DIY gas boiler repair. Full review of gas boilers Mora Top Mora top boiler turns on itself

Read also

Errors and malfunctions of Mora Top gas boilers

Gas boiler malfunctions Mora Top with display indication

Error E0- The boiler does not work

Gas does not pass through the gas fittings, the burner has gone out, the pump does not work.

Malfunction of the internal element of the control and regulation unit - Replacement of the control and regulation unit.

Error E1- Wall-mounted boiler Mora Top does not work

The switch does not close. The gas fittings do not open the gas passage, the burner does not ignite, the pump does not work.

1. Lack of water in the heating system, the heating water filter is clogged - Clean the filter.

2. Lack of water in the heating system, defective pump - Replace the pump.

3. Lack of water in the heating system, the pump is set to stage 1 - Set the pump to the recommended stage 2 or 3.

4. Lack of water in the heating system, there is air in the system - Add water to the recommended pressure. De-air the heating system by switching between heating and domestic water heating modes. Turn the boiler off and on again using the ON/OFF button.

5. Insufficiently movable or completely stationary axis of the flow switch heating water transmitting movement to the switch - Remove the switch box from the flow sensor body (pull out the stopper). By turning the boiler on and off again (turning the pump on and off), you can release the fixed axis. If the axis remains motionless, you can move it with your finger.

6. Large gap between the axle, the motion transmission arm and the switch - Correct the position of the plastic motion transmission arm.

7. Defective switch - Replace the switch.

8. The electrical connection circuit between the switch and the control and regulation unit is broken - Check the contact of the connector in the control and regulation unit. Check the wires to the switch.

Error E2- Mora Top wall mounted boiler does not work

The burner goes out as a result of a disruption in the gas supply through the gas fittings. When the flame goes out, the next ignition attempt occurs. The pump runs until the next ignition attempt, then stops.

1. Loss of burner flame as a result of a gas supply failure - Press the RESET button.

2. Loss of flame due to burner clogging (for example, only partially burns) - Clean the burner - outlet openings.

3. Electrode malfunction - the electrical connection line is broken - Replace the electrode.

4. Faulty ignition transformer or broken electrical connection line - Check and replace the ignition transformer.

5. Incomplete or broken contact in the electrical connection circuit of the ignition transformer and the control and regulation unit - Monitoring the contact of the connector in the control and regulation unit.

6. Don't correct connection phases when connecting the boiler to the electrical network - Make the correct phase connection.

7. Disconnecting the fuse reverse thrust when the temperature is exceeded as a result of leakage of combustion products (partial or complete obstruction of the chimney) - Control of the patency of combustion paths - exhaust pipes or chimney. To resume the boiler function, press the RESET button.

8. Defective reverse thrust fuse - Replace the fuse.

9. The electrical connection circuit of the reverse thrust fuse is broken - Check the electrical connection line.

10. The contact in the connection between the reverse thrust fuse and the control unit is broken - Check the contact of the connector in the control and regulation unit.

11. Disabling the emergency thermostat as a result of exceeding maximum temperature heating water. Gas supply to the burner is interrupted - Find out the reason for the water overheating.

12. Defective emergency thermostat - Monitor the emergency thermostat (must be closed at temperatures below 95°C), replace if necessary.

13. Violation of the electrical connection circuit of the emergency thermostat - Monitoring the electrical connection line.

14. The contact in the connection between the emergency thermostat and the control and regulation unit is broken - Check the contact of the connector in the control and regulation unit.

15. Incorrect position of the ignition electrode - Check the position of the electrode. The distance between the end of the electrode and the burner plate should be 3-4 mm.

16. Loss of flame due to failure to open the main gas valve - Check the contact of the main gas valve connector in the control unit. Replace the defective valve.

Error E3- Heating water temperature sensor is open. The Mora Top gas boiler does not work either in heating mode or in domestic water heating mode.

The burner flame goes out as a result of a disruption in the gas supply through the gas fittings; the pump does not work.

1. Malfunction of the heating water temperature sensor - Replace the temperature sensor.

4. The contact in the connection between the temperature sensor and the control and regulation unit is broken - Check the contact of the connector in the control and regulation unit.

