He managed it on his own: the man built a barn from wooden pallets. The result impressed both him and his neighbors. Building a small shed from pallets Shed from pallets

It would seem that pallets are a simple material that is often considered akin to garbage. However, with a little resourcefulness and hard work, you can build a comfortable shed in your country house. And such a barn will not be inferior in strength and appearance to similar buildings made from other building materials. The idea of building a shed from pallets will especially appeal to those who protect their own budget and know how to save money.

Construction Technology Review

Savvy craftsmen came up with a simple and quick way construction from pallets. These elements are cleaned and fastened together with boards, slats, chipboard sheets, self-tapping screws, nails, staples, and wire. The structure is assembled from pallets, like a construction set.

Choosing pallets and pallets for your shed

Pallets or pallets are containers that ensure the safety of goods during transportation. Such containers are made of plastic or wood. Moreover, for the construction of a barn it is worth paying attention to wooden pallets. One of best options– larch . This wood has sufficient strength and is resistant to moisture. A larch barn will last a very long time.

In Russia, wooden pallets are made in the following sizes:

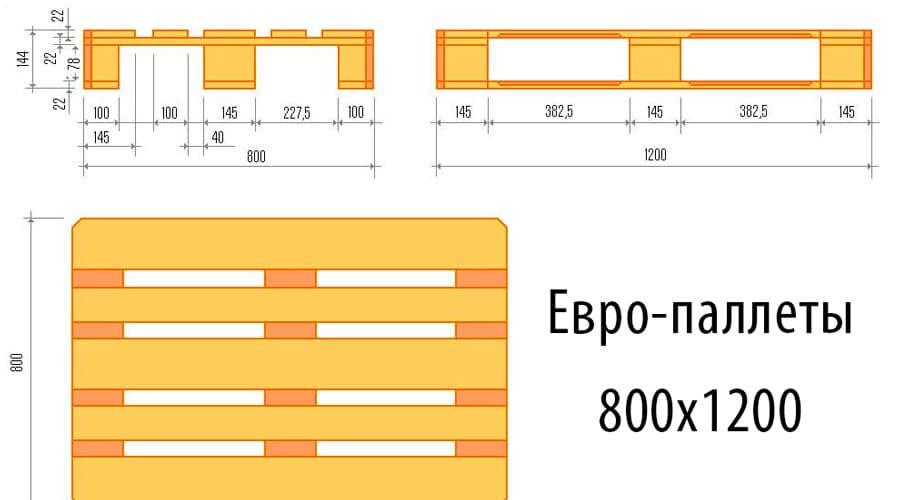

- 80x120 cm, flooring thickness 2.2 cm;

- 100x120 cm;

- 120x120 cm, board thickness up to 2.5 cm;

- 120x160 cm;

- 120x180 cm.

Pallets are also available in other sizes, for example, 32x40, 36x42 and 48x48 inches. Euro pallets have dimensions of 120x80x15 cm and 120x100x15 cm. For construction in the best possible way Pallets with a deck thickness of 2.5 cm are suitable.

Design of a change house

A barn is a stationary building that should ensure the safety country tool, personal belongings and other similar items. Based on your own preferences and free space on the site, you should determine the desired dimensions of the building. Ideally, the length, height and width should be multiples of the pallet dimensions. In this case, you will not have to cut the elements.

You may also be interested in construction technology.

Example: if 120x120 cm pallets are available, then optimal dimensions barn - 480 (L) x 240 (W) x 240 (W). You will need 24 pallets for the walls and 8 for the floor.

It is better to make the ceiling covering from boards. Also, boards will be needed to fasten the pallets together. And it is recommended to use timber 100x100 or 150x150 cm as the lower, upper trim and corner posts.

For construction you will also need: sheets of moisture-resistant plywood, fasteners, a screwdriver, vapor barrier film, insulation, fire-retardant impregnation, roofing material, roofing material, bitumen mastic.

Calculation of approximate costs, prices of materials

New pallets are sold at a price of 250-300 rubles. Used pallets are half the price. Pine timber will cost approximately 5-6 thousand rubles per cubic meter, larch timber - two and a half times more expensive. A 25x100 mm edged board made of pine costs from 3,500 to 6,500 rubles per cubic meter.

Moisture-resistant sanded birch plywood:

- 8x1525x1525 mm – 550 rubles per sheet;

- 12x1220x2440 – 1050 rubles per sheet.

A set of doors with fittings or a gate for a barn can be purchased for 1-5 thousand rubles. Ruberoid costs about 300 rubles. per roll, bitumen mastic - from 270 rubles per container weighing 16 kg.

