Folding boat covered with tarpaulin. Portable boats. Collapsible boats. Creating a project with drawings

Read also

4. Portable boats

The main characteristic of ships of this type is transportability, i.e. the ability to be carried and transported by any type of transport. The ensuing restrictions on size and weight make it necessary to give preference to rowing boats, but larger vessels are also produced, designed to install an outboard motor, which, when disassembled, fit in the trunk or on the roof of a car.

4.1. Collapsible boats

Folding hunting boat (Fig. 4.3)- one of the simplest collapsible boats in design. Designed for a single fisherman. You can cast a spinning rod from it while standing. The hull of this folding boat is made of 1.5 mm thick duralumin sheets, connected to each other using a rubberized belt 2-4 mm thick with rivets. When ready for use, the stern of the boat is held in place by two spacers made of duralumin pipes.

Folding hunting boat (Fig. 4.3)- one of the simplest collapsible boats in design. Designed for a single fisherman. You can cast a spinning rod from it while standing. The hull of this folding boat is made of 1.5 mm thick duralumin sheets, connected to each other using a rubberized belt 2-4 mm thick with rivets. When ready for use, the stern of the boat is held in place by two spacers made of duralumin pipes.

“Taimen” (Fig. 4.4) is a commercially produced kayak. Single, double and triple “Taimen” are designed for tourist voyages along routes of high complexity. Contours with smoothly trimmed stems and large camber of the frames provide the qualities necessary for this. All elements of the collapsible frame are made of duralumin.

Unsinkability is ensured by six thermal packs - one each in the bow and stern and four on the sides with a total volume of 130-140 liters, which is enough to keep a fully submerged kayak afloat with one oarsman. The rowers' seats on two- and three-person kayaks are located further from the midships, which significantly increases the maneuverability of the boat. In the middle of the hull there is a special cargo compartment, in which one more person can be placed for short-term exits.

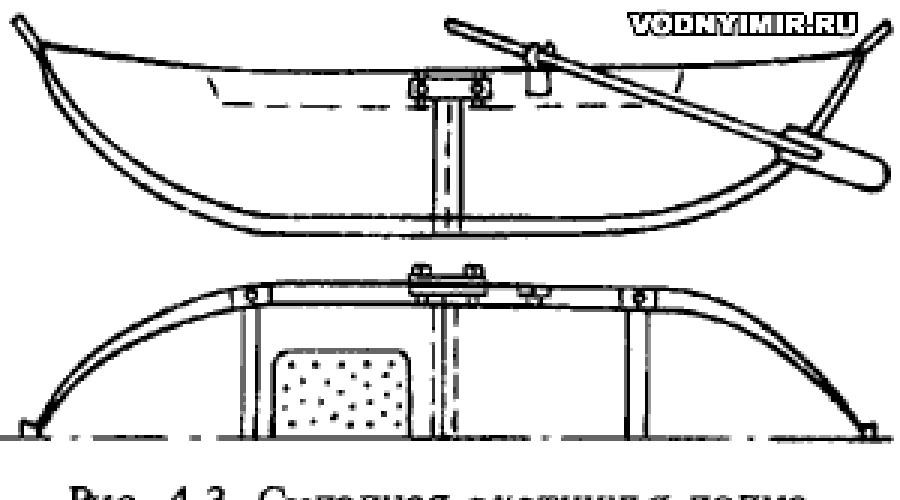

LR-01 (Fig. 4.5) - motor-rowing boat, which, like collapsible kayaks, has a collapsible frame and a soft rubberized shell. The transom made of duralumin sheet with a plywood cover is designed to install an outboard motor with a power of 1 kW (2 hp). Transverse cans made of plywood and foam increase the rigidity of the hull, and together with thermal packaging placed in the bow and along the sides, provide emergency buoyancy.

The boat's seaworthiness is not inferior to non-collapsible vessels of the same dimensions, and has good speed with oars and with a motor.

Sectional canoe (Fig. 4.6) can be used for long-distance tourist voyages and walks in versions with oars, outboard motor or sail. The boat project was awarded 1st prize at the NTO competition. acad. A. N. Krylova (boat project for self-building). The dimensions and weight of the boat allow it to be transported on the roof rack of any car.

The relatively narrow hull of the canoe has an almost flat bottom with small radius chines, which ensures good stability and satisfactory performance under motor. Raising the keel line at the ends improves turning ability, which is especially important when passing rapids. Shifting the greatest width to the stern reduces the trim that occurs when sailing under a motor alone.

