Log house Canadian log house cutting: how to do it yourself. What is so attractive about Canadian logging? House felling using Canadian technology

Canadian logging involves the use of round planed logs as a building material for the manufacture of log houses. coniferous species wood The wood used for these purposes is one whose wood is endowed with a dense structure and unsurpassed quality.

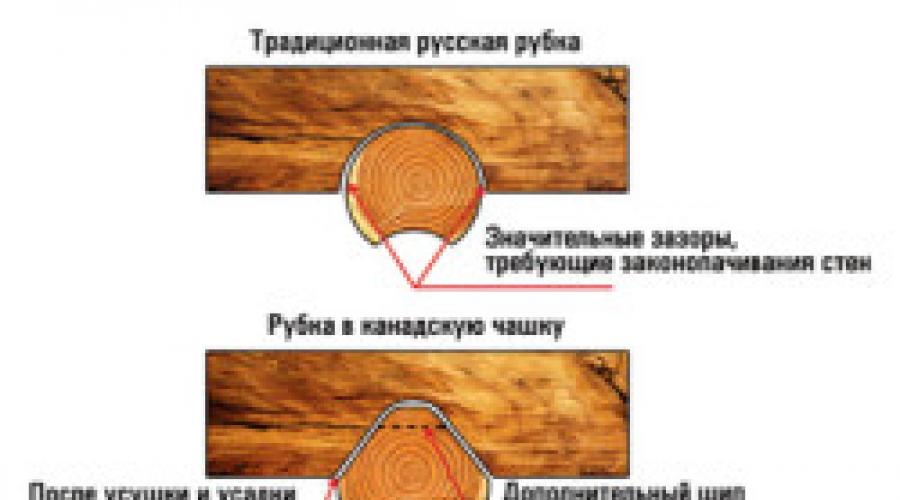

Scheme of processing logs using Canadian felling.

Canadian logging technology is actually a variation of Russian, since it originated in ancient times in our country. Even if you remember traditional dwellings indigenous people of Canada (from the north - Eskimos, from the south - Indians), then there is a clear external difference from the log hut. The name appeared much later than the Canadian logging itself. Having originated here, the technology did not take root in Russian spaces. In Canada, on the contrary, it gained particular popularity and began to be used everywhere, which is why it acquired its current name.

The corners in a wooden frame are most susceptible to rotting. This is due to the fact that in the traditions of Russian cutting “in the oblo” it is customary to place the bowl bottom down. Whereby storm water easily penetrates the bowl, which absolutely cannot happen when chopping in Canadian style.

All over the world today, felling of log houses is carried out using the Russian-Canadian technology “into the bowl”. The buildings erected using this technology are distinguished by reliability and entertainment, durability and practicality. Private construction wooden log houses under bathhouses and at home is gaining momentum more and more. But in our country, Canadian technology is not considered widespread due to the insufficient number of craftsmen to implement it. Much more often they use the usual Russian cutting.

However, among practical people who want to see their home built according to all the rules, felling using the Canadian method is gaining increasing popularity.

Canadian technology

When is it preferable? classic style with a round log according to tradition, but you don’t want to get drafty corners and constant caulking, then it makes sense to choose the Canadian hand-cutting technology. The main difference between the Canadian and Russian logging is the presence of wedges, the peculiarity of the design of self-locking corner locks, which eliminate blowing, high degree precision manufacturing wooden parts log house Even after decades, log houses built according to the rules of Canadian technology do not lose their unique beauty appearance and consumer characteristics. Cutting using Canadian technology combines the traditions of style and best methods in wooden house construction.

The main advantages of logging using Canadian technology:

- The selection of each log is carried out very carefully. Sanding and planing is carried out exclusively manually. What can’t be said about a rounded log, so compare this various material it is forbidden.

- The bowl and groove for laying the insulation are selected exclusively by hand.

- High-precision fit of the log allows you to eliminate gaps between the elements. Trapezoidal bowl. The walls of a chopped log house look like a solid mass, and the insulation is absolutely not noticeable.

- Manual felling in Canadian style has the peculiarity that it preserves the strength of the outer layer of wood, which significantly increases the period of operation of the chopped structure.

- There are no gaps between the logs due to the special arrangement of the insulation along the log. It fits into the groove and is not noticeable from the outside. Moreover, the log house retains the natural bends of the log. Therefore, each log house has a unique appearance.

