DIY garden wooden chair drawings. We make a comfortable garden chair with our own hands. DIY wooden shell chair

Read also

In the considered option for making an Adirondack chair with your own hands, the design features are preserved, but there are no difficult carpentry joints. It will not be difficult to repeat the project by making wooden parts according to our drawings and assembling the product using screws.

The work uses planed 20 mm pine boards, galvanized screws 4.5x40 mm, bolts 10x60 mm with a square headrest and nuts with washers. A jigsaw and a grinder will speed up the process, and a hand router will allow you to carefully round the edges, but all workpieces can be cut with a regular hacksaw, and the burrs can be removed manually with sandpaper.

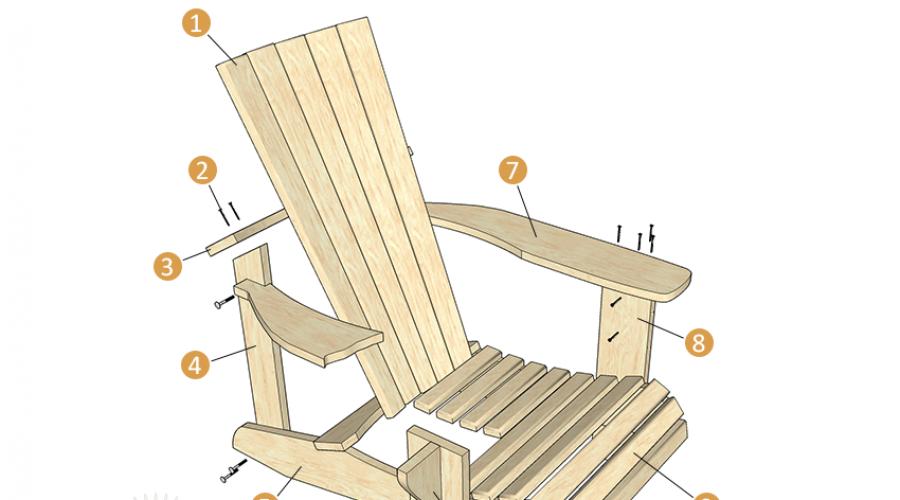

Adirondack chair structure: 1 - backrest bar; 2 - screws; 3 — upper cross member; 4 - posterior leg; 5 — side support (spar); 6 - bolts; 7 — armrest; 8 — front leg; 9 — seat bar; 10 — armrest support

Adirondack chair structure: 1 - backrest bar; 2 - screws; 3 — upper cross member; 4 - posterior leg; 5 — side support (spar); 6 - bolts; 7 — armrest; 8 — front leg; 9 — seat bar; 10 — armrest support

Manufacturing of parts

The most complex elements of the chair are the two side supports of the seat. Make a full-size template on paper for the spars.

Side support drawing

Side support drawing

Draw the bottom side of the part, raise the first perpendicular segment on the left and two more at corresponding angles to point A. Mark point C and draw a cutout for the cross tie as shown in the diagram.

Mark an angle of 75° with vertex C, extend its lower side with a line. Draw an arc with a radius of 116 mm, measure the angle at point D and connect them with a segment.

Draw a curve between points A and B using a square grid or an improvised pattern as in the photo.

Place the cut template on the board, avoiding large knots and leaving small ones away from the edges of the workpieces. Trace the contours and file the parts using a saw on straight sections, and cut out the curly contours with a jigsaw. Guide the tool blade in the direction of the grain so that the wood is less likely to chip.

Transfer the drawings of the remaining elements of the chair onto the boards, also using a template, or draw directly on the blanks and mark the next identical part according to the first one cut out.

Drawings of parts: 1 - upper backrest guide; 2 — lower cross member of the backrest; 3 — armrest (2 pcs.); 4 — armrest stop (2 pcs.)

Drawings of parts: 1 - upper backrest guide; 2 — lower cross member of the backrest; 3 — armrest (2 pcs.); 4 — armrest stop (2 pcs.)

The shape of the curves of the armrests is not structurally important; you can draw them by hand or using a pattern. Mark the second part in a mirror image so that the chips when sawing are at the bottom of the workpiece.

Parts drawing: 1 — backrest strip (7 pcs.); 2 — seat bar (8 pcs.); 3 — front leg (2 pcs.) 4 — rear leg (2 pcs.)

Parts drawing: 1 — backrest strip (7 pcs.); 2 — seat bar (8 pcs.); 3 — front leg (2 pcs.) 4 — rear leg (2 pcs.)

Sand the ends, joining similar pieces together if possible. Route the edges of the top surfaces of the armrests and backrest slats, or simply soften the sharp edges with a sander.

Assembling the chair

Wooden furniture always begins to rot from the joints, the internal surfaces of which cannot be processed on a finished chair. Therefore, cover the parts with 2-3 layers of antiseptic before assembly.

