Section 1.5 mm what is the load. Technical characteristics of the VVG cable. What is wire cross-section and how to determine it

Read also

This material will focus on how NOT to choose a cable cross-section.

I often see that the required cable cross-section is chosen based on the number of kilowatts that can be “loaded” on this cable.

Usually the argument goes like this: “A cable with a cross-section of 2.5 mm2 can withstand a current of 27 amperes (sometimes 29 amperes), so we set the machine to 25 A.”

And in practice, sometimes you come across socket groups protected by a 25A circuit breaker, and lighting - by a 16A circuit breaker.

This approach when choosing circuit breakers leads to overheating, melting and damage to the insulation, and as a result - to a short circuit and fire.

Let's refer to table 1.3.4. from PUE.

The permissible long-term current for copper wires laid hidden is 25 A. Everything seems to be correct, is it so?

If you install the machine at 25A, which is called “head-on”, and from we remember that the thermal protection of the machine can operate when the rated current is exceeded by 13%, which in our case will be 25x1.13 = 28.25A. And the response time will be more than an hour.

And if there is an overload of 45%, the thermal release will operate in less than 1 hour, i.e. 25Ax1.45=36.25 A. But it can work in an hour.

It is clear that at such currents the cable will simply burn out.

If you install a 16A machine on the lighting, the result will be similar, you can calculate it yourself.

In addition, sockets are produced for a maximum current of 16A, and switches - 10A. If you install overrated circuit breakers on sockets and lighting, this will lead to their melting, destruction of contacts and potentially a fire. I think you've seen melted sockets - the result of connecting a very powerful load that the sockets are not designed to handle.

REMEMBER! In our apartments and houses, socket groups are made with a 2.5 mm2 cable with the installation of a 16A circuit breaker, lighting groups are made with a 1.5 mm2 cable with the installation of a 10A circuit breaker. A lower denomination is possible, but a larger one is not!

A variation of this approach: the machine knocks out, especially for the kitchen outlet group where powerful appliances are connected. In reserve, a 32A and even 40A machine is installed. And this is with wiring done with a 2.5 mm2 cable!!! The consequences are obvious and discussed above.

There are also situations when a cable with a larger cross-section (for example, 4 mm2) is laid up to the branch box, and then the lines are separated at 2.5 mm2 each and a machine is installed at 25A or 32A.

The circuit breaker current must be selected based on the weakest point in the line, in our example, this is a 2.5 mm2 cable. Therefore, such a group still needs to be protected by a 16A machine.

If you set the machine to 25A, then when a load close to 25A is connected to one of the sockets, the cable to the branch box will burn out, but for a cable with a cross-section of 4 mm2 from the branch box to the circuit breaker, this will be normal mode.

All these points must be taken into account when calculating the cable cross-section.

Watch detailed video:

Calculation of cable cross-section. Errors

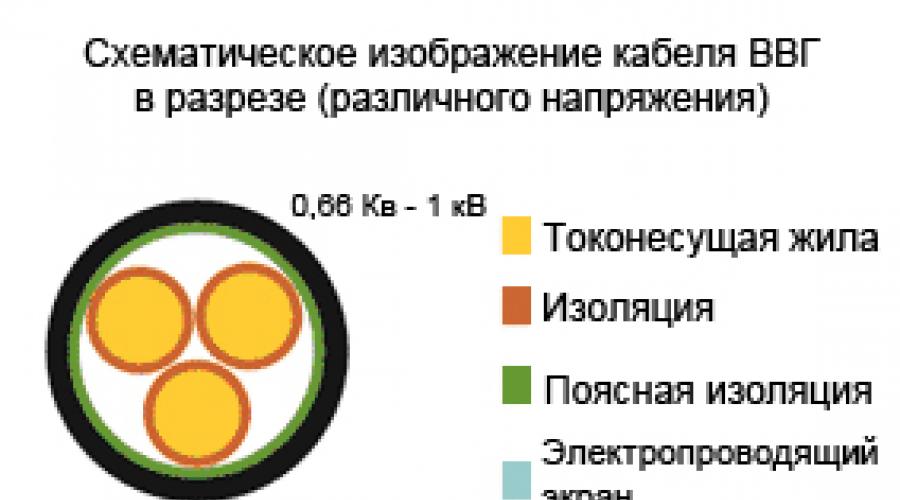

Technical characteristics can vary significantly depending on what type of wire it is, what marking it has, how many cores it contains, and other parameters. However, it is possible to identify a number of key characteristics that, to one degree or another, apply to each of the power cables of this type.

The VVG cable is manufactured according to OKP code 352100.

Description and technical documentation

The dimensions of the cable largely depend on the number and type of cores that it contains. The minimum diameter of the core gives 1.5 mm 2 in its cross-sectional area. The maximum cross-sectional area of the core is 240 mm 2 in a single-core cable, 95 mm 2 in a two- or four-core cable and up to 50 mm 2 in a five-core cable. The cross-sections of neutral conductors (in the case of a smaller cross-section than the main ones) and grounding conductors, depending on the cross-section of the main conductors up to 50 mm 2, are given below.