The hull is a free-standing fiberglass structure, divided into three sections with paired watertight bulkheads at the joints. Two corrugations molded in the middle part of the boat on a flat bottom serve as stiffening ribs and at the same time protect the hull from abrasion. The division of the hull into three sections of unequal length and its asymmetry relative to the midsection not only simplifies packaging (the bow section is inserted into the stern and together with it into the middle one), but also allows it to be assembled in several versions. From the bow and middle sections, for example, a planing motorboat is formed for a motor with a power of up to 15 kW (20 hp).

Before you start building a wooden boat, you need to prepare the main part of such a structure - the sides. To do this, you need to take the smoothest, longest, wide enough boards that are made of spruce or pine.

Look at the photos of homemade boats and you will see that there are no boards on its sides that have knots - this is very important. The boards for this part of the boat must remain in a dry place under slight pressure for at least one year.

Choosing boards for work

Before production begins, it is necessary to once again make sure that the boards are absolutely suitable for the job. Next, for each board you need to measure the required length and carefully cut them at an angle of 45 degrees. These boards will go to the bow of the boat.

After this, you need to plan them and check that the boards connected to each other do not have any gaps. Then treat the ends with an antiseptic.

The next step is to prepare the bow of the boat, using a triangular block. It should be one and a half times longer than the width of the sides. The timber is also planed and covered with a layer of antiseptic.

Further instructions for making a boat with your own hands is to select a suitable board for the stern of the boat. Do not neglect the supply, because it is better to cut off the excess later than to search and start all over again.

Boat assembly

When the elements of the wooden boat are assembled, you need to begin assembling the product. You should start from the bow. Both sides and the triangular block must be connected to each other using self-tapping screws. It is advisable to immediately cut off the protrusions at the top and bottom so that they do not interfere in the future.

The next step is very important and responsible, since it is necessary to give the future boat its shape. You need to decide on the width of the boat and place a spacer in the middle. Choose a board for the spacer that is the same size as the height of the boat, so the sides will not burst.

Once the brace is properly installed, you can begin to shape the boat, call a few people to help or stock up on ropes to hold the structure in place.

Use the drawings and adjust the dimensions of the stern to make the boat so that when connecting the back wall and sides there are no gaps or cracks.

When the backdrop is installed, cut off the excess part from below, and on top you can make an element in the form of a triangle. Next we are working on the spacers, which will constantly maintain the shape of the boat, as well as the seats, which are installed on top of the spacers. You can determine the number, as well as the location of these elements yourself, so it can be one, two or more places.

We align everything on the bottom in one plane and treat the entire surface with a protective layer. When the glue dries, start making the bottom of the boat.

The best option for the bottom would be a galvanized sheet of metal. Try to find a sheet that matches the size of the boat.

How to make the bottom of a boat with your own hands

Place the future boat on a sheet of metal and trace its boundaries with a marker, do not forget to take a few centimeters of extra space just in case, you can always trim off the excess.

The next step is to cover the connection of the boat with its bottom with a special silicone sealant along the entire length in one line. On top of the sealant, until it has dried, a cord is laid in several rows - all this is necessary to ensure that the bottom of the boat is airtight and does not let water inside.

When this process is completed, we move on to connecting the bottom to the frame. Carefully place the bottom of the boat over the bottom of the boat. Use nails or screws to connect.

Start connecting from the middle and move towards the edges of the boat. Do the work as slowly and carefully as possible, as this part is very important.

We cut off the excess metal that sticks out more than 5 mm from the edge of the boat, and bend the rest with a hammer. It is also important to protect the bow of the boat from external factors using the same metal. Cut a rectangle of tin to the size of the boat.

Wherever wood and metal are connected, it is necessary to go through with sealant and lace. By this time, before you start “wrapping” the bow with metal, you need to treat the entire boat with an antiseptic.

Be sure to make a fastening on the bow for the chain. This will help if someone wants to steal a brand new boat, since on a body of water it will attract special attention due to its newness.

Before you build a boat, think through and look at all the ideas that you can use to make a boat. Perhaps you will choose a special material for yourself that will be more convenient for you to work with, or maybe you need special protection or massiveness.

Do not forget to cover the bottom with special paint on the back side, since galvanized metal is destroyed over time when in contact with water. The wooden parts of the boat must be coated with several layers of special impregnation and the boat must be left to dry in the shade.

For convenience, a wooden flooring can be laid out inside the boat at its bottom. This way the bottom will not rattle when you move along it.

At this point the boat will be ready. Read in more detail the article on how to make the best homemade boats with a description to find out some other nuances that may be useful to you in future construction.

DIY boat photo

Homemade plywood boat (master class, photo, step by step)

So we finally got around to fulfilling our old dream and started building a boat. For the first time I chose an easy project, so to speak for training. I went to the production of similar boats in Cherepovets and there I spied something and bought the missing materials, for which special thanks to the owner of the shipyard.