Most of the components of the chair are connected with screws; the guide holes for them are drilled with a combined countersink, selected according to the thickness of the screws. When they want to hide the caps, they are deepened and covered with glue plugs.

Place a scrap board on the table and place the left side support and front leg on top. Align the workpieces according to the drawing, mark the drilling points.

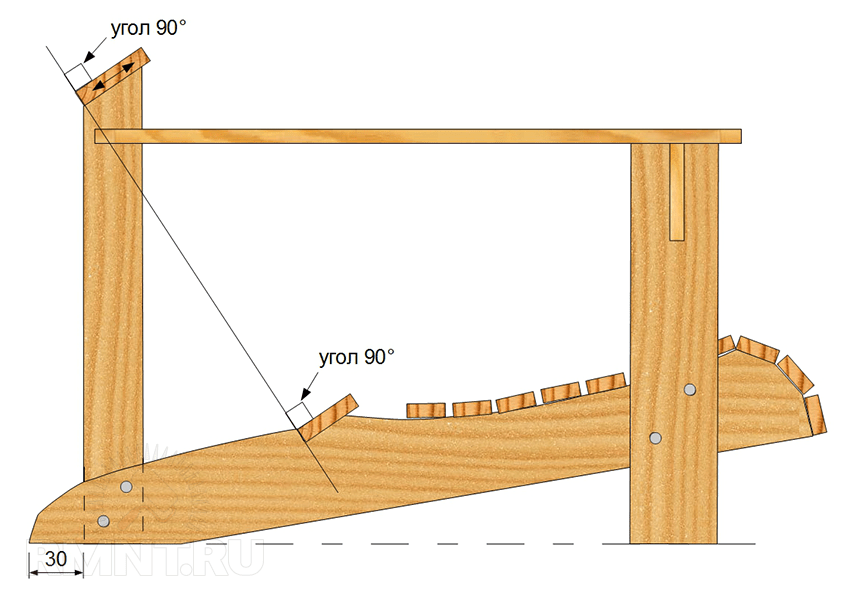

Chair side assembly diagram

Chair side assembly diagram

Make holes for the bolts and fasten the parts. Install the rear leg, placing it perpendicular to the bevel of the support. Assemble the right side of the frame in the same way. Connect the sides of the chair with the lower backrest crossbar and the first seat rail.

Install supports on the front legs, securing them with clamps for convenience. Screw the armrests with screws.

Secure the top backrest rail, aligning it with the bottom crossbar. Right now it is possible to correct possible millimeter-by-millimeter marking inaccuracies and uneven cuts.

Small errors can be eliminated by shifting the upper cross member and trimming the angle under it. In extreme cases, you will have to unscrew the bottom crossbar and adjust the cutout.

Mark the center lines on the cross boards and on the center backrest strip. Holding the latter at the top with your hand or grabbing it with a clamp, drill a pilot hole and tighten the bottom screw. Check the vertical position and secure the top of the rail.

Screw all the strips one by one at even intervals. Take a piece of string and tie one end to a pencil and the other to a nail secured at the junction of the seat and backrest. Draw a radius of curvature, cut the strips according to the markings and sand the edges.

Having adjusted the width of the last seat rail, put it in place. Inspect the assembled chair and sand down markings, chips and other defects. Carefully sand the top surfaces of the backrest and seat parts.

Coat the wood with oil if you want to preserve its natural shade. Use synthetic resin glaze to create an opaque colored surface.

Making a chair with your own hands from wood is easy and fun, and such furniture will fit equally harmoniously into the interior of an apartment or a small country house. This item will undoubtedly become your favorite vacation spot. In addition, you can make it yourself, even if you have no woodworking skills. To do this, you need a drawing, which you can make yourself or take a ready-made project. Otherwise, you will need to purchase materials for work and tools, and then begin this exciting process.

Choosing a model

There are many different options for wooden chairs. They all differ in type of design, design, and the presence of additional parts.

Table 1. Models of wooden products

| View, illustration | Description |

|---|---|

| Such structures are characterized by good wear resistance; they rarely deform even as a result of constant use. Such products are installed in dining rooms, offices and other premises. Antique-made furniture pieces are especially popular. To do this, they use various paints in cans and special design techniques. |

| These are very comfortable chairs, they have an aesthetic appearance. Compared to the previous model, this product requires more careful care, otherwise it will quickly lose its original appearance. Such designs can be placed in any type of room: in the living room, children's room, even in the kitchen. The model involves a solid frame, and the seat, back, and armrests are upholstered with soft material. In addition, the products differ in the degree of filling. |