Larger options are much less common. The most common among VVG cables with conductors of unequal cross-sections are cables with three main and one neutral conductor (the so-called “three plus”).

The outer diameter of the electrical wire is directly proportional to the number of cores and the nominal cross-section. With an area of 1.5 mm2, the cable diameter starts from a size of 5 mm and can reach up to 53.5 mm in four-core versions. In the same way, the weight of one kilogram of cable increases, starting from 39 kg/km and reaching several tons, so the weight of the wire must be taken into account when designing its installation.

The outer diameter of the electrical wire is directly proportional to the number of cores and the nominal cross-section. With an area of 1.5 mm2, the cable diameter starts from a size of 5 mm and can reach up to 53.5 mm in four-core versions. In the same way, the weight of one kilogram of cable increases, starting from 39 kg/km and reaching several tons, so the weight of the wire must be taken into account when designing its installation.

The nominal and minimum values of the radial insulation thickness for VVG cables with a cross-section of up to 50 mm 2 for an operating voltage of 0.66 kV and 1 kV are given in the table.

The thickness of the protective sheath of the VVG electrical wire depends on the twisting diameter of the insulated conductors under the sheath. The nominal and minimum values of the shell thickness are given in the table.

Continuous-permissible current VVG

The continuous-permissible current that a given cable supports varies depending on the number of cores, their cross-section, and also on where the electrical wire runs - in the ground or in the air. The minimum current is 19 A, in any case, it is better to check the specifications of the specific cable that you are purchasing. Permissible load currents for electrical wires with a cross-section of up to 50 mm 2 laid in air are indicated in the table.

| Nominal cross-section of cores, mm2 | Permissible load current, A | ||

| With two main cores | With three main cores | With four main cores | |

| 1,5 | 24 | 21 | 19 |

| 2,5 | 33 | 28 | 26 |

| 4 | 44 | 37 | 34 |

| 6 | 56 | 49 | 45 |

| 10 | 76 | 66 | 61 |

| 16 | 101 | 87 | 81 |

| 25 | 134 | 115 | 107 |

| 35 | 166 | 141 | 131 |

| 50 | 208 | 177 | 165 |

The rated current, in this case, can be 0.66 or 1 kilowatt, and its frequency is 50 hertz. The power with a minimum cable cross-sectional area reaches 3.5 kW. As for resistance, it varies depending on the cross-sectional area of the cores. When it is equal to 1.5 mm2, then the resistance is 12 MOhm/km, when it is less than 4 mm2 - 10 MOhm/km, when it is 5 mm2 - 9 MOhm/km, and from 10 to 240 mm2 this figure is 7 MOhm/km . It is customary to take into account the resistance at a temperature of +20 degrees Celsius.

Technical characteristics of VVG power cable

The electrical resistance of the current-carrying cable cores up to 50 mm 2 at direct current should be no more than that indicated in the table.

The electrical resistance of the insulation per 1 km of length at a temperature of 20 0 C is at least 7 - 12 MOhm, depending on the cross-section of the conductors.

Finished cables must withstand alternating voltage testing at a frequency of 50 Hz for 10 minutes. The voltage is applied between the cores and is 3 kV for cables with a rated voltage of 0.66 kV and 3.5 kV for cables with a rated voltage of 1 kV.

Power cable storage conditions

Wires are stored under canopies or in closed rooms. It is also allowed to store cables on drums in open areas in a sheathed form. At the same time, the shelf life changes: in closed premises the shelf life will be 10 years, under a canopy in the open air - 5 years, on drums in open areas - only 2 years.

Wires are stored under canopies or in closed rooms. It is also allowed to store cables on drums in open areas in a sheathed form. At the same time, the shelf life changes: in closed premises the shelf life will be 10 years, under a canopy in the open air - 5 years, on drums in open areas - only 2 years.

Weight and dimensions: main parameters

Approximate external dimensions and weights of individual cables with a cross-section of up to 50 mm 2 for packaging and transportation purposes are given in the table below. Depending on the manufacturer, these figures may vary with a 10% deviation.

| Cable cross-section | External size value for packaging and transportation purposes, mm | Weight value for packaging and transportation purposes, kg/km |

