Homemade wood sanding machine with your own hands. Homemade belt and disc sanding machines Homemade wood sanding machines with your own hands

Wood is a rather capricious material. Therefore, to give wooden structures an aesthetic shape, prepare their surface for further processing by sanding the wooden surface. Window frames, vents, doors, and moldings are subjected to grinding.

Making the surface smooth is done using grinding machines. They allow you to level the surface of the workpiece and eliminate all roughness ranging in size from 0.02 to 1.25 microns.

Types of grinding machines

Wood sanding machines are divided into the following types:

- design features;

- the nature of the tasks being solved;

- processing accuracy;

- permissible geometric dimensions of processed parts;

- power of installed engines;

- manufacturer ratings;

- cost with a set of attached equipment.

Modern manufacturers present three types of design of such machines: disk, belt, cylinder. Each of these species has its own highly specific subspecies. For example, they are available in the following versions:

- narrow-belt (allow grinding of wooden structures with complex geometric shapes);

- units equipped with a fixed table (capable of processing only wooden workpieces with flat rectangular surfaces);

- machines equipped with a freely moving table (they are used for grinding large-sized wooden structures - doors, panels, door slopes).

The nature of the tasks to be solved determines the classes of this equipment. The main classes (sometimes called models) are:

- belt grinding machines;

- vibrating tools such as delta grinders;

- disc-type grinding machines (orbital and eccentric);

- specialized angle grinders;

- combined type grinding systems.

Despite such a variety of ready-made factory tools, home craftsmen prefer to develop and assemble a wood grinding machine with their own hands to carry out simple grinding operations.

Principle of operation

The operation of a belt-type grinding machine is based on the principle of counter-movement of an abrasive belt located on two rotating drums and the processed wooden part. Both drums are located at a certain distance from the desktop surface. To ensure the required grinding quality, the following parameters must be correctly taken into account:

- size (number) of abrasive applied to the tape;

- the tension force of the belt on the rotating drums;

- the speed of its movement;

- the force of pressure on a moving wooden part.

Incorrect selection of these parameters significantly degrades the quality of grinding. For example, if the pressure on the workpiece is insufficient or the rotation speed of the drive drum is too high, some places on the workpiece will remain unprocessed, that is, they will not be polished. On the contrary, if there is excessive pressure from the belt on the surface and insufficient speed of the belt, burns and changes in the color of the wood are possible. Therefore, when assembling a grinding machine with your own hands, it is necessary to provide for the possibility of adjusting these parameters.

Design features of the machine

The design of the machine depends on the selected principle of processing the part. If the principle of belt grinding is chosen, then the machine includes the following elements: motor, two shafts (drive and driven), housing, (bed), working surface, abrasive belt.

In so-called disc-type machines, rotating discs with fixed abrasive wheels are used on a frame with a motor as a grinding device.

Application areas of the machine

Each of the manufactured machines performs a predetermined list of technological operations.

The drum-type system produces high-quality sanding of flat wood pieces. Processing of chipboard, OSB or MDF, including those covered with veneer, is allowed.

Processing of large, long, non-standard wooden wood products (for example, molded structures) is carried out using profile grinding equipment. Finished workpieces are fed to the grinding unit via a conveyor chain.

To grind the surface of wooden products that have a complex geometric shape (decorative frames, artistic products), belt sanding machines equipped with a freely moving table are used.

DIY grinding machine

The desire to make wooden structures yourself is always faced with the need to equip your workshop with sawing and grinding machines. Modern manufacturers produce them in a wide range. Such machines have good performance and high reliability. The most important and quite significant drawback is their high cost.

Therefore, many craftsmen try to assemble a grinding machine from existing components. The most experienced ones try not to limit themselves to a machine capable of performing only one function; they immediately try to assemble a universal machine capable of performing several functions: cutting wooden blanks, grinding followed by polishing, removing old coatings and preparing surfaces for renovation.

This is possible because the basis of any home-made machine is a frame on which are mounted: an engine, drive and driven drums, a set of additional equipment (saw, cutter, grinding wheels, and so on).

Calculation of grinding machine power

Before you begin assembling the machine, you must calculate its power. To correctly make such an assessment, it is necessary to determine the following parameters:

- power consumed by the electric motor;

- rotation speed of the selected engine;

- the area of contact of the entire surface of the part with the moving abrasive belt;

- grinding ratio;

- coefficient of friction between the back side of the belt used and the surface of the drums.

Based on data on these parameters, the power of the future unit can be determined.

How to make a belt sander

The basis of the machine is a powerful frame that can withstand the weight of all equipment and perform the function of damping the resulting vibration. The frame of the bed is best fastened by welding. A plate is attached to the top. Chipboard with a thickness of at least 22 mm is chosen as such a plate.

An electric motor is mounted on the frame. The engine power must be no lower than the calculated one. The number of revolutions must be at least 1500 rpm. A gearbox is attached to the anchor to transmit rotation to the drive drum. The required diameter directly depends on the engine speed. It determines the speed of the belt at the moment of friction against the surface of the part.

The following relationships can be given as an example. When the belt speed is 20 m/sec, the diameter should be 20 cm. To prevent the slipping effect, rubber covers are placed on the drums. It is more expedient to make the platform for installing the drums at a slight slope. This will create smooth contact of the tape with the surface being treated while moving.

If you plan to process parts made of different types of wood, it is advisable to provide the possibility of changing the rotation speed of the drum. The above technique shows that it is quite easy to assemble a grinding machine with your own hands.

What to make the bed out of

The frame to which all other elements of the machine are attached is a powerful bed. It must have a large margin of safety and have good weight and size characteristics. It is made from sheet steel more than 5 mm thick.

The most acceptable dimensions of a homemade frame are considered to be the following dimensions: 500x180x20 millimeters. For a bed of this size, the optimal dimensions of the working platform are 180x160x10 millimeters.

For the convenience of further work, it is necessary to mark the work site. Three holes are made for its fastening. Then it is secured to the frame with three bolts.

Selecting and installing a motor for the machine

Calculations and operating experience of this type of units show that the engine must have a power of at least 2.5 kW. The shaft rotation speed must be 1500 rpm or more. The speed of movement of the abrasive belt largely depends on the engine rotation speed. This seriously affects the quality of processing. In turn, the speed of the belt affects the diameter of the drums.

