Heat transfer resistance of external doors and gates. External entrance doors: wooden, plastic and metal External doors with reduced resistance

Read also

Using table A11, we determine the thermal resistance of external and internal doors: R nd = 0.21 (m 2 0 C)/W, therefore we accept double external doors; R ind1 = 0.34 (m 2 0 C)/W, R ind2 = 0.27 (m 2 0 C)/W.

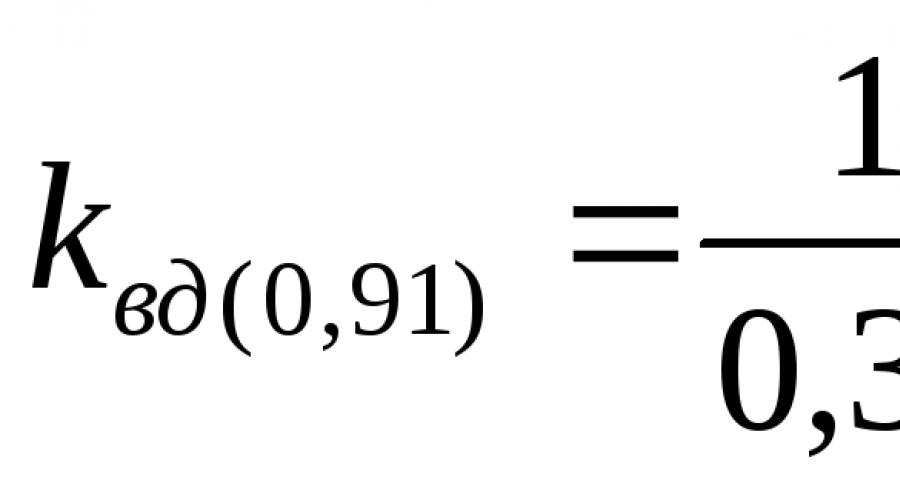

Then, using formula (6), we determine the heat transfer coefficient of external and internal doors:

W/m 2 o C

W/m 2 o C

W/m 2 o C

W/m 2 o C

2 Calculation of heat losses

Heat losses are conventionally divided into basic and additional.

Heat losses through internal enclosing structures between rooms are calculated if the temperature difference on both sides is >3 0 C.

The main heat losses of premises, W, are determined by the formula:

where F is the estimated area of the fence, m2.

Heat losses, according to formula (9), are rounded to 10 W. The temperature t in corner rooms is taken to be 2 0 C higher than the standard one. We calculate heat losses for external walls (NS) and internal walls (BC), partitions (PR), ceilings above the basement (PL), triple windows (TO), double external doors (DD), internal doors (DV), attic floors (PT) ).

When calculating heat losses through the floors above the basement, the temperature of the coldest five-day period with a probability of 0.92 is taken as the outside air temperature tn.

Additional heat losses include heat losses that depend on the orientation of the premises in relation to the cardinal directions, from wind blowing, from the design of external doors, etc.

The addition for the orientation of enclosing structures to the cardinal points is taken in the amount of 10% of the main heat losses if the fence is facing east (E), north (N), northeast (NE) and northwest (NW) and 5% - if west (W) and southeast (SE). The addition for heating the cold air rushing through the external doors at a building height of N, m, is taken as 0.27 N from the main heat loss of the outer wall.

Heat consumption for heating the supply ventilation air, W, is determined by the formula:

where L p is the supply air flow rate, m 3 / h, for living rooms we take 3 m 3 / h per 1 m 2 of living space and kitchen area;

n – density of outside air equal to 1.43 kg/m3;

c – specific heat capacity equal to 1 kJ/(kg 0 C).

Household heat emissions complement the heat output of heating devices and are calculated using the formula:

,

(11)

,

(11)

where F p is the floor area of the heated room, m 2.

The total (total) heat loss of a building Q floor is defined as the sum of heat losses from all rooms, including staircases.

Then we calculate the specific thermal characteristic of the building, W/(m 3 0 C), using the formula:

,

(13)

,

(13)

where is a coefficient taking into account the influence of local climatic conditions (for Belarus  );

);

V building – volume of the building, taken according to external measurements, m 3.