|---|---|---|

| Flat cables | (a x b) | |

| 2x1.5 | 5 x 7.5 | 70 |

| 2x2.5 | 5.5 x 8 | 90 |

| 2x4 | 6 x 9.5 | 140 |

| 2x6 | 7 x 10.5 | 180 |

| 3x1.5 | 5 x 9.5 | 95 |

| 3x2.5 | 5.5 x 11 | 135 |

| 3x4 | 6 x 13 | 200 |

| Stranded cables | Diameter | |

| 3x1.5 | 8 | 90 |

| 3x2.5 | 9,5 | 135 |

| 3x4 | 11 | 200 |

| 3x6 | 12 | 260 |

| 3x10 | 14,5 | 410 |

| 3x16 | 17 | 590 |

| 3x25 | 20,5 | 810 |

| 3x35 | 23 | 1300 |

| 3x50 | 27 | 1700 |

| 3x4+1x2.5 | 12 | 230 |

| 3x6+1x4 | 14 | 310 |

| 3x10+1x6 | 16 | 480 |

| 3x16+1x10 | 19 | 650 |

| 4x1.5 | 8,5 | 110 |

| 4x2.5 | 10 | 170 |

| 4x4 | 12 | 240 |

| 4x6 | 13 | 320 |

| 4x10 | 16 | 510 |

| 4x16 | 19 | 750 |

| 4x25 | 23 | 1150 |

| 4x35 | 26 | 1550 |

| 4x50 | 31 | 2200 |

| 5x1.5 | 9,5 | 135 |

| 5x2.5 | 11 | 205 |

| 5x4 | 13 | 300 |

| 5x6 | 14 | 405 |

| 5x10 | 17,5 | 630 |

| 5x16 | 21 | 950 |

| 5x25 | 26 | 1450 |

| 5x35 | 29 | 1900 |

| 5x50 | 35 | 2700 |

Temperature and operating conditions

Particular attention should be paid to the temperature conditions for which these cables are adapted. The temperature at which the electrical cable is laid should not be lower than -15 C. Operation is allowed in wider temperature ranges, which start at -50 C and reach +50 C. However, if unusual situations arise, the temperature can rise to + 70 C without any problems, and in an emergency the cable can withstand short-term heating up to +80 C. Humidity should not exceed 98%. The minimum bending radius is at least 7.5 times the cable diameter. Service life - 30 years.

Electric-220.ru

When choosing cable and wire products, first of all, you need to pay attention to the material used in manufacturing, as well as the cross-section of a particular conductor. To make the right choice, it is necessary to calculate the cross-section of the wire according to the load. With this calculation, the wires and cables will ensure, in the future, reliable and safe operation of all electrical wiring. Wire cross-section parametersThe main criteria by which the cross-section is determined are the metal of the current-carrying conductors, the expected voltage, the total power and the value of the current load. If the wires are not properly sized for the load, they will continually heat up and eventually burn out. It is also not worth choosing wires with a cross-section larger than necessary, as this will lead to significant costs and additional difficulties during installation. Practical definition of sectionThe cross-section is also determined in relation to their further use. So, in a standard apartment, copper cable is used for sockets, the cross-section of which is 2.5 mm2. For lighting, conductors with a smaller cross-section can be used - only 1.5 mm2. But for electrical devices with high power, from 4 to 6 mm2 are used. This option is most popular when calculating the cross-section of the wire according to the load. Indeed, this is a very simple method; you just need to know that a 1.5 mm2 copper wire can withstand a power load of over 4 kilowatts and a current of 19 amperes. 2.5 mm - respectively, withstands about 6 kilowatts and 27 amperes. 4 and 6 mm freely transfer power of 8 and 10 kilowatts. If connected correctly, these wires are sufficient for the normal operation of all electrical wiring. Thus, it is possible to create even a certain small reserve in case of connecting additional consumers. When calculating, operating voltage plays an important role. The power of electrical appliances may be the same, however, the current load arriving at the cores of the cables supplying power may be different. So wires designed to operate at 220 volts will carry a higher load than wires designed for 380 volts.

|

el-cab.ru

How can you find out the cable cross-section by the diameter of the core?

Each of us has gone through renovations at least once in our lives. During the repair process, it is necessary to install and replace electrical wiring, because it becomes unusable after prolonged use. Unfortunately, on the market today you can find a lot of low-quality cable and wire products. Due to various methods of reducing the price of a product, its quality suffers. Manufacturers underestimate the insulation thickness and cable cross-section during the production process.

One of the ways to reduce the cost is to use low-quality materials for the manufacture of the conductive core. Some manufacturers add cheap additives when making wires. Due to this, the conductivity of the wire is reduced, and, therefore, the quality of the product leaves much to be desired.

In addition, the declared characteristics of the wires (cables) are reduced due to the reduced cross-section. All the manufacturer’s tricks lead to more and more low-quality products appearing on sale. Therefore, you should give preference to those cable products that have quality confirmation in the form of certificates.

The price of a high-quality cable is the only, and perhaps the main, drawback that negates a lot of the advantages of this product. A copper cable and conductor product, which is produced in accordance with GOST, has the declared cross-section of the conductor, the composition and thickness of the sheath and copper core required by GOST, is produced in compliance with all technologies, and will cost more than those products that were produced in artisanal conditions. As a rule, in the latter option you can find a lot of shortcomings: a reduced cross-section by 1.3-1.5 times, imparting color to the veins due to steel with the addition of copper.

Buyers rely on price when choosing a product. The main focus is on finding a low price. And many of us can’t even name the manufacturer, let alone the quality of the cable. It is more important to us that we found a cable with the required marking, for example, VVGp3x1.5, but we are not interested in the quality of the product.

Therefore, in order to avoid getting into trouble, in this article we will consider several ways to determine the cross-section of a cable based on the diameter of the core. In today's tutorial I will show how such calculations can be made both with and without the help of high-precision measuring instruments.

We calculate the wire cross-section by diameter

In the last decade, the quality of cable products has decreased especially noticeably. The resistance that suffers the most is the wire cross-section. On the forum I often noticed that people were dissatisfied with such changes. And this will continue until the manufacturers begin to react to this brazen theft.