Table 2. Product types by design features

| View, illustration | Description |

|---|---|

| These are very compact structures that have a folding mechanism, due to which they can be moved without any problems. Such designs will be appreciated by travelers and lovers of country holidays. | |

| Such products are ergonomic and suitable for small spaces. Similar designs come with a rigid frame or with soft upholstery. | |

| This product has an unusual appearance and is easy to manufacture. The process uses hardwood and wire. This chair is ideal for a cottage or country house. |

| Pieces of furniture of this type have a truly royal appearance, because they resemble a high throne. They are made of wood and then can be upholstered with soft fabric. An armchair with high support will fit perfectly into any classic-style interior. | |

| The main feature of this product is the arched legs. Making it yourself is quite difficult, because not every beginner will be able to achieve the correct rounded shape of wooden blocks. This activity requires certain skills, but the result will be magnificent, and the rocking chair will become a favorite resting place for all family members. |

Features of working with wood

Wood has long been considered the most popular material used in the manufacture of furniture to this day. This is due to a large number of positive qualities: wood is quite easy to process, even a beginner can handle this process. To prepare products, you can use simple tools; it is not necessary to purchase high-tech equipment.

You can purchase lumber at an affordable price in almost a hardware store, while ready-made furniture structures made from solid wood have a fairly high cost. That is why it is recommended to make such simple products as a chair with your own hands.

The main advantages of natural wood are:

- Environmental Safety. This material is non-toxic, therefore any harm to human health is excluded.

- Wood has good strength; it rarely deforms due to impacts and other mechanical influences.

- A structure of any configuration can be made from wood. In addition, such products will harmoniously fit into any room with any interior design.

In order to buy high-quality wood, you should consider the following features of the material:

- the humidity level should be no more than 12-13%;

- there should be no cracks, other damage or traces of mold on the surface;

- there should be a minimum amount of resin.

You should pay attention to such points when purchasing ready-to-use lumber. In some cases, it becomes necessary to dry the wood yourself, after which it will need to be treated with a special compound to protect against fungus.

Important point! It is better to purchase material taking into account the stock, because not in all cases it is possible to accurately calculate the required quantity. In addition, during the work there is a risk of damaging any part.

An equally important criterion is the type of wood. When making outdoor furniture, only varieties with the most durable texture are suitable. These include pine, rowan, larch, and oak.

If a heavy load is expected to be placed on the product, then it is better to choose linden or alder. Material of this structure is a little more difficult to process, but it will last for many years.

If the chair will be installed near any pond or swimming pool, then it is advisable to purchase fine-pored wood for manufacturing - this will avoid problems with deformation of the structure.

Prices for construction boards

Construction boards

Video - How to choose boards?

DIY garden chair

Before starting work on the manufacture of the chair, it is necessary to prepare the following materials and devices:

- cedar veneer;

- screws;

- wood glue;

- sandpaper;

- finishing varnish;

- drying oil;

- scotch;

- thick paper for patterns;

- plane;

- saw;

- milling equipment;

- hacksaw;

- drill;

- clamps;

- a simple pencil;

- measuring tape.

Prices for the range of drills

Preparing parts

Step one: First you need to make patterns for the design, marking the dimensions of the parts on thick cardboard. In our case, we should get the following elements:

- legs (4 pieces) – 2x25x78 centimeters and 2x7.6x53 centimeters;

- back - 2x28x91 centimeters;

- armrests - 2x12x40 centimeters (2 pieces) and 2x7.5x61 centimeters;

- connecting strip - 2x5x58 centimeters;

- additional strip (2 pieces) – 1.2x2x2.5 centimeters.

Step two: you need to cut out the parts from cardboard, and then transfer them to the wood (circle), after which you can saw the parts of the future chair. This should be done very carefully - the peculiarity of cedar boards is that they are susceptible to chipping, so cutting should only be done along the grain.

Connecting parts

Step one: Before starting assembly, all parts must be thoroughly treated with an antiseptic against fungus and dried. Only then can you proceed to the next steps.

Step two: We adjust the finished parts to the required size and at the same stage leave markings for the holes for fasteners.

Step three: Using a drill, we make holes for the fasteners, and then fix the parts together.

Step four: We fix the chair leg (back) at an angle of 90 degrees, and fix it on the other side in the same way. It is necessary to connect the sides of the structure.

Step five: We put up supports and then secure them with clamps.

Step six: install the backrest guide from above using screws, adjusting it to the transverse bar from below. We mark the markings with a simple pencil on all the crossbars, as well as on part of the back, after which we make a hole, holding the bar.

Step seven: We make curves by cutting the boards along the marked lines.

Step eight: The last step is to sand the entire surface of the chair using sandpaper. It is important to achieve perfectly smooth wood without burrs. Then you need to treat the product with heated drying oil and cover it with several layers of varnish.

Video - Simple wooden chair

DIY rocking chair

During the manufacturing process the following will be required:

- plywood sheets;

- cardboard;

- putty;

- dye;

- pencil;

- ruler;

- tape measure;

- sandpaper

- jigsaw;

- fasteners;

- drill.

Step-by-step instruction

Step one: preparing the details. The entire structure of the chair consists of two side parts, three horizontal connecting strips and 35 crossbars (needed to create the seat).