Room 101 – kitchen; t in =17+2 0 C.

We calculate heat loss through the outer wall with a northwest orientation (C):

outer wall area F= 12.3 m2;

temperature difference t= 41 0 C;

coefficient taking into account the position of the outer surface of the enclosing structure in relation to the outside air, n=1;

heat transfer coefficient taking into account window openings k = 1.5 W/(m 2 0 C).

The main heat losses of the premises, W, are determined by formula (9):

Additional heat loss for orientation is 10% of Q main and is equal to:

W

W

Heat consumption for heating the supply ventilation air, W, is determined by formula (10):

Household heat emissions were determined using formula (11):

The heat consumption for heating the supply ventilation air Q veins and household heat emissions Q household remain the same.

For triple glazing: F = 1.99 m 2, t = 44 0 C, n = 1, heat transfer coefficient K = 1.82 W/m 2 0 C, it follows that the main heat loss of the window Q main = 175 W, and additional Q ext = 15.9 W. Heat loss of the outer wall (B) Q main = 474.4 W, and additional Q add = 47.7 W. Floor heat loss is: Q pl. =149 W.

We sum up the obtained values of Q i and find the total heat loss for this room: Q = 1710 W. Similarly, we find heat loss for other rooms. The calculation results are entered into Table 2.1.

|

Table 2.1 - Heat loss calculation sheet |

|||||||||||||||

|

Room number and its purpose |

Fence surface |

Temperature difference tв – tн |

Correction factor n |

Heat transfer coefficient k W/m C |

Main heat losses Qbas, W |

Additional heat loss, W |

Heat. to the filter Qven, W |

Life heat output Qlife, W |

General heat loss Qpot=Qmain+Qext+Qven-Qlife |

||||||

|

Designation |

Orientation |

Size a, m |

Size b,m |

Area, m2 |

For orientation | ||||||||||

Continuation of Table 2.1

Continuation of Table 2.1

Continuation of Table 2.1

|

ΣQ FLOOR= 11960 |

|||||||||||||||

After the calculation, it is necessary to calculate the specific thermal characteristics of the building:

,

,

where α-coefficient, taking into account the influence of local climatic conditions (for Belarus - α≈1.06);

V building – volume of the building, taken according to external measurements, m 3

We compare the resulting specific thermal characteristic using the formula:

,

,

where H is the height of the building being calculated.

If the calculated value of the thermal characteristic deviates from the standard value by more than 20%, it is necessary to find out the reasons for this deviation.

,

,

Because  <

< then we accept that our calculations are correct.

then we accept that our calculations are correct.

Amendments to the Federal Law “On Technical Regulation”, which allowed the sale on the territory of the Russian Federation of products certified for compliance with the norms and requirements of foreign regulations, significantly facilitated the activities of importing companies and retail chains, but not the choice of metal doors by Russians. Even the European EN, international ISO and the German DIN standards most often used in Russia are quite difficult to get acquainted with for free, and the regulations of the USA (ANSI), Japan (JISC) or Israel (SII) and China (GB/T), from where A large share of imported metal doors are supplied to our country - this is simply unrealistic for the vast majority of our compatriots.

If you haven't made your choice yet, take a look at our offers

As a result, the risks of buying metal doors that do not meet the operational characteristics of the very concept of a security steel door are very high. Moreover, the advertising labels (“elite”, “prestigious”, “safe”, “armored” metal doors) that are universally “hung” on steel door blocks by selling companies in the vast majority of cases do not correspond to the meaning put into these symbols. Thus, “elite” metal doors with visually good cladding with wooden overlays can have a honeycomb filling of the leaf with cardboard, which makes them an effective heat exchanger in winter, and the hall or corridor behind the entrance doors can, in terms of temperature, become an internal refrigerator chamber. “Armored” metal doors are a sheathing metal sheet 0.6-0.8 mm thick, which can be opened with an ordinary can opener, and “safe” metal door panels with a good set of insanely expensive locks can be removed from the door frame or together with the frame from the opening using a pry bar and a nail puller or kick it out.