A similar incident happened to me. I bought two meters of wires marked VVGng 3x2.5 sq. millimeter. The first thing that caught my eye was the very thin diameter. I thought that, most likely, they slipped me a wire of a smaller cross-section. I was even more surprised when I saw the inscription on the insulation VVGng 3x2.5 sq. mm.

An experienced electrician who deals with wires every day can easily determine by eye the cross-section of a cable or wire. But sometimes even a professional has difficulty doing this, not to mention beginners. Calculating the wire cross-section by diameter is an important task that needs to be solved right in the store. Believe me, this minimal check will be cheaper and easier than repairing fire damage that may occur due to a short circuit.

You probably ask why it is necessary to calculate the cable cross-section by diameter? After all, in a store, any salesperson will tell you which wire you should buy for your load, especially since there are inscriptions on the wires indicating the number of cores and cross-section. What's so complicated about it? I calculated the load, bought a wire, and did the electrical installation. However, not all so simple.

Sometimes there is no tag on the coil of wire or cable at all indicating the technical characteristics. Most likely, this is the situation that I described above - the non-compliance of conductor and cable products with the requirements of modern GOSTs.

In order to never become a victim of deception, I strongly recommend that you learn to determine the cross-section of the wire by diameter yourself.

Undersized wire cross-section - what is the danger?

So, let's look at the dangers that await us when using low-quality wires in everyday life. It is clear that the current characteristics of current-carrying conductors decrease in direct proportion to the decrease in their cross-section. The load capacity of the wire decreases due to the reduced cross-section. According to the standards, the current that the wire can pass through is calculated. It will not collapse if less current passes through it.

The resistance between the cores decreases if the insulation layer is thinner than required. Then, in an emergency situation, when the supply voltage increases, a breakdown may occur in the insulation. If, along with this, the core itself has a reduced cross-section, that is, it cannot pass the current that, according to standards, it should pass, the thin insulation begins to gradually melt. All these factors will inevitably lead to a short circuit and then to a fire. A fire occurs from sparks that appear during a short circuit.

Let me give you an example: a three-core copper wire (for example, with a cross-section of 2.5 sq. mm.), according to regulatory documentation, can pass 27A through itself for a long time, usually 25A is considered.

But the wires that come into my hands, produced in accordance with the specifications, actually have a cross-section of 1.8 square meters. mm. up to 2 sq. mm. (this is with the stated 2.5 sq. mm.). Based on the regulatory documentation, the wire has a cross-section of 2 square meters. mm. can carry a current of 19A for a long time.

Therefore, if such a situation happens that along the wire you have chosen, which supposedly has a cross-section of 2.5 square meters. mm., the current designed for such a cross-section will flow, the wire will overheat. And with prolonged exposure, the insulation will melt, followed by a short circuit. Contact connections (for example, in a socket) will collapse very quickly if such overloads occur regularly. Therefore, the socket itself, as well as the plugs of household appliances, may also be subject to melting.

Now imagine the consequences of all this! It’s especially disappointing when a beautiful renovation has been made, new appliances have been installed, for example, an air conditioner, an electric oven, a hob, a washing machine, an electric kettle, a microwave oven. And so you put the buns in the oven to bake, started the washing machine, turned on the kettle, and even the air conditioner, since it became hot. These switched on devices are enough to cause smoke to come out of junction boxes and sockets.

Then you will hear a pop, which is accompanied by a flash. And after that the electricity will disappear. It will still end well if you have circuit breakers. What if they are of low quality? Then you won't get away with a bang and a flash. A fire will start, accompanied by sparks from the wiring burning in the wall. The wiring will burn in any case, even if it is tightly walled under the tile.

The picture I described makes it clear how responsibly you need to choose wires. After all, you will use them in your home. This is what it means to follow not GOSTs, but TUs.

Formula for wire cross-section by diameter

So, I would like to summarize all of the above. If there are those among you who did not read the article before this paragraph, but simply skipped over, I repeat. Cable and conductor products often lack information about the standards according to which they were manufactured. Ask the seller, according to GOST or TU. Sellers sometimes cannot answer this question themselves.

We can safely say that wires manufactured according to specifications in 99.9% of cases have not only a reduced cross-section of current-carrying conductors (by 10-30%), but also a lower permissible current. Also in such products you will find thin external and internal insulation.

If you have gone through all the stores and have not found any wires produced in accordance with GOST, then take a wire with a +1 reserve (if it is produced in accordance with the technical specifications). For example, you need a 1.5 sq.m. wire. mm., then you should take 2.5 sq. mm. (released by TU). In practice, its cross-section will be equal to 1.7-2.1 square meters. mm.

Thanks to the cross-sectional reserve, a current reserve will be provided, that is, the load may be slightly exceeded. So much the better for you. If you need a wire with a cross-section of 2.5 sq. mm., then take one with a cross section of 4 sq. mm., since its actual cross-section will be equal to 3 sq. mm.