Error E4- The domestic water temperature sensor is open - The Mora Top gas boiler continues to operate in heating mode and in domestic water heating mode.

The temperature control function is taken over by the heating water temperature sensor - problems with maintaining the temperature of the service water.

1. Malfunction of the domestic water temperature sensor - Replace the temperature sensor.

2. The connection contact of the temperature sensor is broken - Check the connection contact.

3. Temperature sensor electrical connection circuit failure - Monitoring the electrical connection line.

4. The contact in the connection between the temperature sensor and the control and regulation unit is broken - Check the contact of the connector in the control unit.

Error E5- Malfunction on the safety module - Mora Top boiler does not work.

The burner flame goes out as a result of a disruption in the gas supply through the gas fittings; the pump runs continuously.

1. Disabling the emergency thermostat as a result of exceeding the temperature of the heating water. Stopping the gas supply to the burner - Find out the cause of overheating.

2. Defective emergency thermostat - Monitor the emergency thermostat (must be closed at temperatures below 95°C), replace if necessary.

3. Violation of the electrical connection circuit of the emergency thermostat - Monitoring the electrical connection line.

4. The contact in the connection between the emergency thermostat and the control and regulation unit is broken - Check the contact of the connector in the control unit.

5. Non-connection of the pressure switch - obstruction of the combustion products outlet or air supply - Eliminate the cause of the obstruction of the combustion paths.

6. Defective pressure switch - when the fan is turned on, it does not connect - Replace the pressure switch.

7. Violation of the electrical connection circuit of the pressure switch - Monitoring the electrical connection line.

8. Contact is broken in the connection between the pressure switch and the control and regulation unit - Check the contact of the connector in the control unit.

9. Fallout or damage to the tube connecting the pressure switch and the fan - Check, if necessary, replace the tubes.

10. Fan does not accelerate, burnt out motor, hardened impeller bearing, mechanically blocked valve - Check fan functions, replace if necessary.

11. Fan electrical connection circuit is broken - the fan does not accelerate - Check the electrical connection line.

12. The contact between the fan and the control and regulation unit is broken - Check the contact of the connector in the control unit.

Malfunctions of Mora Top gas boilers without indication on the display

The boiler has insufficient power - the temperature of the heating or service water does not reach the set value

The Mora Top boiler operates constantly at minimum power.

1. Violation of the electrical connection circuit of the modulation coil - Monitoring the supply cable of the modulation coil. Monitoring the connector contact in the control and regulation unit.

2. Defective modulation coil - Replacement of the gas valve.

3. The maximum and minimum boiler power are incorrectly adjusted - Adjust the maximum and minimum boiler power.

The Mora Top wall-mounted boiler does not heat domestic water - the burner does not light

A. A small flow of domestic water.

1. The domestic water filter is clogged - Clean the domestic water filter.

2. The differential valve is stuck - Clean the differential valve.

3. Low water pressure - Increase water pressure.

B. The service water flow is sufficient, but the 3-way valve cannot be adjusted.

1. The tubes between the differential valve and the 3-way valve are clogged - Clean the connecting tubes.

2. Hardened three-way controlled valve - Swing the valve by turning the service water on and off. Replace the 3-way valve.

3. The membrane in the hydraulic part of the three-way valve is cracked - Replace the membrane.

B. The flow of domestic water is sufficient, three-way valve rearranged.

1. Large gap between the axis of the rearranged three-way controlled valve, the movement transfer arm and the switch - Adjust the movement transfer arm.

2. Defective domestic water switch - Replace the switch.

3. Violation of the electrical connection circuit between the switch and the control and regulation unit - Check the contact of the connector in the control and regulation unit.

The wall-mounted boiler Mora Top does not heat the domestic water insufficiently or does not heat the domestic water at all - the burner is on

The water flow is sufficient, the temperature of the service water is low.

The secondary heat exchanger is stuck in the hydraulic unit - Clean the heat exchanger.

Heating water flows out through the safety valve

A. After heating the heating water, the pressure in the heating system will increase by 2.5 bar - the water flows out through the safety valve; When the heating water cools, the pressure will decrease - less than the filling pressure.

1. Gas leak from the expansion vessel - Check the valve on the expansion vessel, replace it if necessary; increasing the pressure to the recommended value.