This is what the boat should look like:

Today I cut out sheets of plywood and began the most important and difficult process, in my opinion, which is cutting and gluing sheets of plywood. Because If the length of the boat exceeds the length of standard sheets of plywood, then they have to be spliced; there are many ways to do this, but I chose the most technically complex, but also more aesthetic option of miter gluing.

Let's mark it.

We process the plywood sheets first with a plane and then with a sander.

This is what it looks like during processing.

This is how the sheets should fit and stick together.

After adjusting the parts, I glued them together and placed them under the press.

That's all the preparatory work on the boat for now; after the sheets are glued together, I'll start marking and cutting out the parts.

At first I practiced miter joints on scraps of plywood and it was scary to look at, but experience came from working on the “finish” version :) I hope I can continue to master everything.

That's about the boat.

Basic data:

Maximum length............2.64 m

Maximum width............1.28 m

Side height...........................0.38 m

Body weight........................30 kg

Load capacity...................180 kg

Crew...................................2 people

Permissible power p/motor...2.5 hp

Today was a day of fruitful work and great progress :)

He pulled the sheets out from under the press and removed the strips between which they were sandwiched. The joint turned out to be smooth and very strong (then we tried to break the scraps from the bottom, but it did not break at the joint of the sheets). In this way we obtained blanks of the required length for making the boat.

I start marking by marking the center line, from which all the dimensions will then go.

Here I drew the bottom of the boat, it looks like it turned out beautifully:

I start cutting. It is advisable to use a jigsaw at high speeds, and use files for shaped cutting of plywood so as not to tear the edges of the sheets.

We follow the markings strictly :)

Half of the bottom is ready.

Here's the bottom in its entirety :)

We mark one side, then we put two blanks on top of each other and fasten them with clamps, after which we cut out both sides at once.

I mark and cut out the transom.

At the joints of the plywood sheets, we remove the chamfer with a grinder and begin sewing the boat with copper wire clips.

We carry out work from stern to bow.

You can't do this without an assistant.

I also try hard to sew everything beautifully :)

These are the seams you get.

Here the boat is ready :)

Try it on for yourself :)

And upside down.

Today we have really moved towards the final stage of completing the project :)

The first thing I did was pull all the staples tighter. I checked the geometry of the boat. Then I used a chisel to edge the brackets at the internal joints of the sides. After all this, I cut out temporary spacers and secured them in the places where the frames were installed.

While doing these things in the new room, I constantly felt eyes on me. By the way, here is a view of the straightened boat from the stern.

To make the seams more even, I decided to fill the lines with masking tape, it turned out beautifully.

I decided to glue it in the evening, but in the meantime I drew out the frame templates and began assembling them.

Here are the finished frames, assembled using epoxy glue and self-tapping screws.

I finally started gluing the internal seams, I didn’t think it would be such a painstaking job :) For the first time, everything seemed to work out great. The resin has saturated the fiberglass fabric normally, there are no bubbles anywhere.

This is how the seam turns out, smooth and transparent. The photo shows that the structure of the wood is visible through three layers of glass tape, which means everything is normal.

Here's what was done last time: the frames were adjusted and the fenders were screwed on.

Today I installed the frames in place and secured them with glue and screws, and cut out reinforcing linings for the transom.

After that, I turned the boat over, removed all the staples from the wire and began rounding the seam joints.

And now that everything was prepared, I started gluing the external seams.

The seams turned out smooth and well saturated, even I like it myself.

Seams on the transom.

Today I finished shaping the boat’s hull, next time I’ll install the benches and start preparing for painting.

The sides are fastened not only with glue, but also reinforced with three layers of glass tape on each side, this turns out to be fiberglass. The self-tapping screws from the frames can be completely removed; after gluing, they will no longer be needed. By the way, some people do just that. Such a boat can be assembled without a single screw in the hull.

Today I went to make a boat only in the evening, because... I waited for the glue to set well. I checked the external seams, I really liked how it was done, it turned out to be strong fiberglass. After that I decided to make slats for the benches. I also cut out and fitted the stem to the bow of the boat.

Here are the slats of the front bench attached.

Here is the middle bench.

I also cut slats for the rear bench, but it’s too early to install them.

Apparently prolonging the pleasure of the process, or maybe out of a desire to do everything efficiently, I’m making the boat slowly and little by little :)

Today I bought glue, screws and high-quality lumber without knots. All this was intended to install the keel and outer stringers. These necessary elements will give greater strength to the bottom, as well as protect the boat while mooring to the shore, and protect the paintwork from scratches.

I cut out the slats, sanded them and installed them in place using glue and screws.

