Homemade measuring tool. DIY accessories for power tools. Making a pipe bender with your own hands

For household repairs and work on summer cottage Various power tools are used. Specialized ones are produced for them additional devices and devices, many of which can be manufactured with my own hands. It is better to get complex industrial devices ready-made, but workbenches, tables, attachments and almost everything else can be made without the help of others. Handmade devices for power tools can be adjusted to the required technical conditions.

Classification of devices for power tools

Do-it-yourself power tool accessories are usually systematized into the following categories:

- Tools and attachments for processing. These are hand-held devices, which include grinding attachments and bars for grinders and drills.

- Devices for modifying the position, mounting a certain cutting angle, drilling and the rest. These are the main surfaces, standards, guides. They will be able to carry out different external type, are often made of metal or wood.

- Dust removal devices. Similar devices are used to remove sawdust, dust, and shavings from the working plane. It is not so difficult to make such devices with your own hands; as a rule, pre-existing fan holes in the equipment are used for mounting.

- You assemble grinding attachments, structures or bars designed for surface treatment with your own hands. For example, for grinding wooden surface or to clean the alloy, you can use a wooden plate with a handle on top. In its working side it is strengthened sandpaper required grain size. The model of the platform can be anything, it is only important to choose the right abrasive material.

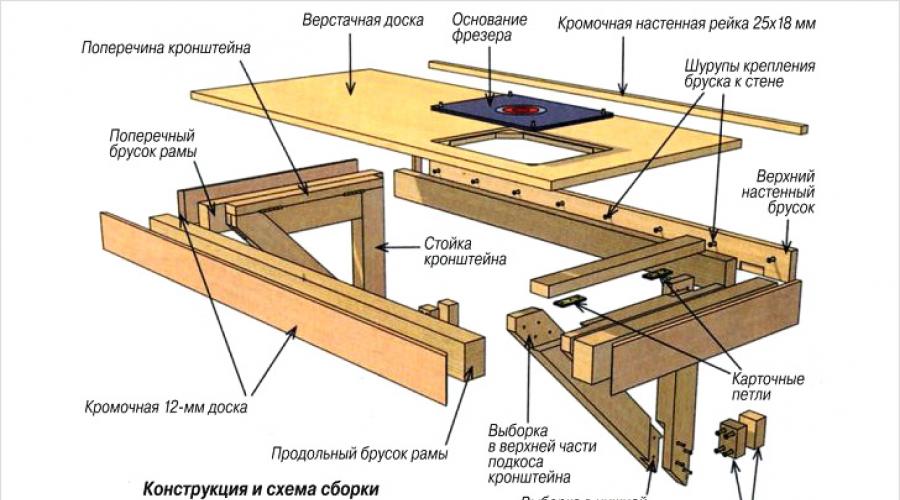

Diagram of the milling table device

Attachments for power tools vary, but sometimes they are large scale, as is the case with milling machines and saws.

It is recommended to choose an improved table that will contain everything, without exception, necessary for a comfortable and comfortable dangerous work. The most common type is considered milling table, produced in the form of a large board with an opening for a router and a guide board. Scale worktop may be different, everything without exception depends on what kind of work will be carried out. The most ideal type is a table with legs of the required height. And the working and guide boards are made from chipboard sheets. In this case, vices and clamps can be taken into account on the surface. It is generally better to make table legs replaceable and provide a backup set.

Workbenches for power tools

To work with numerous devices, it will be necessary to improve workplace. For a home workshop or a car garage, a small, small-sized and universal workbench. It is not so difficult to make it without the help of others; you just need to specifically improve your choice of what functions it is needed for. In general, it is more correct to make a workbench that can be used at any height, including on a table.

Then it will be possible to position the power tool comfortably and change its position if necessary. For work, it is recommended to use various hard woods; a common material is maple, which is easy to process and yet has the required hardness and strength.

To register on the table, it is possible to attach comfortable legs or clamps to the installation. A workbench requires a vice; they are often used in work, which guarantees an improvement in its quality.

