Sanding drum. Tools for grinding Make a drum for sandpaper

Read also

Sanding various wooden parts– a necessity faced by everyone who wants to make repairs in their home, or with my own hands create some decorative element.

Of course, you can sand small parts with regular sandpaper, but to cope with a large amount of work, you should change the sandpaper to a grinding machine. It will help to significantly save time and quickly bring the part into the appropriate form. One of these useful devices is also a drum sander.

Classification and structure

Drum-type grinding devices belong to calibration class machines. This type of grinding machine is most often used for working on wood, but it can also be used to process other materials.

A cylindrical grinding wheel (drum) allows you to calibrate boards and slats of various lengths and configurations. The workpiece can also be made from different materials: Chipboard, veneer, etc.

Structure of the grinding apparatus:

- Cylindrical grinding drum.

- Feeding device.

- Dust removal device.

- Working surface.

- Drum speed converter.

- The motor that drives the grinding cylinder.

- Bed for fastening key components of the machine.

- Drum height regulator.

- Operator protection device.

The main structural elements of a drum machine are listed here. Depending on the specific model of the device and the specifics of its purpose, the configuration may vary slightly.

Main device models

Drum-type machines can be purchased ready-to-use. There are several of the most popular and widespread brands for the production of these devices. It makes sense to present their individual models.

JET Company. The American company specializes in the production of modern machines of various types, including drum machines. Its product line includes several grinding machines with a cylindrical working wheel.

- JET DDS-225. This machine is one of the most powerful devices of this type in the manufacturer’s line. It is used both in home workshops and in small industries. Characteristic– double grinding drum. The cost of this machine is appropriate - from 150,000 rubles.

- JET 10-20 PLUS. Compact grinding device that allows you to process up to 50 centimeters of surfaces. Perfect for small home workshops. The cost does not exceed 25 thousand rubles.

- JET 16-23 PLUS. It is considered one of the most versatile machines of its type. It is used for processing building materials, kitchen appliances and even musical instruments. Most often, such a machine is used in small furniture production enterprises.

Corvette 57. Machine made in China, which is quite different high quality assembly and wide functionality. The machine is designed for grinding flat surfaces wooden blanks and turning parts to required sizes. The machine has a fairly affordable price - 24 thousand rubles.

In addition to these machines, there are also good options from German manufacturers. It is worth noting that depending on the price, German companies They also offer corresponding sets of capabilities for their devices. Minimum amount, for which you can purchase a grinding machine in the basic configuration - 15-16 thousand rubles.

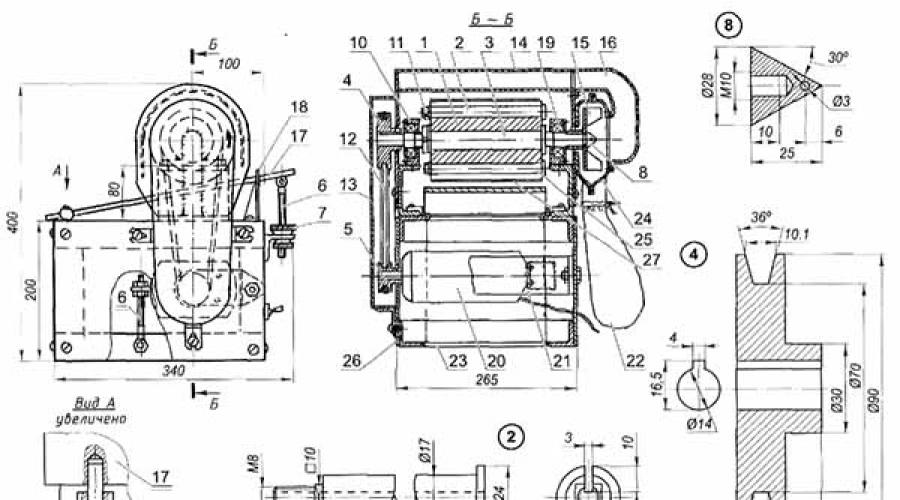

Video: step by step production drum grinding machine.

How to make a grinding machine with your own hands?

If it is not possible to shell out a fairly round sum for decent option drum sander, then you should try to make it yourself. For a person who is well versed in mechanics, this is not too much difficult task. In addition, this way you will be able to save significant financial resources.