A higher probability of getting an entrance door with good performance properties is to buy metal doors certified to comply with the norms and requirements of Russian standards, but you need to know at least the basic standardized parameters that determine the level of quality and serviceability of a metal door. The basic standard that determines the design and basic operational properties of a metal door in Russia is GOST 31173-2003 “Steel door blocks”, and the level of protection of locking mechanisms is GOST 5089-2003 “Locks and latches for doors. Technical conditions".

Fireproof metal doors in terms of fire resistance, smoke and gas tightness, but not protective properties are regulated by GOST R 53307-2009 “Building structures. Fire doors and gates. Test method for fire resistance", and bulletproof and explosion-proof metal doors - a number of provisions of GOST R 51113-97 "Banking protective equipment. Requirements for burglary resistance and test methods."

The frames of metal door leaves are made from rolled products in accordance with GOST 1050-88 “Calibrated rolled products, with special surface finishing from high-quality carbon structural steel”; sheet metal is used for cladding in accordance with GOST 16523-97 “Rolled thin sheets of high-quality and ordinary quality carbon steel of general quality purpose" or GOST 16523-97 "Rolled thick sheets of carbon steel of ordinary quality" (for reinforced or protective metal doors), less often according to GOST 5632-72 "High-alloy steels and corrosion-resistant, heat-resistant and heat-resistant alloys."

Important: “Armored”, “safe” metal doors, like “iron” doors, do not exist by definition. Metal doors for residential premises are not manufactured in burglary resistance classes higher than V (GOST R 51113-97) for technical reasons - increased strength properties entail an increase in the mass of the finished door block to values incompatible with installation in conventional wall openings and operation of doors at manual opening of the canvas. Massive doors with high burglary resistance classes are used in bank vaults and have electromechanical control drives.

GOST 31173-2003 standards, simplified for understanding.

GOST 31173-2003 classifies and normalizes metal doors according to:

- according to thermal protection properties determined by the reduced heat transfer resistance - class 1 with a reduced heat transfer resistance of at least 1.0 m2 °C/W, class 2 with a reduced heat transfer resistance from 0.70 to 0.99 m2 °C/W, class 3 with a reduced heat transfer resistance of 0.40 -0.69 m2 °C/W.

Important: Metal doors of class 1 have the best heat-insulating properties, class 3 has the worst, but any metal doors cannot have a reduced heat transfer resistance below the threshold value of class 3 - 0.4 m2.°C/W, which corresponds to that used in European regulations acts, the heat transfer coefficient Uwert is no more than 1/0.4 = 2.5 W/(m2K). It must be remembered that for Moscow, from October 1, 2010, according to the standards of the City Program “Energy-saving housing construction in the city of Moscow for 2010-2014. and for the future until 2020" the reduced heat transfer resistance of enclosing structures (windows, balcony and external entrance doors) must be no less than 0.8 m2.°C/W, and according to EnEV2009 standards for external doors the upper threshold value of the heat transfer coefficient is not more than 1.3 W /(m2K). Therefore, in the capital, metal doors entering from the street must be certified for heat-insulating properties of classes 1 or 2;

resistance to burglary, determined by the class of strength characteristics and the class of protective properties of locking mechanisms - standard metal doors with strength class M3 and III - IV class of security properties of locks according to GOST 5089-2003, reinforced metal doors with strength class M2 and III - IV class security properties of locks, security metal doors with strength class M1 and class IV security properties of locks;

Important: Strengthening the protective properties of metal doors (burglary resistance) depends on the strength properties of the door block (with increasing strength characteristics from class M3 to M1, the burglary resistance of a metal door increases). Even standard doors cannot have locks with security properties lower than class III, and the level of security properties increases from class I to class IV. The class of security properties of a lock is determined not by its design or brand, but by the number of secrets that should be for locks with: cylinder mechanism of class III - 10 thousand, class IV - 25 thousand; disk cylinder mechanism of class III - 200 thousand, class IV - 300 thousand; lever mechanism of class III - 50 thousand, class IV - 100 thousand.

mechanical characteristics (strength classes), determined by the magnitude of static loads applied in the plane, in the free corner zone, in the area of the door hinges, as well as dynamic loads applied in the direction of opening the door and shock loads in both directions of opening the door.