- The carpenter's craftsmanship is crowned by the tightly fitted log joints at the corners, accurate to the millimeter. The own weight of the logs, combined with a tight fit, makes the log house strong and reliable for centuries. The external monumentality evokes a genuine feeling of admiration.

A log house does not require maintenance; it can be used for several hundred years. Anyone who has ever tried to live in such a house made of wood is unlikely to want to return to a brick or block structure, because own home gives a lot of positive emotions.

Northern pine for cutting in Canadian style

If you are thinking about what kind of wood to build a house from, then it makes sense to give preference to pine.

Pine grows almost everywhere on Russian territory. It can grow up to 50 meters in height, and up to 1.3-1.5 meters in thickness.

Due to its wide distribution, pine has gained great popularity in individual construction from logs. In terms of cost, log buildings made from pine are much cheaper than other similar buildings made from other types of wood. However, efficiency is not the most important thing for which you should choose a pine house. Pine is rich in resins and phytoncides. Thanks to them, it is installed inside the structure healthy microclimate. If anyone was inside pine house, then he still remembers the freshness and atmosphere filled with the aromas of the forest, which is necessarily installed inside a residential building. Warmth is another distinguishing feature chopped pine house. It is well heated in winter and provides a beneficial chill in summer, which does not depend on the number of degrees of heat outside the house.

It is important to note that the log house is made of round log(carriage) does not require mandatory facing works. Pine wood is endowed with an attractive amber hue.

Larch for cutting in Canadian style

Larch is also considered a relative of pine. She happens to be coniferous tree, often found in Russian areas.

Larch is a long-liver, its age can reach up to 400 years and even more. The diameter of a tree varies more than a meter, however, its height reaches 50 meters.

Having increased density, the wood of this species is not easy to process. This "minus" is one. There are more advantages: houses made of larch are distinguished by beautiful physical and mechanical characteristics, high parameters of elasticity, bending and compression. The strength of this type of wood is 30% higher than that of pine. In addition, it is resistant to moisture and rot due to the high resin content in its trunk.

Larch resin not only perfectly repels moisture, but is also a natural antiseptic. Therefore, the atmosphere of a pine house will always be clean and fresh.

Historically, Canadian logging is a type of Russian logging, only in Canada this type of logging has taken root better. In fact, the “Canadian bowl” lock is a Russian “fat tail” lock, or otherwise a lock with a groove. But a division has developed and precisely for this reason, now you can find two types of log cabins on the market: Russian log cabin and Canadian log house more simply, “Canadian”. In appearance, these two types of log houses differ, and each type of log house has its own unique design features. Appearance Canadian log house is more natural due to the precise manual adjustment of log locks and the absence of mechanical rounding of logs.

The peculiarities of the Canadian log house lie in the design of log locks and methods preliminary preparation logs In this article we will talk about the Canadian log house or, more correctly, the Canadian log house or the “Canadian bowl” log house.

Canadian log house - preparation of logs

For a Canadian log house, logs with a diameter of up to 500 mm are selected. Logs for a classic Canadian log house are processed only by hand. In this case, the sapwood of the log is necessarily preserved. Let me remind you, sapwood is outer layer wood about 40 mm. This outer layer, “hardened” as the tree grows, is more resistant to scratching, blueing, and mold.

The wood chosen is pine or larch. The log house matures, that is, dries and settles, within 12-18 months. After this, the log house is dismantled and reassembled on the customer’s foundation.

Canadian log castle

The castle of the Canadian log house has the shape of a trapezoid. Trapezoidal cuts are made on the lower log. The same shape is repeated on the walls of the castle bowl of the upper log. The Canadian Bowl is made using a chainsaw.

The "Canadian Bowl" is hand-selected. The bowl is removed in such a way that after laying it on the lower log there is no gap between the castle bowl and the log. Peculiarity Canadian cutting in its maturation. The log house is cut and assembled on the manufacturer's premises. A log house matures in 12-18 months.

During maturation, the log house goes through two stages. The first stage is drying. When drying, gaps form between the logs and in the locks. At the second stage, the log house settles. During the settling process, the gaps disappear, and the lock seems to be “pulled” onto the log, making the connection very tight.