As a finished device, you can use the motor that is installed on washing machines. You can also select an engine from other household units, for example, a powerful pump or other device suitable in terms of power and speed.

Master and slave drums

The drive drum is firmly fixed to the electric motor pulley. The driven drum is fixed on a separate axis. To ensure its free rotation, bearings are attached between the shaft and the drum.

DIY sanding belt

Abrasive belts for such machines have a fabric base. Calico or a fabric of similar density is used as a base. Abrasive chips are applied to the surface of the material on one side using special glue. Depending on the grain size of this crumb, it is divided into large, medium, small and zero.

In principle, such a tape can be made independently. Select the required fabric and apply abrasive powder of the required fraction to it. By applying glue to the surface of the material and sprinkling it with this powder, you can obtain a sanding belt of the required size. However, it should be recognized that modern industry produces such a wide range of such consumables that it is better to use the factory one.

Sanding machine from a hand sander

Very often, to carry out simple grinding operations, homemade wood grinding machines are made using ready-made grinding machines.

A mounting system for a grinding machine is being manufactured. It is mounted on a pre-prepared frame. Grinding wheels intended for processing wooden workpieces are attached to its shaft. Instead of such a machine, you can use an ordinary electric drill. This design allows sanding of simple wooden parts of limited size.

You may also be interested in the following articles:

How to assemble a sharpening machine with your own hands DIY wood slotting machine

The cost of a factory-made grinding machine is quite high. If you can't afford a power tool, you can try making one yourself. On such a machine it will be possible not only to grind wooden workpieces, but also to sharpen the tool. There are three types of grinding machines you can assemble with your own hands: belt, disk and drum.

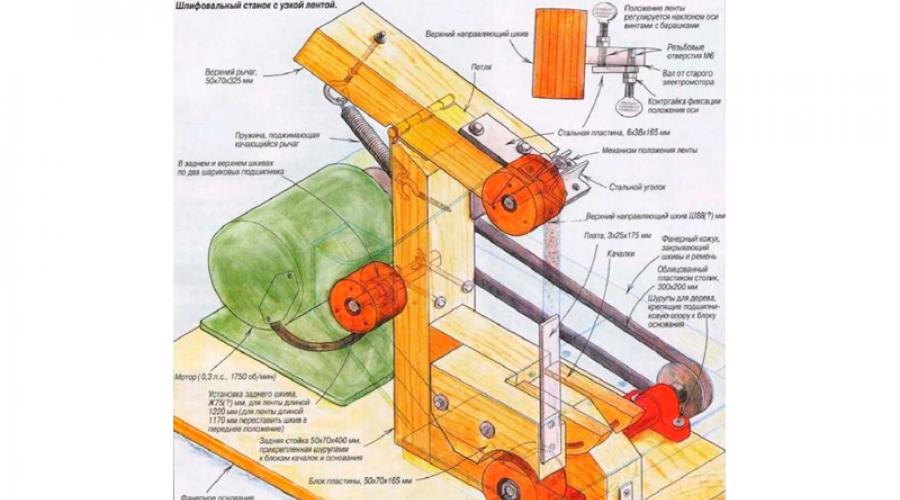

To assemble a belt-type grinding machine, you will need an electric motor, a durable frame and rollers on which the belt will rotate. Be sure to have a drawing or detailed diagram on hand indicating all components and dimensions. We offer an example of a diagram of a machine with a wooden bed in the photo.

The following photo shows the finished design of the machine. In this embodiment, the arrangement of the three working shafts is designed so that the moving belt forms a vertical grinding plane. A belt drive is used as a drive.

The machine design can use four rollers. One of them is the leading one and is mounted directly on the electric motor shaft. The photo shows an example of such a design. Installing four rollers allows you to get two grinding planes: horizontal and vertical.

The wooden frame smoothes out the vibration of a running electric motor, however, wood is short-lived. It is optimal to cut a workpiece measuring 50x18 cm from steel 2 cm thick. One edge of the frame is made perfectly flat in order to attach a platform for the electric motor to it. For the next part, you will need steel 1 cm thick. The area is cut out 18x16 cm in size, and then secured to the frame with a bolted connection.

A large electric motor power is not needed for such a machine. A motor from an old washing machine will do. If greater productivity of the grinding machine is required, then it is advisable to find an electric motor with a shaft speed of 1500 rpm with a power of 2.5 to 3 kW. High-quality grinding can be achieved by moving the sanding belt at a speed of 20 m/s. To achieve such parameters, working drums with a diameter of 20 cm are used. If you make the rollers thinner, you will have to reduce the speed of the motor shaft using a gearbox, which is extremely inconvenient.

The drive drum can be mounted on the motor shaft. If this option is not suitable, a separate unit is made. The drive shaft with bearings is fixed to the frame. A belt drive pulley is installed at this end, and a drive drum is installed at the other end. Then a pulley is also mounted on the electric motor shaft and a V-belt is put on. The driven rollers rotate freely on bearings.

The belt drive pulleys will have to be turned on a lathe, and the rollers can be made from square pieces of chipboard measuring 20x20 cm. The plates are stacked on top of each other until a total thickness of 24 cm is obtained. A hole is drilled in the center of the square plates, a threaded pin is inserted and the plates are pulled together tightly on both sides with nuts. The square blank is machined to form a drum with a diameter of 20 cm.

When grooving the roller, a thickening is provided in its central part. In relation to the edges of the drum, the difference should be 3 mm. Due to the thickening, the belt will not move off the rollers. The surface of the wooden drum is covered with rubber. An old bicycle tube will do. Rubber will prevent the belt from slipping on rollers.

To make a sanding belt, cloth-based sandpaper is suitable. You can cut a solid strip of the required length, the edges of which are glued end to end. If there is no long strip of sandpaper, cut a strip of durable fabric and sew it into a ring. The sandpaper is cut into rectangles and then glued onto a strip of fabric. When making a sanding belt, it is important to choose high-quality glue so that the sandpaper does not peel off.

Manufacturing of disc grinding machine

The disk machine is considered the easiest to manufacture. The principle of its operation is reminiscent of ordinary electric emery. Assembly of the grinding machine is presented in instructions with step-by-step photos:

- The power plant of the machine is a three-phase electric motor. This choice is not accidental, since changing the phase when connecting allows you to organize reverse. The motor can be connected to a 220 V network via capacitors.