Materials for the roof and foundation arrangement will cost 2-5 thousand rubles. Mineral wool (8 pieces per package, 1,200×600×50 mm) costs from 65 rubles/m2 or 385 rubles/pack. Izospan (vapor barrier) costs approximately 1,650 rubles/roll (70 sq.m).

How to build it yourself

Laying the foundation

It is not necessary to make a capital foundation. For example, you can clear the area, fill it with sand, crushed stone and pour a floating concrete pad, which will also serve as the floor of the barn.

Another option is a columnar base. In this case, concrete will be poured into pre-dug holes, the walls of which are wrapped with roofing felt. It will be necessary to install metal rods into the freshly poured solution, to which the walls of the shed will be attached.

Making the bottom trim

You can skip this point of work, saving on building materials. The beams are cut according to the dimensions of the poured foundation. At the corners, 4 beams are joined using the “wood floor” or “paw” method..The frame is connected to the foundation with anchors through holes drilled in the beams.

Installing corner posts

This point is also a recommendation. The lower trim and racks will increase the rigidity of the structure, but if you need to save money, you can do without these beams. Corner posts are attached to bottom harness dowels, metal perforated corners and self-tapping screws. Additionally, jibs are nailed for reliability.

Laying the subfloor

Floor joists are connected to the bottom trim metal plates(fastening perforated corners) and self-tapping screws. Edged boards are laid on the joists. The lags and boards are fastened with nails (20 cm long).

You will find all the information about the construction of wooden outbuildings and cabins.

Walling

Work begins from any of the corners of the barn. The first pallet is taken, placed on its edge (with the flooring inside the shed), screwed or nailed to the bottom frame and vertical beam. It is advisable to check verticality with a bubble level.

The second pallet is nailed in the same way. The structure can be further strengthened with perforated mounting angles.

The first row of pallets must be fastened with boards, nailing them into the grooves between the pallet decks. Don't forget to pre-cut the opening for the door or gate. Pallets can also be fastened with wire.

Even if they were installed vertical beams in the corners, before installing the second row, it is necessary to nail vertical boards to the pallets of the first row. They will become stiffeners and prevent the walls of the barn from tilting.

Roof and roofing

Before installing the roof and roofing covering the ceiling is constructed and secured top harness. The latter is either a 100x100 beam, nailed along the perimeter of the shed walls, or double 25x100 boards installed on the edge. If the roof of the barn is single-pitched, then the framing is done only on two sides - from the rear of the building and from the facade.

Floor boards are laid edgewise on the mounted frame, which can simultaneously serve as rafters.

The roof structure may vary, however general rules arrangement roofing pie remain unchanged.

A waterproofing film (or roofing felt) is stretched over the rafters and the sheathing is stuffed. Next is the installation of the roofing finishing coating– profiled steel sheet, ondulin, slate, etc. If necessary, roof overhangs are sheathed.

Insulation, vapor barrier and cladding of the structure

The roof of the barn can be insulated from the inside. To do this, mineral wool slabs should be inserted between the rafters, tensioned vapor barrier film, nail thin slats of additional sheathing and attach the material finishing, for example, moisture-resistant plywood sheets.

The walls of the barn also need insulation. Selected insulation ( budget options: polystyrene foam scraps, straw, wood sawdust) will have to be inserted with inside walls into the space between the flooring and the pallet runners. The inside walls are also covered with a vapor barrier (the film is stretched horizontally, the second row should overlap the first by 10-15 cm). It is convenient to secure the film with a stapler.

Plywood, OSB or other sheathing material will be attached over the vapor barrier. Additionally, the cladding can be plastered or painted to extend its “life.” wooden walls barn.

One of the most economical ways finishing - plastering the walls with clay.

For the manufacture of plaster mortar Only environmentally friendly components are used: sand, clay, dung, sawdust, wool, straw, felt, pine needles. Occasionally add a small amount of cement.

For finishing For a barn, a clay-sand mixture with the addition of any fiber (for decorative purposes) is suitable. It is better to experiment in advance by mixing various components in small quantities. The clay must be soaked for a day before adding it to the solution.

Before plastering, a fine mesh mesh is stretched over the walls of the shed. It is molded onto the mesh in pieces clay plaster. Optimal thickness finished coating – 3 cm.

Before applying the second finishing layer, you will have to wait for the already applied solution to dry. This may take up to 4 weeks. The second layer of plaster is quite thin. When applied, it is leveled with a spatula.

Door installation

The door to the barn can be made from edged boards, nailing it on both sides to a rectangular frame made of bars. It is better to assemble the door frame from quality lumber, securing the structure long screws And polyurethane foam. When the box is secured in the opening, all that remains is to screw the hinges, door handle and locking hardware (such as padlock lugs).