After dismantling the frame and assembling it locally, insulation is placed in the castle bowl. This additionally seals the frame, and what is typical is that the seal remains invisible, and the walls of the frame do not require re-caulking.

class="eliadunit">

Wooden houses made from solid logs or beams are distinguished by their durability and environmental friendliness. They keep warm in winter, cool in summer, and natural circulation air, which is also saturated with the healing aromas of wood, allows you to get maximum pleasure from staying in a spacious house.

Today, such wooden masterpieces, after decades, are again becoming popular among Russians, because housing made of solid logs or timber is fashionable, practical and beneficial for the health of its inhabitants. But planning to buy wooden frame or order a house from the Log Structures company based on a unique project developed specifically for you, you should initially familiarize yourself with some of the features of their production technology, which will subsequently affect the operational characteristics of the housing. It is worth noting that regardless of the technique used or combination thereof, the house or bathhouse built by the company’s craftsmen differs high quality and evoke a sea of positive emotions in the owners not only during the first acquaintance with the project, but also throughout for long years living in a house.

Individual project

Individual project

Individual project

Over the course of a couple of years, the process of shrinkage of the wood from which the frame is made takes place. Since, when drying out, the log decreases in diameter by 5-15%, the shape of the bowls and grooves changes, and gaps appear.

After drying, the house shrinks. At this stage, the differences in technology are most noticeable. As a result of shrinkage in classic version Noticeable gaps remain, which must subsequently be sealed with tow or jute. And when making a Canadian log house, thanks to the cuts and the triangular wedge-shaped joint, jamming occurs, during which a dense cut is formed at the corners, which is distinguished by its aesthetic appearance and retains heat in the house.

Over time, the Canadian log house was improved, as a result of which a tenon, popularly called a “tail tail,” was added to the hems and trapezoidal shape of the log house. It is designed to prevent the corners from being blown through and to insulate them after the house has dried out and settled.

Canadian logging technology is widely used by the Logged Constructions company during the implementation of projects for the construction of houses and baths, using timber or logs for this. Professional companies produce quality training and the laying of logs, resulting in a cozy, luxurious and warm wooden structure.

Wooden houses are becoming increasingly popular. Especially cottages made of logs. And if the traditional joining of wood “into a bowl” is already familiar to many by hearsay, and to some in practice, then the technology of Canadian felling has not yet firmly taken root in our region. But in vain. After all, a house assembled from Canadian logs ends up being warmer and more durable. And all thanks special technology cutting grooves-bowls for joining wood.

This technology was originally used in the construction of log houses in Russia. However, due to the complexity of the process, I did not find wide application among the architects. In turn, in Canada, where the climate is winter time just as harsh as in Russia, the technology is firmly rooted and operates to this day. A special feature of this type of cutting is self-jamming locks, which subsequently do not allow cold air into the house from the corners.

Features of a Canadian home

Canadian log houses have a number of manufacturing features that affect the quality finished house. Thus, to assemble a cottage, only chopped logs are used, from which only upper layer- bark. The lower protective layers of wood - bast and sapwood - are not touched. As a result, the tree for Canadian home has increased strength and resistance to precipitation, unlike rounded wood.

In addition, chopped round timber as a result of such manual processing has a difference in cross-sections at both ends - the butt (the lower, thicker part of the tree) and the top (the thinnest part). After sanding, the log is subjected to manual chopping for the purpose of forming Canadian bowls.

Important: when assembling walls from such chopped Canadian logs, you should alternate laying the ends of the butt and top to compensate for differences in the height of the crowns and thereby level the horizontal position of the logs. In addition, the overall evenness of the walls of the house will depend on this method of masonry.

Advantages of Canadian logging

A similar Canadian technology for assembling a cottage from a log frame has a number of advantages in comparison with cottages made from rounded logs assembled into a Russian bowl:

- Thus, the Canadian groove for connecting logs in the corners has a trapezoidal shape, which is a full-fledged locking connection. As a result, the strength of joining wood in this way increases significantly.

- Thanks to the tight fit of the locks in the bowls using Canadian technology, the house does not require additional caulking of the gaps. All corners will already be warm and windproof.

- After the natural shrinkage of the house, the gaps and cracks during the Canadian assembly of the log house are minimal, or even completely absent, which additionally has a positive effect on the heat capacity of the cottage.

- In turn, the increased heat capacity of the log house allows you to economically spend resources on maintaining and heating the house.