- The working disk is cut out of plywood 1.5 cm thick. Two identical blanks are glued together. The result is a disk 3 cm thick. A hole is drilled strictly in the center, the diameter of which is equal to the thickness of the electric motor shaft.

- To assemble the frame, it is better to use an edged board, and the guides and work table are cut out of 1.5 cm thick plywood. Wood is better suited for making the machine than metal. Wood dampens engine vibrations.

- The working disc can be used for grinding and even sharpening. It is important to choose the right abrasive materials. They must be Velcro and fit for their purpose. If you need to grind a product made of stone or granite, stick a “Turtle” diamond wheel onto the working disc.

- To sand a wooden workpiece, glue a circle of sandpaper to the working disk.

- There are similar Velcro circles for metal. This disc can be used to sharpen knives, axes and other tools.

When designing a disc sander, it is important to consider safety. The rotating working disk is covered with a protective arch on top. An adjustable heel is provided on the work table, which serves as a stop for the workpiece.

The tabletop of the machine should not be varnished or painted. Over time, an unevenly worn coating will create difficulties in moving the workpiece being processed.

Making a drum machine for sanding boards

To make a drum machine, a frame is assembled. You will need hardwood timber. An electric motor with a pulley is attached to the bottom of the frame. A drum with bearings will come from a used conveyor. The sandpaper is cut into strips and wound tightly end-to-end on the work roller. Along the edges of the drum, the paper is secured with clamps.

The work roller is attached to the frame from above. The machine table top will be located under it. A pulley is mounted on the drum shaft and a belt drive with a motor is created. The tabletop is made adjustable with screws so that you can sand boards of different thicknesses. To avoid vibrations of the machine, it is advisable to fix the legs of the bed to the floor.

If you try and make an effort, then any unit considered will work no worse than a factory-made grinding machine.

Belt Sanding Machine Design

Wood is widely used to make all kinds of products and parts. In order to process a wooden piece properly, various equipment is used. Careful, high-precision processing of wood is carried out on belt sanding machines, which, as a working tool, have an abrasive belt .

The design of the grinding unit includes:

- An abrasive belt that can be positioned horizontally or vertically. It is installed on the frame and placed between the rotating drums.

- Lead and slave drums. The rotation of the drive drum occurs due to an electric motor, which transmits torque through a belt drive. The rotation speed of the leading element, and therefore the speed of movement of the belt, can be adjusted by specially established surface treatment modes.

- The equipment table can be wooden or metal. More complex workpieces can be sharpened on a metal base.

- The electric motor should have a power of about 2.8 kW and be capable of providing the belt with a normal speed of 20 meters per second.

- A special installation hood must be installed so that dust generated during operation can be removed during the technological process.

Length of the machine and its working tools depends on the length of the products. which will be processed on it. It is much more convenient to work with workpieces that are shorter than the working surface.

What are grinding machines used for?

As a rule, the equipment is used for finishing mechanical processing of products at the final stages of production. Belt sanders can work with both wood and metal.

Woodworking equipment is capable of finally level the surfaces. remove roughness and irregularities in the form of elevations or depressions, remove burrs, grind curves, do internal grinding, achieve even and smooth surfaces of the product.

Metal cutting machines work with non-ferrous metals in the form of flat, round and rectangular blanks and with plain and alloy steel. They are capable of efficiently grinding large-diameter pipes and round timber in a short time.

In addition, belt sanders intended:

- for sanding products before the paint coating procedure;

- for processing bar and panel blanks, their side edges and ends;

- for processing flat surfaces;

- for grinding curved surfaces.

Manufacturing instructions

Having studied the design of the equipment, you should decide what its main elements will be made of.

What to make the bed out of?

It is best to make a desktop from thick iron. The ideal dimensions of the canvas are 500x180x20 mm. However, the larger the dimensions of the bed, the more options for various parts that can be processed on it.

It is best to make a desktop from thick iron. The ideal dimensions of the canvas are 500x180x20 mm. However, the larger the dimensions of the bed, the more options for various parts that can be processed on it.

Large work surface will be much more convenient and functional than a small bed. To make it you will need:

- Cut one side of the canvas prepared for the table using a metal milling machine.

- Make markings.

- Drill three holes in the end of the cut piece.

- Using three bolts, secure the working platform to the frame.

Selecting and installing a motor for the machine

The motor for the unit can be a motor from a washing machine. If this is not available, then you can select a motor whose rated power will be up to 3 kW, and the operating intensity will be about 1500 rpm. The power unit for the grinding machine should be tightly and securely fixed to the frame.

Master and slave drums

You can make such elements for a grinding machine yourself from a material such as chipboard. To do this you need:

- Cut out blanks measuring 200x200 mm from a sheet of chipboard.

- Assemble a package 240 mm thick from the resulting blanks.

- Fold everything and grind it to the optimal diameter of 200 mm.

- Attach the drive drum to the motor shaft. It will set the tape in motion.

- The driven drum is secured around the machine axis on bearings. In this case, there must be a special bevel on the side of the drum. This will help ensure the tape touches the work surface softly.

When making drums, it is worth considering that diameter of their central part should be a couple of millimeters larger than the outer diameter. This is necessary to ensure stable operation of the equipment, since the flexible tape will be located in the middle of the drum.

DIY sanding belt

You can use several sanding strips as a sanding belt. They will need to be cut into pieces 200 mm long and glued together. The ideal base for the canvas would be a tarpaulin.

You can use several sanding strips as a sanding belt. They will need to be cut into pieces 200 mm long and glued together. The ideal base for the canvas would be a tarpaulin.

Having assembled the structure from all the selected elements, you can safely begin processing the wood.

Sanding machine from a hand sander

Taking a hand-held grinder as a basis, the remaining parts of the equipment can be made with your own hands from chipboard, pine and birch bars. The U-shaped stop is glued with PVA glue, the remaining elements of the unit are connected with screws.

The base of the machine can be connected by loops two pieces of chipboard. For greater strength, the hinges are secured with M6 bolts.

The grinding machine is installed to the base using bars, which are pre-fitted to the shape of the body and glued with pieces of rubber on top.

At the front, the sander is secured with suitable sized furniture confirmers. With their help, the grinding plane can be set in the desired position.