Drill attachments

During operation, the drill may need various attachments. They make it possible to simplify work, make it simpler, more comfortable, and faster. A huge number of homemade products are used for the drill, which numerous manufacturers today have taken as the basis for the study of specialized kits. The list of devices that you can make with your own hands is huge.

Accessories for power tools:

Various accessories for power tools are needed in order to make the work more convenient and simpler.

It is not always possible to buy such devices, of course, and they are often only needed for a couple of times. For this reason, it is much easier to do them without the help of others, spending not so much time.

Owners of private houses and hobbyists dream of creating a home carpentry workshop. They buy interesting power tools and try to make their own carpentry tools. For these purposes, they use an electric drill, a circular saw, and a jigsaw.

Experts advise beginners not to buy cheap tools. You need to focus on average price options. In addition to tools, it is necessary to provide shelves and cabinets for storing materials and various small items.

Carpentry equipment

“Advanced” craftsmen have good workbenches with vices, rare machines and tools that are very necessary for making furniture:

The ubiquitous grinder

Every man has a power tool called an angle grinder. Actually it's Grinder, with which they perform abrasive cutting of metal, stone, ceramic tiles and other materials. To do this, install a special abrasive disk with a thickness of 0.7 to 2.5 millimeters. The diameter of the cutting disc is from 115 to 180 millimeters, it all depends on the hardness of the material being processed.

The peculiarity of this machine is the high speed of the electric motor, for example, the Whirlwind UShM-125 has 11 thousand revolutions per minute. It is this indicator that light weight, only 2.5 kilograms, excites the minds of home craftsmen to adapt it to perform types of metal-cutting work unusual for it.

Homemade grinders are available in every garage and home workshop, and each master makes a device for his own needs.

Cutting machine

A homemade option for the workshop is offered - cutting machine, suitable for cutting angles, pipes, square profiles, fittings. The design of the device is simple:

- Desktop;

- spring return brackets;

- platform for attaching an angle grinder;

- emphasis

For this purpose, special protection is made, similar to the standard casing that comes with the tool. It has a slide, two handles and rotating device. The slide looks like a plate measuring 200 x 120 millimeters, with a slot for the saw blade to exit.

The plate is attached on one side to the casing on a hinge, the other to a steel strip with a 9 mm wide slot for sliding along an M8x1.5 pin, which is on the casing for fixing with a wing nut.

Two handles are welded to the casing to hold the sawing machine during operation. Cutting and sawing thin lumber is very convenient, and the high speed of the machine carpentry machine allow you to easily cut material up to 30 millimeters thick.

Vertical drilling model

The frame can be made from pieces of angle 50x50 millimeters and steel sheet 5 mm thick. To do this, weld two corners along the edges of the sheet along the entire length; they will serve as legs. Table size 350 x 200 millimeters. Weld a bracket on top with square pipe 80 mm high for mounting a stand.

The stand or guide for the drill is made of a square pipe three millimeters thick. A section is welded into the upper hole water pipe eight millimeters long. A cable tensioning mechanism is inserted into it. The height of the stand is 700 millimeters. The stand is inserted into the bracket and crimped with four bolts - two on two sides of the square pipe.

The carriage is a movable unit on which the drill is attached. It is made of 50x50 corners welded together, the height is 170 millimeters, the eyes are made of strip three millimeters thick. An axle is inserted into the eyes, around which the cable is wound.

A continuation of the axis is the handle that drives the carriage.

The carriage drive consists of an axis on which a cable and a handle are wound. One end of the cable is fixed to the bottom bracket. The upper end of the cable is fixed in the pipe at the upper end of the rack. A special bracket is attached to the carriage with seat for an electric drill. The drill itself is tightened with a special clamp made from a strip 2 mm thick and 40 mm wide.

Homemade turning device

There are a lot of homemade designs of wood lathes. They are united by the presence of four main nodes:

- drive unit;

- bed;

- tailstock;

- handyman

The only difference is in the choice of drive. Whoever has any electromechanical devices is installed on the product:

- electric drill;

- Bulgarian;

- milling cutter;

- electric motor from a washing machine.