- In addition, we note that houses using Canadian technology for preparing logs last more than a hundred years, while a log house made from rounded wood into a familiar bowl has a service life of about 80 years.

- In addition, I would like to note that massive and good houses made from chopped round timber and assembled in a Canadian bowl, they look aesthetically pleasing, beautiful and expensive.

Types of wood for a Canadian home

To assemble a durable log house, you need to select a type of wood that will have higher performance characteristics. Considering that the climate in Russia is moderate, and winters can be quite severe, it is necessary to select logs made from northern cold-resistant wood species. Most often used coniferous varieties. The following are especially popular:

- Siberian pine. Great option for the construction of a log cottage. Pine logs have an affordable price in tandem with optimal technical characteristics. Harvested in the cold season, a pine log has high density and minimal humidity, which contributes to a small shrinkage of the finished log house. In addition, pine releases valuable phytoncides into the atmosphere, which have a beneficial effect on health, and in particular respiratory system household members. Pine logs retain heat well, resist water and are not susceptible to rotting. In addition, pine is easier to process manually.

- Larch. More expensive construction material, but at the same time more durable. Larch logs are particularly dense, making them more difficult to work with than pine. But larch logs are resistant to moisture. Moreover, under the influence of water, larch becomes even stronger and denser. It is worth noting that this moisture-resistant type of wood does not rot long years, which has a positive effect on the strength of the entire structure. The price of larch logs is several times higher than pine, which makes it less in demand. Most often, larch is used as a material for backing boards and lower crown log house

- Spruce. This type coniferous wood has increased fibrousness.

That is why the spruce log, although good for health, is mainly used for internal partitions Houses. Since when wet, spruce will open its pores and fibers, absorbing excess moisture. But inside, spruce wood will look unique. Smooth light shade along the entire length of the round timber and the valuable aromas of the resins that the log will emit inside the house make it quite popular. - Cedar. It is considered an elite type of wood because it has increased strength and a noble shade. A cedar log means the durability of a cottage and a light cedar aroma in the air of the log house. But the price of a cedar log stops the developer and forces him to use simpler types of wood.

Important: for any type of wood, Canadian bowl cutting requires high precision and professionalism. Otherwise, assembling a house using Canadian technology will not make sense - the locks simply will not fit together or will have a weak connection.

Technology of cutting logs under the Canadian bowl

This technology is reminiscent of chopping a house using the Scandinavian method. However, for the installation of a Scandinavian log house, a carriage is used - a prepared log with cuts on the sides. Log houses for the Canadian bowl are built only from round timber.

Using Canadian technology, the log bowl is made with a ledge, which, when connecting the logs at the corners, ensures the locking of the lock. That is, the upper log is equipped with a trapezoidal bowl with an outlet, which is put on the lower perpendicular log with a corresponding groove bed. As a result, when pressed, two logs are connected into a lock. After shrinking and shrinking the house, such bowls, unlike standard Russian ones, are compressed around the bed more tightly, which reduces the likelihood of blowing through the corners. In turn, the standard Russian bowl, when the log shrinks, on the contrary, expands its semicircle, making the gaps even larger.

It is worth noting that the formation of the Canadian bowl, ledges and notches on the log is done exclusively by hand. This requires professionalism from the master. Assembling a cottage using Canadian technology can take up to a year or even more, since it requires high precision cutting. That is why a log house assembled from round timber into a Canadian bowl will be more expensive than a cottage made from rounded wood. Today, not many companies provide such a service (construction of a Canadian log house). Therefore, if you decide to mount just such log house, as indicated in the photographs below, you will have to look for specialists of this particular profile. And then your log house will be a treat for all your neighbors and friends! After all, the house assembly technology, proven over centuries, guarantees the reliability and strength of the house.

Photo Canadian houses from log:

Canadian Cutting

The main advantage of Canadian felling, undoubtedly, is the minimization of gaps - cracks on the sides of the bowls, after the logs shrink. This advantage still does not 100% exclude the appearance of cracks at the joints of logs, as well as cracks on the log itself.

And therefore, the use of sealant, subsequently, and often during the construction stage, is INEVITABLE. And it turns out that talking about the absence of cracks becomes inappropriate. It is logical to ask: “Why then is this argument (about the absence of gaps) presented as an advantage? If the sealant closes ANY gaps anyway.