Important: Strength class M1 has the best mechanical characteristics, strength class M3 has the worst, but any metal door sold today must have mechanical characteristics not lower than strength class M3;

air and water permeability, determined by indicators of volumetric air tightness and water tightness limit - classes 1-3.

Important: The air and water permeability of a metal door deteriorates from class 1 to class 3, but the air tightness of any metal door for residential premises must be at least class 3 and not more than 27 m3/(h m2);

in terms of sound insulation, determined by the airborne noise insulation index Rw - class 1 with an airborne noise reduction of 32 dB, class 2 with an airborne noise reduction of 26-31 dB, class 3 with an airborne noise reduction of 20-25 dB.

Important: Metal doors of class 1 have the best soundproofing properties, class 3 has the worst, but the airborne noise insulation index is determined in the frequency band from 100 to 3000 Hz, corresponding to spoken language, telephone or alarm clock calls, TV with built-in speakers, radio, and does not characterize the ability a metal door to block the noise of cars, airplanes, etc., as well as structural noise transmitted through the rigidly connected structure of the house/building;

reliability of operation, determined by the number of cycles of opening/closing of the door leaf. This value for internal metal doors must be at least 200 thousand, and for external entrance metal doors at least 500 thousand.

Important: A metal door must be certified for compliance with the norms/requirements of Russian regulations, but with differentiation based on basic operational properties and resistance to burglary. If the manufacturer/selling company claims compliance of a metal door with foreign regulations, then comparative information with similar (or similar) indicators of Russian standards must be provided.

Metal doors deserve greater confidence, for which not only a certificate is provided, but also test reports confirming compliance of operational parameters and resistance to burglary with Russian standards. Ideally, a metal door should have a passport in accordance with the requirements of GOST 31173-2003, which, in addition to manufacturing details and design features, indicates:

- mechanical class;

- reliability (opening cycles);

- breathability at? P0 = 100 Pa (value in m3/(h.m2) or class);

- airborne noise insulation index Rw in dB;

- reduced heat transfer resistance in m2.°C/W.

1.4 Heat transfer resistance of external doors and gates

For external doors, the required heat transfer resistance R o tr must be at least 0.6 R o tr of the walls of buildings and structures, determined by formulas (1) and (2).

0.6R o tr =0.6*0.57=0.3 m²·ºС/W.

Based on the accepted designs of external and internal doors according to Table A.12, their thermal resistances are accepted.

External wooden doors and double gates 0.43 m²·ºС/W.

Single internal doors 0.34 m²·ºС/W

1.5 Heat transfer resistance of light opening fillings

For the selected type of glazing, according to Appendix A, the value of thermal resistance to heat transfer of light openings is determined.

In this case, the heat transfer resistance of the fillings of external light openings R approx must be no less than the standard heat transfer resistance

determined according to table 5.1, and not less than the required resistance

R= 0.39, determined according to table 5.6

Heat transfer resistance of the fillings of light openings, based on the difference in the calculated temperatures of internal air t in (table A.3) and external air t n and using table A.10 (t n is the temperature of the coldest five-day period).

Rt= t in -(- t n)=18-(-29)=47 m²·ºС/W

R ok = 0.55 -

for triple glazing in wooden split-pair sashes.

When the ratio of the glazing area to the filling area of the light opening in wooden frames is equal to 0.6 - 0.74, the specified value of R ok should be increased by 10%

R=0.55∙1.1=0.605 m 2 Cº/W.