How to ensure long service life

A long service life for your shed can be achieved by treating everything wooden parts antiseptic. The wood will not rot or deteriorate.

- It is also advisable to arrange ventilation in the barn so that the air does not stagnate and conditions are not created for the growth of mold and mildew.

- If you plan to store vegetables in the shed, it is important to ensure that there are no rodents and insects that will damage the wall material.

- For convenience, you can install in the barn floor shelving. It is convenient and functional, and from the use of classic wall hooks and wall shelves It's better to refuse.

How to properly build a chicken coop is outlined.

Video

In this video you will be shown how to make a shed from pallets.

Conclusion

A pallet shed is unusually cheap, but with proper finishing it looks presentable and fits well into the design summer cottage. There is no longer any need to spend huge amounts of money on building materials, because any utility block can be easily built with your own hands from scrap materials.

We've all seen them - hundreds of thousands of blogs and posts talking about how great pallets are. They can be used for different purposes. For example, build your own shed from pallets. Imagine a whole building in which you can store garden tools, temporarily unused household items, spare parts for a car.

An owner was found who acted in the spirit modern trends and posted construction details online. So, if desired, his “feat” can be repeated by anyone who reads this simple “instruction”.

Where to buy pallets?

In Russia, pallets are sold at timber trading centers and in organizations that sell lumber. Durable stands (pallets, Euro pallets) for refrigerators and other equipment are sold by companies through a network of free advertisements. Sometimes it's not at all waste material. The owners are giving it away for nothing. In general, depending on your luck. In any case, the cost of pallets is low. This is a profitable solution.

For several months, a man (let's call him Nick) had been saving up pallets. Finally, he decided that the collected amount was quite enough to bring the project to life. Indeed, a whole mountain of “wooden wealth” has grown in the yard. Domestic cats, seeing that their favorite place would soon become inaccessible for walks, probably became sad.

Making the foundation

The craftsman decided to build a shed on the side of his yard where there was a slight slope. He was faced with the task of leveling the site. During the course of this work and preparing the excavation for the foundation, Nick accumulated a whole mountain of small stones. He hasn't figured out how to use them yet. But it's a matter of time.

The master decided to make the foundation from hollow concrete blocks, which he purchased on a free classifieds site. The estimated dimensions of the barn are 6x8x16 m. Quite large. After the work began, it turned out that there were not enough foundation blocks. I had to worry about purchasing an additional number of prefabricated structural elements.

We build walls

In the end everything was laid in the trenches in even rows and poured cement mortar. At the same time, Nick installed metal rods in the corners and in the center of each side of the perimeter to give future design the required degree of stability.

It's time to build the walls, that is, horizontally install the pallets one after another, bolting them together. For strength and stability, the lower part of the pallets was screwed to the foundation blocks. Once the corners were connected, the structure was even stronger and more stable than Nick had expected.

Adjusting the height

Since I was standing hot weather, a light awning appeared over the construction site, protecting from direct sunlight.

The man didn't want the barn to be too tall, so he shortened the top pallets by half. In his case, this was also convenient because the neighbors would not unwittingly “look” into the storage room.

At first it was planned that the floor of the barn would be level with the ground, but given that rain is rare in this area and there is no need to be afraid of flooding, the decision was made to deepen it bottom part premises. Thus, inner space became more voluminous.

Building a roof

Nick used the few remaining pallets to construct a simple barn roof that would not be in the way of the neighbors. Once the vault was formed, the craftsman disassembled the remaining pallets into slats and used them to make the sheathing.

After the structure was covered with inexpensive siding, the barn began to resemble a structure that had cost a lot of money to build. Small pieces of glass became windows, which provided the utility room with natural light.

Fence parts and back wall buildings form a single fence. Nick decided to stop there and returned to the façade. Here he organized a place to store firewood. To create a small wood-burning “terrace,” the owner installed a tin canopy and made a gutter to drain rainwater, which he directed into a barrel.

Cheap and cheerful

When the barn was completely ready, the man moved to internal work- made shelves from lumber. According to the owner himself, it took him about $500 to build the building. This money is mainly a duty on the purchase of siding, shingles, mortar, fasteners.

An amazing homemade pallet shed helped organize the yard space. On everything about everything from family budget spent 500 dollars, while the cost of such work sometimes reaches several thousand! The labor costs definitely paid off with a decent result.

In one of our articles we looked at... As a result, you were able to verify once again that human ingenuity knows no bounds.

Continuing this topic, we can say that this is not the only area where pallets can be used.