In this design, the most labor-intensive stage is the creation of the sidewalls, so it is recommended to mark them on cardboard, then cut them out, and only then transfer them to the wood.

Step two: To make the side parts, you need to take multi-layer plywood 3 centimeters thick. Then you should transfer the part from the cardboard to the plywood sheet and carefully cut it out with an electric jigsaw.

Step three: after which the side parts must be thoroughly sanded with sandpaper and their edges trimmed using a grinder or milling equipment.

Step four: From plywood of the same thickness you will need to make horizontal connecting strips 120 centimeters long and 10 centimeters wide. After which they need to be sanded with sandpaper, but you should not process the edges with a router.

Prices for the popular range of circular saws

A circular saw

Step five: you need to take a block of wood 5x2.5 centimeters and cut it into 35 pieces, 120 centimeters each. After which they should be sanded and the edges removed.

Step six: in the middle part of the outer arc of the sidewalls, at the back and near the legs, we mark the places where the horizontal strips are fixed. After which these marks should be duplicated on the other side. Then you can make holes for the fasteners.

Step seven: We make through holes on the end parts of the sidewalls, and then connect the frame with horizontal strips using screws.

Step nine: The last step will be thorough surface treatment. To do this, you must first fill all the holes and go over the wood with sandpaper. Then the surface is coated with a primer and several layers of varnish.

Country house chair made from pallets

You can make such a design with your own hands, spending only a few hours. During the work you will need the following:

- wooden pallets (you can buy new ones or disassemble old ones that are no longer used);

- hammer;

- nails;

- sandpaper;

- fastenings;

- primer.

Prices for wood preservatives

Impregnation for wood

Step-by-step instruction

Step one: in this case we will need to take two pallets of the same size, which will then be divided into parts. Moreover, if the design involves the presence of additional decorative elements, then more pallets will be needed.

Step two: The surface of the wood should be thoroughly sanded.

Step three: First you need to connect the parts of the seat and backrest together. At this stage, you can make a small cut to get the slope of the back.

Connecting the back and seat

Step four: It is better to fix all parts with screws, because connections made from nails are not very reliable.

Important point! Some craftsmen prefer to secure the design parts with glue. In this case, it is better to use heat-resistant options, so that the structure does not deform even in extreme heat and does not crack in the cold.

Lately, it’s not uncommon to see homemade interior items made from pallets when visiting someone. These are structures used to transport goods. , it turns out, it’s not so difficult to make, and in terms of its quality it can be even better than what you can buy in a store.

DIY wooden shell chair

To make the structure you will need the following:

- sheet of bent plywood;

- sandpaper;

- jigsaw;

- paints and varnishes;

- wood glue;

- fasteners.

Step-by-step instruction

Step one: Before you begin the process of making such an unusual chair, you should prepare a drawing. You should do it yourself, relying on ready-made diagrams. It is important to correctly indicate the dimensions of the parts.

Step two: We cut the parts along the marked lines. In order not to make a mistake, you can first practice on an unnecessary piece of wood, and only then move on to a plywood sheet.

Step three: then all parts should be varnished in 3-4 layers. It is better to choose high-quality paints and varnishes. In this case, you will need to first sand them with sandpaper. This is done in order to protect the structure from the negative effects of the environment.

Step four: You can connect the parts of the chair together using wood glue or self-tapping screws. If you choose the second option, it is important to screw the screws in as deep as possible so that they are not noticeable.

Decorating wooden furniture

An equally important stage in furniture manufacturing is decor. At the same time, it is not necessary to purchase expensive accessories for such purposes, because you can even use old, unnecessary things, pillows.

You can cover the back and seat with padding polyester, and stretch decorative fabric on top. Fasten the upholstery to a wooden structure using a furniture stapler. In addition, the back is sometimes decorated with buttons, which are covered with the same fabric. You can hide the marks from the staples with decorative edging or various laces.

At this stage you will have to show your imagination. You can decorate the surface using paint of different colors - this will allow you to get a unique product that suits your interior specifically.

Frequently asked questions from beginning furniture makers

Before you start making this or that design, you should familiarize yourself with the list of questions that beginners in this business often have.

How to cut parts?

When cutting longitudinal parts, it is better to use a circular saw, and for transverse parts, an electric jigsaw.

Prices for popular models of jigsaws

How to connect parts of the structure?

For connections that carry the main load, you will need to use euroscrews or self-tapping screws. In other cases, the parts are assembled using wooden choppers and glue.

Paint or varnish?

The choice of materials for processing depends on the quality of the wood itself. If the material does not have any defects, it can be treated with stain and then a layer of varnish can be applied. If stains appear on the surface, the wood must first be puttied, coated with a primer, and only then painted.

How to reduce the consumption of paints and varnishes?

Quite often, during final finishing, the paint is quickly absorbed into the surface, which is why bald spots remain on it. This happens because natural wood has a porous structure. That is why professionals recommend pre-treating it with drying oil.