1.6 Heat transfer resistance of internal walls and partitions

| Calculation of thermal resistance of internal walls | ||||

| Coef. thermal conductivity material λ, W/m²·ºС | Note | |||

| 1 | Pine timber | 0,16 | 0,18 | p=500 kg/m³ |

| 2 | Indicator name | Meaning | ||

| 3 | 18 | |||

| 4 | 23 | |||

| 5 | 0,89 | |||

| 6 | Rt = 1/αв + Rк + 1/αн | 0,99 | ||

| Calculation of thermal resistance of internal partitions | ||||

| Name of the construction layer | Coef. thermal conductivity material λ, W/m²·ºС | Note | ||

| 1 | Pine timber | 0,1 | 0,18 | p=500 kg/m³ |

| 2 | Indicator name | Meaning | ||

| 3 | coefficient heat transfer internal surface of the enclosing structure αв, W/m²·ºС | 18 | ||

| 4 | coefficient heat transfer external surfaces for winter conditions αн, W/m²·ºС | 23 | ||

| 5 | thermal resistance of the enclosing structure Rк, m²·ºС/W | 0,56 | ||

| 6 | heat transfer resistance of the enclosing structure Rt, m²·ºС/W Rt = 1/αв + Rк + 1/αн | 0,65 | ||

Section 13. - tee for passage 1 pc. z = 1.2; - outlet 2 pcs. z = 0.8; Section 14 - branch 1 pc. z = 0.8; - valve 1 pc. z = 4.5; The local resistance coefficients of the remaining sections of the heating system of a residential building and garage are determined similarly. 1.4.4. General provisions for designing a garage heating system. System...

Thermal protection of buildings. SNiP 3.05.01-85* Internal sanitary systems. GOST 30494-96 Residential and public buildings. Room microclimate parameters. GOST 21.205-93 SPDS. Symbols for elements of sanitary systems. 2. Determination of the thermal power of the heating system The building envelope is represented by external walls, the ceiling above the upper floor...

... ; m3; W/m3 ∙ °С. The condition must be met. The standard value is taken from Table 4 depending on. The value of the standardized specific thermal characteristics for a civil building (tourist base). Since 0.16< 0,35, следовательно, условие выполняется. 3 РАСЧЕТ ПОВЕРХНОСТИ НАГРЕВАТЕЛЬНЫХ ПРИБОРОВ Для поддержания в помещении требуемой температуры необходимо, ...

Designer. Internal sanitary and technical installations: at 3 o’clock – Ch 1 Heating; edited by I. G. Staroverov, Yu. I. Schiller. – M: Stoyizdat, 1990 – 344 p. 8. Lavrentieva V. M., Bocharnikova O. V. Heating and ventilation of a residential building: MU. – Novosibirsk: NGASU, 2005. – 40 p. 9. Eremkin A.I., Koroleva T.I. Thermal regime of buildings: Textbook. – M.: ASV Publishing House, 2000. – 369 p. ...

The general diagram of the design procedure for thermal protection of buildings required in accordance with Scheme 1 is presented in Figure 2.1.

Where R req , R min – normalized and minimum value of heat transfer resistance, m 2 ×°C/W;

, – standard calculated specific heat energy consumption for heating buildings during the heating period, kJ/(m 2 °C day) or kJ/(m °C day).

|

||||

|

||||

method “b” method “a”

|  |

||

Change project

NO

YES

Where R int , Rext - heat transfer resistance on the inner and outer surfaces of the fence, (m 2 K)/W;

R to- thermal resistance of the layers of the enclosing structure, (m 2 × K)/W;

R pr– reduced thermal resistance of a non-uniform structure (structure with heat-conducting inclusions), (m 2 K)/W;

a int, a ext – heat transfer coefficients on the inner and outer surfaces of the fence, W/(m 2 K), are taken according to the table. 7 and table. 8 ;

d i– thickness of the layer of the enclosing structure, m;

l i– coefficient of thermal conductivity of the layer material, W/(m 2 K).

Since the thermal conductivity of materials largely depends on their humidity, their operating conditions are determined. According to Appendix “B”, the humidity zone is established on the territory of the country, then according to Table. 2, depending on the humidity regime of the room and the humidity zone, the operating conditions of the enclosing structure A or B are determined. If the humidity regime of the room is not specified, then it is allowed to accept it as normal. Then, according to Appendix “D”, depending on the established operating conditions (A or B), the thermal conductivity coefficient of the material is determined (see Appendix “E”).