You can improve an already made metal-cutting structure by adding additional functions to it. For example, can be placed horizontally on a workbench or table drilling machine. The drive is electric drill. The tailstock will be a work table in which a hole is drilled along the axis of the drill in the chuck and a thread is cut for screwing the fixed center.

Additionally, install a hand rest, securing it to the movable bracket of the rack. The workpiece is fastened with one end in a trident clamped in a drill chuck, and the other end in a fixed center. For a small number of simple parts - a quite good homemade woodworking machine with devices and equipment for the manufacture of shaped parts obtained by turning.

The list of tools and mechanisms for a workshop or garage is limited only by the area of the room and material opportunities owner. Despite the fact that many products are made from waste, the costs of purchasing parts and tools required for assembly are quite significant.

Sometimes it is cheaper to get a service from a specialized workshop than to do the work yourself.

The article discusses a large number of homemade machines and devices, and the arrangement of a place for their convenient storage in a home workshop.

You will definitely like these ideas

Roll rag holder

How to optimally place tools and accessories

The author of the channel “Inexpensive with your own hands” decided to equip his small workshop and make it exemplary, taking as a basis one of the approaches that are implemented in production, making a number of homemade devices. Everything in it is organized according to the Japanese 5S system. The home workshop is located in a small building.

A little about general organization premises. You see that the walls are made of wood. The building in which everything is housed is cold, half brick. Therefore, we had to insulate it to extend the season of use. We used lining, foamed polyethylene penoflex, which were laid inside. The ceiling insulation is done in the same way, plus a plastic coating.

The interior contains predominantly blue and yellow colors. Blue color, according to psychologists, stimulates creativity. This is the color for creative places. Yellow creates joy, good mood. It has a beneficial effect on performance. Everything the author of this idea does according to the rules industrial design in pleasant tonic colors.

There is not a lot of space in the workshop, so there is a reasonable question: where to carry out large-scale work? Answer. They are performed outdoors; for this purpose, there is a specially welded, convenient and functional workbench with a vice and holes for fasteners. Cool machines in this Chinese store.

Other principles underlying the organization of the workshop

Principle 1. Divide items into necessary and unnecessary

This is the principle of separating machines and devices according to their intended purpose. We are not talking about metalworking technology here.

Not all subjects are equally important for work. Some are used more often, some are used less frequently. This must be taken into account when placing them. In close proximity to the workplace, what is needed frequently and should be at hand is involved in work. This includes a ruler, knives, level, pliers, screwdrivers, keys, and a meter. Everything is within arm's reach. This allows you to reduce access time.

Devices and tools that are rarely needed or for specialized work are removed from the workplace in an optimized home workshop. The desk must be clean before work begins and ready for assigned tasks. Not particularly urgently needed and things should be located in a place that access to which should not take more than 30 seconds. The tool should also be put back in its place quickly after use.

Principle 2. Determine its place for each item

Each item should have its own place. When the question arose of choosing a method for placing the tool, the first idea was to do everything yourself. But in one of the stores, the author of the video saw a panel for sale for 1,150 rubles, he purchased it as a tool holder. M6 bolts are used for fixation. The panel has standard holders, which would take a very long time to make yourself.

Not only are specific locations identified for an item, but designations are used. For example, big and. It is convenient for each item to have its own specific address. It is better if the address is visualized or signed.

When working in a workshop, you may need to perform phone call or accept it. The phone used should also be at hand to access the Internet and search for the necessary information on current work problem. It is convenient to use a car holder for this.

Each of the keys has a denomination signed in the corresponding cell. In other cases, it is not always possible to place labels due to the small size of the cells.

A hand engraver hangs on the wall. A magnetic kitchen holder is used for knives.

Fixed machines that may move from their place during work are marked with their address on adhesive tape.

The tables that are located in the workshop are made independently, from profile pipe. The tables themselves must also be located in their place, so the places where they should be are also marked.

To keep your home comfortable and convenient, you need complex technology. It greatly facilitates household work, but its maintenance requires certain skills and knowledge. Not everyone knows all the capabilities of modern tools and does not use them to the fullest. If you change them a little, you can get convenient homemade tools for the workshop.