In addition to furniture, you can make other things that will become a useful acquisition for your garden.

Today we will look at what else can be made from ordinary pallets. The given options will allow you to see in simple objects an idea that you can bring to life yourself.

Options for buildings made from pallets. How to do it yourself?

Let's take a closer look at wooden pallets. We can say that this is a horizontal plane with sides. And what will we see if we turn it over? vertical position? It resembles a screen, but what if you put not just one next to it, but, say, ten? As a result, we have a fence! With a little imagination, you can give such a fence an original and beautiful look.

To calculate required quantity pallets, you need to know their width and the perimeter of the site. Then they need to be cleaned from chips, various irregularities, and dirt. We dig a trench and install support pillars (metal pipes), make drainage (sand, stones), pour concrete.

We attach pallets between the posts, and the height of the fence is regulated by the number of pallets. The top edge of such a fence can be trimmed, the surface itself can be painted, and various decorations can also be attached to it. In the end you will succeed beautiful fence for minimal money.

Continuing the theme of fencing, you can make from pallets decorative screens and vertical green walls that can be used to camouflage old buildings or divide a large area into zones.

Such a building made from pallets for a summer house, like a gazebo, will decorate your site. It will be openwork, filled with light and at the same time cozy and secluded. You also need to make a foundation for it, clean the pallets and treat them with protective compounds.

By installing them on top of each other, we form the walls, but before this we need to make the floor (can be made from the pallets themselves) and the frame of the gazebo on which we will attach the pallets.

The frame can also be made of wood, from pillars installed at a certain distance and cross lintels. You can grow decorative vines along such walls.

By the same principle you can do summer house . To close the gaps between the pallet boards, we recommend sewing up the walls from the inside. This will create pockets on the outside where you can plant them in the spring. ornamental plants, spices, and edible greens.

Another option (more labor intensive)– we embroider wooden pallets and build a house from individual boards. We make the frame from thick transverse ones, and thin sheathing of the walls. All nails must be removed. Window frames can also be made from the same boards.

First we make the floor by laying logs, which we cover with chipboard or lay planks on. Then we build a frame for the walls and roof, and cover our house with boards. We cover the roof with chipboard sheets, roofing felt and flexible tiles on top.

Now the summer house is ready, all that remains is to paint it. It can be used as a room for work and relaxation. I really like this design small size your children, whose imagination will easily find use for it in their games.

In warmer countries, such houses are built both for temporary and permanent residence. They will be equipped with all necessary furniture and other amenities.

The idea discussed above can also be used to build utility structures on the site. A shed made of pallets will look modern and original, without disturbing the overall picture. The result is a beautiful, durable building for minimal money.

Structures made from pallets can be covered with siding if desired. In this case, not a single person will guess what the building is made of until you enlighten him on this matter.

In addition, pallets can be used to create another construction option - a chicken coop.

Wood - environmentally friendly pure material, so pallets are very useful if you decide to have poultry. The scheme is the same as for building a house, but you don’t have to make a foundation if the structure is temporary, for the summer. Clearances in the pallets will be provided natural ventilation and illumination. If desired, you can sheathe the chicken coop on three sides with chipboard sheets.

Pallets also make a durable dog house. The main thing is to provide good coverage for the roof to prevent water from getting inside, and to sheathe the walls to protect the pet from the wind.

Someone will ask - what about the bathhouse? We would not advise you to use wooden pallets for this, except perhaps for using a bathhouse in the warm season or for building a summer shower.

But if you want to take a steam bath in winter, you will have to use other materials, because the sauna must retain heat for a long time, so you will have to insulate the walls.

As you can see, many different buildings can be made from pallets for the garden. This is a very profitable investment of time and effort, since the material is not at all expensive, and the boards are very durable, which means the structures will last longer.

A country or city house is wonderful, even wonderful. But no achievements of architecture and design, no landscaping can cancel the fact that auxiliary structures must also be prepared. For their construction they can sometimes be used exclusively original materials and designs.

Peculiarities

Almost every homeowner can build a shed from pallets with their own hands. Wooden pallets are already used in the manufacture of tables and sofas, beds and flower beds, but there is every opportunity for more serious construction. In theory, these designs are not intended to construction work, and from the outside the building does not look very solid. However, for simple business purposes, this solution turns out to be quite acceptable, especially considering the minimal costs.

There is no need to buy the pallets themselves; they are simply thrown away after the completion of large construction projects; money must be paid for:

- nuts;

- self-tapping screws;

- other fasteners;

- boards;

- roofing products and some other elements.