In order to assemble a drum sanding machine at home, you need to acquire the following parts:

- Grinding drum. Cylindrical shape the device can be created on the basis of “garbage” building materials. For these purposes, even pieces of wooden blocks are often used, which are evenly attached to a special metal axis using glue. In this case, special attention should be paid to the tight fit of these bars to each other. The drum can also be made on the basis of a polyvinyl chloride pipe with a diameter of up to 10 cm, which is placed on an iron rod with a diameter of 1.5-2 cm. It should be slightly shorter in length than the rod itself. We insert special plugs with holes for the rod into the ends of the pipe. We recommend securing the plugs with screws. We thread and secure the rod. We wrap a thick layer of rubber onto the pipe, onto which the sandpaper will be attached.

- Engine. It is best to use a working engine from an old one washing machine(like pulleys, belts, etc.). The optimal motor power should be from 200 to 300 W. It is desirable that the motor is also asynchronous and single-phase. RPM level – 2000-3000.

- Frame. The design should be simple and convenient. It is best for the machine body to consist of two side panels, a spacer and the table itself. Special attention You should pay attention to the strength and rigidity of the work table, which should not be deformed when the workpiece being processed is pressed onto the drum. The desktop must consist of a base and a moving part.

Once the main parts of the machine have been assembled separately, you can begin final assembly the entire apparatus. First of all, you should attach the motor to the bottom of the machine body in place of the pre-drilled holes. Sanding drum installed in the upper part of the housing and attached to two bearings, which are located on the side walls of the housing.

Then we attach special pulleys to the drum and motor and tighten the drive belt. After all the necessary preparations with electrical wires, we fasten the desktop with special bolts that will hold it on required level. Experts strongly recommend installing a protective casing on the machine.

It is worth noting that self-creation A drum sander also does not come without certain costs. First of all, this concerns your time, but the machine will cost you less than a factory one only if you have a working motor. Without an engine and certain skills, it is almost impossible to create a cheap analogue of a branded machine.

The vast majority of grinding operations in everyday life are carried out manually or using a drill. This is understandable. Buying expensive specialized equipment for use at home, where grinding operations, as a rule, vary greatly in type, is not always advisable.

Exist various devices for manual and mechanized grinding. All of them can be divided into two main types.

- Tools that directly perform the processing of the part are hand-held devices, which include sanding blocks (pads, whetstones) and grinding attachments for a drill or grinder, which are all kinds of support plates and drums.

- Devices that ensure the required position of the grinding tool relative to the part - guides, supporting surfaces, etc.

TO separate species This includes devices for dust removal, which, due to the abundance and harmfulness of grinding dust, should also not be neglected.

Hand sanding tools

When working manually, to ensure the necessary processing parameters, a variety of grinding devices are used.To the simplest hand-held devices include sanding pads, which may be called: sanding blocks, sanding bars, etc. Depending on their shape, they can be used to process both flat and shaped surfaces.

The sanding block consists of three main elements - a body with a working surface on which the sandpaper is stretched, a clamping mechanism that secures the sandpaper to the sandpaper, and a handle to which force is applied during sanding. The latter may be absent as an independent element; in this case, its role is played by the body. Clamping mechanism can also be replaced with other elements that perform its function, for example, or Velcro.

There are many types of branded pads available, differing from each other in shape and method of attaching the sandpaper. The housing is most often made of plastic, working surface which is covered soft material, helping to smooth out irregularities.

The simplest pads for grinding are easy to make yourself. Wood is best suited for this. It is advisable to paste over or cover the working surface with a soft material, such as felt.

Most simple design The bar consists of two pieces of board or chipboard, tightened together with screws - so that the skin covers the bottom piece, and its ends are clamped between the parts.

If you put in a little more effort, you can make a more functional block in which the skin will be clamped with a wing nut, which is much faster and more convenient than using screws for this.

For processing large surfaces, if for some reason a power tool is not suitable, it is best to make your own grinding “plane”. His possible design shown in the figure below. It is so simple that it does not need explanation. The dimensions of the device are determined by specific operating conditions - the parameters of the plane being processed and the physical data of the worker.

Sanding plane

For grinding edges located at an angle of exactly 90° to the adjacent surface, a device that allows you to ensure the required right angle will be useful. It is shown schematically; the specific implementation can be anything.

Device for sanding edges (end view): 1 - base, 2 - handle, 3 - side stop, 4 - stiffener, 5 - sanding paper, 6 - strip of felt.