If the fence includes structures with inhomogeneous inclusions (floor panels with air gaps, large blocks with heat-conducting inclusions, etc.), then the calculation of such structures is carried out using special methods. These methods are presented in appendices “M”, “N”, “P”. In the course project, such structures are the floor panels of the first floor and the ceiling of the last floor; their reduced thermal resistance is determined as follows.

A). By planes parallel to the heat flow, the panel is divided into sections that are homogeneous and heterogeneous in composition (Fig. 2.2, A). Areas of the same composition and size are assigned the same number. The total resistance of the floor panel will be equal to the average resistance. Due to their size, the sections have a unequal effect on the overall resistance of the structure. Therefore, the thermal resistance of the panel is calculated taking into account the areas occupied by the sections in the horizontal plane, using the formula:

Where l reinforced concrete – coefficient of thermal conductivity of reinforced concrete, taken depending on operating conditions A or B;

R a . g.─ thermal resistance of a closed air layer, taken according to table. 7 at a positive air temperature in the interlayer, (m 2 K)/W.

But the obtained thermal resistance of the floor panel does not coincide with the data of the laboratory experiment, so the second part of the calculation is performed.

B). By planes perpendicular to the direction of heat flow, the structure is also divided into homogeneous and inhomogeneous layers, which are usually denoted by capital letters of the Russian alphabet (Fig. 2.2, b). The total thermal resistance of the panel in this case is:

where is the thermal resistance of layers “A”, (m 2 K)/W;

RB– thermal resistance of layer “B”, (m 2 K)/W.

When calculating R B it is necessary to take into account the varying degrees of influence of areas on the thermal resistance of the layer due to their sizes:

The calculations can be averaged as follows: the calculations in both cases do not coincide with the laboratory experiment data, which are closer to the value R 2 .

The calculation of the floor panel must be done twice: for the case when the heat flow is directed from bottom to top (ceiling) and from top to bottom (floor).

The heat transfer resistance of external doors can be taken according to table. 2.3, windows and balcony doors - according to table. 2.2 of this manual

The required total heat transfer resistance for external doors (except balcony doors) must be at least 0.6  for the walls of buildings and structures, determined at the estimated winter temperature of the outside air, equal to the average temperature of the coldest five-day period with a probability of 0.92.

for the walls of buildings and structures, determined at the estimated winter temperature of the outside air, equal to the average temperature of the coldest five-day period with a probability of 0.92.

We accept the actual total heat transfer resistance of external doors  =

= , then the actual heat transfer resistance of external doors is

, then the actual heat transfer resistance of external doors is  , (m 2 ·С)/W,

, (m 2 ·С)/W,

, (18)

, (18)

where t in, t n, n, Δt n, α in – the same as in equation (1).

The heat transfer coefficient of external doors k dv, W/(m 2 ·С), is calculated using the equation:

.

.

Example 6. Thermal engineering calculation of external fences

Initial data.

Residential building, t = 20С .

Values of thermal characteristics and coefficients tхп(0.92) = -29С (Appendix A);

α in = 8.7 W/(m 2 ·С) (Table 8); Δt n = 4С (Table 6).

Calculation procedure.

We determine the actual heat transfer resistance of the outer door  according to equation (18):

according to equation (18):

(m 2 ·С)/W.

(m 2 ·С)/W.

The heat transfer coefficient of the external door k dv is determined by the formula:

W/(m 2 ·С).

W/(m 2 ·С).

2 Calculation of the heat resistance of external fences during the warm period

External fencing is checked for thermal resistance in areas with an average monthly air temperature in July of 21°C and above. It has been established that fluctuations in the outside air temperature A t n, С, occur cyclically, obey the sinusoidal law (Figure 6) and cause, in turn, fluctuations in the actual temperature on the inner surface of the fence  , which also flow harmoniously according to the law of a sinusoid (Figure 7).

