Homemade oven pressure cooker. Homemade oven pressure cooker Ovens made of sheet steel

Read also

These small, simple ovens have different designs and are used for various purposes. Entirely metal, heating, made of sheet steel of various thicknesses. They are divided into simple and frame. In the former, the body is formed by the sheet itself, in the latter, under it, like under a shirt, there is a frame - a steel frame. The latter are more convenient for self-made. Metal furnaces are round, square, rectangular shape.

These small, simple ovens have different designs and are used for various purposes. Entirely metal, heating, made of sheet steel of various thicknesses. They are divided into simple and frame. In the former, the body is formed by the sheet itself, in the latter, under it, like under a shirt, there is a frame - a steel frame. The latter are more convenient for self-made. Metal furnaces are round, square, rectangular shape.

Small heating stoves can be made of bricks in square or rectangular shapes. They are suitable for heating and for drying rooms, products, lumber, etc.

Roofing steel stoves are only suitable as temporary ones: they quickly burn out. To protect the housing from burning out and to increase its heat transfer from inside lined - lined with bricks, a quarter or half; You can do the same with adobe or clay concrete. Clay - very thick clay, difficult to knead with runes; adobe concrete - the same adobe, but with the addition of fine brick crushed stone.

Lined stoves heat up more slowly, but also retain heat longer. It should be recalled that earlier in rural areas Many stoves were made from adobe and they served for decades.

Furnace lining can be different thicknesses: from 10 to 120 mm. Up to 70 mm it is more advisable to make it from glycobit or clay concrete, above - from brick.

All stoves require particularly strict compliance with fire safety measures. It should be recalled that metal ones heat up very strongly, often red-hot. They must be placed as far as possible from flammable objects - at a distance of 1000 mm.

Closely located easily flammable partitions are plastered with a layer of lime, lime-gypsum or cement mortar thickness of at least 28 small, on felt, upholstered with shingles or fine metal mesh. Instead of plaster, sometimes the same surfaces are lined with felt with brick.

To avoid fires, a so-called pre-furnace sheet made of roofing steel measuring 500X700 mm is attached in front of each stove. It is laid on felt soaked in clay mortar. They do it like this. The blank cut from the sheet is painted on both sides oil paint, dried. The felt is moistened in a creamy clay solution (it will protect the felt from overheating, as well as from moths), laid on the firebox sheet, and dried well. Then the resulting “sandwich” is carefully placed under the firebox of the stove with the metal facing up and nailed to the floor with nails.

SHEET STEEL OVEN

Regardless of the shape and thickness of the sheet from which they are made, their joints are joined at the edges by lying folds, welding or riveting.

Stoves can be with or without insurance policies. The latter are placed on the so-called trenches - brick racks with a height of at least 130 mm. Then the air, circulating under the trenches, will cool the floor. At the installation site for both stoves, it is necessary to put felt impregnated with clay, cover it with roofing steel, and place the stove on top - on legs or trenches.

Rice. 1. Furnaces made of roofing steel (A - a simple furnace, B - (improved, C - a furnace with a steel sheet, D - with a pipe in back wall, D - frame stove with cast iron stove):

1 - legs, 2 - ash door, 3 - firebox door, 4 - box or casing, 5 - pipe, 6 - grate, 7 - ash pan, 8 - cast iron plate.

Let's consider the main types of designs of metal homemade stoves.

Simple oven(Fig. 1 A) consists of a steel box with a pipe at the top and a firebox door on the opposite side. It is more difficult to line such a furnace. It is more practical to make it with a removable top.

This stove may not have a blower, but it will work better if you drill several holes at the bottom of the door or under it, 15-25 mm above the bottom edge of the stove. These holes can be closed with a special valve, regulating the supply of air to the furnace necessary for complete combustion of the fuel.

Improved furnace(Fig. 1B). It consists of a box or casing, legs, a ash door, a firebox, a grate - cast iron or sheet steel with punched holes, - a pipe with metal pipe and a blower or ash pit. The pipe is assembled from several sleeves and two tracks.

The stove does not have a massive body capable of accumulating heat, so it, like the previous one, heats up quickly, but cools down even faster.