Also today I installed a stem and a bow eye bolt for tying a rope or anchor rope.

Work had to be stopped for today because... the whole thing should be firmly grasped; for this I used additional weights.

By the way, the bench blanks have already been cut out, but they will be installed after painting the inside of the boat.

Policy regarding the processing of personal data

1. General Provisions

This personal data processing policy has been drawn up in accordance with the requirements of the Federal Law of July 27, 2006. No. 152-FZ “On Personal Data” and determines the procedure for processing personal data and measures to ensure the security of personal data of JACKBOT-MASTER LLC (TIN 6313548928 KPP 631301001) (hereinafter referred to as the Operator).1.1. The operator sets as its most important goal and condition for carrying out its activities the observance of the rights and freedoms of man and citizen when processing his personal data, including the protection of the rights to privacy, personal and family secrets.1.2. This Operator's policy regarding the processing of personal data (hereinafter referred to as the Policy) applies to all information that the Operator may receive about website visitors.

2. Basic concepts used in the Policy 2.1. Automated processing of personal data – processing of personal data using computer technology; 2.2. Blocking of personal data – temporary cessation of processing of personal data (except for cases where processing is necessary to clarify personal data); 2.3. Website – a collection of graphic and information materials, as well as computer programs and databases that ensure their availability on the Internet at the network address http://site; 2.4. Information system of personal data - a set of personal data contained in databases, and information technologies and technical means that ensure their processing; 2.5. Depersonalization of personal data - actions as a result of which it is impossible to determine without the use of additional information the ownership of personal data to a specific User or other subject of personal data; 2.6. Processing of personal data – any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data;2.7. Operator - a state body, municipal body, legal or natural person, independently or jointly with other persons organizing and (or) carrying out the processing of personal data, as well as determining the purposes of processing personal data, the composition of personal data to be processed, actions (operations) performed with personal data;2.8. Personal data – any information relating directly or indirectly to a specific or identified User of the website http://site;2.9..10. Providing personal data – actions aimed at disclosing personal data to a certain person or a certain circle of persons; 2.11. Distribution of personal data - any actions aimed at disclosing personal data to an indefinite number of persons (transfer of personal data) or to familiarize with personal data to an unlimited number of persons, including the publication of personal data in the media, posting in information and telecommunication networks or providing access to personal data in any other way;2. 12. Cross-border transfer of personal data – transfer of personal data to the territory of a foreign state to an authority of a foreign state, a foreign individual or a foreign legal entity; 2.13. Destruction of personal data – any actions as a result of which personal data are destroyed irrevocably with the impossibility of further restoration of the content of personal data in the personal data information system and (or) as a result of which the material media of personal data are destroyed.

3. The Operator may process the following personal data of the User 3.1. Last name, first name, patronymic.3.2. Email address.3.3. Telephone numbers.3.4. Details of the identity document.3.5. Address of actual place of residence and registration at the place of residence and (or) place of stay.3.6. The site also collects and processes anonymized data about visitors (including cookies) using Internet statistics services (Yandex Metrica and Google Analytics and others). 3.7. The above data below in the text of the Policy are united by the general concept of Personal Data.

4. Purposes of processing personal data 4.1. The purpose of processing the User’s personal data is to inform the User by sending emails; conclusion, execution and termination of civil contracts; providing the User with access to services, information and/or materials contained on the website; informing the User by sending SMS messages (solely for notification purposes, for informational purposes only).4.2. The Operator also has the right to send notifications to the User about new products and services, special offers and various events. The User can always refuse to receive information messages by sending the Operator a letter to the email address info@site with the note “Refusal of notifications about new products and services and special offers.”4.3. Anonymized data of Users, collected using Internet statistics services, serves to collect information about the actions of Users on the site, improve the quality of the site and its content.

5. Legal grounds for processing personal data 5.1. The Operator processes the User’s personal data only if it is filled out and/or sent by the User independently through special forms located on the website. By filling out the appropriate forms and/or sending his personal data to the Operator, the User expresses his consent to this Policy. 5.2. The Operator processes anonymized data about the User if this is allowed in the User's browser settings (saving cookies and using JavaScript technology are enabled).

6. The procedure for collecting, storing, transferring and other types of processing of personal data The security of personal data processed by the Operator is ensured through the implementation of legal, organizational and technical measures necessary to fully comply with the requirements of current legislation in the field of personal data protection. 6.1. The operator ensures the safety of personal data and takes all possible measures to prevent access to personal data by unauthorized persons. 6.2. The User's personal data will never, under any circumstances, be transferred to third parties, except in cases related to the implementation of current legislation. 6.3. If inaccuracies in personal data are identified, the User can update them independently by sending a notification to the Operator to the Operator's e-mail address info@site marked “Updating personal data.” 6.4. The period for processing personal data is unlimited. The User may at any time withdraw his consent to the processing of personal data by sending a notification to the Operator via email to the Operator's email address info@site marked “Withdrawal of consent to the processing of personal data.”