The machine is attached to the base from the back with a block and two screws. To ensure that the thrust pad and the grinding plane are in line, pieces of soft rubber can be glued under the body.

In the horizontal part of the U-shaped stop, you can make a groove for moving a small carriage, which may be useful I use an electric planer for sharpening knives .

After securing and adjusting the grinder, the machine can be used.

Having studied the options for making a belt sanding machine with your own hands and strictly following the instructions, you can acquire multifunctional equipment. Such equipment will be capable of not only grinding wood products, but also sharpening any cutting tools.

Homemade wood sanding machine with your own hands

During the manufacture of wooden structures, it is imperative to clean their surfaces. Manual labor will take a long time and will not be productive. Factory grinding centers are expensive. Therefore, in some cases it is more advisable to make the machine yourself.

Drum machine design

Factory grinding machine

Manufacturing should begin with studying the design features of this type of equipment. The drum-type grinding machine is designed for processing wooden surfaces, leveling them and removing burrs.

The device belongs to a type of wood surface grinder that performs a calibration function. There are many models and types of equipment. But the main task before making a unit with your own hands is choosing the optimal design. The best option is to familiarize yourself in detail with factory analogues and draw up a manufacturing scheme based on the data obtained.

Structurally, the machine must consist of the following components:

- frame. The main parts of the equipment are attached to it;

- power unit. Most often, an asynchronous electric motor is installed for this purpose;

- grinding drum. It is important to choose the correct diameter and method for removing chips. With your own hands you can make a base on which the sanding tape is installed. Or order a cylindrical head with a cutting edge from a professional turner. It all depends on the type of work;

- device for changing the frequency of the motor shaft;

- Desktop. The workpiece will be placed on it. When making a machine with your own hands, experts recommend making this component from fiberglass;

Additionally, drum grinding equipment can be equipped with a mechanism for removing dust and chips from the processing area. It is also recommended to make a working table with a variable height relative to the snare drum. This will allow you to process part of the end of the wooden workpiece.

If grinding the outer or inner surface of the board is necessary, the drum should be positioned horizontally. At the same time, it is possible to adjust it in height.

Types of drum grinding machines

Drum machine for wood with horizontal processing

The next step is to select the design of the wood cutting machine. The main parameter is the shape of the wooden blank and the degree of its processing. Homemade drum-type equipment is designed to form even and smooth surfaces with a small area.

Factory production lines require dedicated processing centers. They have complex functionality and can perform several operations simultaneously. However, their main disadvantage is their high cost. Therefore, it is not advisable to consider them as home equipment.

The following types of machining centers exist:

- surface grinding. Processing is performed in one plane. Can be used as an example for self-production;

- cylindrical grinding. Designed for processing cylindrical surfaces. For this purpose, the package includes several nozzles with different diameters;

- planetary. With their help, a flat plane is formed on products with a large area.

To complete a small home workshop, surface grinding models are most often chosen. They are distinguished by their simple design, availability of components and relatively quick production.

In addition to leveling, drum sanders can be used to remove layers of paint or varnish. They are used for do-it-yourself restoration of old furniture or wooden interior parts.

Making your own grinding machine

Homemade drum for grinding

The simplest model of a do-it-yourself machine is a drill that is mounted on a bed. Sanding cylinders are machined from wood and sandpaper with the required grain size is attached to their surface.

But this design has little functionality. For processing medium volumes, it is recommended to make woodworking equipment according to a different principle. First of all, you need to choose the right power unit. Most often, an electric motor with a power of up to 2 kW and a speed of up to 1500 rpm is used. These requirements are met by asynchronous models, which can be taken from old household appliances - a washing machine or a vacuum cleaner.

The procedure for making a homemade machine.

- Frame. It should be quite stable. Therefore, it is made from sheet steel with a thickness of 1.5 mm or more. As an alternative, you can consider plexiglass with a thickness of 10 mm.

- The engine is installed so that the shaft is in a vertical plane.

- Drum for processing. If you plan to perform only grinding work, an abrasive belt is installed on it. For deeper processing, you will need to make a steel cone with a cutting edge.

- Desktop. It is located at the top of the diagram. It is recommended to make it adjustable relative to a fixed cylinder.

- Control block. DIY designs rarely provide the ability to adjust the engine speed. Therefore, the block will consist of buttons to turn the unit on and off.

During operation of the equipment, shavings and wood dust will inevitably be generated. You can improve the design by installing a pipe from a household vacuum cleaner into the processing area.

In the video you can see an example of the work of a structure made by yourself:

Example drawings

How to make a grinding machine with your own hands: instructions, description and recommendations

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world. This girl's name is Melanie Gaydos, and she burst into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Our ancestors slept differently than we do. What are we doing wrong? It’s hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

What is it like to be a virgin at 30? I wonder what it’s like for women who didn’t have sex until almost middle age.

Never do this in church! If you are not sure whether you are behaving correctly in church or not, then you are probably not acting as you should. Here's a list of terrible ones.

15 Cancer Symptoms Women Most Often Ignore Many signs of cancer are similar to symptoms of other diseases or conditions, which is why they are often ignored. Pay attention to your body. If you notice.

Top 10 Broke Stars It turns out that sometimes even the biggest fame ends in failure, as is the case with these celebrities.

Belt grinding machine: study and do it yourself

A belt grinding machine is used in cases where it is necessary to perform finishing processing of parts, that is, as equipment for carrying out finishing technological operations. Most often, such machines are used in the furniture industry; they are used to process parts made from various types of wood. But a belt grinding machine can also be used to process metal parts, for which a belt with an appropriate abrasive material is used.

Application areas of the machine

The main tasks performed by the belt grinding machine are: final leveling of the surface being processed, bringing the level of surface roughness to the required level, bringing the processed surfaces to the level of smoothness before covering them with varnish and other finishing materials. The belt machine is also used to eliminate minor defects of the processed surface: depressions, elevations and burrs, processing the finishing coating: removing sagging primer and varnish, burr, grinding internal surfaces, processing roundings on the surface of the part.

A factory-produced option, the drawings of which can be used to create a similar homemade device.

The band saw can be used to process parts made of various materials: wood, plain and alloy steel. non-ferrous metals. Conveniently, using a belt machine you can process parts that have different shapes: quadrangular, round and flat. Using such equipment, it is possible to process round and tubular parts with a large cross-sectional diameter.