During combustion, the temperature in the furnace reaches 700°C, so it is better to line it. And for ease of use, you should install a removable top. Near the firebox and ash pan, the lining may be slightly thicker than at the rear wall.

Furnaces with additional improvements(Fig. 1 C, D). The two previous ovens can be used for cooking and heating food. It will be more convenient and faster to do this if you slightly modernize the firebox. It is recommended to install at a distance of 50-70 mm from the top steel sheet to form a horizontal channel. To do this, it is best to stretch the wire under the sheet in two places and bend the sides at the sheet itself. The sheet is laid so that it fits tightly between the side and rear walls, but can be freely removed for replacement in case of burnout. If the pipe chimney attached to the back wall, then the sheet is given the shape indicated in Figure 1 D.

Frame steel oven(Fig. 1 E) is the most universal. To make it, you can use a commercially available upper cast iron stove- solid or with one or two burners the right size. According to the dimensions of this plate, the frame is made from angle steel so that there are gaps of at least 10-15 mm between its sides and the plate - for the thermal expansion of the metal when heated. If the slab, for example, is 1000X600 mm in size, then the frame is 1015 X X615 mm.

Uprights and side struts made from steel angles are attached to the frame, lined with sheet steel using welding or rivets, lined, a grate and a steel sheet for the horizontal channel are laid. It is convenient to cook or heat food on such a stove; it heats the room well. It must be emphasized that the bottom of the furnace is also lined.

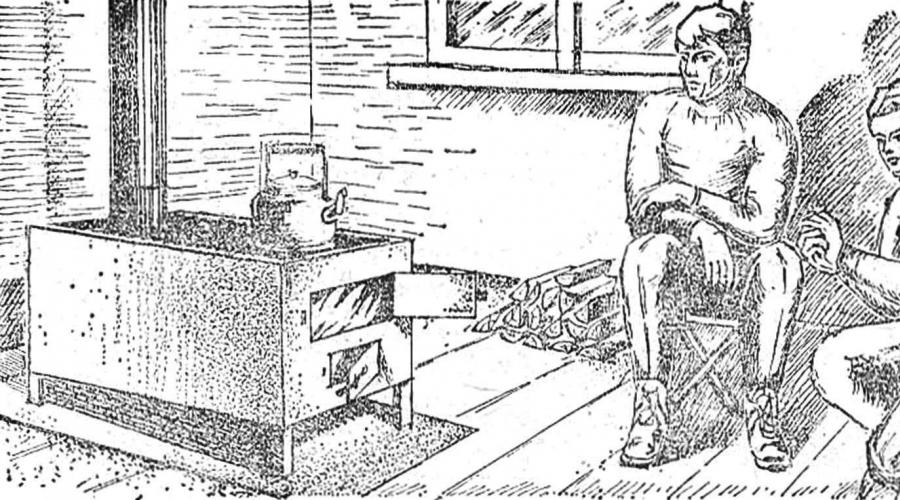

OVEN-PRESSURE COOKER

This stove quickly boils water and cooks or steams livestock feed. This requires much less fuel than other similar stoves. It can be portable or stationary.

The design of the furnace is shown in Figure 2. With a casing made of roofing steel, a galvanized or enameled cone-shaped tank with a lid is inserted. A pipe d 100 mm is connected to the stove, like a samovar, with a wind extinguisher. The pipe is put on the pocket pipe, and it is fastened to the side of the casing with rivets. A hole is cut in the casing of the iodine pocket. Two handles are attached to both sides of the casing for possible carrying of the stove installed on the poles. Door size - 150X170 mm. The ash pan tilts under the firebox door.

A tray with holes is placed at the bottom of the casing, which serves as a grate and protects the bottom from rapid burning. For the same purpose, an insert is placed on the pallet, the diameter of which is 20 mm less than the inner diameter of the casing. In the insert, strictly opposite the door, there is an opening equal to it.

(A - general form, B - front view, C - side view, D - version with a cone-shaped casing):

1 - casing, 2 - cone-shaped tank, 3 - pipe, 4 - pocket with pipe, 5 - handle, 6 - legs, 7 - ash pan, 8 - firebox door, 9 - pan, 10 - insert, 11 - blower holes.