So let's get back to our question. The conductor has a cross section in the form of a circle. Surely, you remember that in geometry the area of a circle is calculated using a specific formula. It is enough to substitute the resulting diameter value into this formula. After making all the calculations, you will get the wire cross-section.

- π is a constant in mathematics equal to 3.14;

- R - radius of the circle;

- D is the diameter of the circle.

This is the formula for calculating the cross-section of a wire by diameter, which for some reason many are afraid of. For example, you measured the core diameter and got a value of 1.8 mm. Substituting this number into the formula, we get the following expression: (3.14/4)*(1.8)2=2.54 sq. mm. This means that the wire whose core diameter you measured has a cross-section of 2.5 sq. mm.

Calculation of a monolithic core

When you go to the store to buy wire, take a micrometer or caliper with you. The latter is more common as a wire cross-section measuring device.

I’ll say right away that in this article I will calculate the cable cross-section by diameter for the VVGng 3*2.5 mm2 cable from three different manufacturers. That is, the essence of all the work will be divided into three stages (this is only for monolithic wire). Let's see what happens.

To find out the cross-section of a wire (cable) consisting of one wire (solid core), you need to take a regular caliper or micrometer and measure the diameter of the wire core (without insulation).

To do this, you need to first clear a small section of the wire being measured from insulation, and then start measuring the current-carrying core. In other words, we take one core and remove the insulation, and then measure the diameter of this core with a caliper.

Example No. 1. Cable VVG-Png 3*2.5 mm2 (manufacturer unknown). The general impression was that the cross-section immediately seemed too small, which is why I took it for an experiment.

We remove the insulation and measure with a caliper. I got a core diameter of 1.5 mm. (not enough though).

Now we return to our formula described above and substitute the obtained data into it.

It turns out that the actual cross-section is 1.76 mm2 instead of the declared 2.5 mm2.

Example No. 2. Cable VVG-Png 3*2.5 mm2 (manufacturer "Azovkabel"). The general impression is that the cross-section seems to be normal, the insulation is also good, it looks dense and they didn’t skimp on materials.

We do everything in the same way, remove the insulation, measure, we get the following numbers: diameter - 1.7 mm.

We substitute into our formula for calculating the cross-section by diameter, we get:

The actual cross-section is 2.26 mm2.

Example No. 3. So the last example left is cable VVG-Png 3*2.5 mm2, manufacturer unknown. The general impression is that the cross-section also seemed underestimated, the insulation is generally removed with bare hands (no strength at all).

This time the core diameter was 1.6 mm.

The actual cross-section is 2.00 mm2.

How to choose the right cable for connecting a consumer? This question is not as simple as it might seem at first glance. When choosing, you need to take into account many nuances, know the length of the line and the total power of the devices connected to it, and only after that, using formula for calculating cable cross-section , choose the most suitable option. In this article we will consider in detail all the nuances associated with the selection and type of cables.

A cable is a wire covered with insulation that serves to transmit electricity from a source to a consumer. Today's market is ready to offer customers many types of similar wires: aluminum, copper, single-core, multi-core, single- and double-insulated, with a cross-section from 0.35 mm2 to 25 mm2 or more. But most often, to connect household consumers, cables with a thickness of 0.5 to 6 square meters are used - this is quite enough to power any equipment.

Classic cable for wiring in an apartment

Why is it necessary to select insulated conductors, and not buy the first one you come across? The thing is that the thickness of the conductor determines the current strength it can withstand. Eg,the permissible current for copper wires 1 mm thick is up to 8 Amperes, aluminum - up to 6 Amps.

Why not just buy the thickest wire possible? Because the thicker it is, the more expensive it is. In addition, a thick cable needs to be hidden somewhere, a groove must be cut for it in the ceiling and walls, and holes must be made in the partitions. In a word, there is no point in overpaying, because you won’t be driving a KAMAZ to buy bread.

If you choose a wire with a smaller diameter, it simply cannot withstand the current passing through it and will begin to heat up. This leads to insulation melting, short circuit and fire. Therefore, you should never rush when choosing a high-quality cable for connecting any devices - first think about what exactly will work on the new line, and then choose the thickness and type of cable.

How to calculate the power of devices

First, let's look at the option selection of cable cross-section according to power devices connected to it. How to count correctly?

Think about which devices will be powered by a particular cable. If you pull it into the hall, then a TV, computer, vacuum cleaner, audio system, set-top box, hair dryer, floor lamp, aquarium lighting or other household appliances can simultaneously operate from the outlet in the room. Add up the power of all these devices and multiply the resulting value by 0.8 to get the real figure. Indeed, it is unlikely that you will use them all at the same time, so 0.8 is a reduction factor that will allow you to adequately estimate the total load.

If you are counting for the kitchen, then add up the power of an electric kettle, electric oven and hob, microwave, dishwasher, toaster, bread maker and other available/planned appliances. The kitchen usually consumes the most energy, so it should have either two cables with separate circuit breakers, or one powerful one.

So, to calculate the total power of all devices, you need to use the formula Ptotal = (P1+P2+…+Pn)*0.8, where P is the power of a specific consumer connected to the outlet.