Design features of the machine

The working tool of any belt surface grinding machine is a belt on the surface of which abrasive powder is applied. It is made in the form of a ring and is placed between two rotating drums, one of which is the leading one and the second is the driven one.

Rotation to the drive shaft of the tape machine is transmitted from an electric motor, which is connected to it via a belt drive. The speed of movement of the belt mechanism can be adjusted, thereby changing the processing modes of parts. The belt of a surface grinding machine can be positioned horizontally or vertically, as well as at a certain angle, which is allowed by some models of equipment in this category.

When choosing a belt sanding machine model for processing a particular part, it is important to consider the length of the surface that needs to be sanded. It is much more convenient to process parts on such machines whose surface length is shorter than the length of the abrasive belt and work table. If such conditions are met, the quality of processing will be much higher.

A homemade version of the machine is not so difficult to implement in a home workshop

The belt grinding machine can have different designs: with a movable and fixed work table, with a free belt. A separate category includes wide-belt equipment, the peculiarity of which is that their work table, which is also a feeding element, is made in the shape of a caterpillar. In those equipment models that have a work table in their design, the abrasive belt is located in a horizontal plane, and in equipment with a free belt that does not have a work table, it can have a different spatial position.

A mandatory structural element of any belt sanding machine, including a tabletop one, is an exhaust device, which is necessary to remove dust generated in large quantities during the processing process. Both a professional and any homemade grinding machine used in a home workshop or garage are powered by an electric motor.

Principle of operation

The main operating parameters of a belt sanding machine include the feed speed and the force with which the belt is pressed against the workpiece. Parameters such as the degree of grain size of the abrasive belt should be selected depending on the material from which the workpiece is made, as well as the degree of roughness that the surface of the machined product should have.

The characteristics of the material being processed, in particular its hardness, primarily influence the grit size of the abrasive belt to be selected. Processing modes that are directly related to each other are feed speed and tape clamping force. So, if grinding is carried out at high speed, but with insignificant pressing force of the abrasive belt, then some areas of the surface of the part may turn out to be untreated. If, on the contrary, you increase the clamping force and reduce the feed speed, you may encounter the fact that burns and blackening of the material may appear in certain areas of the surface being processed.

Another variation of the machine - view from the working surface of the belt

The results of grinding are also influenced by how well the abrasive tape is glued together. In order to obtain high quality processing and not encounter malfunctions in the operation of the belt machine, you should not use abrasive belts that are glued incorrectly or have torn edges. When putting the tape on the equipment shafts, it should be positioned so that the overlapping end of the seam does not ride up against the surface of the workpiece, but slides along it. Learn more about gluing tape in the video below.

Any, including a manual grinding machine, must provide the ability to adjust the belt tension, which is ensured by moving a movable shaft that is not driven. Tape tension is a very important parameter, when choosing which you should follow the “golden mean” rule. If the sanding machine belt is pulled too tightly, this can lead to its rupture during operation, and if its tension is too weak, it will cause slippage and, as a result, excessive heating. The main characteristic for determining the degree of tension of the tape is its deflection, which is measured by lightly pressing on its surface in a tense state.

A manual belt grinding machine can be serviced by one operator, who moves the work table with the workpiece and rotates it so as to bring all areas of its surface under the abrasive belt.

How to make a belt sander

Many home craftsmen and professionals are wondering how to make a grinding machine with their own hands. The reason for this question is quite simple: the high cost of serial grinding equipment, which not everyone can pay off if not used regularly. In order to make such equipment, you will need several main components: an electric motor, rollers and a reliable frame. Naturally, drawings of such a device or a photo of it would not be superfluous. Also at the end of the article you can watch videos on assembling a tape machine on your own.

The motor for belt grinding equipment is not difficult to find; it can be removed from an old washing machine. You will have to make the frame yourself; for this you can use a sheet of metal with dimensions 500x180x20 mm. One side of the frame should be cut very evenly, since it will be necessary to attach the platform on which the electric motor will be mounted to it. The platform for the electric motor should also be made of a sheet of metal with dimensions 180x160x10 mm. Such a platform must be secured to the frame very securely using several bolts.

Another version of the bed

The efficiency of a belt sanding machine directly depends on the characteristics of the electric motor that is installed on it. If you are planning to make a grinding machine with your own hands, then an electric motor with a power of 2.5–3 kW, developing about 1500 rpm, is quite suitable for you. In order for the sanding belt to move at a speed of 20 m/s when using such a motor, the drums must have a diameter of about 200 mm. What’s convenient is that if you choose an engine with these characteristics, you won’t need to make a gearbox for your grinding machine.

The drive shaft is connected directly to the electric motor shaft, and the second - driven - must rotate freely on an axis, which is installed in bearing units. In order for the abrasive belt to touch the surface of the workpiece more smoothly, the section of the frame on which the driven shaft is installed should be slightly beveled.

You can make shafts for a belt sanding machine from a chipboard with minimal financial costs. Simply cut square blanks of 200x200 mm in size from such a plate, drill central holes in them and place them on the axle with a package with a total thickness of 240 mm. After this, all you have to do is grind the resulting package and make it into a round shaft with a diameter of about 200 mm.

Drawings and detailed analysis of some parts of a machine made of wood.

Wood belt sander (click to enlarge)

Table tilt adjustment mechanism Plate block Belt tensioner Machine assembly

In order for the tape to be located strictly in the middle of the shaft, the diameter of its central part should be 2–3 mm larger than at the edges. And to prevent the tape from slipping on the drum, it is necessary to wrap a layer of thin rubber on it, for which you can use an old tire from a bicycle wheel, having previously cut it along its entire length.

The sanding belt for such a machine, the optimal width of which should be 200 mm, is made from ordinary emery cloth. The standard cloth is cut into strips of the required width, and an abrasive tape is already glued from them. It should be borne in mind that the material is glued end-to-end; for this purpose, dense material is placed on the reverse side, which will strengthen the resulting seam. The properties of such a seam are greatly influenced by the glue; it must be of very high quality, then the material will not tear along the seam after a short period of use.

Several more options for manufacturing belt grinding machines can be seen in the video below.

On a homemade belt sanding machine, you can not only process wood products, but also use it to sharpen various tools: chisels, pruners, knives, axes, etc. In addition, such machines can process parts that have a curved surface.

Wood sanding machine - make it yourself or buy it?