The tank can be with or without handles. If it has handles, measure its diameter 20 mm below the handles and make a casing based on this diameter. If the tank does not have handles, then, stepping back from the upper edge of the sides by 70-100 mm, measure its diameter. The tank must fit tightly into the roofing steel casing: then hot gases do not leak out in these places, but heat the tank inside the casing.

The tank is made of galvanized steel or aluminum. The first is only suitable for heating water or boiling laundry. In the latter case, a tray with holes made of galvanized steel, aluminum or wood should be placed at the bottom of the tank so that the laundry does not burn.

The casing can be composite, consisting of several sheets, which are held together by welding or rivets.

The combustion hole is located 47 mm from the bottom of the casing. The door should be 10 mm larger than the combustion opening in length and width. Under the firebox, 4 holes d 15 mm are made to supply air to the iodine pan.

It is possible to make the casing from thicker metal - for durability, but its upper part is made round so that there is practically no gap between it and the tank.

If it is impossible to buy or make a cone-shaped tank, use a straight or large pan: then the casing is made cone-shaped. It may be straight, but to do this, the top is covered with a lid with a hole into which a pan with handles or other vessel is inserted.

A stove of this design is sometimes made of brick, adobe or adobe concrete. It is installed permanently, under a canopy. Over time, the adobe or clay concrete oven is fired, and a solid ceramic shard is formed from the inside. At proper care This type of stove lasts for a long time.

STOVE

This original stove can be made from two old steel barrels (Fig. 3A). In one there is a firebox with a ash pit and a water tank, in the other there is a heater that heats the room and produces steam if you pour water on the heated stones.

It's designed like this. Below is the ash pit, above it is the grate, and above is the firebox itself. A tank is inserted into the barrel. To use heat efficiently, a hole is made in the middle of the barrel and a pipe is attached. A second barrel is connected to it, the pipe of which is located at the very bottom. To keep this barrel at the required level, it is placed on a stand. A hole is cut in the side and closed with a lid. Through this hole the barrel is filled with stones. A hole is made in the upper end of the barrel for attaching a pipe onto which pipe sleeves d 100-120 mm are put on.

(A - general view, B - section of the stove, C - heater with drying chamber, G - heater with independent firebox):

1 - blower, 2 - firebox, 3 - casing, 4 - tank, 5 - pipe, 6 - door to the heater, 7 - stones, 8 - dryer.

In addition to its direct purpose, the heater can also serve as a dryer. To do this, a little less stones are placed, the hole for the door is enlarged, guide corners are attached inside on both sides, along which trays with food are pushed into the drying barrel.

A square or rectangular dryer (Fig. 3B) is more convenient, and it is easier to attach guide corners to it. The hole for placing baking sheets is made across its entire width, and the door is the same.

You can make a dryer with your own firebox (Fig. 3G), but you can also make a combined dryer by attaching a heater to the first barrel using a pipe.

A. SHEPELEV, engineer

Let's talk about a type of sauna stove called a skoropark. This model has fans and critics. Some consider it a convenient, innovative option for a steam room, while others are sure that the good old heaters are better. Let's understand the features of speed parks together.

1 - ash pan; 2 — retractable ash drawer; 3 — cast iron grate; 4 - firebox; 5 — steam superheater; 6 — closed heater; 7 — drain fitting; 8 — tank for hot water and the formation of saturated steam; 9 - steam line; 10 - safety valve; 11 — rotary handle of the tank lid; 12 — tank cover; 13 - chimney; 14 — water supply pipeline to the heater; 15—exit point for superheated steam; 16 — remote fuel channel; 17 — translucent screen; 18 — combustion control valve

A skoropark is not just a stove, but a wood-burning stove-conditioner designed to quickly supply hot steam. Such models are designed for steam rooms with a volume of 12-20 m3 and are capable of heating the room to required temperature literally in half an hour in summer and 40 minutes in winter.