7. Cross-border transfer of personal data 7.1 The operator, before starting the cross-border transfer of personal data, is obliged to make sure that the foreign state to whose territory it is intended to transfer personal data provides reliable protection of the rights of the subjects of personal data. 7.2 Cross-border transfer of personal data to the territory of foreign states that do not meet the above requirements can only be carried out if there is consent in writing from the subject of personal data to the cross-border transfer of his personal data and/or execution of an agreement to which the subject of personal data is a party.

8. Final provisions 8.1. The User can receive any clarification on issues of interest regarding the processing of his personal data by contacting the Operator via email [email protected]. 8.2. This document will reflect any changes to the Operator’s personal data processing policy. The policy is valid indefinitely until it is replaced by a new version. 8.3. The current version of the Policy is freely available on the Internet at

This time, the editors provided the pages of the “Built by Amateurs” section to the authors of original portable watercraft of the simplest design. Each reader can do any of them with his own hands. You don’t have to spend a lot of time looking for the necessary materials or premises for assembly: a few meters of rubberized fabric, duralumin tubes or wooden slats, the help of a wife who owns a sewing machine - and the boat is ready.

True, none of the presented designs resemble a “real” boat either in shape or in its seaworthiness; These structures can only be used on quiet rivers and forest lakes. What attracts them is the ability to carry them in a backpack, which is important for hunters and tourists hiking along mixed routes - on foot and along the river, when carrying a kayak weighing 25-30 kg is simply difficult. From this point of view, the idea of the multi-purpose use of a boat, which serves as a backpack, a tent, and a bunk, developed by Muscovite V. A. Strogonov, is interesting; To assemble it, you don’t even need to take special slats with you - suitable thin trunks can be picked up in the forest.

Assessing this design from the point of view of a shipbuilder, one can note its stability, which is quite sufficient for crossing a river or fishing near the shore, as well as the presence of a reserve of buoyancy (in inflatable chambers) in case of damage to the fabric lining.

However, it is possible to do without rigid longitudinal struts altogether, if you let air perform their role. To do this, longitudinal inflatable cylinders can be provided on the panel in place of the side sections of the skin: they can easily be made in the form of a strip of a second layer of rubberized fabric sewn from the inside of the body. True, this will require more careful work and the use of airtight material. Apparently this is not a problem for the home boatbuilder; after all, Muscovite V.P. Demyanov was able to produce a portable inflatable catamaran, which in terms of weight is practically not inferior to V.A. Strogonov’s set, but is distinguished by even greater stability and better sailing performance. V.P. Demyanov’s conclusion is also correct that to increase the carrying capacity, in principle, it is more advisable to increase the size of the cylinders than to take with you another additional cylinder. Obviously, the increase in weight in this case will not be greater, but speed qualities and stability will increase to an immeasurably greater extent.

With a slight improvement in the contours of the inflatable floats and the installation of a centerboard, a Medusa-type catamaran can turn out to be a good tackling vessel - this is evidenced by the positive experience of operating similar foreign pleasure boats.

The boat of Kiev resident A.P. Lisitsa can be useful for a city dweller who goes fishing and does not intend to overcome vast expanses of water. Packed in a flat bag, it is no different from a portable suitcase and does not at all constrain the owner when traveling on a bus or train. The principle of expanding the soft shell can also be applied to larger boats of a different configuration, different from a box with an inclined front wall. The disadvantages of A.P. Lisitsa’s boat include the low survivability of the structure and the lack of buoyancy reserve. If the casing is damaged, the fisherman will have to swim to the shore. The width of the boat and the height of the side are critical values, which should be increased slightly. An emergency reserve of buoyancy in the form of thin slabs of durable PVC foam can be provided in the design of the seat and footrest (for example, by gluing the foam to their lower surface). It is enough to have 12-15 cubic meters. decimeters of buoyancy volume - and the boat will simultaneously serve as a reliable life-saving device. We do not recommend going out on such a boat without life-saving equipment, even in low water.

Finally, very wide opportunities for recreation on the water are provided by a collapsible floating dacha-tent, designed by Muscovite N.P. Mittrakh. The owner of such a cottage is as free to choose a route as a kayaker, but can sit on his vessel with much greater comfort and, moreover, is freed from the daily worries of setting up a tent.