Let's sum it up

Making a wooden chair with your own hands is quite simple. For beginners, the most important thing is to be patient and carefully read the instructions for preparing parts and subsequent assembly. Otherwise, this is a simple product that won’t take too much time to make. At the same time, compliance with safety precautions is an equally important point, so during work it is necessary to use protective gloves for your hands and goggles for your eyes.

Furniture stores offer a wide range of different pieces of furniture. They all have different shapes and designs, but it is much more interesting to make the product yourself. To make a wooden chair with your own hands, you will need the ability to use tools and the desire to work. And to make the task easier, there are many detailed drawings and lessons on making furniture.

Model selection

Making a chair from wood is a labor-intensive task, but anyone can do it. Having found the best option and some free time, you can get to work. The process itself consists of developing detailed drawings and preparing parts, which will then need to be combined into one whole. All instructions have a standard algorithm of actions, in which they first prepare the parts, make holes for fasteners, fasten the parts with screws and glue, and finally paint the product or varnish it.

The assembly of the chair must take place taking into account the established plan so as not to make a single mistake.

The work of making a wooden chair begins with determining its type. After all, not every type of chair can be made with your own hands; some of them require either mechanized actions or professional skills. After studying all the possible options, you need to choose the one that is right for you. It is unwise to take on a complex drawing right away, because in the end nothing will work out.

Chairs that you can actually do it yourself:

- Soft– the main thing here is the frame and upholstery. A correctly assembled product and neat upholstery are the key to success. This product can be placed in any place convenient for you to create a cozy corner for relaxation.

- Folding- This is a more complex option, but more functional. The frame of the product is made in such a way that it can be expanded and folded with some pressure. This chair will be the perfect item for a country trip.

- Kentucky- a simple version of the product, but very original in appearance. To create it, you only need bars and wire.

- Sliding– their design is more complicated than a regular chair, but a beginner can easily handle it. A sliding product will help save space in a small room and can replace a full bed.

- On wheels– the main thing in their design is to install stable wheels that will be able to move both an empty chair and a chair with a person sitting in it. This is a pragmatic option for disabled or elderly people.

- High back– these products can be hard or soft, the main thing is that they have a comfortable high back. Making it is no more difficult than a regular chair.

- Rocking chair– these products are not suitable for beginners, but for experienced craftsmen this is a completely doable task. The main thing in the design of the chairs is the arched bases, due to which they will swing.

Wood as the main material

Making a wooden chair can be quite easy if you choose the appropriate method. You can use an old armchair or stool if it is not possible to purchase individual parts. Even from a banquette you can make a small chair that any child will like. To create a classic chair, boards, bars, and logs are usually used. A solid wood product has a number of advantages over other pieces of furniture, because wood is an environmentally friendly material that is absolutely harmless to health.

Natural wood is not a cheap material, but it is precisely this that is the key to the quality of a homemade chair. Once you are confident that the wood is of high quality, you can begin creating a work of art. There should be no knots or cracks on solid wood or bars. All parts must be carefully polished, and only then proceed to assembly. A special coating will protect the material from insect attack and drying out.

For making a chair it is better to use oak, birch, ash or alder because they have a unique beauty. These materials allow the product to serve for a long time without squeaking or cracking. The beauty of the product can be emphasized by high-quality textiles that will be used for its upholstery.

The main advantage of wood is its environmental friendliness. This is what makes it different from other materials. It is widely used in construction because it is relatively easy to obtain and costs less than many other materials.

Wood is very durable and can compete even with metal. It does not lend itself to plastic deformation and withstands shocks and loads well. It is easy to work with, and therefore you can make a chair from wood yourself. The disadvantages of this material include intolerance to moisture and high temperatures. When exposed to water, wood swells and crumbles, so you need to first coat it with varnish.

Manufacturing workshops

Step-by-step instructions will help to minimize work time and save material consumption. The most popular step-by-step instructions for making chairs:

Chair for the garden

First you need to prepare the necessary tools and materials: electric saw, plane, hand router, hacksaw, screwdriver, drill, centimeter, screws, glue and boards. Procedure:

- The boards need to be cut out four legs (2 pcs. 2/2.5/7 cm, 2 pcs. 2/7.6/5 cm). Then you need to make the back size 2/2.7/9 cm, two armrest supports size 2/1.2/4 cm and rear support 2/7.6/6 cm. You will need a jumper to work. (2/5.1/5 cm) and planks (1.2/2/2 cm).

- Based on the drawings, you need to prepare the basic details. The most difficult thing is making the side supports. Therefore, before cutting, you need to print a full-size template of this element or draw it yourself on a large sheet of paper.

- To cut straight sections of parts you will need a power saw, and in order to cut out shaped elements, you need to use a jigsaw.

- First you need make wedge-shaped supports for the armrests, and then use glue and screws to attach them to the front legs.

- Next stage - sawing out the armrests and rear support.