Copper wires are better for wiring and can withstand greater loads

Copper wires are better for wiring and can withstand greater loads Choosing thickness

Once you have determined the power, you can select the cable thickness. Below we provide table of wire cross-sections by power and current for classic copper wire, since aluminum is no longer used to create wiring today.

| Cable cross-section, mm | For 220 V | For 380 V | ||

| current, A | power, kWt | current, A | power, kWt | |

| 1,5 | until 17 | 4 | 16 | 10 |

| 2,5 | 26 | 5,5 | 25 | 16 |

| 4 | 37 | 8,2 | 30 | 20 |

| 6 | 45 | 10 | 40 | 25 |

| 10 | 68 | 15 | 50 | 32 |

| 16 | 85 | 18 | 75 | 48 |

Attention:When choosing, keep in mind that most Russian manufacturers save on material, and a 4 mm2 cable may actually end up being 2.5 mm2. Practice shows that such “savings” can reach 40%, so be sure to either measure the cable diameter yourself or purchase it with a reserve.

Now let's look at an example calculating wire cross-section based on power consumption . So, we have an abstract kitchen, the power of the appliances is 6 kW. We multiply this figure 6*0.8=4.8 kW. The apartment uses one phase, 220 volts. The closest value (you can only take it as a plus) is 5.5 kW, that is, a cable 2.5 square meters thick. Just in case, we have a reserve of 0.7 kW, which “smoothes out” the savings for manufacturers.

It should also be borne in mind that if the wire is working at its limit, it will heat up quickly. Due to heating to 60-80 degrees, the maximum current is reduced by 10-20 percent, which leads to overload and short circuit. Therefore, for critical sections of the chain, an increased coefficient should be used, multiplying the value not by 0.8, but by 1.2-1.3.

Correct calculation of cable thickness is the key to its long service life

Correct calculation of cable thickness is the key to its long service life Most often, copper structures with a thickness of 1.5 squares are used for laying lighting systems, for sockets - 2.5 squares, for powerful consumers - 4 or 6 squares (machines are installed at 16, 25, 35 and 45A, respectively). But this use is only suitable for standard apartments or houses that do not have powerful consumers. If you have an electric boiler, boiler, oven or other appliances that consume more than 4 kW, then you need to calculate the cables for each specific case, and not use general recommendations.

The aboveuses boundary values, so if you get calculated numbers overlapping with encyclopedic ones, then try to take a cable with a reserve. For example, if our kitchen had a power of 7 kW, then 7 * 0.8 = 5.6 kW, which is greater than the value of 5.5 for a 2.5 square cable. Take a cable of 4 squares with a reserve or divide the kitchen into two zones by connecting two 2.5 mm2 cables.

What to do with the length

If you are counting cables in an apartment or small house, then you don’t have to make any adjustments to the cable length at all - it’s unlikely that you will have branches 100 meters or more in length. But if you are laying wiring in a large multi-story cottage or shopping center, then you must take into account possible losses along the length. Usually they are 5 percent, but it is more correct to calculate them using a table and formulas.

So, the load moment is calculated as the product of the length of your wire and the total power consumption. That is, the length of your cable is calculated as the product of the cable length in meters and the power in kilowatts.

In the table below we see how losses depend on the cross-section of the conductor. For example, a cable with a thickness of 2.5 mm2 with a load of up to 3 kW and a length of 30 meters has a loss of 30x3 = 90, that is, 3%. If the loss level exceeds 5%, then it is recommended to choose a thicker cable - there is no need to skimp on your safety.

| U, % | Load moment, kW*m | |||||

| 1,5 | 2,5 | 4 | 6 | 10 | 16 | |

| 1 | 18 | 30 | 48 | 72 | 120 | 192 |

| 2 | 36 | 60 | 96 | 144 | 240 | 384 |

| 3 | 54 | 90 | 144 | 216 | 360 | 575 |

| 4 | 72 | 120 | 192 | 288 | 480 | 768 |

| 5 | 90 | 150 | 240 | 360 | 600 | 960 |

This table of loads for the cable cross-section valid for a single-phase network. Three-phase is characterized by an average increase in load size of six times. The value increases three times due to distribution over three phases, and two times due to the neutral conductor. If the load on the phases is uneven (there are strong distortions), then losses and loads increase greatly.

Correct connection of machines with copper cable

Correct connection of machines with copper cable You should also consider which consumers will be connected to your wire. If you plan to connect halogen low-voltage lamps, then try to place them as close to the transformers as possible. Why? Because if the voltage drops by 3 volts at 220 volts, we simply won’t notice, and if the voltage drops by the same 3 volts at 12 volts, the lamps simply won’t light up.

If you spend selection of wire cross-section for current for an aluminum cable, keep in mind that the resistance of the material is 1.7 times higher than that of copper. Accordingly, losses in them will be greater by the same 1.7 times.

Types of cables

Now let's look at what kind of cables you can choose to create electrical wiring on site. Remember that according to standards, wires can only be laid in a closed way in boxes or pipes. In this case, the cables are laid freely - they can even be run along the surface, which is often practiced in wooden and log houses.

