-millimeter fiberglass reinforcement strand can be used. Few people know, but today building slabs from stressed concrete with fiberglass reinforcement are already being produced. But in production such material is much more expensive, so almost 90% of the range, including for foundations, are custom-made products.

Application options for glass reinforcement

An undeniable advantage of steel reinforcement is the very well predictable behavior of the metal under the most difficult loading conditions. All existing skyscrapers and high-rise buildings are built only on steel reinforcement; moreover, most of these “wonders of the world” have an internal metal frame.

Glass fittings for high-rise buildings or highly loaded foundations will not be suitable. The structural mechanics of foundations is, in general, a whole science, primarily due to the complex interaction of individual parts of the foundation with the soil, with the walls of the entire structure.

In the existing foundation model, the most problematic areas are the corner zones, where the reinforcement experiences tensile, bending and shear loads. In these places, not every steel reinforcement is able to provide a rigid connection of corner blocks. The metal reinforcement in the foundation block achieves this only due to a combination of high ductility and elasticity. Fiberglass reinforcement cannot be used in these foundation units. Despite its high longitudinal strength, it will not be able to withstand twisting and cutting at the corner contact point of the foundation.

The strength and ductility of fiberglass reinforcement will be sufficient to build a foundation and basement, one or two-story house. But provided that in the corner joints of the foundation, special couplings will be used to splice the reinforcement at right angles. Moreover, fiberglass is easy and simple to use for a simple strip foundation 70-90 cm deep.

The use of fiberglass reinforcement in combination with special grades of concrete for the foundation is considered successful. Often, when special additives are used in the foundation to enhance frost resistance or water resistance, steel reinforcement begins to corrode intensively. Especially in foundations on soils with a high salt content or in close proximity to transformer substations.

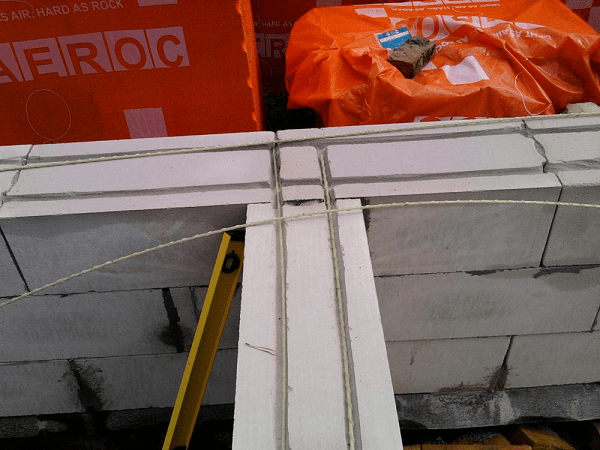

Within the walls low-rise buildings, especially from aerated concrete block, arbolite stone and any other building material that has low rigidity and contact strength, the use of fiberglass reinforcement is even encouraged. It is much simpler and easier to work with than a steel bar.

In addition, composite reinforcement is simply ideal for attaching external insulation or masonry facing bricks, where either galvanization or stainless steel is required. And, even more so, it is worth using thin glass thread for work on basement foundation blocks.

Conclusion

Another problem characteristic of Russian reality, which is definitely worth mentioning. This is the low quality of the fiberglass reinforcement itself. domestic manufacturer. Almost every coil with reinforcement has fracture defects.

During storage and transportation, a metal rod can be stolen or barbarically unloaded in an inconvenient place far from the foundation. But in any case, its quality will not suffer. Fiberglass thread can be easily damaged during transportation and not even notice it. It is definitely impossible to lay such reinforcement in the foundation.

Which appeared on construction market relatively recently, it has both advantages and disadvantages, which the consumer must be aware of. Despite the assurances of manufacturers that this product is a complete replacement for metal fittings, its use cannot be considered justified in all situations.

What is fiberglass reinforcement

The so-called composite reinforcement is a fiberglass rod around which a carbon fiber thread is wound, which serves not only to strengthen the structure of such a product, but also to ensure its reliable adhesion to concrete mortar. This type of fittings has both pros and cons, and its use should be approached very carefully.

The elements for fixing carbon fiber reinforcement bars to each other are plastic clamps. Conveniently, the connection of elements of such fittings does not require the use of welding, which is undoubtedly a big plus.