- To smooth out all the unevenness of the part, they are cleaned with sandpaper. Then you need to cut off the ends of the support, press the back part to the back for support and mill along the edge of the surfaces.

- The assembly process of parts should begin after how they will all be treated with an antiseptic.

- Hind legs must be installed perpendicular to the bevel of the support, and after that the side parts of the backrest and the first seat bar are connected. To fasten the parts, you need to make holes for the bolts.

- Having installed the supports, you need secure them with clamps. The upper part of the backrest must be secured with screws, aligning it with the lower transverse part. The planks need to be cut according to the markings, first drawing a radius of curvature.

Having finished the work, you need to sand all surfaces and hide the screw heads with wooden plugs. You can treat a finished wooden chair with oil impregnation.

Shell

This unusual chair can be made with your own hands using drawings and diagrams, which it is advisable to create in a computer application and then print. This is necessary in order to obtain accurate dimensions and contours of all complex geometric parts. Procedure:

- All parts need to be cut out with a jigsaw. Movements should be smooth so that no unevenness remains. It is advisable to work with bent plywood after the master has previously practiced on a piece of unnecessary wood.

- It is important to varnish all elements so that they look aesthetically pleasing and are not exposed to external influences. But before that, it is necessary to sand all the unevenness and chips and clean the surface from dirt and dust. The varnish must be of good quality and must be applied in at least two layers.

The chair is assembled using wood glue, which secures all the parts. In order for this process to proceed without incident, you need to secure the gluing areas with clamps. Instead of the glue method, you can use self-tapping screws, but you need to screw them in deeply so that their heads are not visible.

From pallets

To manufacture this product you will not need drawings or preparation of additional elements. A homemade chair from pallets can be made in just a couple of hours:

- First you need to disassemble the pallets and remove old nails from them. They are unsightly and can cause injury.

- To give the pallets a decent appearance, they need to be sanded, after which all the parts must be assembled again.

Modern man is accustomed to surrounding himself with all sorts of amenities wherever he needs. And country estates are no exception: in private houses and summer cottages, we also want to spend time in comfort, without parting with the usual urban conditions. Therefore, you need to think about purchasing comfortable country furniture that will be comfortable and durable.

An excellent solution for garden plots would be a cozy country chair in which you can enjoy spending time in the fresh air. Choosing the right chair for your garden is a responsible matter; you need to take into account several features of garden furniture.

Differences between country chairs and ordinary furniture in apartments

The country chair is more practical; it is specially designed for outdoor use. It is made from special materials that dry quickly or do not get wet at all, do not fade in the sun and are not inferior in convenience and practicality. Also, such material is easy to clean and practically does not wear out.

A distinctive feature of armchairs and chairs for the garden is their mobility: they can be easily moved around the site, and some can even be folded and stored indoors. Therefore, by moving the chair to the right place, you can sunbathe in the sun or relax in the shade.

And if you are looking for a good massage chair for your cottage, then we recommend the US MEDICA store; they have the largest selection and variety of models, which will allow you to find the ideal solution. Modern massage chairs are not only comfortable and practical, but also beautiful and will easily help you quickly relieve fatigue. Comfort and modern design will help make the time spent in the chair truly enjoyable.

And if you are looking for a good massage chair for your cottage, then we recommend the US MEDICA store; they have the largest selection and variety of models, which will allow you to find the ideal solution. Modern massage chairs are not only comfortable and practical, but also beautiful and will easily help you quickly relieve fatigue. Comfort and modern design will help make the time spent in the chair truly enjoyable.

In the photo you can see what a massage chair will look like in the interior of a private home

It is worth understanding what options are available on the market, and what rules should be followed when purchasing.

Types of chairs for the garden

Manufacturers of country furniture provide a wide selection of interesting solutions that will suit even the most picky client. There are several main types of garden chairs, each with its own purpose and characteristics.

When purchasing, consider how you will use it to ensure it is as functional as possible. Below are photos of garden chairs, which are worth talking about in a little more detail.

Plastic chair for the garden

The most budget and unpretentious option. The variety of shapes and colors makes it possible to choose the right solution for relatively little money. A chair made of plastic cannot be called practical: it can crack or bend.

For health-conscious people, the plastic option may not seem the best, but manufacturers of modern furniture are trying to minimize the harm from plastic. Before purchasing, be sure to check the quality of the product; it should not emit unpleasant odors.

But due to their simplicity and low cost, they have become quite popular among buyers. They can easily be replaced with new ones if the old ones suddenly become unusable or your mood changes. If you like change, a couple of new armchairs or stools in a bright color will add variety.

Folding chairs

Since country furniture is quite often made of wood, it does not like high humidity. Therefore, in order to preserve your purchase for many years, it is necessary to put it under a canopy in rainy weather.

Furniture that can be folded and moved at any time is very mobile and convenient. This can be either a folding chair or a chaise lounge chair. Such models do not take up much space; when folded, they can be stored in a country house.