One of the main tasks when making homemade bars is reliable fastening skins for them. Except mechanical clamps(using screws, nuts, etc.) in homemade sanding blocks, you can use other methods of attaching sandpaper.

You can simply nail it at the ends with small nails. The method is easy to implement, but inconvenient if you have to change the skin frequently.

An acceptable way to secure sandpaper is by gluing it. Adhesives that make it relatively easy to separate the skin from the base when replacing it are suitable for this.

Sometimes they use wedges to secure the skins. Cuts are made in the block, into which the edges of the skin are tucked and wooden wedges are driven. Cuts and wedges can be of different sizes.

Accessories for drills and grinders

Manual grinding requires a lot of effort and time. For significant volumes grinding work It is advisable to use a power tool - a drill or grinder, in particular. To turn the latter into a grinding tool, they must be equipped with a suitable grinding attachment - a support plate or drum.

Sanding pads. These attachments are a disk made of plastic or rubber to which a circle of sandpaper is attached. Plastic plates have a soft or not very soft layer between the base and Velcro, for better adhesion of the skin to the surface being treated. Drill plates have a shank in the form of a rod; for angle grinders, they have a thread for screwing them onto the output shaft of the angle grinder. The grinding attachment for the grinder can be converted into a drill attachment by screwing an adapter with a shank into it.

But due to the rigidity of the grinder attachment, strictly vertical arrangement drill relative to the plane when grinding is practically impossible. When using a rigid plate (it’s easier to work with a flexible one), any slight tilt leads to the edge of the plate biting into the workpiece and the drill trying to escape from your hands, which leads to an increase in tilt and a deeper bite into the edge of the circle. This leads to clearly visible depressions on the treated surface. Therefore, only grinding attachments that can compensate for the tilt of the drill are suitable for the drill: either rubber, or with a thick soft layer between the plastic base and Velcro, or with a movable pin attachment.

Hard plates are only suitable for use with a fixed drill, such as the one shown below.

If you can’t find a suitable drill attachment for grinding on sale, and you have a hard attachment, then you can make a thick soft layer between the plastic base and the Velcro with your own hands.

The Velcro is carefully cut off with a stationery (construction) knife, and a large round sponge for washing the body is glued as a soft layer. When the sponge is compressed during the grinding process, the symmetry may be broken (the Velcro with the sandpaper moves in one direction), but at drill speeds (3000 rpm) this is not critical; it will not work with an angle grinder.

Combined attachments for grinding on a drill are produced, in which the shank can be in two positions relative to the working surface - be rigidly locked with it or have a degree of freedom (unlocked). In the latter case, the working surface of the tool has the ability to adapt to the inclination of the drill, due to which the processing is obtained without the formation of indentations. But the price of such devices is close to the price of orbital sanders.

To make the shank movable, a cone nut is twisted (in the photo below with a similar device, it is twisted to the chuck).

The skin is attached to the plates using Velcro. This fastening method requires special sandpaper, on which a reciprocal layer of Velcro is applied.

Sanding drums. Drill sanding drums are a cylinder with a shank; sanding paper in the form of an endless belt (a strip of sandpaper glued together at the ends) or a strip of sandpaper with free ends is attached to the cylinder. Unlike the support plate, in which the working surface is located perpendicular to the axis of rotation, in drums it is located parallel to it.

To ensure that the skin sits tightly on the drums, the latter have various mechanisms tension. According to the principle of operation, there are two of them - increasing the outer diameter of the drum (used for an endless belt) and tensioning the abrasive belt using a special mechanism (used for open belts). An increase in the diameter of the drums is being implemented different ways- by pumping them up (for pneumatic models), by compressing them in the axial direction (for drums with rubber elements). The tension of an open tape can be done in different ways. This is most often done by using a rotating screw that tightens the ends of the sandpaper. Below are several reel options with different types skin tension.

A drum for endless sanding belts can be made by placing rubber pads between wooden discs. When the axial bolt is tightened, the rubber is crushed, expanding radially and securely fixing the sanding paper placed on the drum.

Grinding attachments using a drill. Grinding parts with a plate or drum while holding a drill in your hands is not as easy as it might seem to someone who has never done it himself. In many cases more high-quality surface can be achieved by securing the instrument motionless. Especially when processing small parts that are easy to manipulate by holding them in your hands. There are grinding attachments that allow you to secure a power tool, making it completely or partially immobile.