, which also flow harmoniously according to the law of a sinusoid (Figure 7).

Thermal resistance is the property of a fence to maintain a relative constant temperature on the inner surface τ in, С, with fluctuations in external thermal influences  , С, and ensure comfortable indoor conditions. As you move away from the outer surface, the amplitude of temperature fluctuations in the thickness of the fence, A τ , С, decreases, mainly in the thickness of the layer closest to the outside air. This layer with a thickness of δ pk, m, is called a layer of sharp temperature fluctuations A τ, С.

, С, and ensure comfortable indoor conditions. As you move away from the outer surface, the amplitude of temperature fluctuations in the thickness of the fence, A τ , С, decreases, mainly in the thickness of the layer closest to the outside air. This layer with a thickness of δ pk, m, is called a layer of sharp temperature fluctuations A τ, С.

Figure 6 – Fluctuations in heat flows and temperatures on the surface of the fence

Figure 7 – Attenuation of temperature fluctuations in the fence

Thermal resistance testing is carried out for horizontal (covering) and vertical (wall) fences. First, the permissible (required) amplitude of temperature fluctuations of the internal surface is established  external fencing taking into account sanitary and hygienic requirements in the expression:

external fencing taking into account sanitary and hygienic requirements in the expression:

, (19)

, (19)

where t nl is the average monthly outdoor temperature for July (summer month), С, .

These fluctuations occur due to fluctuations in the design temperatures of the outside air  ,С, determined by the formula:

,С, determined by the formula:

where A t n is the maximum amplitude of daily fluctuations in the outside air for July, С, ;

ρ – solar radiation absorption coefficient by the outer surface material (Table 14);

I max, I avg – respectively the maximum and average values of total solar radiation (direct and diffuse), W/m 3, accepted:

a) for external walls - as for vertical surfaces of western orientation;

b) for coatings - as for a horizontal surface;

α n - heat transfer coefficient of the outer surface of the fence under summer conditions, W/(m 2 ·С), equal to

where υ is the maximum of the average wind speeds for July, but not less than 1 m/s.

Table 14 – Solar radiation absorption coefficient ρ

|

Material of the outer surface of the fence |

Absorption coefficient ρ |

|

Protective layer of light gravel roll roofing | |

|

Red clay brick | |

|

Silicate brick | |

|

Cladding with natural stone (white) | |

|

Lime plaster, dark gray | |

|

Light blue cement plaster | |

|

Cement plaster dark green | |

|

Cream cement plaster |

The magnitude of actual vibrations on the inner plane  ,С, will depend on the properties of the material, characterized by the values of D, S, R, Y, α n and contributing to the attenuation of the amplitude of temperature fluctuations in the thickness of the fence A t. Attenuation coefficient

,С, will depend on the properties of the material, characterized by the values of D, S, R, Y, α n and contributing to the attenuation of the amplitude of temperature fluctuations in the thickness of the fence A t. Attenuation coefficient  determined by the formula:

determined by the formula:

where D is the thermal inertia of the enclosing structure, determined by the formula ΣD i = ΣR i ·S i ;

e = 2.718 – base of natural logarithm;

S 1 , S 2 , …, S n – calculated coefficients of heat absorption of the material of individual layers of the fence (Appendix A, table A.3) or table 4;

α n – heat transfer coefficient of the outer surface of the fence, W/(m 2 ·С), is determined by formula (21);

Y 1, Y 2,…, Y n is the coefficient of heat absorption of the material on the outer surface of the individual layers of the fence, determined by formulas (23 ÷ 26).

,

,

where δi is the thickness of individual layers of the enclosing structure, m;

λ i – thermal conductivity coefficient of individual layers of the enclosing structure, W/(m·С) (Appendix A, Table A.2).

The heat absorption coefficient of the outer surface Y, W/(m 2 ·С), of an individual layer depends on the value of its thermal inertia and is determined in the calculation, starting from the first layer from the inner surface of the room to the outer one.