The operation of the speed park, the diagram of which is clearly shown in the photo, is simple:

- Water is poured into the tank. The standard tank volume is 40-60 l. According to reviews, this is enough to take a steam bath and there is still hot water left for washing;

- Firewood is placed and lit in the combustion chamber. You already know how to properly light a stove. In order for the steam room to warm up as quickly as possible, kindling should be carried out with the damper and air supply valve open;

- Soon the water in the tank will boil and the steam will begin to actively warm up the steam room. According to reviews, condensation may appear on the walls during the process, especially in winter time of the year. But after the room warms up, it disappears.

1 — combustion control valve; 2 — translucent screen; 3 — remote fuel channel; 4 — tank for hot water and the formation of saturated steam; 5 — tank cover; 6 - chimney; 7 - filler funnel; 8 — Leidenfrost chimney heater; 9 — rotary handle of the tank lid; 10 - safety valve; 11 - steam line; 12 — drain fitting; 13 — steam superheater; 14 - firebox; 15 — cast iron grate; 16 — pull-out ash drawer

1 — combustion control valve; 2 — translucent screen; 3 — remote fuel channel; 4 — tank for hot water and the formation of saturated steam; 5 — tank cover; 6 - chimney; 7 - filler funnel; 8 — Leidenfrost chimney heater; 9 — rotary handle of the tank lid; 10 - safety valve; 11 - steam line; 12 — drain fitting; 13 — steam superheater; 14 - firebox; 15 — cast iron grate; 16 — pull-out ash drawer

As we can see in the diagram, pressure cookers can have a slightly different design, especially in terms of the presence of an open or closed heater and its location. The operating principle remains unchanged.

Important! The most dangerous place in the steamer there is a steam outlet. According to reviews, steam comes out under slight pressure, it's more like it bursts out of the spout of a kettle while boiling. However, to reduce the risk of being scalded by the hot steam coming out of the hole, it is placed against the wall of the steam room so that it does not flow towards people.

You can install a steam oven in such a way that the firebox door remains behind the wall, and the rest of the part from which the steam comes is located inside the steam room.

Based on user reviews, we can include the following advantages of speed park:

- quick heating of the steam room;

- there is no need to supply water with a ladle, everything happens without human intervention, steam is constantly supplied during the burning of wood;

- the atmosphere of a Russian bathhouse is created in the room, not a dry, but a wet steam room;

- by regulating the combustion of wood, opening and closing the dampers, you can regulate the temperature in the steam room - from low, comfortable for children, for example, to high, for those who are commonly called “steelworkers” - those who like to warm up to the fullest;

- the steam stove is no more dangerous than conventional sauna stoves, even safer, if, of course, you follow all operating rules;

- water vapor superheats to a temperature of 400°C. Not every sauna stove is capable of this.

Users include the following disadvantages of speed parks:

- in a small steam room it turns out too high humidity, uncomfortable. As you remember, such stove models are designed for rooms from 12 m3. If the steam room is smaller, it will not only warm up extremely quickly, but will also be filled with steam, which not everyone can withstand. However, you can always open the windows or door, regulate the burning of wood and reduce the steam supply;

- Many people miss the atmosphere from the heater, when water pours onto hot stones. In this case, you can buy a pressure cooker with a mini-heater open type or separately put a net with stones;

- It is recommended to dry the steam room after use. For this purpose, the stove will have to be lit again full power, open all ventilation ducts and a window. Many people think this unnecessary hassle;

- In the pressure tank, if you use tap water, sediment and deposits will quickly form; you will have to clean it regularly, otherwise the channels will become clogged.

The “Skoroparka 2017” stove is a further development of the TMF line of innovative wood-burning sauna stoves with continuous steam generation for instant cooking Russian steam bath. The oven is designed for a steam room volume of 12 to 24 cubic meters.

The price of the “Skoropark 2017” kit, in addition to the stove itself with a heater, includes a hot water tank with a capacity of 52 liters and the first shielded chimney starting module, cooled by steam.

This stove was made based on seven years of experience in the design, operation, criticism and wide public discussion of previous models of sauna stoves with continuous steam generation.

The oven has all the advantages of previously produced TMF steam ovens, namely:

The main tool for preparing a Russian steam bath is superheated water steam with a temperature of up to 400°C at the outlet of the oven.

Allows you to obtain and maintain the classic conditions of a Russian steam bath in the shortest possible time with minimal human intervention.