The editors' portfolio contains several more descriptions of similar (may their authors forgive us!) primitive boats. Not all of them meet modern requirements for pleasure and fishing boats. But the very fact of the appearance of such home-made structures indicates an existing shortage in the industrial production of small-sized portable boats - watercraft for fishermen and tourists. Apparently, the need for them should mainly be met by expanding the production of inflatable boats - reliable in operation, technologically advanced in large-scale production and therefore inexpensive. It would be useful to produce into the retail chain simply elongated inflatable cylinders of two or three standard sizes, using which one could, like a children’s construction set, assemble catamarans or even rafts of various carrying capacities.

We cannot turn a blind eye to the other side of the portable boat problem. As a rule, these homemade vessels find themselves beyond any supervision of navigational and technical inspections, although they often have a far from safe design. Serial production of tested and approved samples would greatly help reduce the number of accidents on the water.

Canvas boat

The folding boat I made is convenient for transportation by any type of transport. Dimensions of the assembled boat: length 2 m, width 0.8 m, side height 0.35 m; when folded, the package measures 1X0.35X0.15 m.The main parts of the boat are two folding longitudinal frames, cross braces including seat and footrest, and a canvas cover. Frames and spacers can be made from duralumin square or slats (waste packaging containers for motorcycles or furniture are suitable). For the cover you need 6 m of rubberized fabric or thin tarpaulin, provided it is impregnated with rubber glue or other waterproof compound.

The ends of the slats for joining into frames are cut into subtrees. The seat and footrest are assembled from plywood, reinforced with slats, and attached to the frames on detachable hinges (loops from the window are used, from which the pins are knocked out and replaced with wire of a slightly smaller diameter).

The cover is made from two three-meter pieces of fabric, sewn together with the edges overlapping by 6-7 cm. These gluing points are first cleaned with sandpaper, separated with a lath so as not to clean off excess, then glued together with rubber glue. It is better to glue two people together so that there is no delay or distortion during gluing. You need to place something hard under the gluing area or glue it on a flat floor. After gluing, the connections are stitched. A full-length strip of tarpaulin is glued over the joint.

The longitudinal frames are temporarily fastened with slats so that the boat is 80 cm wide, then the resulting frame is placed on a cover laid with the rubberized layer down. Excess material on the sides is cut off, leaving only 2 cm at the bend. It is better not to cut off the tarpaulin at the corners of the frame, but to bend it, just as they wrap candies with paper or make boxes for them. The extra square that is formed when bending is cut off, and the joint is stitched manually. The tarpaulin should be pulled as tightly as possible.

To make it easier to pull the cover on, loops - petals with holes - are sewn to its upper edge. These loops are folded over the top of the side frames and placed on metal hooks (medium sized nails without heads, bent into an L shape). Then the boat is turned upside down and strips of tarpaulin 6-7 cm wide are attached along the longitudinal frames to protect the cover from wear.

The assembly sequence is as follows. The side frames in a half-bent position must be inserted into the cover, pointing exactly to the corners and immediately putting the side loops sewn on top of the cover onto the hooks. Then, with a push, the frames are straightened to their full length. The upper struts are inserted, then the seat, footrest and transverse slats along the bottom in the bow and rear of the boat.

The “undertaking” is simply simple in design. I made it myself at home from readily available materials, such as old ski poles and thick tarpaulin. The frame is assembled from duralumin tubes 16X0.7 and 14X0.7, 450-1400 mm long. Almost all tubes are straight; during assembly, they are simply inserted into crosspieces, corner couplings and tubular brackets. After assembly, the entire frame is tightened along the bottom with two diagonal cables from corner to corner, and the side along the upper edge is covered with a cable around the entire perimeter. Subsequent covering with tarpaulin and lacing it to the frame gives the entire structure final rigidity.

All brackets and crosspieces are made using wire-reinforced paste prepared on the basis of ED-6 epoxy resin (resin - 100 parts by weight, dibutyl phthalate - 20 parts by weight, hexamethylenediamine - 10 parts by weight, aluminum powder or sawdust - in ratio 1:1 to the volume of binder). To obtain a reliable connection, the metal must first be thoroughly cleaned with a file and degreased with white spirit; The parts to be connected are connected with wire with a diameter of 1-1.5 mm, then a cementing paste is applied and the assembly is kept at a temperature of 50-70 ° C until the paste completely hardens. The tubes, if there are cracks in them, are filled with paper so that the paste does not penetrate inside.

The sheathing of the floating boat - a rectangular panel 2500X4000 with eyelets along the edges (200 mm pitch) - is loosely laced to the tube bordering the upper edge of the side. The underwater part of the skin is made of thick waterproof tarpaulin, and the sides above the waterline are made of raincoat fabric. All joints are stitched with sewing thread No. 10 in two or three seams and impregnated with rubber glue (you can use a solution of 1 part by weight of raw rubber in 2 parts by weight of B-70 gasoline). The weight of the finished skin is about 7 kg. Pockets with flaps with buttons are sewn to the inside of the sides for storing small items.