2. The membrane in the expansion vessel is cracked - Replace the expansion vessel.

B. The pressure in the heating system is increased by 2.5 bar due to the domestic water pressure.

The valve on the hydraulic unit for adding water to the heating system is not closed - close the valve.

The boiler does not ventilate well

The cap on the purge valve is tightened - Check the cap on the purge valve. He must be released.

__________________________________________________________________________

__________________________________________________________________________

____________________________________________________________________________________________________________________________________________________

_______________________________________________________________________________

__________________________________________________________________________

Wall mounted gas flow heating boilers MORA are designed for heating rooms with heat losses of up to 18 or 23 kW.

Standard boilers are used for space heating, and can also be adapted to heat domestic water in an attached storage water heater.

Combination boilers serve both for heating and for heating domestic water.

Removal of combustion products in boilers of this type carried out into the chimney or using a fan (“Turbo”)

Combination boilers |

Standard boilers |

||||||||

Boilers with combustion products exhaust |

down the chimney |

||||||||

"turbo" - version C 12 |

|||||||||

Boiler installation. Commissioning

When installing, commissioning and servicing the boiler, it is necessary to comply with certain rules established by state regulations and the requirements of the manufacturer. The user must carefully study the “Operation Manual”, “Warranty Card” and subsequently follow the rules set out in them.

Installation

To install the boiler, as well as for its further safe and economical operation, it is necessary to have a professionally completed project for the entire heating system. The boiler can only be installed by a specialized service organization authorized by the manufacturer. To operate the boiler, only the type of gas indicated on the type plate of the product can be used. An installed and assembled boiler must not be moved to a new location. The boiler must be installed so that the socket for electrical connection of the boiler is located in accessible place. If it is necessary to interfere with the operation of the boiler, be sure to remove the plug from the electrical outlet. The boiler is designed for mounting on a wall made of non-flammable material. There should be no objects made of flammable materials on the boiler itself or at a distance of 100 mm from it.

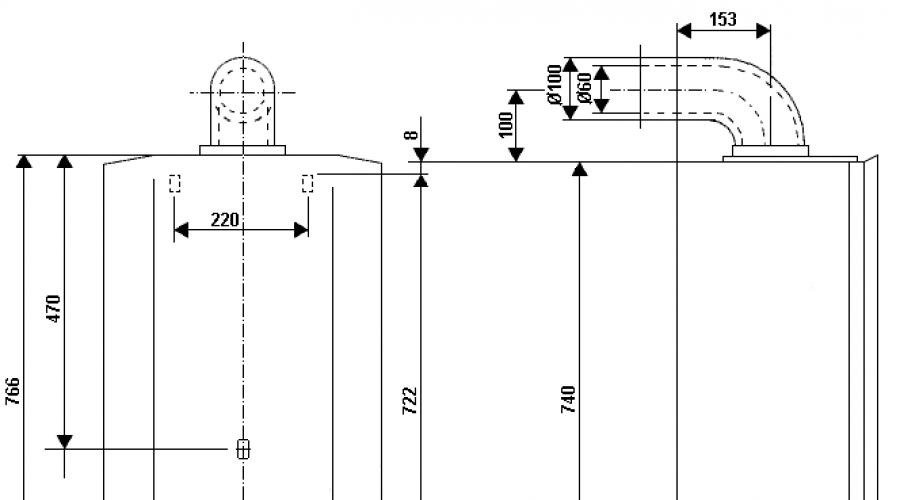

Main Dimensions

MORA 5118, 5122

MORA 5120, 5121, 5124, 5125

MORA 5119, 5123

Commissioning

Commissioning of the boiler can only be carried out by a specialized service organization authorized by the manufacturer, which has a permit (license) from the relevant State Supervision Services.

When putting the boiler into operation, a specialist from an authorized service organization must do the following:

check the tightness of connections

adjust the boiler (if necessary)

check all boiler functions

familiarize the User with the rules for servicing and caring for the boiler

warn the User about the need to comply safe distances from the boiler to walls made of flammable material, and how to protect them

Description of the boiler operation

Heating - with connected room thermostat

The boiler will start working when it receives a signal from the room thermostat about a decrease in temperature in the heated rooms.