If the first layer has D i ≥1, then the heat absorption coefficient of the outer surface of the layer Y 1 should be taken

Y 1 = S 1 . (23)

If the first layer has D i< 1, то коэффициент теплоусвоения наружной поверхности слоя следует определить расчетом для всех слоев ограждающей конструкции, начиная с первого слоя:

for the first layer  ; (24)

; (24)

for the second layer  ; (25)

; (25)

for nth layer  , (26)

, (26)

where R 1 , R 2 ,…, R n – thermal resistance of the 1st, 2nd and nth layers of the fence, (m 2 ·С)/W, determined by the formula  ;

;

α in – heat transfer coefficient of the inner surface of the fence, W/(m 2 ·С) (Table 8);

Based on known values  And

And  determine the actual amplitude of temperature fluctuations of the internal surface of the enclosing structure

determine the actual amplitude of temperature fluctuations of the internal surface of the enclosing structure  ,C,

,C,

. (27)

. (27)

The enclosing structure will meet the heat resistance requirements if the condition is met

(28)

(28)

In this case, the enclosing structure provides comfortable room conditions, protecting against the effects of external heat fluctuations. If  , then the enclosing structure is not heat-resistant, then it is necessary to use a material with a high heat absorption coefficient S, W/(m 2 ·С) for the outer layers (closer to the outside air).

, then the enclosing structure is not heat-resistant, then it is necessary to use a material with a high heat absorption coefficient S, W/(m 2 ·С) for the outer layers (closer to the outside air).

Example 7. Calculation of the heat resistance of an external fence

Initial data.

Enclosing structure consisting of three layers: plaster made of cement-sand mortar with a volumetric mass γ 1 = 1800 kg/m 3, thickness δ 1 = 0.04 m, λ 1 = 0.76 W/(m·С); insulation layer made of ordinary clay brick γ 2 = 1800 kg/m 3, thickness δ 2 = 0.510 m, λ 2 = 0.76 W/(mС); facing silicate brick γ 3 = 1800 kg/m 3, thickness δ 3 = 0.125 m, λ 3 = 0.76 W/(m·С).

Construction area - Penza.

Estimated internal air temperature t in = 18 С .

The humidity level of the room is normal.

Operating condition – A.

Calculated values of thermal characteristics and coefficients in the formulas:

t nl = 19.8С;

R 1 = 0.04/0.76 = 0.05 (m 2 °C)/W;

R 2 = 0.51/0.7 = 0.73 (m 2 °C)/W;

R 3 = 0.125/0.76 = 0.16 (m 2 °C)/W;

S 1 = 9.60 W/(m 2 °C); S 2 = 9.20 W/(m 2 °C);

S 3 = 9.77 W/(m 2 °C); (Appendix A, Table A.2);

V = 3.9 m/s;

A t n = 18.4 С;

I max = 607 W/m 2 , , I av = 174 W/m 2 ;

ρ= 0.6 (Table 14);

D = R i · S i = 0.05·9.6+0.73·9.20+0.16·9.77 = 8.75;

α in = 8.7 W/(m 2 °C) (Table 8),

Calculation procedure.

1. Determine the permissible amplitude of temperature fluctuations of the internal surface  external fencing according to equation (19):

external fencing according to equation (19):

2. Calculate the estimated amplitude of fluctuations in outside air temperature  according to formula (20):

according to formula (20):

where α n is determined by equation (21):

W/(m 2 ·С).

3. Depending on the thermal inertia of the enclosing structure D i = R i ·S i = 0.05 · 9.6 = 0.48<1, находим коэффициент теплоусвоения наружной поверхности для каждого слоя по формулам (24 – 26):

W/(m 2 °C).

W/(m 2 °C).

W/(m 2 °C).

W/(m 2 °C).

W/(m 2 °C).

W/(m 2 °C).

4. We determine the attenuation coefficient of the calculated amplitude of fluctuations of the outside air V in the thickness of the fence using formula (22):

5. We calculate the actual amplitude of temperature fluctuations of the internal surface of the enclosing structure  , С.

, С.

If the condition, formula (28), is met, the structure meets the requirements of heat resistance.