Issues unlimited amount superheated steam, unattainable for traditional ovens quality.

Allows you to quickly change the microclimate in the bath - from the softest and most comfortable to extreme

hot.

Time for heating the steam room to the temperature and humidity characteristic of a Russian steam bath summer period approximately 15-20 minutes, in winter about 30-40 minutes.

Many potential buyers of sauna steam stoves had previously refrained from purchasing them, since these stoves had a very unusual appearance, they did not have a heater, and the built-in tank for hot water and steam generation was not large enough.

Therefore, the main differences between the new Skoroparka 2017 stove and previous models are the familiar classic design TMF sauna stoves, a built-in non-ventilated heater and a tank for hot water and steam generation increased to 52 liters.

Since the Skoroparka 2017 oven has installation dimensions middle-class TMF sauna stoves, it can be easily installed in their place.

The design of the main components has changed significantly sauna stove with continuous steam generation: firebox, heater, water heating tank and superheater.

The fuel tank has become rectangular and more spacious. Now it is designed for a large length of firewood - up to 50 cm. The side and rear surfaces of the firebox are cooled by air convection. The stove received a built-in, unventilated heater with a capacity of 20 liters, heated from below by radiation from the flame and from the side by convection heat from exhaust hot gases. The heater allows you to sharply raise the humidity in the steam room for steam accents.

The tank for heating water and steam generation has increased significantly in volume - up to 52 liters. It is made from of stainless steel 2 mm thick. All sealed welds The tanks are T-shaped, placed outside, easily accessible for inspection and repairable at home. The tank is heated from below by radiation from the flame, and from the side by convection heat from the exhaust hot gases. Heating surfaces of the steam generation tank increased to 26 square decimeters, which increased the steam component of the furnace’s thermal power.

The built-in tank of the stove has a wide neck, through which it is convenient to pour water from a bucket, and it is easy to inspect and clean the tank. The tank neck has a sealed lid with a convenient lock. There is an emergency valve on the tank lid that reduces the pressure in the tank in the event of emergency situation.

To maintain a constant water level in the tank, it can be connected to an additional large-volume tank through either of two collapsible taps located on both sides of the stove.

The furnace's steam transfer unit has become a pipe-type one - now it is built into the chimney starting module, which is part of the furnace. Since the temperature in the chimney changes significantly depending on the intensity of the furnace operation, the temperature of the steam leaving the steam room from the superheater also changes along with it. This is done in order to obtain high-temperature steam for quick warming up of the steam room and moderately hot steam for steaming with a broom and preventing the steam room from drying out.

Between the hot wall of the chimney starting module and its outer casing there is a spiral guide along which steam from the boiling stove tank passes from bottom to top along a spiral path and is overheated to the desired temperature from the thermal radiation of the chimney wall.

In the first time after lighting the furnace and before the start of steam generation, the outer casing of the tube superheater is significantly heated for rapid heating of the steam room by thermal radiation. After the start of steam generation, its temperature drops sharply and thermal radiation from the tube superheater is almost not felt. On top of the tube superheater, at the point where the superheated steam exits, a conical deflector is installed for better dissolution of steam in the steam room air.

The Skoropark 2017 oven cooks steam bath with slightly higher relative humidity at the same temperature than previously produced steam ovens and without reducing the relative humidity during the steaming process.

3 modifications of the “Skoroparka 2017” stove are commercially produced: with a standard fuel channel and a stainless glazed door for firing the stove from the adjacent room, with a short fuel channel and a stainless glazed door for firing the stove from the steam room, and with a large translucent “Vitra” screen for firing the stove from adjacent room. All modifications of the stove are available in anthracite decor.

The design of the furnace is shown in Figure 2. A galvanized or enameled cone-shaped tank with a lid is inserted into a casing made of roofing steel. A pipe with a diameter of 100 mm is connected to the stove, like a samovar, with a wind extinguisher. The pipe is put on the pocket pipe, and it is attached to the side of the casing with rivets. A hole is cut in the casing for the pocket. Two handles are attached to both sides of the casing for possible carrying of the stove mounted on legs. Door size - 150 x170 mm. An ash pan is attached under the firebox door.