The second advantage is the visual effect, since the planes of the trims, even if they are poorly (not Canadian) executed, add a positive feeling to the log house. However, this is, as they say, a matter of taste, and there is no arguing about tastes.

For “hunting is worse than bondage”, if a person wants, let him do it - We are “For”, with both hands!

The disadvantages include a significant reduction in the thickness of the logs at the joining points, i.e. in the corners. Especially with double stitching (both above and below). This, as a consequence, reduces the thermal insulation of the corner.

And also, since the sapwood is completely removed from the corner, the working life of this connection is reduced. It's simply durability. Illiterate execution further aggravates this problem.

Want to know our opinion about Canadian logging?

The myth that CANADIAN CUTTING is Cool.

You can PR and Exploit any popular topic, but there is a Fact that you cannot avoid. You can only “close your eyes” to it. Or Don't see it because you haven't studied the topic.

Where is the ancestral home of the Canadian logging?

It's very simple if you ask yourself:

Where did you get it from? North American Indians could there be log cabins? If they mainly led a nomadic lifestyle, then why did they need log houses? True story Russia has deep roots. Those who don't like it know this very well. And the great-grandchildren of those Russians who walked with their feet across the lands of once Russian Alaska are learning more and more.

If the well-forgotten old is passed off as “new” - this will be another brand and money out of thin air. Because there are many who like to repackage a well-known product into a “new” one. It sells better that way. Since “it differs in that...” And there is more freedom with arguments.

This method of connecting a log structure justified only in certain cases. And not without its shortcomings.

To start...

Name: “Canadian cabin” comes from an artificial surge in the popularity of this sophisticated technology in Canada. Its roots are in Russia, for it was brought from there, as one of the many varieties of Russian cutting. This technology is found in different nooks and crannies of the world. And residential buildings made of logs using this technology acquire a certain special attractiveness due to the geometry of the connections. Especially if they are executed COMPETENTLY, because there are also “other” executions...

It’s called “As we could” and “as we could.” This is “refinement”. One can only laugh at this kind of “refinement,” because the log becomes so thin at the joints that the cups sometimes break off.

To prevent the groove from “climbing” onto the edge, you need to sacrifice the groove, making it Already. And such a narrowing of the groove width will naturally worsen the thermal insulation. You can simply compare: will the groove width be 15-18 cm (up to 25 cm), or 7-8 cm, and sometimes 6 cm? These are places in the wall 6 cm thick! Well, where is this good?

Disadvantage of Canadian Logging The problem is that too much thickness is cut off from the entire log mass. This is undesirable for a log house. Moreover, the undercuts in the bowls are hewn out. And it turns out a little deep.

If you make an upper notch, and then another lower one, then from the entire mass of the log there remains an “isthmus” with a cross-section of less than 30% of the log’s cross-section. A small triangle from the circle remains.

Usually they put a thick tangle of insulation in there and think that everything turned out great. But what can you do with the fact that the log is cut by 70-75%, 25-30% remains and the edges are very poorly protected? And you have to make special efforts to ensure that they can withstand loading. Especially transportation. Otherwise, it may simply not withstand the shock or pressure on the road or during loading.

There was a case in our practice: A team was cutting down a house using Canadian technology, with double slabs. This was a long time ago and was a big curiosity back then.

The foreman with sparkling eyes told everyone about the Canadian cabin. Even then, from his stories, we had questions about this technology.

When we looked WHAT they are cutting down, our fears were confirmed. And then they cut, one might say, “a C grade.”

The connections in the corners seemed so weak, since the logs in the corners were heavily sawed through, that they seemed to be very unreliable. And one element, it was a one and a half meter long extension under the balcony, was somehow restless to look at. Not only was the thickness of the bowl “nothing”, but it also had no lower stems. It felt like he was just hanging in the air and was about to fall.

I say to the foreman: “Well, it might fall off you.” And he answered me that he was not going to correct the mistakes of the designers, as it was drawn - that’s how we do it.

Well, as a result, it fell off when loading it into the car. And what the balcony is now supported on is unknown. How they solved this problem is not known.

And it turns out that you need a competent approach, taking into account these nuances, which allows you to avoid such troubles.

If Canadian logging is what you want, we can perform it this way,

What You will sleep peacefully.

To do this, you just need to deviate from some of the canons established for Canadian logging, and everything is guaranteed to fall into place.