After receiving the signal, the pump accelerates and the gas fittings open the flow of gas to the main burner. Heating water flows from the pump to the heat exchanger, where it is heated and then enters the heating system.

The heating water temperature is recorded by the heating water temperature sensor. Heating of heating water continues until the boiler is turned off when the desired (set) temperature in the heated rooms is reached.

Thus, the process is repeated as long as the boiler is connected to the electrical network.

The heating water temperature is set to the maximum value.

Heating - without room thermostat

The pump runs constantly. The operation of the boiler is controlled by a control and regulation unit in accordance with the temperature of the heating water, installed by the User control knob on the boiler panel

Heating of domestic water (combined boilers)

Heating of domestic water has priority over heating of heating water.

The flow of water through the domestic water flow fuse will introduce the boiler into the process of heating domestic water when the 3-way controlled valve changes the direction of movement of the heating water, and it passes through the secondary heat exchanger, and from there back to the pump. The heated heating water in the secondary heat exchanger heats up the service water.

After the end of the selection of warm domestic water, the boiler will automatically switch to the heating process.

Heating of domestic water (standard boilers)

Boilers intended for heating can also be used to heat domestic water in the MORA storage water heater. The storage water heater is connected to the heating system, domestic water is heated with warm water. heating water("WATER-WATER" system).

When installing the boiler together with storage water heater it is necessary to use a three-way valve with an internal microswitch, and room thermostat- these elements are supplied upon additional request.

Security systems

Safe operation of the boiler is ensured by the following elements:

Heating and utility water flow sensors- will not allow ignition of the main burner if there is insufficient water flow.

Emergency thermostat- closes the gas supply to the boiler if the maximum is exceeded permissible temperature water in the heat exchanger.

Backdraft fuse (boilers with combustion products discharged into the chimney)

If a blockage occurs chimneys(even partial), which will contribute to the entry (leakage) of combustion products into the room, then the backdraft fuse will register an increase in the temperature of the surrounding space and cause the gas supply to the main burner to close.

The boiler can be put back into operation by re-igniting the pilot burner only after the fuse has cooled down, i.e. after approximately 10 minutes.

Pressure switch (boilers with exhaust of combustion products "TURBO")

If the pipes for removing combustion products become clogged (even partially), or fuel combustion deteriorates (below the established norm) under the influence of a decrease in fan speed (voltage drop in the electrical network), or the fan does not work, then thanks to the pressure switch the boiler will not turn on, so that combustion products did not accumulate in the closed combustion chamber.

The backdraft safety device or pressure switch must be functional during boiler operation and their functions must not be affected by anything (for example, a change in position).

If the backdraft safety device or pressure switch fails repeatedly, you must contact an authorized service organization to troubleshoot the problem and carry out an operational test.

Boiler operation

Control Panel

The control panel in boilers MORA 5118, 5120, 5121, 5122, 5124, 5125 is located in the lower part of the boiler behind the casing and will be accessible if the casing is lifted up approximately 100 mm.

ON/OFF button

When you press the "ON/OFF" button, the boiler turns on or off. When the boiler is turned on, the button will light up.

Heating water temperature adjustment knob

Designed for installation required temperature heating water in the range from 30 to 80°C. If the room thermostat is functioning, the heating water temperature is set to the maximum value.

"SUMMER-WINTER" mode switch (installed only on combination boilers)

When the switch is set to the "WINTER" position, the boiler is prepared for operation - heating heating water or domestic water.

When the switch is set to the "SUMMER" position, the boiler is only ready for the process of heating domestic water. This mode is mainly used in summer period when there is no need to heat the premises.

Thermometer

Shows the temperature of heating water leaving the boiler.

For boilers MORA 5119 and 5123

- thermometer installed on the boiler casing

- the "ON/OFF" button and the heating water adjustment button are located on the left, under the boiler

Preparing the boiler for operation

When preparing the boiler for operation, you must do the following:

check the water pressure in the heating system

open the inlets and outlets of heating water (or utility water) - (valves under the boiler)

open the gas supply to the boiler

When putting the boiler into operation, a qualified specialist from an authorized service organization must:

Check the pump mode - it should be set to stage 3.