A tray with holes is placed at the bottom of the casing, which serves as a grate and protects the bottom from rapid burning. For the same purpose, an insert is placed on the pallet, the diameter of which is 20 mm less than the internal diameter of the casing. In the insert, strictly opposite the door, there is an opening equal to it.

The tank can be with or without handles. If it has handles, measure its diameter 20 mm below the handles and make a casing based on this diameter. If the tank does not have handles, then, stepping back from the upper edge of the sides by 70 -100 mm, measure its diameter. The tank must fit tightly into the roofing steel casing: then hot gases do not leak out in these places, but heat the tank inside the casing.

The tank is made of galvanized steel or aluminum. The first is only suitable for heating water or boiling laundry. In the latter case, a tray with holes made of galvanized steel, aluminum or wood should be placed at the bottom of the tank so that the laundry does not burn.

The casing can be composite, consisting of several sheets, which are held together by welding or rivets.

The combustion hole is located 47 mm from the bottom of the casing. The door should be 10 mm larger than the combustion opening in length and width. Under the firebox, 4 holes 0 15 mm are made to supply air under the tray.

The casing can also be made from thicker metal for durability, but its upper part is made round so that there is practically no gap between it and the tank.

Rice. 1. Do-it-yourself pressure cooker:

(L - general view, B - front view, B side view, D - version with a cone-shaped casing):

1 - casing, 2 - cone-shaped tank, 3 - pipe 4 - pocket with pipes, 5 - handle, 6 - legs, 7 - ash pan, 8 - firebox door, 9 - pan, 10 - insert, 11 - blower holes.

If it is impossible to buy or make a cone-shaped tank, use a straight or large pan: then the casing is made cone-shaped. It may be straight, but to do this, the top is covered with a lid with a hole into which a pan with handles or other vessel is inserted.

A stove of this design is sometimes made of brick, adobe or adobe concrete. It is installed permanently, under a canopy. Over time, an adobe or clay concrete oven is fired from the inside - a solid shard is formed - ceramics. With proper care, this stove will last for a long time.

A bit of bath theory: the most comfortable range of combinations of temperature and humidity in a Russian bath is determined as the sum of temperature values in degrees Celsius (for example, 65°C) and relative humidity in percent (for example, 45%). In our example, the sum of the values is 110, which corresponds to a comfortable value (110-120). We recommend maintaining the air temperature in the steam room in the range from 50°C to 70°C.

It turns out that the Russian steam bath is good and loved by everyone, but, unlike a dry-air bath, preparing it is long and troublesome. And why? But because a lot of “correct” finely dispersed steam can only be obtained from a mountain of hot stones.

And we thought, what if we exclude this longest procedure from the process of preparing a Russian steam bath - heating large mass stones up high temperature. And we did it! With the Skoropark stove you can get an unlimited amount of the lightest hot steam without any stones at all.

Just pour water into this stove and 15-20 minutes after it boils, go steam. The oven itself will prepare you a Russian steam bath. That's why it's called a steam oven.

Skoropark, Geyser and kettle - what's the difference?

We repeat - as a pair! Saturated heavy steam rises from the kettle, it burns, it is impossible to breathe!

We repeat - as a pair! Saturated heavy steam rises from the kettle, it burns, it is impossible to breathe!

It produces high-quality steam because it contains that same mountain of hot stones - in the inner and outer heaters. But maintaining a special microclimate in the bathhouse requires skill and experience, as well as constant control on the part of the person steaming.

The steam park constantly accumulates real and life-giving steam, which creates background humidity and correct, and most importantly stable, conditions. The air in the bathhouse is not too dry, it’s easy to breathe! The secret is that the steam is additionally heated (read more below in the section Construction of the Speed Park, and also watch the video).

Skoroparka - user reviews at Banyafest

The Skoropark stove has more than once become a participant in the international-class sauna event Banyafest. And there were always queues for the bathhouse with the Skoropark stove and it always received rave reviews from users. These two videos contain not just emotions, but the opinions of experts in bath procedures.

The Skoropark stove has more than once become a participant in the international-class sauna event Banyafest. And there were always queues for the bathhouse with the Skoropark stove and it always received rave reviews from users. These two videos contain not just emotions, but the opinions of experts in bath procedures.