When assessing the feasibility of using fiberglass reinforcement, it is necessary to consider all the pros and cons of its use in individual situations. This approach will ensure high efficiency this material as a means of strengthening building structures for various purposes.

If you do not take into account the characteristics of fiberglass reinforcement and do not compare them with the parameters similar products made of metal can cause serious damage to the future building structure or finishing elements. That is why, before you start choosing elements for reinforcing concrete structures, you should understand in which cases the use of certain products is more appropriate.

Main advantages

Among the advantages of carbon fiber reinforcement, it is worth highlighting the following.

- An important advantage of fiberglass reinforcement is its low specific weight, which makes it possible to use it for reinforcing light structures made of cellular concrete and some other building materials. This allows you to significantly reduce the weight of structures that are reinforced with its help. Meanwhile, the weight of a conventional concrete structure when using fiberglass reinforcement will decrease slightly, since the building material itself has an impressive mass.

- Low thermal conductivity is also an advantage of fiberglass reinforcement. When using such reinforcement in concrete structures, no cold bridges are formed (which cannot be said about metal reinforcing elements), which significantly improves their thermal insulation parameters.

- The high flexibility of fiberglass reinforcement allows it to be shipped to the customer in coils, rather than cut into individual rods. Thanks to compact form packaging, transporting such fittings is much easier, for which you can use the trunk of any passenger car, and this seriously reduces the cost of delivering material to the site of construction work. The use of reinforcing elements, which are shipped not as cut rods, but in coils, also makes it possible to reduce material costs by reducing the number of overlaps. This has a positive effect on both the strength characteristics of the future concrete structure and its cost, which is especially important when performing construction work.

- The advantage of fiberglass reinforcement, such as its durability inside a concrete structure, is considered quite controversial. Metal fittings, being in an isolated state, are also not subject to negative influence external factors, which ensures durability of its use.

- Carbon fiber reinforcement is a dielectric material, which is an advantage of products made from of this material. Electrically conductive metal fittings are more susceptible to corrosion, which negatively affects its durability.

- Compared to metal reinforcing elements, fiberglass products are not exposed to chemically active environments. This advantage of fiberglass reinforcement is especially important in cases of construction of buildings in winter time, when various salt solutions are added to concrete, accelerating the hardening process.

- Being a dielectric, carbon fiber reinforcement does not create radio interference inside the building, unlike metal rods. This advantage is important when there are many reinforcing elements in a concrete structure. Otherwise, the use of composite reinforcement will not be a disadvantage, but it will not be so relevant.

Fiberglass reinforcement also has disadvantages, which potential consumers should also be aware of.

Main disadvantages

The disadvantages of fiberglass reinforcement are associated with its following characteristics.

- The disadvantages of fiberglass reinforcement include, in particular, the fact that it cannot withstand high temperatures. At the same time, it is difficult to imagine a situation where a reinforcement cage located inside concrete can be heated to a temperature of 200 degrees.

- Enough high price- this is a conditional disadvantage, given the fact that for reinforcement concrete structures you can use fiberglass reinforcement of a smaller diameter in comparison with metal products.

- Carbon fiber reinforcement does not bend well. This drawback limits its use in creating reinforcing frames for concrete structures. Meanwhile, bent sections of the reinforcement frame can be made from steel elements, and then they can be extended using fiberglass rods.

- Reinforcement made of fiberglass does not withstand fracture loads well, which is very critical for concrete structures. Accordingly, their reinforcing frame must successfully withstand such loads, which reinforcement made of composite materials cannot boast of.

- Unlike metal reinforcement frames, fiberglass products have less rigidity. Because of this drawback, they do not tolerate vibration loads that occur when pouring them using a car mixer. When using this technique, the reinforcement frame is subjected to significant mechanical loads, which can cause its breakdown and disruption of the spatial position of its elements, therefore quite high demands are placed on the rigidity of such concrete structures.

Considering the advantages and disadvantages of fiberglass reinforcement, it is difficult to say how much better or worse it is made of metal. In any case, the choice of this material should be approached very reasonably, using it to solve the problems for which it is really intended.