Start the boiler according to the instructions

Check the pilot burner flame

Extinguish the pilot burner flame - after 5-7 seconds the main burner should go out

After the pilot burner goes out, check the response time solenoid valve in the gas fittings - after 40-50 seconds a characteristic click should be heard.

Check the function of the boiler switching to reduced power

Perform burner control:

check the main burner, the flame should only be near the outlet openings,

check the stability of the flame along the entire length of the burner plates.

Starting the boiler

The boiler is a fully automatic device. The main burner is ignited automatically by a signal from the boiler automation system from the ignition burner, which is constantly burning. The pilot burner is ignited manually. As additional equipment You can install piezo ignition on the boiler.

Boiler ignition sequence

Set the gas valve control knob (located under the boiler casing) to the “pilot burner ignition” position. Keeping the handle pressed in this position, manually light the ignition burner (if there is an additionally installed piezo ignition, press the piezo ignition button several times until the ignition burner lights up);

After igniting the pilot burner, continue to hold the gas valve button (approximately 5-7 seconds). Then release and make sure stable combustion pilot burner;

turn the gas valve handle into operation mode. The boiler is ready for operation;

turn on the "ON/OFF" button - the button will light up. In the "Winter" mode, the main burner will light up; in the "Summer" mode, the boiler will start working if hot water is drawn off.

Decommissioning of the boiler

Long term

Long-term decommissioning of the boiler is carried out during maintenance and repair:

unplug the power cord from the socket

close the gas and water supply taps

Short-term

move the ON/OFF button to the "OFF" position

leave the power cord plug in the socket

Leave the gas and water supply taps open

Prevention. Maintenance. Safety precautions when operating the boiler

Before starting operation, the User must carefully and thoroughly study the “Operation Manual.”

Any manipulations or operations with the boiler that do not meet the requirements of the “Operation Manual” are unacceptable.

Installation, commissioning, preventive inspections and troubleshooting must be carried out only by trained specialists from a service organization authorized by the manufacturer, which has the necessary state approvals and licenses. Information about all manipulations and operations with the boiler must be entered in the “Warranty Card”.

During operation, the User must periodically monitor its operation.

MORA gas boilers should not be used for purposes not specified in the “Operation Manual”.

The boiler must be turned off if work is being carried out in the room where it is installed that could change the environment (for example, working with paints, adhesives, etc.). The boiler can be turned on and used only after such work has been completed and the room has been thoroughly ventilated.

Modern gas boilers are quite complex technological equipment. With proper care and proper handling, the gas boiler will serve for a long time without any failures. However, even the most expensive and functional equipment has its own resource, after which it begins to appear. various kinds malfunctions.

Knowing the main causes of problems and how to eliminate them, you will be able to repair your gas boiler with my own hands. This is a very painstaking, responsible, but in most cases relatively not hard work.

First of all, it is necessary to establish why any malfunctions may occur in the operation of gas heating boilers. A number of different factors can lead to problems.

Electricity

Modern gas boilers are equipped by various means automation. These products, in turn, are powered by electricity. And, despite the fact that it is already the 21st century and systems for using alternative sources energy, the problem of stability of power grids remains relevant for many regions, especially for remote villages and all kinds of holiday villages.

A sudden shutdown or a strong surge in electricity is one of the main enemies of any modern gas boiler.

To avoid all the associated troubles, buy a high-quality stabilizer in advance. Do not spare money to purchase this device - cheap models are of little use, so it is better to immediately allocate funds to purchase a good stabilizer from famous manufacturer. Rest assured, if the automation breaks down, you will spend much more money on its repair and replacement.

Water

Often used at home wall models gas boilers. Such devices are simultaneously responsible for heating the premises and preparing hot water.

The design of wall-mounted boilers includes a flow-through heat exchanger. Low quality hard water with various inclusions - main enemy gas boiler heat exchanger. Moreover, under the influence of low-quality water, the heat exchanger can fail in just one season.

To prevent such damage, install special filters. The best option– a complete water purification system. With it, your boiler will work for as long as possible, and using purified water is much safer for your health.

Installation errors

Any knowledgeable person will tell you: installation and piping of gas heating equipment should only be carried out by qualified specialists.