Covering the frame with tarpaulin at the corners requires some experience. The tarpaulin should be folded so that the outer folds, which inevitably form at the corners, are directed from bow to stern - along the course of the water. On the inside, two sheets of corrugated fiberglass 1.5 mm thick are laid on the bottom, attached with belts to the bottom tubes. This type of flooring is rigid enough to support the weight of people or cargo.

For shelter from bad weather, a tent with a gable roof is used, stretched on rafter posts installed in the sockets of the side crosspieces. The tent is made of soft MMP polyvinyl chloride film with a thickness of 0.15-0.20 mm.

The crew (on trips it usually consisted of 4-5 people) is placed on folding seats made in the form of a frame made of 14X0.7 duralumin pipe covered crosswise with wide braid. It is also very comfortable to sit on air mattresses, which are laid on the bottom along the sides and attached to the frame; They, naturally, serve not only as a place of rest, but also as a means of providing emergency buoyancy.

When disassembled, the floating boat fits into two relatively small packages - one with a diameter of 100 and a length of 1700 mm and the other with dimensions 500X900. The entire process of assembling the vessel, from unpacking the bales to installing the seats, can be completed by two people in 40 minutes. Disassembly takes even less - 25 minutes.

We built “Zateya” 12 years ago. Since then, we have sailed on it more than 3000 km along quiet rivers and lakes in the most remote, protected places of the Ryazan Meshchera. On our first trip we went with only a pair of oars (and then covered more than 250 km). And when they attached a water-jet motor made from a D5 bicycle motor to the “transom”, the average ground speed increased to 5-6 km/h, and “Zateya” turned into a floating “rest home” for a family crew.

It should also be emphasized that despite the primitiveness of the device (not to mention its appearance, which provokes ridicule from specialists), our “Zateya” is a completely reliable vessel: underwater obstacles and waves are no more dangerous than, for example, for a kayak with a soft skin. Over all these years, the canvas hull did not have any holes. Some mobility of the skin and elasticity of the frame soften the blows when encountering driftwood, stones and snags. It’s quite simple to push our “Venture” off the shallows or any other obstacle. By the way, the relatively light weight of the hull makes it easy to pull it onto land and use the floating house at rest stops.

No steering device is needed, since the “Zateya” is well controlled by oars or, even more so, by a rotary motor-oar.

We believe that this version of a portable floating boat has a number of advantages. In addition to the simplicity of the design, these are, for example, transportability and low weight (hull 22 kg plus equipment 13 kg) with a large load capacity (450 kg) and useful area (3.0X1.5 m), low draft (about 100 mm), high stability.

Catamaran in a backpack

The collapsible inflatable four-seater catamaran “Medusa”, built with my own hands in a small apartment (where, by the way, it is stored in winter and summer, without bothering anyone, on the mezzanine) has already served me for three navigations. There are 26 hikes behind us, including one-day walks along the rivers and reservoirs of the Moscow region (Oka, Ugra, Moscow, Protva, Desna, Uchinskoye and Pirogovskoye reservoirs). People of different ages took part in these voyages of the Medusa - from 8 to 70 years old, and no one complained of inconvenience. There were no accidents, thank Neptune.The catamaran in the rowing version weighs only 7 kg, and with the mast, rudder and sails - 12 kg. It takes only about half an hour to assemble and prepare the Medusa for sailing. Two of our friends, who have their own collapsible kayak, in cases where the time budget is limited to Saturday and Sunday, readily prefer the Medusa to it.

The length of all rigid structural elements does not exceed 140-160 cm. A small bunch of such slats and tubes and a backpack, barely half filled, is what a disassembled vessel looks like, which can be transported by all types of transport, including a car and an airplane.

Making a catamaran does not present any difficulties, except for the search for light and durable material for floats. Two-layer aluminum fabric “500” (“silver”, as it is popularly called) turned out to be quite suitable. A float with a capacity of 200 liters glued together from it weighs less than a kilogram. Depending on the size of the crew, you can inflate not only two, but also three such floats. In especially critical cases (for example, when going on a hike in late autumn, and even with passengers who did not know how to swim), we had to use the fourth float: the result was no longer a trimaran, but a raft with a carrying capacity of half a ton.

We tested a total of nine floats of varying sizes and shapes. For short trips together, floats with a length of 2100-2400 mm and a diameter of 300-340 mm are best suited. If the trip is long and the crew consists of four people, it is more profitable to take not three floats made of “500” fabric, but two larger ones made of thick fabric, rubberized on both sides; it sticks well and allows you to give the float a more streamlined shape. With a maximum diameter of 400-420 mm, such a float has a volume of about 350 liters.