You already know how to calculate cable cross-sections by power, Therefore, let's consider the principle of cable selection. For installation in residential premises, the classic VVG is best suited (it is better to choose the one marked NG - non-flammable). NYM is well suited for connecting to a panel or a powerful consumer. Let's look at the types of cables in more detail.

VVG is a cable with copper conductors protected by a polyvinyl chloride “jacket”. The wires are covered with an additional plastic sheath, which prevents possible breakdowns and breaks. This cable can be used even in damp areas, it bends well and protects the surface from fire. For wiring, a flat wire is best suited, in which the wires are located in the same plane - it takes up minimal space.

NYM is a product containing several copper strands coated with non-ferrous metal filled with non-flammable rubber. On top, the cores are packed in polyvinyl chloride insulation (sometimes several layers are used). In most cases, it has non-flammable properties and does not emit harmful gases at critical temperatures. It has excellent flexibility - it is very easy to lay it in corners, display it on various surfaces, etc.The main thing is to do it right selection of wire cross-section according to current, taking it with a small margin.

PUNP is a classic flat-shaped installation wire that is used to connect various consumers. Very often used to create inexpensive wiring in apartments and houses. Has two/three cores covered with polyvinyl chloride. It has a flat shape.

There are many other cables - armored, reinforced, for laying in damp rooms and areas with a high risk of explosion. But the ones listed above are used most often.

Now you know how calculate the wire cross-section for the load and which cables to choose to create a complete electrical wiring. We remind you - always make a power reserve of 20-30 percent to avoid troubles.

When electric current flows through a cable, some energy is lost. It goes to heating the conductors due to their resistance, with a decrease in which the amount of transmitted power and the permissible current for copper wires increase. The most acceptable conductor in practice is copper, which has low electrical resistance, suits consumers in terms of cost and is available in a wide range.

The next metal with good conductivity is aluminum. It is cheaper than copper, but more brittle and deforms at the joints. Previously, domestic domestic networks were laid with aluminum wires. They were hidden under the plaster and the electrical wiring was forgotten for a long time. Electricity was mainly used for lighting, and the wires easily withstood the load.

With the development of technology, many electrical appliances appeared that became indispensable in everyday life and required more electricity. Power consumption increased and the wiring could no longer cope with it. Now it has become unthinkable to supply electricity to an apartment or house without calculating the electrical wiring according to power. Wires and cables are chosen so that there are no unnecessary costs, and they fully cope with all the loads in the house.

Cause of heating of electrical wiring

The passing electric current causes the conductor to heat up. At elevated temperatures, the metal quickly oxidizes, and the insulation begins to melt at a temperature of 65 0 C. The more often it heats up, the faster it fails. For this reason, wires are selected according to the permissible current at which they do not overheat.

Wire cross-sectional area

The shape of the wire is made in the form of a circle, square, rectangle or triangle. Apartment wiring has a predominantly round cross-section. The copper busbar is usually installed in a distribution cabinet and can be rectangular or square.

The cross-sectional areas of the cores are determined by the main dimensions measured with a caliper:

- circle - S = πd 2 / 4;

- square - S = a 2 ;

- rectangle - S = a * b;

- triangle - πr 2 / 3.

The following notations are used in the calculations:

- r - radius;

- d - diameter;

- b, a - width and length of the section;

- π = 3.14.

Calculation of power in wiring

The power released in the cable cores during its operation is determined by the formula: P = I n 2 Rn,

where I n - load current, A; R - resistance, Ohm; n - number of conductors.

The formula is suitable for calculating one load. If several of them are connected to the cable, the amount of heat is calculated separately for each energy consumer, and then the results are summed up.

The permissible current for copper stranded wires is also calculated through the cross section. To do this, you need to fluff the end, measure the diameter of one of the wires, calculate the area and multiply by their number in the wire.

for different operating conditions

It is convenient to measure wire cross-sections in square millimeters. Roughly assessing the permissible current, mm2 of copper wire passes 10 A through itself without overheating.

In a cable, adjacent wires heat each other, so for it it is necessary to choose the thickness of the core according to the tables or with an adjustment. In addition, sizes are taken with a small margin in the direction of increase, and then selected from the standard range.

Wiring can be open or hidden. In the first option, it is laid outside along surfaces, in pipes or in cable ducts. The hidden one passes under the plaster, in channels or pipes inside structures. Here the working conditions are more stringent, since in enclosed spaces without air access the cable heats up more.

For different operating conditions, correction factors are introduced by which the calculated continuous permissible current should be multiplied depending on the following factors:

- single-core cable in a pipe more than 10 m long: I = I n x 0.94;

- three in one pipe: I = I n x 0.9;

- laying in water with a protective coating type Cl: I = I n x 1.3;

- four-core cable of equal cross-section: I = I n x 0.93.

Example

With a load of 5 kW and a voltage of 220 V, the current through the copper wire will be 5 x 1000 / 220 = 22.7 A. Its cross-section will be 22.7 / 10 = 2.27 mm 2. This size will provide the permissible heating current for copper wires. Therefore, here you should take a small margin of 15%. As a result, the cross-section will be S = 2.27 + 2.27 x 15 / 100 = 2.61 mm 2. Now to this size you should select a standard wire cross-section, which will be 3 mm.