One of the main methods of processing wood (after cutting, of course) is sanding. The manual method has been known for a long time - a wooden block is wrapped in sandpaper, and with the help of such a simple device the workpiece is given the required shape.

The method is unproductive and requires considerable physical effort. Craftsmen who work with wood regularly use small-scale mechanization.

Types of grinding machines

There are a variety of ready-made devices on sale that can be used to process wooden workpieces of any size. To understand the mechanism of operation, consider some of them:

Disc grinding machine

Based on the name, the working surface is made in the form of a disk.

The design is quite simple - a circle with good rigidity is put on the axis of the electric motor. The outer surface has a Velcro coating on which sandpaper is attached. No gearboxes or drive mechanisms are required. The grinding force is small, the rotor axis can handle the load quite well.

A hand rest is installed in the transverse plane, at the level of the center of the disk. It can have a hinged mount, which allows you to process workpieces at a fixed angle.

A feature of disk machines is the adjustment of processing speed without changing the number of axis revolutions. You simply move the workpiece along the radius of the circle. At a uniform angular velocity, the linear velocity at the periphery is higher.

Belt Sanding Machine

A strip of sandpaper, joined into a continuous strip, is stretched between two shafts.

Moreover, the emery in the working area does not sag under the pressure of the workpiece. A persistent working plane made of material with a low coefficient of friction is installed under the tape. By pressing the material being processed to the plane, the operator receives an endless abrasive surface.

The quality and ease of processing cannot be compared with manual tools. In the mass production of wooden products, such a sled is an indispensable attribute of any workshop.

The main feature is the predictable result throughout the entire plane. You can level the ends of a sufficiently long length.

The working surface can be horizontal or vertical, as well as the direction of movement of the belt.

Drum Sanding Machine

Such a device can be classified as a grinding unit with some stretch. The main application is horizontal leveling of planes using the jointer method.

The principle of operation is as follows: sandpaper is attached to one or two drums. The most common method is spiral winding. Below, under the drum, there is a flat table. The distance between the processing surface and the table is adjustable. By setting a fixed height, you can calibrate products of the same type, leveling the thickness of the workpieces.

Two-in-one grinding machine

To save space (and money), manufacturers often combine two types of fixtures in one design.

This not only reduces purchasing costs, but also improves ease of use. When processing one part, you can take advantage of two grinding units at once: disk and belt. In this case, one engine is used, and the load on it does not increase much.

Looking at the finished designs, it becomes clear how to make a grinding machine with your own hands. There are no problems with consumables, so you can immediately design the device for specific tasks. Any universal device is inferior to a narrow-profile one.

DIY grinding machine

When you have a ready-made (and shareware) electric motor, all the mechanisms are designed around it. If you still have to purchase an engine, it makes sense to choose it according to its parameters.

The main characteristic is, of course, power. The revolutions are not so important; they can be adjusted by the pulley (for belt drives) or the diameter of the circle (for disk models).

Calculation of grinding machine power

As an example, consider a belt drive.

Motor power is calculated using a complex formula, but if you have the initial data, it is not difficult to obtain the desired value.

- q – pressure of the workpiece on the working surface of the emery (N/cm²)

- S – area of contact between the workpiece and the emery (cm²)

- K is the coefficient of the working surface of sandpaper in relation to the workpiece. Depends on the grain size and density of the wood. Value limit: 0.2 – 0.6

- k – coefficient of friction of the back side of the emery on the thrust working plane

- U – speed of linear movement of the belt (m/s)

- n – system efficiency.

Important! Traditionally, when making homemade products, calculations are made “by eye”. Then, when you turn it on for the first time, it turns out that the power is either excessive (we shoot sparrows with cannons), or the engine stops at the slightest pressure of the workpiece on the working plane. Therefore, the calculation of parameters should be taken more seriously.

If you decide to create a woodworking machine with your own hands, you will need drawings. The illustration shows how important it is to comply with all standards and dimensions.

Even with a slight misalignment, the machine simply will not work. The tape will “move” to the side, and the motor shaft will vibrate. And the tension unit must be assembled with high precision.

You should also take care of safety (the sharp edge of the sanding tape can cause serious injury when rotating). And sawdust (or worse, wood dust) flying in all directions requires eye protection. Usually a simple transparent screen over the work area is enough.

Homemade wood sanding machine - an example of a successful design

Don't forget about work safety. On top of the rotating disk we attach an arch - a protective casing. This measure is not for aesthetics; touching the rotating disk can break your finger or seriously damage your skin.

Important! The surface of the tool rest must be sanded to perfect smoothness. The varnish coating is undesirable; it will wear off unevenly and the workpiece will be difficult to move.

Similarly, you can assemble a drum machine. It will be useful, for example, when preparing boards for flooring or a wooden table.

The main thing is the massive frame. The support bearings and wide drum are taken from a decommissioned conveyor belt, as is the motor.

The main task is to ensure an ideal horizon between the drum axis and the tabletop. The working surface is ground until final polishing. It is better to take harder material for the table.

Oak boards are too expensive, so you can use beech. A mandatory element of a drum sander is a table height adjuster. The screw mechanism must have a lock to prevent spontaneous unwinding due to vibration.

If the bed is not very heavy, you should secure the legs to the floor. Otherwise, the machine may overturn during work. When processing thick and uneven boards, the force applied is serious.

Conclusion:

There is absolutely no need to spend your savings on purchasing industrial machines. All the designs considered can be made independently.

During the manufacture of wooden structures, it is imperative to clean their surfaces. Manual labor will take a long time and will not be productive. Factory grinding centers are expensive. Therefore, in some cases it is more advisable to make the machine yourself.

Drum machine design

Manufacturing should begin with studying the design features of this type of equipment. The drum-type grinding machine is designed for processing wooden surfaces, leveling them and removing burrs.

The device belongs to a type of wood surface grinder that performs a calibration function. There are many models and types of equipment. But the main task before making a unit with your own hands is choosing the optimal design. The best option is to familiarize yourself in detail with factory analogues and draw up a manufacturing scheme based on the data obtained.