All floats are single-section with inflatable tubes (nipples) glued into the upper part, which allows air to be inflated even while afloat. The floats are inflated with homemade bellows, like a beekeeper's smoker, and often simply with their own lungs.

The rigid frame of the catamaran is assembled from slats with a section of 50X20 or 30X40 using wing bolts. The floats are attached to this frame using a wide braid that encircles them around their circumference.

Two crossbars 1400 mm long are made of aluminum square: folding canvas seats on aluminum tubular frames can be attached to them, which can be easily folded back when switching to sailing.

The mast is composite, made of three wooden blocks, fastened with bolts, or duralumin tubes with couplings. My tubular mast turned out to be less rigid than a wooden one, but it is convenient in that a gaff and boom (composite), made from aluminum ski poles, are inserted into its two long links (1600 mm long) during transportation. Percale sails weigh no more than a kilogram.

The catamaran is controlled under sail by a simple balancing rudder with an area of 6 dm2, which is attached with a clamp to the stern cross member. You can also use one of the oars for this purpose. “Medusa” does not go steeply into the wind, although when installing the windshields, this is apparently not excluded.

When rowing with short oars, like a canoe, the catamaran develops a speed of 5-6 km/h in calm water. True, we are lagging behind the kayak, but we are catching up on lost time while clearing dams and other obstacles. Under sail with a tailwind, the speed reaches 8 km/h.

When going on a hike, I usually tie two inflatable mattresses across the catamaran (one way or another I have to take them if I have an overnight stay). In this case, of course, we don’t take seats.

The mattresses will not allow the catamaran to capsize and sink, and in the worst case, we always have with us a waterproof bag with spare clothes (so far it has never come in handy). We always put a spare float, a bottle of glue and a piece of fabric for patches in the backpack.

Before difficult long hikes, we strengthen the frame with additional connections (two longitudinal and one transverse). Instead of a net, we stretch a tarpaulin on top and add two more oars.

Set of equipment for fisherman and hunters

The proposed set of lightweight equipment - weighing no more than 4 kg - for hunters and fishermen can be made at home within one or two days. It consists of just a few parts, various combinations of which turn into a backpack, tent, boat or bed.The main parts of the kit are a panel measuring 2.7x2 m, two floats and a luggage strap.

The middle part of the canvas, which serves as a tent and the shell of the boat, is cut out from rubberized fabric, the sides are made from a raincoat. To be able to set up the tent, there are 8 eyelets (holes) and two straps for stretching the roof ridge. The panel is attached to the ground with pins made of 2.5-3 mm wire (stainless steel); By the way, on a hike they can also be used as a tripod for a pot.

The floats of the boat are two bags made of any lightweight material, 1080 mm long and 480 mm wide, each containing three inflated soccer ball chambers. The tubes of the chambers are led out through holes covered with thread. The space between the chambers is filled with available material - reeds, hay, dry leaves, etc. Six canvas pockets must be sewn to each bag for the slats that make up the frame of the boat.

The slats of the boat frame and oars can be made of composite duralumin tubes, but where possible, it is easier to cut them out of dead wood in the forest. Then you will only need to take with you two plywood blades and two oarlocks cut from thick rubber, for example, from a car inner tube.

Two longitudinal slats supporting the upper edges of the sides are inserted into special pockets 3, sewn to the panel from the inside (cutouts 4 must be made in the pockets for oarlocks); the ends of the slats rest against fabric sockets on the float covers. Two more slats with a diameter of about 25 mm are inserted into the same sockets in the middle of the side height and on the bottom. After assembly, the cord 5 is tightly wrapped, the entire structure acquires the necessary rigidity. The edges of the cloth hang down inside the boat along the sides, and during rain they can be pulled up like a protective apron. On the bottom you need to either make a light lattice (slan), or just throw a few branches. A comfortable seat for rowing is made from a rubber cushion enclosed in a fabric cover.

A boat turned upside down becomes a camp bed.

To pack the kit, use a luggage strap with a removable leather handle (purchased in the store). The same belts are used for additional tightening of the two upper slats when assembling the boat, and also as guy ropes when installing a tent.

I have been using this set of equipment for several years on hikes in the Moscow region, Arkhangelsk and Vologda regions. It is very convenient for hunting and fishing in sparsely populated areas where it is difficult to get a boat.

A “suspended” bed, a tent and, in addition, a gauze canopy provide protection from mosquitoes and dampness, even on wet, swampy soil.

A slow-moving but quite stable boat allows you to raft on calm rivers and swim on small lakes.