Heat dissipation during cable operation

A conductor cannot heat up from passing current indefinitely. At the same time, it gives off heat to the environment, the amount of which depends on the temperature difference between them. At a certain moment, an equilibrium state occurs and the temperature of the conductor becomes constant.

Important! With correctly selected wiring, heating losses are reduced. It should be remembered that you also have to pay for irrational ones (when the wires overheat). On the one hand, a fee is charged for excess consumption on the meter, and on the other hand, for replacing the cable.

Selecting wire cross-section

For a typical apartment, electricians do not particularly think about which wiring sections to choose. In most cases the following are used:

- input cable - 4-6 mm 2;

- sockets - 2.5 mm 2;

- main lighting - 1.5 mm 2.

Such a system can cope with the load quite well if there are no powerful electrical appliances, which sometimes need to be supplied with separate power.

Great for finding the permissible current of a copper wire, a table from a reference book. It also provides calculation data when using aluminum.

The basis for choosing wiring is the power of the consumers. If the total power in the lines from the main input is P = 7.4 kW at U = 220 V, the permissible current for copper wires will be 34 A according to the table, and the cross-section will be 6 mm 2 (closed installation).

Short-term operating modes

The maximum permissible short-term current for copper wires under operating modes with a cycle duration of up to 10 minutes and operating periods between them of no more than 4 minutes is reduced to a long-term operating mode if the cross-section does not exceed 6 mm 2. For a cross section above 6 mm 2: I add = I n ∙0.875/√Т p.v. ,

where T p.v is the ratio of the duration of the working period to the duration of the cycle.

Power off in case of overloads and short circuits is determined by the technical characteristics of the circuit breakers used. Below is a diagram of a small apartment control panel. Power from the meter is supplied to the 63 A DP MCB, which protects the wiring to the 10 A, 16 A and 20 A individual line breakers.

Important! The operation thresholds of the circuit breakers must be less than the maximum permissible wiring current and higher than the load current. In this case, each line will be reliably protected.

How to choose the right input wire for an apartment?

The value of the rated current on the input cable to the apartment depends on how many consumers are connected. The table shows the necessary devices and their power.

The current strength based on known power can be found from the expression:

I = P∙K and /(U∙cos φ), where K and = 0.75 is the simultaneity coefficient.

For most electrical appliances that are active loads, the power factor cos φ = 1. For fluorescent lamps, electric motors of a vacuum cleaner, washing machine, etc., it is less than 1 and must be taken into account.

The long-term permissible current for the devices given in the table will be I = 41 - 81 A. The value turns out to be quite impressive. When purchasing a new electrical appliance, you should always think carefully about whether your apartment network will support it. According to the table for open wiring, the cross-section of the input wire will be 4-10 mm 2. Here you also need to take into account how the apartment load will affect the general building load. It is possible that the housing office will not allow connecting so many electrical appliances to the entrance riser, where a busbar (copper or aluminum) passes through the distribution cabinets under each phase and neutral. They simply won’t be able to handle the electricity meter, which is usually installed in a switchboard on the landing. In addition, the fee for excess consumption of electricity will increase to impressive sizes due to multiplying factors.

If wiring is done for a private house, then the power of the outlet wire from the main network must be taken into account. The commonly used SIP-4 with a cross section of 12 mm 2 may not be enough for a heavy load.

Selection of wiring for individual consumer groups

Once a cable has been selected for connecting to the network and an input circuit breaker that protects against overloads and short circuits has been selected for it, it is necessary to select wires for each group of consumers.

The load is divided into lighting and power. The most powerful consumer in the house is the kitchen, where an electric stove, washing machine, dishwasher, refrigerator, microwave and other electrical appliances are installed.

For each socket, 2.5 mm 2 wires are selected. According to the table for hidden wiring, it will pass 21 A. The supply diagram is usually radial - from Therefore, 4 mm 2 wires should approach the box. If the sockets are connected by a cable, it should be taken into account that a cross-section of 2.5 mm 2 corresponds to a power of 4.6 kW. Therefore, the total load on them should not exceed it. There is one drawback here: if one outlet fails, the rest may also become inoperative.

It is advisable to connect a separate wire with a circuit breaker to a boiler, electric stove, air conditioner and other powerful loads. There is also a separate entrance to the bathroom with a machine and an RCD.

A 1.5 mm 2 wire is used for lighting. Now many people use basic and additional lighting, where a larger cross-section may be required.

How to calculate three-phase wiring?

The calculation of what is permissible is affected by the type of network. If the power consumption is the same, the permissible current loads on the cable cores will be less than for single-phase.

To power a three-core cable at U = 380 V, the following formula is used:

I = P/(√3∙U∙cos φ).

The power factor can be found in the characteristics of electrical appliances or it is equal to 1 if the load is active. The maximum permissible current for copper wires, as well as aluminum wires at three-phase voltage, is indicated in the tables.

Conclusion

To prevent overheating of conductors during prolonged loading, the cross-section of the conductors, on which the permissible current for copper wires depends, should be correctly calculated. If the conductor power is insufficient, the cable will fail prematurely.