Sun loungers have migrated from beaches to summer cottages, as they are very comfortable and easy to care for. The material is durable and comfortable, and the ability to transport it only adds to its advantages. A bright and comfortable sun lounger on the site will give you the opportunity to get a gorgeous tan without visiting the beach or solarium.

Wicker chair for the garden

The consumable material for weaving is willow vine: it is practical and flexible at the same time, and wicker patterns look appropriate and beautiful in nature. By attaching a soft seat made of quick-drying fabric to the wicker structure, you can get a cozy option, ideal for relaxing in the fresh air.

The wicker chair is almost not deformed and does not wear out. With a little practice, you can make such a chair yourself; it will delight you for a long time.

Rocking chair for a summer house

If you want to take a break from the hustle and bustle and enjoy the surrounding greenery, a rocking chair is the right solution for you. This piece of furniture is made of wood, metal or willow: the material is safe and environmentally friendly.

This model should not be treated as an attribute of the elderly generation; modern rocking chairs are represented not only by classic versions, but also by unusual ones, somewhat reminiscent of a large swing. Thanks to the large number of options, you can buy a stylish chair that brings comfort.

Hanging chair

An unusual and original solution that looks very impressive and modern, ideal for suburban areas. It can be installed either on a special stand or suspended on brackets from a tree branch.

When choosing such a model, be sure to calculate the load on the fasteners to eliminate the possibility of breakage.

Find out detailed information about all characteristics in the store at the time of purchase. Products can be made from artificial rattan or bamboo, or woven from wicker. You have the opportunity to purchase hanging structures of any complexity in our store at a reduced price.

Do-it-yourself garden chair

Some models of chairs, despite their comfort and excellent appearance, are quite expensive. Not every middle-income summer resident wants to shell out for expensive models, and the first thought that comes to mind is to build something cozy and practical on their own.

Only an experienced craftsman can make an original and interesting chair with a complex design, but even a beginner can make a simple armchair for a summer cottage. An ordinary wooden chair fits perfectly into natural landscapes, it can be quite durable and practical if made properly.

To get a good result, you will need high-quality materials: hard woods such as oak or walnut are ideal. You will need not only boards and tools, but also special coatings: paints and varnishes for wood that resist rotting and getting wet.

Thanks to the processing of the finished product, it will last much longer, but even with a coating, you should not test the strength of the chair by leaving it in the rain. Cut out all the blanks according to the diagrams and instructions, treat them with a protective coating and assemble the finished chair.

However, not everyone likes to assemble furniture themselves; it is much easier to purchase ready-made products. Because chairs produced by companies specializing in the production of furniture inspire more confidence and guarantee a certain level of build quality.

In the store you can find a chair that matches the style and color. You can purchase both a set of compact portable armchairs and chairs for the dining area, and a small cozy chair for relaxing outdoors. There are significantly more variations.

Where to buy a chair for a summer house?

For people who do not want to tinker with boards and waste their free time, there are ready-made designs for every taste. By finding the optimal solution at a competitive price, you will enjoy the purchase.

But it is worth remembering that truly high-quality products cannot be cheap. It is advisable to purchase quality products during the discount season. Our store is holding sales on chairs for the garden: we offer you to purchase beautiful products at a favorable price.

Photos of chairs for the garden

The dacha plot serves not only for growing vegetables and fruits, but also for complete recreation in nature. This is best done in a luxurious and reliable chair made by yourself. We’ll talk about how to make it, what materials, tools and knowledge you’ll need below in the article.

If you like to tinker with wooden crafts, it will not suit you to install standard plastic chairs in your own area. Not only do they not fit into the natural atmosphere of the kingdom of plants and flowers, but they are also unreliable.

In addition, their design does not always contribute to proper rest. Therefore, in this case, we offer you a simple model of a wooden garden chair that will organically fit into the landscape of a suburban area. You will not need any special skills, such as for forging or welding metal products, although knowledge of carpentry is desirable.

Requirements for country wooden furniture

Special conditions of use require that the design meet certain parameters. Then it will last long enough in its original form.

Let's look at them in more detail:

- Immediately count on the fact that the chair needs to be made transportable, then in case of bad weather you can quickly hide it under. Of course, special antiseptics and paints used to protect wood will allow the structure to withstand atmospheric influences, but we advise you not to test it in such cases.

- Choose hardwood for garden furniture, including oak, beech and walnut.. Although the price of such materials is higher, the quality of the construction will be excellent. Aspen, larch, cedar and pine are also less susceptible to rotting, but the disadvantage of the latter is its sensitivity to impact. Even a small one is enough to create a dent on the chair, which will then be difficult to remove.

- Particular attention should be paid to protecting the material from atmospheric influences.. This is due to the fact that it can be exposed to sunlight for a long time and is often exposed to heavy rain, so you need to protect it from such tests.

Preparation for protection begins at the stage of harvesting wood for furniture making. Place the boards under a canopy in a stack, press them heavy on top and leave them to dry. It’s very good if you were able to immediately buy dry, high-quality lumber.