If you gradually acquire models from popular brands, they will turn out to be durable and reliable assistants. In addition, devices are needed for positioning and securing workpieces during processing. It will be at the dacha

As inventory accumulates home handyman it should be sorted into groups:

- plumbing and carpentry tools;

- devices;

- electrical equipment.

Drawers and cabinets allow you to place everything. Keeping equipment clean and tidy makes it possible to create a comfortable working environment and ensure long-term preservation of tools.

Homemade tools for woodworking

Wood processing is most common in household. Useful homemade tools for the workshop primarily include a workbench. It should be at a comfortable height. Its lid is located at the level of bent palms. If you need to raise it, bars of the required thickness are installed on the dowels below.

Making a modern workbench

The classic workbench consists of a lid with front and rear vices. This design is more suitable for manual work. It is poorly suited to working with power tools due to the fact that workpieces can be difficult to secure. You can buy a modern compact workbench MASTER cut 1000 worth 12 thousand rubles, which folds. You can install it on it hand tools: circular saw, jigsaw and router. But then it will have to be redone. Good characteristics has a Festool MFT 3 workbench. However, the price of 30 thousand rubles makes you think. The master will be able to make homemade devices for the home workshop that work just as well.

To make a workbench, you will need smooth plywood without knots. The thickness must be at least 20 mm. By installing a jigsaw on it from below, you can cut boards and small bars along, across, at an angle, as well as complex curved profiles. The tool performs additional functions of a circular saw and a band saw.

First, the tabletop is made. An arc-shaped groove is cut into it to install a guide for workpieces, which can be mounted at any angle. A guide with a slot is also made under the jigsaw. Its width is selected to match the size of the tool sole.

The sides should be cut out of plywood and glued to the tabletop to give it rigidity. The legs of the workbench are made of timber. Can be made metal carcass, and then attach the tabletop to it with screws. Then the structure will be light and durable. The guides from below are attached to the tabletop with furniture nuts.

The jigsaw is installed from the bottom of the workbench lid - “upside down”. Only the file remains visible from above. For ease of use of the jigsaw, an additional switch is installed. The guide should also be easy to remove so that the tool blade can be easily replaced. For easy access to the underside, the tabletop can be made folding and hinged.

The workbench takes up little space and can be installed even at home. To do this, it is made foldable so that it can be easily disassembled and stored in a closet or pantry.

How to make a workbench for a summer house

For work in the country or in country house you need a powerful workbench. The table top is made from thick edged boards up to 2 m long. It will not be superfluous if it is additionally secured with self-tapping screws. The bottom perimeter of the tabletop is sheathed with timber. The table legs are made with a square section of 120x120 mm. They can be buried in the ground or attached to a reinforced concrete base. The entire structure is treated with an antiseptic and covered with drying oil.

When the workbench is installed, do-it-yourself devices are mounted on it: guides, devices for fastening workpieces and power tools.

How to make a pipe bender with your own hands

In a subsidiary farm it is necessary to have a bending device metal pipes and profiles. simplest homemade instrument for bending pipes with a diameter of up to 20 mm - this is a steel plate with welded pins. By inserting a workpiece between them, it can be bent to the desired curvature. Such simple devices the pipe is crushed at the bend. To prevent this from happening, you need to fill the pipe tightly with sand. Warming it up will also help. blowtorch, which any master has.

To improve the quality of bending, instead of pins, 2 profiled rollers and a locking element are used. You can also make a special profile from a steel angle and plate and attach it to a workbench that has a solid base. In the picture, the structure is attached directly to the boards. You can make it portable by mounting it on a steel sheet and securing it to the bottom of the tabletop. Then the pipe bender, which has to be used quite rarely, will not interfere with carpentry work. Portable device, like other homemade tools for the workshop, can be used in the garage. It is convenient to secure it there, and it may be needed not only for pipes.

Homemade circular saw

Branded machines have high prices, but for a private user, a homemade tool for a home workshop is quite suitable. It can be made on the basis of manual, cheaper models.

The workbench for the circular saw must be stable. A frame with a slot for a disk is attached to the tabletop. The best material is a sheet of metal or durable wood that can withstand heavy loads. It has a slight thickness, which makes it possible to use most of the disk and cut products of sufficient thickness. In addition, the tool itself and the machine tool attachment are attached to the frame. The guide bar is made to slide on a steel or aluminum slide, or is secured using clamps.