Structurally, the machine must consist of the following components:

- frame. The main parts of the equipment are attached to it;

- power unit. Most often, an asynchronous electric motor is installed for this purpose;

- grinding drum. It is important to choose the correct diameter and method for removing chips. With your own hands you can make a base on which the sanding tape is installed. Or order a cylindrical head with a cutting edge from a professional turner. It all depends on the type of work;

- device for changing the frequency of the motor shaft;

- Desktop. The workpiece will be placed on it. When making a machine with your own hands, experts recommend making this component from fiberglass;

Additionally, drum grinding equipment can be equipped with a mechanism for removing dust and chips from the processing area. It is also recommended to make a working table with a variable height relative to the snare drum. This will allow you to process part of the end of the wooden workpiece.

If grinding the outer or inner surface of the board is necessary, the drum should be positioned horizontally. At the same time, it is possible to adjust it in height.

Types of drum grinding machines

The next step is to select the design of the wood cutting machine. The main parameter is the shape of the wooden blank and the degree of its processing. Homemade drum-type equipment is designed to form even and smooth surfaces with a small area.

Factory production lines require dedicated processing centers. They have complex functionality and can perform several operations simultaneously. However, their main disadvantage is their high cost. Therefore, it is not advisable to consider them as home equipment.

The following types of machining centers exist:

- surface grinding. Processing is performed in one plane. Can be used as an example for self-production;

- cylindrical grinding. Designed for processing cylindrical surfaces. For this purpose, the package includes several nozzles with different diameters;

- planetary. With their help, a flat plane is formed on products with a large area.

To complete a small home workshop, surface grinding models are most often chosen. They are distinguished by their simple design, availability of components and relatively quick production.

In addition to leveling, drum sanders can be used to remove layers of paint or varnish. They are used for do-it-yourself restoration of old furniture or wooden interior parts.

Making your own grinding machine

The simplest model of a do-it-yourself machine is a drill that is mounted on a bed. Sanding cylinders are machined from wood and sandpaper with the required grain size is attached to their surface.

But this design has little functionality. For processing medium volumes, it is recommended to make woodworking equipment according to a different principle. First of all, you need to choose the right power unit. Most often, an electric motor with a power of up to 2 kW and a speed of up to 1500 rpm is used. These requirements are met by asynchronous models, which can be taken from old household appliances - a washing machine or a vacuum cleaner.

The procedure for making a homemade machine.

- Frame. It should be quite stable. Therefore, it is made from sheet steel with a thickness of 1.5 mm or more. As an alternative, you can consider plexiglass with a thickness of 10 mm.

- The engine is installed so that the shaft is in a vertical plane.

- Drum for processing. If you plan to perform only grinding work, an abrasive belt is installed on it. For deeper processing, you will need to make a steel cone with a cutting edge.

- Desktop. It is located at the top of the diagram. It is recommended to make it adjustable relative to a fixed cylinder.

- Control block. DIY designs rarely provide the ability to adjust the engine speed. Therefore, the block will consist of buttons to turn the unit on and off.

Homemade machine

Sanding wood is a mandatory procedure prior to finishing. To perform the work, special machines are used that operate on different principles and grind the material in different directions. However, the price of such devices is quite high. For a home craftsman, it is not always advisable to purchase equipment that will be used occasionally. It is better to make a wood grinding machine with your own hands, which will cost much less and allow you to get a completely effective device.

There are three main designs of wood sanding machines:

- Disk.

- Tape.

- Drum.

1-Disk machine 2-Belt machine 3-Drum machine

Disc machine It is a rotating disk on the plane of which an abrasive (sandpaper) is fixed. Grinding is done by applying the edges or side surfaces of the part to the disk, for which a table or support bar is installed approximately in the middle. This design is optimal for sanding straight or convex edges.

Belt type consists of two drums installed either vertically or horizontally. One of them is drive, the second is tension. The abrasive is a loop of sandpaper that is glued together using a template. The loop is installed on both drums and tensioned. After starting the engine, it forms a constantly moving strip of abrasive. Sanding occurs by pressing the tape to the surface of the part using a special clamp (“iron”). It moves left and right, ensuring that the sandpaper is pressed against all areas of the surface being treated.

Drum machine Used for grinding concave edges. It is a rotating cylinder of relatively small diameter (6-8 cm), on which the abrasive is installed.

The simplest designs are disk and drum. Making a tape machine is much more complicated, but its efficiency is much greater. Such installations allow high-quality grinding of panels and large-area parts, ensuring high surface quality.

To install a tape machine in a workshop, you will need a large area, which must be taken into account when choosing a design.

Features and Specifications

The main feature of wood sanding machines is a specific method for adjusting the quality of processing. It occurs by changing the grain size of the abrasive. Typically, the process begins with sandpaper with a coarse grain, then successively reduces its size and completes the procedure by sanding with fine sandpaper. In total, 2-3 shifts are used, but there may be more gradual methods.

The second feature is the method of installing the abrasive. If a pre-glued loop is installed on a belt machine, then a circle of sandpaper must be secured to a plane on the disk structures. The best way is to use Velcro, but the easiest way is to stick the abrasive onto adhesive or double-sided tape. The second method is simpler, but also more expensive.

The technical characteristics of each machine are slightly different from each other.

The technical characteristics of each machine are slightly different from each other.

For disk installations:

- Diameter of the working body.

- Rotational speed.

For band machines:

- Tape width.

- The size of the working base (the distance between the centers of the drive and tension drums).

- Loop speed.

- Range of movement of the desktop in the vertical and horizontal plane.

- Length of the blank for gluing the loop.

For drum machines:

- Working cylinder diameter.

- Cylinder height.

- Rotational speed.

All these parameters depend on the planned productivity, the size of the installations, and the size of the parts being processed. It is necessary to take into account the volume of expected work, the size of the parts, and the specifics of processing.

Expert opinion

Levin Dmitry Konstantinovich

The cleaner the surface should be as a result of grinding, the better the quality of the machine should be made. Beats, irregularities and other defects will cause scratches that can significantly deteriorate the quality of processing.

Advantages and disadvantages

The advantages of grinding machines include:

- Quality and speed of processing.

- High performance.

- The ability to obtain the surface of the desired roughness.

- The ability to process not only the wood itself, but also pre-grind the finishing layer.

The disadvantages are:

- Release of a large amount of dust, requiring the organization of a dust removal system.

- Large quantities of consumables (abrasive) of several sizes.

- Difficult to manufacture and maintain (this especially applies to belt installations).