During operation, the workpieces must be sanded, impregnated with an antiseptic, and then with hot drying oil. At the next stage, dry them and coat them with varnish for exterior use.

- The texture relief and decorative cut of the tree will depend on the number of undeveloped branches and knots, i.e. the more there are, the better. Such a polished surface can resemble strolling grape snails.

Tip: when assembling a wooden chair for a summer house, the fasteners should be embedded in the material, then you will avoid puffs on clothes and scratches.

How to prepare for work

First of all, it is necessary to collect in advance all the tools that may be needed, as well as the material. In our case, all blanks, with the exception of the insert strips, will be cut from cedar boards, the thickness of which should be at least 20 mm.

| Details | Dimensions in mm:

|

| Material |

|

| Tools |

|

Manufacturing process

Preliminary stage - cutting out the main elements

Let's start work by cutting out the parts. To do this, we will prepare a detailed drawing, this will make it easier for us to continue making the chair.

Prepare the parts that will later become the back legs and back. To do this, try to carry out all work based on a detailed drawing with explanations, where there are appropriate tips. After checking it, mark and cut out the necessary blanks.

Cut out the rear legs, backs, seats and armrests from wide panels.

Get them by gluing boards that need to be matched to the color and texture of the wood.

Tip: select the grooves for the keys in advance, positioning them so that they are invisible after finishing cutting the parts.

- Cut out the back legs using a cardboard stencil. Attach the template to the blank that will be used as a leg and trace it with a pencil. Connect and tighten the two blanks together with masking tape so that you can cut both at the same time.

Carry out cutting with a small margin. To adjust parts to size, use a router or plane.

- Cut out the back. To do this, cut the workpiece so that the glue line falls exactly in the middle between the boards. Bevel the bottom end of the backrest at an angle of 12.5° to match the profile of the back legs. Round the top edge to a 9mm radius.

Having completed this work, you can begin assembling the product; for this you will need to cut out and adjust other parts in place.

We continue to work

Below are instructions for assembling and cutting the remaining elements.

Back and hind legs

- Drill holes for fasteners in advance to prevent the workpieces from cracking.

- To attach the rear legs to the backrest, use screws (50 mm) and glue.

- Connect the side ends of the backrest to the legs at an angle of 12.5°.

- Close the gaps between the parts with insert strips by making them of the appropriate profile. The ends of the planks and the opposite ends of the legs should coincide, which will mean the correct position of the backrest.

- Screw the inserts to the back with screws (l = 50 mm).

Tip: Keep in mind that the strength of the seat will depend on the arrangement of the boards, which should be placed from one leg to the other.

- Take a circular saw and cut the piece to width.

- Mark the sides of the seat, which are located at an angle.

- File the workpiece from the sides along the outer marking line. You don't have to clean the raw ends just yet.

- Select a groove at the rear end of the workpiece, tilt the bottom at an angle of 12.5°. This must be done because the seat will be located at an angle to the back. The joint will be tight, which is what we need.

- Round the front end of the seat.

- Screw the seat to the legs, sand its side edges, and adjust them flush with the back legs.

Seat

Front legs

- Cut out the front legs by bevelling their bottom and top edges 6˚.

- Screw them to the rear ones using screws (l = 32 mm), strengthening the connection with glue.

- Make a leg - a jumper between the legs so that the garden chair receives additional reliability and stability.

You need to cut it to size:

- attach the workpiece to the front legs and mark the fixing grooves. In this case, make the bottom of the groove at an angle of 12.5° to the face;

- select a depth of 9 mm from the high side of the groove;

- attach the jumper to the front ends of the legs using glue and screws (l = 32 mm).

Armrests

- Cut out wedge-shaped supports for them, bevelling their upper edges by 6°.

- Screw the supports to the front legs using glue and screws (l = 32 mm).

- Cut out the armrests, as well as the back support for them.

- Clean the ends of the parts with sandpaper.

- Cut the ends of the support at an angle of 30°, the top edge at 31.5°.

- Press the rear support piece to the back with clamps.

- Reinstall the armrests and loosen the clamps.

- Level the position of the rear support element, ensuring that the armrests are strictly horizontal.

- Tighten the clamps and screw the rear support to the backrest.

- Screw the armrests to the rear support, then to the wedge-shaped supports, and then to the front legs, using glue and screws (l = 50 mm).

Cover the recessed screw heads with wooden plugs and sand them flush. Take hot drying oil and saturate the wood with it, dry the product and varnish. You will end up with a comfortable, classic design with a beautiful texture that your family will appreciate.

Conclusion

A wooden chair for a summer cottage, made independently, will add the necessary flavor. The main thing to remember is that it is necessary to protect the structure from atmospheric influences so that it lasts for a long time. Only familiar tools and materials will be used in the work. The video in this article will help you find additional information on this topic.