Skoropark - questions and answers

- How is it different from conventional ovens?

Conventional sauna stoves only heat and dry the air in the steam room, but this stove constantly humidifies it. Because in this innovative oven, the main tool for preparing a bath is superheated water steam with a temperature of up to 400 C.

- Is she safe?

No more dangerous than other sauna stoves. Each sauna stove contains fire, hot metal, tens of liters of boiling water and scalding hot steam, which are dangerous only if handled carelessly. The Skoropark steam oven is absolutely safe if you follow the instructions in the operating instructions. - Does the steam come out of it under high pressure?

No. The steam comes out at about the same pressure as air from a child's balloon. - Can you get burned by the steam coming out of it?

The place where the steam exits the Skoropark furnace is inaccessible to accidental touch, and at a short distance from it the steam dissolves in the air, quickly cooling to a safe temperature. - How high quality steam does it produce?

The superheated steam from the Skoropark furnace is superior in quality to the steam obtained from any heater, which actually produces not steam, but a steam-water-dust mixture. One way or another, it contains visible water splashes and a suspension of invisible tiny droplets of water, as well as dust from stones and salts dissolved in the evaporated water. The superheated steam coming out of the Skoropark steam oven into the steam room is close to ideal. There is practically nothing in it except individual water molecules. The steam coming out of the Skoropark steam oven is so hot that it can ignite wood, paper and even melt lead. - How to use it to prepare a sauna?

Pour water into the tank and heat the stove as usual, in the mode maximum power. 15-20 minutes after the water boils, when the bath is ready, turn the stove to economy mode combustion. - How does she do it?

After the water boils, invisible superheated steam begins to flow into the steam room from the Skoropark steam oven. It quickly dissolves in the air, bringing into the steam room exactly the amount of heat and moisture that is needed to create the conditions of a Russian steam bath and soaring with a broom. At first, the steam condenses abundantly on the floor, on the ceiling, on the walls, on the shelves and thereby quickly heats them up. Then, after reaching the dew point temperature, they dry out and remain dry and pleasantly warm. - Perhaps the steam in the bathhouse becomes damp?

No. Relative humidity in a steam room in steady state does not exceed 40-60%. This optimal humidity for an ordinary Russian steam bath. - Where to put the extra steam?

The oven does not produce “extra” steam. When the air temperature increases from room temperature to 60 C, its moisture capacity increases several times. And all the steam dissolves in the hot air of the steam room. - How hot is it in a sauna with this stove?

With the Skoropark steam oven you can create any microclimate V bath - from the softest and most comfortable for gentle women and small children to extremely hot for the most seasoned “steel workers”. - How to make it hotter or cooler?

Simply increase or decrease the burning power of wood using a ash stove, as in any sauna stove. Eliminate unwanted overheating of the steam room by ventilation. To sharply increase the humidity, use a chimney heater - pour water from a ladle into it. It is recommended to use or a similar product from other manufacturers. - Where to get it hot water for washing and steaming brooms?

From the same tank where saturated steam is generated. - Why do you need a heater?

The presence of a large mass of hot stones is not necessary for this stove, so the role of the heater in this stove is auxiliary. The heater serves only for periodic steam accents (a sharp increase in humidity). - How to dry a steam room after a bath?

The superheated steam coming out of the Skoropark steam furnace has amazing ability dry wood and stone. To quickly dry the steam room after a bath, heat the stove at full power and fully open the supply and exhaust ventilation openings. - Does it require any special ventilation in the steam room?

Ventilate the steam room in accordance with the operating instructions. It is advisable to also make a hinged window in the steam room, as is expected in Russian baths. - Are there any recommendations for insulation and vapor barrier of a steam room?

Insulate the steam room as thoroughly as possible and provide a vapor barrier. - Is it possible to use it to warm up the washing area adjacent to the steam room?

The washing room adjacent to the steam room can be heated as usual by opening the doors to the steam room after it has been warmed up, provided that the washing room is thermally insulated and equipped with ventilation. - How can you use it to warm up a rest room?

You can warm up the rest room or other dry rooms adjacent to the steam room using a stove-mounted