You can use proprietary drill guides, which are intended primarily for drilling, but can also be successfully used for grinding - mainly with a drum. You can work with them in two ways. By fixing the drill in the guide motionless and moving the workpiece relative to the tool (photo A below), or by moving the guides together with the drill relative to the workpiece, pressing the supporting surface of the guides against the latter (photo B below). In both cases, the tilt of the drum is eliminated, which ensures surface treatment at the desired angle.

You can independently make a simple sanding device from two boards, which allows you to ensure the angle of the sanded edge in relation to main surface exactly 90°.

Removing dust. When sanding wood, a lot of dust is generated, which not only creates inconvenience, but is also harmful to health if inhaled. Dust must be dealt with. The easiest way to do this is to suck it out with a vacuum cleaner, placing the hose closer to the sanding area.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

For the manufacture of a grinding drum (in common parlance, “bosses”).

A block of 90x60x60 mm is used as a workpiece

diagonals are drawn on it and the center for the faceplate is marked so that it is convenient to center

an 8.5 mm hole is drilled in the center in order to subsequently screw a capercaillie into it (a large turnkey screw. It is advisable to drill it using a drilling machine, since in this case the alignment of the hole in the axis of the workpiece is very important

We attach the faceplate to the workpiece

grind the workpiece to lathe

We grind it periodically, checking its cylindricity with a caliper (that is, the diameter of the part should be the same in any place).

As a result, we get this cylindrical part

into which the “cracker” is screwed. Using a caliper with a depth gauge (you can just use a nail of a suitable length) the depth of the hole is measured, and the “cracker” is shortened to fit it using a grinder.

Through long self-tapping screw, coat the walls of the hole with polymer glue. We twist the “cracker” into it and cut off the cap with a grinder, holding it in a vice.

Then we make a small conductor. We take a piece of plywood and a calibrated block.

Having attached the boss blank, we mark the position of the block.

Then, having previously drilled into the edge (a pair of holes with a thin drill for self-tapping screws), we screw the block onto the plywood base. First, one self-tapping screw, then, aligning the block with the square, the second.

Using another self-tapping screw, we attach our under-drum to the resulting frame.

Using a circular saw, we select a groove in the drum along the stop (we adjust the offset of the disk so that it does not catch the axle in any case). We do this in several passes, obtaining approximately a 10 mm niche exactly in the center of the drum.

Then the car “anti-noise” comes into play. Mark 95 mm on it and cut off a long piece with a stationery knife.

We wrap our drum with it without going into the groove.

The excess that overlaps the groove is cut off with the same stationery knife along a smooth block.

A plank like this is cut out of hard wood (it is slightly narrowed at the bottom). A couple of holes are drilled in it.

The drum is wrapped in sandpaper. You must try to ensure that it fits into the groove symmetrically.

The sandpaper is stretched and pressed with this kind of wedge. You can hit it a little with a mallet through a block to immerse it below the grinding surface.

The wedge, plunging into the groove, tightens the sandpaper. All that remains is a pair of self-tapping screws (the holes for them were drilled in advance), we fix the wedge in place.

Ready. the drum is mounted either in drilling machine, you can clamp it into a vertically mounted drill (there are a lot of options).  It performs its function "perfectly"

It performs its function "perfectly"

Homemade grinding drum on a drill.

When sanding wooden products It is necessary to process not only straight planes, but also curly edges. A sanding drum is an indispensable tool for this. You can buy such a drum or make it yourself. For work, use a hand drill or a stationary drilling machine.

Curly edges of joinery parts can be processed in another way, manual router with a copy cutter according to the template. This gives a gain in time and quality, but only when processing a large number of parts. If you have single products, then there is no point in making them for each template. Moreover, to make a template, you will again need a sanding drum; without it you cannot make an accurate template.

As I already said, you can buy a grinding drum, they are sold different diameters and quality. But working with such a device simply by holding the drill suspended is not very comfortable, and most importantly, it is impossible to obtain accurate and high-quality processing.

One of the adaptation options would be to make a small table for a drill. The drill itself is attached to the work table vertically. More from hand drill can be done .

The table can be assembled from scraps of MDF, thick plywood or chipboard (laminate). All parts are attached to each other with self-tapping screws. The product is assembled in the form of a box with a table top. A hole is drilled in the top cover to the diameter of the drum. The bottom edge of the sandpaper should be below the tabletop line. You can also make it from plywood.