Areas of application of fiberglass reinforcement

Reinforcement made of composite materials, the installation rules of which are easy to learn from the corresponding videos, is used in both capital and private construction. Because the capital construction carried out by qualified specialists who are well familiar with the nuances and disadvantages of using certain building materials, let us dwell on the features of using such material in the construction of private low-rise buildings.

- Reinforcement made from composite materials is successfully used to strengthen foundation structures following types: strip, the height of which is greater than the depth of soil freezing, and slab. The use of carbon fiber reinforcement to strengthen foundations is advisable only in cases where the structure is being erected on good soil, where concrete bases will not be subjected to fracture loads that fiberglass elements simply cannot withstand.

- Using fiberglass reinforcement, they strengthen walls whose masonry is made of brick, gas silicate and other blocks. It should be noted that, as a connecting element of walls, composite reinforcement is very popular among private developers, who use it not only to strengthen masonry load-bearing structures, but also to ensure their connection with the facing partitions.

- This material is also actively used to bind elements of multilayer panels. The structure of the latter includes a layer of insulation and concrete elements, which are connected to each other using fiberglass reinforcement.

- Due to the fact that the type of reinforcement in question does not have such a disadvantage as susceptibility to corrosion, it is often used to strengthen various hydraulic structures(for example, dams and swimming pools).

- In cases where it is necessary to effectively increase the rigidity of glued wooden beams, they are also strengthened with fiberglass reinforcement.

- This material is also used in road construction: with its help, they strengthen the layer of asphalt that is exposed to increased loads during its operation.

Summarizing all of the above, it should be noted that fiberglass reinforcement can be used quite effectively, if we take into account its disadvantages and associated limitations, which are specified by the manufacturer.

Can fiberglass reinforcement replace metal counterparts?

Despite the fact that reinforcement made from composite materials is a fairly new material on the construction market, you can already find many recommendations (and even videos) on its use. Considering these recommendations, we can conclude that it is best to use fiberglass reinforcement to strengthen walls built from bricks and building blocks, as well as for communications load-bearing walls with interior partitions.

Fiberglass reinforcement is a building material that is made from glass roving, connected using an epoxy compound based on thermoactive resins. The main feature is lightness; the mass per unit volume is only 2 g/mm³. Working with fiberglass reinforcement is more convenient and economically feasible than working with metal reinforcement. Significantly lower costs are required for logistics and directly during reinforcement.

In addition, due to the fact that fiberglass does not react to aggressive environments, the reinforcement therefore protects concrete from premature destruction, thereby increasing the service life of the object. Fiberglass reinforcement reacts to temperature changes similarly to concrete, which also has a good effect on the strength of the structure.

The strength of fiberglass compared to metal is 2.5 times higher. At the same time, the thermal conductivity index is 100 times lower than the thermal conductivity index of steel. Therefore, a structure that is reinforced with fiberglass does not freeze (does not form “cold bridges”) and a building built using fiberglass will be warmer than a building based on metal reinforcement. This allows you to reduce heating costs, and therefore the material is actively used in the construction of modern energy efficient buildings.

Another undeniable advantage that may interest builders is the fact that fiberglass is surprisingly durable material, which for 100 years after installation does not require additional repair work. This is what fiberglass reinforcement for foundations is famous for.

Fiberglass reinforcement has found its application in many areas of industry, construction, utilities:

- in construction, it is used in the construction of civil and industrial construction projects as a basis for foundations, floors, beams, as well as in the construction of earthquake-resistant belts;

- In the construction and repair of roads, reinforcement is used in the construction of embankments, road surfaces, in the construction of bridges and highway barriers. It is resistant to the effects of reagents that are applied to road surfaces (for example, de-icing reagents), so it can be used both in Moscow and in colder regions.

Fiberglass reinforcement will be an ideal basis for concrete and brick structures. It is used in the creation of supports for power lines and lighting, in the construction of road, sidewalk and fence slabs, as well as in the installation of sleepers on railway tracks. Reinforcement for floors, where a mesh of reinforcement is used, even together with metal, has become widely used.

Fiberglass is used in such building structures as monolithic foundation and foam concrete. It is also actively used in the creation of structures that must have increased resistance to chemicals, for example:

- during the construction of storage facilities for chemical waste and components;

- when installing sewerage systems, water pipelines, land reclamation systems;

- during the construction of port facilities and during the strengthening of coastlines.