Considering the existing shortcomings, before starting assembly, you need to decide how necessary the machine is. If it will be used only occasionally, it is not practical to spend time on manufacturing - you can get by with hand tools.

DIY options

Let's look at how to assemble different types of grinding machines:

Disk

The easiest way to create a disk machine is an electric drill mounted on a table with a grinding wheel installed. Another available option is to fabricate and install a sanding disc onto the circular saw shaft. In this case, it is necessary to assemble a device to reduce the rotation speed (a system of reducing pulleys or an electronic device).

If you need to make a machine from scratch, you will have to assemble:

- Support platform with stand for electric motor.

- Stand or work table.

- A disc for installing abrasives with the possibility of mounting on the motor shaft.

Expert opinion

Levin Dmitry Konstantinovich

As a rule, plywood disks are made, which are installed on the shaft using a coupling and threaded fastening. This unit will have to be ordered from a turner. The height of the table should be such that the disk mount is below its plane.

Tape

To assemble such a grinding installation, you need to proceed in stages:

- Assemble the frame. It consists of two pedestals on which a drive drum with an electric motor and a drive drum with a tension device will be installed.

- Connect the cabinets with a frame on which the desktop will move (horizontally, perpendicular to the movement of the belt).

- Assemble a work table lifting device to adjust the height when processing large parts.

- Make a device for moving the “iron”.

- Make a protective casing and connect the dust extraction system pipe to it.

- Assemble the electrical system for starting and stopping the machine (start button, automatic machine, etc.).

The greatest complexity is presented by the drums for installing the abrasive, the tension devices for them and the table lifting/lowering system. They will have to be partially ordered from a turner, and partially assembled on site. It is unlikely that you will be able to find ready-made units, since they are very specific and rarely found on common mechanisms.

Drum machine

The simplest option would be to install the electric motor so that its shaft passes through the hole in the workbench. To do this, you need to assemble the frame in the form of a support platform with a stand and a vertical plate. Holes are made on it and the electric motor is attached. The drum is installed on the shaft using a threaded fastener. The easiest way to make it is from wood, or use a section from a plastic sewer pipe. Sandpaper is wrapped around the drum and secured with screws or small nails.

In all cases, it is necessary to ensure a low speed of movement of the abrasive. It is necessary to choose electric motors with a number of revolutions of no more than 1000. Band machines are especially dangerous. At high speeds, the edge of the belt can cut through any material and cause serious injury.

Material selection

The easiest way to make a machine at home is from wood. However, it should be borne in mind that it is light in weight and is not able to dampen the beating of the machine. Therefore, you will need high rigidity of the connections and strong fastening of the frame to the floor. Another option is a metal frame made from an angle, channel or I-beam.

Such a machine is more massive, heavier, vibration and beating will be easier to dampen. However, you will need welding work, cutting workpieces and other operations with metal, which is not accessible to everyone. The final choice is determined by the capabilities and preferences of the owner.

Popular models of factory machines

Let's look at the most popular models of grinding machines:

Disc (disc)

Jet JDS-12 220 V

Stationary machine with a massive cast iron frame. Able to dampen vibration or beating when it occurs. Disc diameter - 30 cm. Engine speed - 1400 rpm. The table can be tilted from +15° to -45°.

Chinese disc grinding machine. Compact type, with a disc diameter of 305 mm and a power of 800 W. The base is made of cast iron. The work table has a slot for moving the stop with the ability to rotate at a certain angle to the disk.

Einhell TC-US 400

A combined type machine combining disc and belt types. The diameter of the disk is 15 cm, the blank for gluing the loop is 914 by 100 mm. The belt speed is 276 mmmin, the drum rotation speed is 1400 rpm.

Tape

Jet EHVS-80

Vertical type machine (drum axes). Tape speed - 16 ms. Blank for the loop - 116 by 2260 mm. Machine weight - 110 kg;

ShLPS-6M

Stationary grinding machine with horizontal belt arrangement. The diameter of the pulleys is 34 cm. The maximum size of the part during processing is length 2.5 m, width - 1 m. Table lift height - up to 40 cm. Belt blank - 7470x160 mm. Weight - 670 kg.

Drums

Jet JBOS-5 220 V

A drum machine that provides spindle rotation with simultaneous reciprocating movement in a vertical plane. Rotation speed - 1400 rpm, number of lifts - 30 pcs.min. The desktop can be tilted up to 30° to the horizontal;

Proma BO-25 25000370

Compact grinder with 370 W power. Equipped with a square work table measuring 37 by 37 cm, with the ability to tilt up to 45°. Spindle rotation speed - 1400 rpm. Machine weight - 35 kg.

The number of designs and models of grinding machines is constantly increasing. New developments are appearing with increased processing capabilities and quality. Manufacturers take into account the shortcomings of existing devices and produce more advanced, modified samples.

Care and maintenance

The operation of grinding machines is accompanied by the release of large quantities of dust. To remove it, powerful local exhaust units are used. If they are turned off, the equipment cannot be used - this threatens the health of the employee. However, it is impossible to completely get rid of dust, so after finishing work you should immediately thoroughly clean the machine using an industrial vacuum cleaner and brush.

The abrasive is replaced as it fails or according to technological processing conditions. To maintain productivity, you need to have a supply of ready-made discs with installed sandpaper, or glued sanding belts of different types. They are stored in a closed cabinet so that dust does not accumulate and the surface of the tape does not deform.

During operation, a significant charge of static electricity is generated. To remove it, high-quality grounding is required. It is necessary to periodically check its condition and restore if necessary.

Do you want to assemble a grinding machine yourself?

Certainly!Not really

Let's sum it up

A homemade grinding machine requires sufficient space in the workshop and requires significant quantities of abrasive. When deciding to independently manufacture such a device, you should carefully weigh the need for this and your capabilities.

There are three types of design:

- Disc machines. Easy to make, can be made from a circular saw.

- Drums. Compact devices, ideal for grinding the edges of concave parts.

- Tape. Capable of grinding planes, providing high quality surfaces. They are the most difficult to manufacture due to the large number of specific components and parts.

Manufacturing a machine will require the use of certain tools and materials, the choice of which is determined by the capabilities of the owner. You won’t be able to do it entirely on your own; some components will have to be ordered from a turner. It is important to ensure a low speed of movement of the abrasive so as not to create the risk of injury or destruction of the workpiece.