You can easily attach the legs to this frame, then you will have a separate standing tool. In the version you see in the photo, the box is attached to the desktop.

Almost any drill will do, but for serious work it is advisable to use a more powerful one. The drill is attached to the desktop frame using clamps. I already wrote on the site about horizontal installation drills, in the article.

Homemade sanding drum.

You can not only buy a drum, but also make it yourself. It's actually not that difficult if you have a wood lathe. You can also process the drum on a drilling machine, but it will be more difficult.

I use a metal drum for work, the skin is attached to it metal pin with a slot. The drum is installed on a stationary milling machine. You can turn such a part at special equipment, see article. But such a part can be made using simpler means.

To assemble the device we need vertical axis, a bolt or pin with a diameter of 10/12 mm is suitable for this. and length 100-150 mm. . On this axis we place pieces of plywood, previously cut with a jigsaw with a small margin in diameter. In the center of all parts we drill a hole corresponding to the diameter of the bolt. Lubricate the plywood fragments with glue and tighten the nut. Then it is advisable to turn the drum on a wood lathe, this will result in a more accurate and even surface.

Another option for assembling a homemade drum. Only two plywood parts are placed on the axle, upper and lower, and a piece of hard foam is clamped between them. Simple packaging foam will not work, it is too loose. The product in the photo is assembled exactly like this.

How to glue the skin.

Stores sell sandpaper with self-adhesive inner surface, this is the most convenient option. If there is no such skin, then you can glue a regular one. You need to glue it with an overlap, but you can’t join it on the abrasive, you’ll end up with a bump that will hit the part. For correct sticker You need to mark the overlap at the lower end of the sandpaper, soak it in a solvent and clean off the abrasive.

Don't forget that sandpaper is consumables, and sooner or later it will have to be torn off and a new one glued on. To make this process easier, without damaging the drum itself, you must first stick thick paper and already put the skin on it. I tried attaching the skin with a stapler, but it didn't work very well. The staples wear out quickly and also scratch the workpiece. Still the best option, this is the use of self-adhesive skin.

The diameter of the drum can be different, it depends on what parts you are going to process. But just remember, the smaller the diameter, the faster the skin will wear through. Most suitable option diameter from 60 mm. up to 100 mm. . Most often, the drum is used for processing parts up to 50 mm thick. , so the working height of the drum can be 70-120 mm. .

Every DIYer who to some extent works with wood probably has a separate device dedicated to sanding, be it on sanding machine or manually, but sometimes it happens that the part being processed has round shape Or it needs to be sanded inside. In this article I will tell you how the author made sanding drums with his own hands, with the help of which Finishing work will not be a burden.

To make this homemade product we will need the following materials:

*Wooden planks, their thickness may vary, for an average drum it is 15-20mm.

*Steel rod or ready-made bolt.

*Washers and nuts.

*Sandpaper.

*Carpentry and PVA glue.

*Crowns or so-called ring drills.

*Erasers for banknotes.

First step. In order to start work, we need to decide on the dimensions of the drum, after the dimensions are selected, we select a crown for that same size. Using a bit installed in a drilling machine, we drill out 5 round blanks; you can change this number depending on the desired height and the thickness of the blanks themselves.

Second step. Armed with PVA glue, glue the adjacent surfaces of the finished round blanks and clamp them to each other using a vice, maintain gluing accuracy so that one bar does not extend beyond the edges of the other. At this stage, the strength properties of PVA glue will be sufficient.

Wait for him completely dry, then fasten the bolt in the middle in drilled hole and tighten on both sides with nuts, having previously placed a washer on both sides.

Third step. This stage requires a grinding machine or sandpaper; the first method will be easier and faster. Clamp in cordless drill bolt with a finished drum and grind it with coarse sandpaper, gradually moving to a finer grain size, thereby giving smooth surface to our drum.

Fourth step. The final stage of assembly includes cleaning the drums from dust that was formed in the previous stage, as well as covering the surface with wood glue for gluing the grinding element. Using ordinary scissors, cut out a piece of sandpaper pre-marked to size and glue it to the adhesive surface of the drum, joint to joint, and so that it does not protrude while the glue dries, secure it temporarily with rubber bands for banknotes.

After that. Once the glue has completely dried, you can use the homemade product for its intended purpose, try the drums in action.

Thank you all and good luck with your DIY inventions and gadgets.