Installed from the bottom of the tabletop on the frame. You can also use a grinder or drill, but they are not as effective and do not allow you to use the entire working area of the disk. The fastening can be anything as long as it is reliable.

When working with a circular saw, remember that it has high speeds and safety rules must be followed.

Homemade bow saw

Homemade woodworking tools can be very simple yet effective. These include a bow saw. The thin blade makes it possible to quickly cut big log. It is easy to replace it with a new one when the saw becomes dull. You can make your own bow saw from 3 blocks of durable wood. Two handles with cuts at the ends are connected in the middle by a crossbar using a “tenon-socket” connection. The blade is inserted into the slots and secured with two nails. On the other hand, it is tensioned using a rope loop thrown over the handles and twisted with a knob.

How to sharpen a knife

Hand sharpening for knives is more effective because it produces a strong cutting edge. To facilitate the process, it is widely used homemade device. It consists of a bar with a clamp for the bar, a base for fixing the knife and a stand for adjusting the installation angle.

When the rod with a bar attached to it moves back and forth, the blade is sharpened. The abrasive surface is pressed against the blade only when moving from the heel to the tip. By slightly changing the design of the knife sharpening base, you can also straighten the blades of carpentry tools.

Homemade garage gadgets

A garage is not only a place to hide a car, but also a workshop where you can store tools and carry out repair work.

Shelves and racks

Provide the equipment with your own hands. To do this, a rack is made, which is usually placed on top. Then it will not interfere with movement inside. A small workbench is installed below, in which tools are also stored. It is most convenient to place everything near the back wall of the garage. Then the side passages will be free.

The inspection pit is lined with bricks or concrete is cast, and then covered with a lid so that it does not interfere with the passage.

Making a puller

Normal work on the car is done using standard set tools. Craftsmen make special equipment. A puller is often required to pull bearings together. The most convenient is the three-valve design. Standard device may not be enough. If you make a puller with your own hands, it will last for many years.

Small devices are made from steel sheet 10 mm thick. A pattern is drawn on it and the legs are cut out with a gas cutter. They are processed on an emery machine, adjusting the dimensions. The core is turned out of round timber, the claw holders are welded, the thread for the collar is cut and drilled required holes. The legs are held on by bolts with a diameter of 8-10 mm.

The job of making a puller requires skill with many tools. Helpers may be needed here. A convenient solution is to make removable feet of the desired configurations, which can be changed on a product purchased in a store.

Conclusion

Homemade tools for the workshop allow you to solve many problems in the home and farmstead with with minimal effort and costs.

A good owner always has his own workshop, which he fills with equipment and devices to suit his needs. Some things can be bought, but others can be built with your own hands. And we must not forget about the garage, because all the necessary equipment should also be there.

It is impossible to provide for everything that might ever be needed. Therefore, we will consider the most basic machines and mechanisms that can be useful when working with wood or metal.

How to make a universal machine with your own hands

There is a huge amount various kinds equipment, many of which can be produced independently in one form or another. Craftsmen have even learned to combine several functions in one device.

For example, you can make a universal mechanism from a regular drill that will work like:

- a circular saw;

- grinding;

- cutting;

- sharpener;

- turning.

To make it, you need to attach a drill to the frame. A board with a thickness of 20–25 mm is chosen as the base. The drill is fixed to that part of the body that is intended for attaching another handle.

The location of fixation on the tabletop is selected based on the size of the circular disk, grinding wheel, cutter, or sharpening stone.

To secure the drill, use a firmly fixed threaded rod and nut. Rigidity of fixation is achieved using epoxy glue and, as an addition, a pin 2 mm in diameter. We build a moving sole and that’s it, the base is ready.

To get a homemade circular saw, install a saw blade with a diameter of 15 cm on a drill chuck and make a slot for it in the bed. The saw blade must be protected by a metal casing.

If you plan to use a flat cutter instead of a disk, you need to additionally make a rectangular slot or widen the hole for the saw.