Despite the uniqueness of the product, the price of fiberglass reinforcement in Moscow, which is indicated on our website, is available material and for construction organizations, and for individuals. Its cost is 40-50% lower than the cost of steel reinforcement, which allows you to significantly reduce costs and at the same time improve the quality of constructed objects. In general, composite reinforcement can be called one of the most reliable and efficient building materials of our time.

This reinforcement is made from straight strands of glass or basalt fibers (ASP and ABP, respectively), which are collected into a bundle, impregnated with a thermosetting polymer binder, molded, heated (polymerized) and cooled. The result is a monolithic rod of high strength, which, according to test results, is 3 times higher than the tensile strength of steel, and the weight, in an equal strength ratio, is 9 times less.

Standardly manufactured in the form of rods of any length, at the request of the customer. With a diameter of up to 8 mm inclusive, it can be manufactured in the form of coils (coils) containing 100 meters of reinforcement. dimensions coils: height – up to 8 cm, diameter – up to 1 meter.

release form

With a diameter of 10 mm and 12 mm, it can be manufactured in the form of coils (coil fittings) having a length of 50 meters. Overall dimensions of the coil: height – up to 5 cm, diameter – up to 1.5 meters.

By agreement with the customer, it is possible to produce rods and coils of any length.

Can be manufactured with a smooth, construction, periodic profile:

- ASP-ABP of periodic profile, used instead of steel reinforcement class A-I II (A-400);

- ASP-ABP with a smooth profile is used instead of steel reinforcement of class A-I (A-240).

Fiberglass reinforcement is becoming more and more popular and its use is becoming more and more relevant every year, because it is a complete replacement for traditional steel rods different brands. High strength indicators, optimal operational properties, low specific gravity and low price- these are the factors that determine the popularity of the use of reinforcing non-metallic elements in all areas of construction.

In many areas, the metal is inferior to modern composite alloys. It is expensive, heavy and not as durable as, for example, fiberglass. Fiberglass reinforcement is already confidently competing with metal in construction. In this material from HouseСhief.ru we will look at the unique characteristics of composite building materials, the practice of its use and the selection algorithm.

Read in the article

Areas of application of fiberglass reinforcement

Composite materials have found application in different directions construction. Let's look at the main ones.

| Application area | Peculiarities |

| It is an equally strong replacement for metal structures and can significantly save installation time. The reinforcement spacing is maintained and the joints are overlapped. | |

| Economic benefits of replacing metal with plastic in strip foundations– up to 45%. carried out with knitting wire. | |

| Concrete floors | The principles of reinforcement do not differ from those when using metal; the material is cut. |

| The blind area using reinforcing composite material has high anti-corrosion characteristics and does not suffer from cracking. | |

| Armopoyas | The use of composites in reinforcement significantly increases the seismic resistance of the building and protects it from damage associated with uneven settlement. |

| For floor slabs, it is recommended to combine fiberglass with traditional metal reinforcement in the bottom layer. The joints of the reinforcement are arranged in a checkerboard pattern. | |

| Road construction | Composite materials significantly increase strength and durability road surfaces, bridges, arches and pedestrian . |

| Monolithic construction | Metal parts in monolithic structures suffer from corrosion in one way or another. Composite material increases service life monolithic concrete several times, prevents the formation of cracks and chips in it. |

Basics of the production of fiberglass reinforcement and its structure

For the production of composite building materials, aluminoborosilicate glass is used as a raw material. It is melted at high temperature and special equipment stretched into the thinnest threads.

Strength is achieved precisely due to the multi-layering of the material. The basis is the inner rod, fastened polymer resin, and fibers of a composite composition are wound around it. To speed up polymerization, the reinforcement is fired in tunnel kilns and then cooled under running water.

Properties of composite material

What distinguishes fiberglass reinforcement from other reinforcing materials? Here are its main operational characteristics:

- the weight of rods is 9 times less than similar metal rods;

- the composite composition is impervious to the aggressive effects of moisture, alkalis and acids;

- the thermal conductivity of fiberglass is much less than that of metal - this eliminates its occurrence in building structures;

- transportation of fiberglass is greatly simplified due to its low weight;

- Composite material does not conduct electric current.