A typical pallet is 120 cm long and 80 cm wide. Parts placed in the very first row should be mounted on block supports. It is recommended to cast them from concrete. Since they are used for work wooden elements, you will have to take care of protecting them from rotting and from ignition. It is very important to immediately calculate the need for the material used and take into account all the design features of the barn.

Sequence of work

Carrying out the work step by step, after forming the foundation, you need to attach the pallets to each other using bolts, and drill holes in the mutually transverse boards. Through these holes the blocks are tightened with bolts. It is possible to accurately select the fastening only by taking into account the design of the pallet. The second row is fastened not only to each other, but also to the blocks placed in the first line. Having calculated the required roof slope, you can make pitched roof as reliably as possible, excluding negative incidents.

The sheathing under the roof is made of boards, and on top of them it is permissible to use any roofing material. Most people choose profile metal sheets , because they are mounted simply and without unnecessary problems

In most cases, the foundation is formed from standard concrete blocks. They should be poured at the same level, spaced according to the width of the tray. Then the load level in any part of the circuit will be uniform. The size of the bolts for connecting the pallets is determined individually, focusing on the thickness of the main beam. To connect the tiers, you need to twist them with the same bolts (2 pieces on each side). The front part of the barn is equipped with an insert designed for rafters, so tilting towards the rear is simplified.

Attention: to form the roof it is permissible to use the same pallets or boards with dimensions of 2.5x10 cm. Among roofing sheets from metal, preference should be given to galvanized options. They reflect well Sun rays and help make the atmosphere cooler even on the hottest days. Increase sustainability particle board can be exposed to moisture by covering the outside oil paints. This is exactly the case when the disadvantages of such materials are not too significant.

For decorative cladding outbuildings from wooden pallets You can use chipboard. It is not advisable to use already painted pallets. After all, it cannot be guaranteed that previously used paint of unknown composition will be safe for health. By painting all surfaces themselves, homeowners eliminate this problem altogether. For the same reason, it is advisable to abandon pallets that are marked with the abbreviations IPPC or IPPS.

Such designations indicate that the material was subjected to sophisticated processing with special reagents. This means that, by definition, it is not safe for humans. You should also be careful when using pallets that have previously been used elsewhere. After all, when used on the market, on industrial enterprise or at transport hub wood easily absorbs foreign odors. It is almost impossible to eliminate them: you will have to put up with pungent aromas for months and even years.

The standard instructions for constructing a shed for a summer cottage cannot ignore the fact that it is very important right choice places. For obvious reasons, you should not place storage of tools, firewood and similar items in the most visible place. But moving it away from the house, from the entrance to the site, is also impractical. The most rational option would be to place the auxiliary structure at the same distance from all important places or directly behind the house.

It is not advisable to build a shed in a low area or even in a depression in the middle of a hill. This may result in flooding due to precipitation or melting snow. To realize the plan, the pallets will have to be cleaned. The best way To do this, use a brush with stiff hair, which helps remove all dirt and dust. Taking pallets apart with a nail puller is more difficult than sawing them, but it helps ensure the integrity of the material.

Please note: if the design of the pallets includes twisted nails, you will not be able to remove them with a nail puller. You will have to cut off the problematic fasteners with a grinder.

Installation strip foundation with shallow depth it turns out to be very simple. The required site they are covered in layers with sand and gravel, after which concrete is poured. Dismantling of formwork is allowed 14 days after pouring.

fasten corner posts to the bottom harness you can:

- metal corners;

- dowels;

- self-tapping screws.

The logs on the floor are connected to the strapping in a similar way, and boards are attached to them on top using nails 150 - 200 mm long. The flooring is formed only when the original concrete floor does not suit the owners. It doesn’t matter which side exactly to start building the barn from. The doorway should be formed before laying the second line of pallets. The ceiling covering is made mainly of timber with a cross-section of 100x100 mm, which is fixed around the perimeter.

The roof of a pallet shed, like a regular one, must be equipped with a layer of waterproofing. It is done using roofing felt or on the basis of a special film. It is allowed to cover the roof not only sheet iron, but not too much with slate or any other heavy material. Interesting ideas There are many different options when building a shed using pallets, but each one needs to be carefully considered. You don’t have to limit yourself to just choosing an attractive color.

A completely rational step is to combine a barn with a small greenhouse. This solution is especially good when there is enough space on the site, you need to store little equipment, and the best platform can't be found for him. It is not recommended to make a shed that is snow-white in appearance, because caring for it will be too difficult. You should always be careful to appearance and the interior matched each other. Lilac and others pastel shades They get dirty relatively little, and at the same time bring joy to the owners of the site.

To learn how to wash a shed made of pallets, see the following video.