From this “circular” saw you can build a cutting mechanism. To do this, on a rigidly fixed surface we install a rotating bracket, a miter box that sets the cutting angle, guides and devices that secure the workpiece.

We combine this with circular saw on the bed. Grinding and turning machines are assembled using the same principle.

Video: homemade circular saw + plane

Making a circular saw with a frame

If you want to have a separate circular saw, then you can easily build it from a manual circular saw bought in a store. Such homemade mechanism not designed for too heavy loads, but suitable for occasional use on the farm.

We take a frame of suitable size and fix it on it manual circular saw, make the maximum cut and leave it in that position. We turn the base over with the circular side down and place it firmly on the frame with legs.

We make a guide and everything is ready to go. Please pay Special attention to the height of the machine, you should be comfortable working with it, and its height should be commensurate with your height.

You may also need a pipe bender in the workshop. This is a device that allows you to bend pipes from almost any metal, as well as strips. Bent pipes are required when a person decides to make, for example, a greenhouse or greenhouse or something else like that.

There are different types of pipe benders, let’s say, made independently. There are very simple ones, and there are others that are similar in design to factory ones; they are more difficult to manufacture.

The simplest option homemade pipe bender we get it by sawing the board on one side in a semicircle. Then this workpiece is attached to a stable surface and a limiter is mounted nearby - wooden detail, having a space up to a semicircular blank, into which one end of the pipe is inserted.

Video: we will equip the workshop ourselves

Features of homemade devices and equipment

You can talk for a long time about what equipment you can make for your workshop with your own hands. But everyone has their own needs and capabilities. In addition to homemade devices, there should be places to store tools, as well as a workbench.

You should take the construction of a workbench seriously. You need to think about what will be attached to it, where it will stand, and what materials to build it from. The tabletop can be made of metal or wood.

You can immediately attach a circular saw, for example, or a jigsaw, various kinds of vices, clamps, and so on. It all depends on your idea and need for this or that equipment. But the workbench must be the right comfortable height, stable and well made.

Also in the workroom, various types of cabinets and pencil cases for placing and storing existing tools, which you can assemble with your own hands, are very useful. Can be equipped separate places for storing large tools and separately for small ones, for example, a separate open cabinet for drills.

The convenience of work, how quickly you can find the necessary tool or part and, ultimately, your comfortable well-being depends on how you organize your workspace.

Video: wood lathe

What can be done for the garage

Often, a garage becomes not only a place to store a car, but also for many necessary tools, and sometimes a workshop at the same time. Therefore, here you need to have:

- Tools for car repair.

- Spacious racks for their placement.

- Garage workbench.

- Hooks.

- Shelves or brackets for tires.

- Lamps and heaters.

These devices are easy to assemble with your own hands. The organization of the garage space should be well thought out. Everything should be placed conveniently and not take up much space. Think about whether you need a workbench and where to put it, what size it will be and in what places to place racks and shelves.

A workbench will be needed if you are repairing your car yourself. Typically, all tools are located on shelves and racks next to the workbench. Spare tires are stored either on a special rack or hung on brackets on the walls.

Place all fuels and lubricants on a separate rack. Most often there are some difficulties with storage small parts: screws, nuts and the like. You can take small ones for this glass jars with screw caps.

Screw the lid to the shelf below, sort all the small items into separate jars. This way you can save space and put things in order, and also search the required screw, drills or nuts will now be kept to a minimum.

For these purposes, you can choose another option. You will need magnetic tape, small clear plastic containers with durable lids, and metal flat washers. Fix the magnetic tape vertically in the place you need.

Attach metal washers to the bottom of the containers. Sort all the small fasteners into ready-made containers and hang them on a magnetic strip.

For repairs you will also need inspection hole. And if it is not possible to equip it, then you can build two overpasses to lift the front or rear or side of the car. This will allow you to fully carry out all repair operations. Overpasses are made of timber and durable boards or metal, if possible.

Well, in the end, good lighting is very important for the garage. It can be general and as an addition to portable and local lamps. And make sure that there is more than one outlet in the garage. If you are repairing the car yourself, then you need to think about ventilation of the room.