Fiberglass reinforcement: sizes and types

Significant parameters of this material are weight linear meter, winding pitch and rod section size.

Composite reinforcement with a 15-mm winding pitch is considered the most popular in construction today. Outside diameter The rods can be from 4 to 18 mm, the weight of a linear meter is from 0.02 to 0.42 kg.

Builders divide fiberglass mesh into subtypes based on area of use. They divide it into working, installation, distribution and special.

GOST requirements for composite reinforcement

Application fiberglass materials in construction legalized in 2014: GOST No. 31938-2012 on composite polymer reinforcement. GOST requires this building material the following requirements:

- reinforcing filler must be at least 75%;

- tensile strength – not less than 800 MPa;

- tensile elasticity – not less than 50 GPa;

- adhesion strength to concrete – at least 12 MPa.

Pros and cons of fiberglass reinforcement for private construction

And now about the pros and cons of plastic fittings in individual construction. What can be added to the benefits of using composite material for reinforcement? First of all, its light weight, which makes it possible to significantly reduce total weight designs.

Another important positive factor is the flexibility of fiberglass. It is packaged in compact bays, which greatly simplifies the transportation problem. In addition, this form of release makes it possible to reduce the amount of possible waste during cutting.

What do reviews say about the disadvantages of fiberglass reinforcement? Or is this material so good that it has no flaws? This is wrong. AND main drawback– price. Despite the fact that the manufacturing technology of fiberglass is not that complicated, products made from it are still expensive. The point is most likely that demand still exceeds supply. When the opposite happens, the price will go down. What else is worth paying your attention to is that fiberglass reinforcement does not withstand fracture pressure well.

Important points in choosing composite fiberglass reinforcement

How to protect yourself from poor quality goods? There are several dangerous points that dishonest sellers may try to hide from you:

- inaccurate information about the diameter of the fittings - you must be present when the goods are shipped and personally check the declared dimensions of the goods;

- the product was burned in an oven - check that the color of the fiberglass is uniform in each coil;

- the product is compressed during the manufacturing process - the reinforcement should not have convex parts between the anchoring ribs;

- other violations of the production process - do not buy goods from little-known manufacturers.

Opinions and reviews of professional builders on the use of composite reinforcement in the foundation

The use of composite reinforcement is no different from the procedure metal laying. Feedback from experts on the use of fiberglass reinforcement indicates that the composite material can be used for any type of base. Such reinforcement will last at least 80 years. External and internal reinforcement is acceptable. External, according to builders, is necessary in situations where there is unfavorable environment, For example - .

Discrete reinforcement involves placing fiberglass mesh inside the structure. Can be used as additional reinforcement or combine these two methods of strengthening the foundation.

If you have a choice: which reinforcement is better, metal or fiberglass?

As already mentioned, reviews from builders about plastic reinforcement are confidently moving metal in many positions. The thermal conductivity of fiberglass is 0.35 versus 46 W/m for metal. Fiberglass products are superior to metal in elasticity and ductility, and they are almost three times stronger. So is it possible to use fiberglass reinforcement as the only reinforcing material?

However, steel has not yet given up completely. A comparison of fiberglass and metal reinforcement suggests that steel is more resistant to bending, that is, it does not break under extreme load. This makes it indispensable in the production of floor slabs and other objects subject to deformation. So don’t write off steel products.

Price of composite reinforcement from well-known manufacturers

The cost of plastic fittings is based on its diameter and is measured in linear meters:

- products of the ArmaPlast brand, known for its quality, with a diameter of 6 mm will cost 6-7 rubles per linear meter;

- the price of 8 mm fiberglass reinforcement is 10-12 rubles;

- fiberglass reinforcement 10 mm, price per meter - 14-16 rubles;

- fiberglass reinforcement 12 mm, price per meter - 18-20 rubles.

Fiberglass reinforcement ArmaPlast

Manufacturer's prices shown - please note that retailers will have an additional markup.

What do we get as a result? Without a doubt, composite materials– this is the future of construction. Reviews from experts about fiberglass reinforcement indicate that this material extends the service life of structures and has many excellent characteristics, and is superior to ordinary steel.