Even the slightest errors at the stages of installation and connection of equipment can lead to irreversible consequences. For example, incorrectly performed piping in the case of a cast iron gas boiler with a power of more than 50 kW will lead to the fact that when low temperatures the unit will simply crack.

Therefore, if you are not an experienced gas installer, entrust the installation of the boiler to professionals - this way you will save yourself from many problems in the future.

Weather

Unfavorable atmospheric phenomena can also lead to many different problems. During frosty winters, people turn the heating on almost all the way full power. This leads to a significant decrease in pressure in the gas pipeline system. As a result, boilers cannot reach their full potential.

You will not be able to solve this problem on your own - you still cannot explain to your neighbors that their actions are only aggravating the situation. As a solution to the problem, you can install an additional boiler that runs on a different fuel.

Is it worth repairing the boiler yourself?

A modern gas boiler is a complex and potentially dangerous system. The main danger of such units is the risk of a gas explosion in case of improper handling of the equipment or untimely elimination of various problems.

Various types of automation are responsible for maintaining the operation of the gas boiler at an optimal level. An inexperienced user is often unable to understand its structure. Therefore, to resolve serious problems, it is better to immediately invite specialists.

On your own, you can try to eliminate only visible damage and various contaminants that have led to the failure of the pipe, chimney and other parts of the boiler.

There are a number of typical problems that, in most cases, you can fix yourself. Problems will also be listed, in the event of which you can only protect yourself until a specialist arrives.

If there is a distinct smell of gas or smoke in the room, immediately turn off the boiler and leave the room, opening it for ventilation.

Call a specialist immediately. Trying to solve a gas leak problem on your own without the necessary skills is extremely dangerous and unwise.

Flame sensor failure

If the combustion sensor or gas supply pipe is broken, turn off the boiler and turn off all gas valves and allow the unit to cool completely.

After some time, return to the room to check for the smell of gas. If everything is fine with the draft, try turning the boiler on again. If there is no traction, immediately call a repairman.

Boiler overheating

Overheating is one of the most common problems with modern gas boilers. The reason for this may be a malfunction of automation equipment or a clogged heat exchanger.

Automation repairs cannot be handled without the appropriate knowledge.

You can clean the heat exchanger yourself. The most common materials for the manufacture of heat exchangers are copper and stainless steel. Cleaning them usually isn't a problem, but still be careful.

To clean the heat exchanger, simply remove it and thoroughly clean it with a wire brush. In case of copper heat exchanger, it is better to replace the brush metal sponge used for washing dishes.

Charge fan malfunctions

The problem with fans is their bearings. If your boiler fan stops developing the set number of revolutions, try to fix the problem as soon as possible.

To do this, remove the back of the fan, remove the stator and lubricate the bearings. Perfect for lubrication machine oil, but if possible it is better to use a higher quality carbon composition with heat-resistant properties for this.

It can also lead to problems with the fan. turn-to-turn short circuit. Only a specialist can cope with troubleshooting this problem. Submit the stator for repair to replace the winding, or immediately replace the faulty unit with a new device.

Chimney problems

Often, various malfunctions in the operation of the gas heating boiler Causes excessive clogging of the coaxial chimney.

Remove the chimney and thoroughly clean all its components of soot. This way you will not only return the previous level of efficiency of the unit, but also significantly increase the coefficient useful action boiler

2017-06-20 Evgeniy Fomenko

Basic error codes

If a malfunction is detected, the Mora boiler itself signals this. The error is displayed on the display and, knowing the decoding of error codes, you can easily understand what the problem is.

Such errors are corrected by checking the corresponding unit and replacing failed parts:

- Error e1 - low pressure in the system

- Error e2 - unit overheating

- Error e3 - reserve

- Error e4 - water temperature sensor is faulty

- Error e5 - the memory unit has failed

- Error e7 - control potentiometer is broken

During boiler operation, minor errors related to temperature parameters are possible:

NTC temperature sensor for Mora boilers

NTC temperature sensor for Mora boilers Other faults

When not very serious problems, LED button flashes yellow with a frequency of 1 Hz. In this case, there is a possibility that the boiler itself will correct the malfunction, but in this case its power will be reduced.

In the event of a serious malfunction, the LED button constantly lights up yellow, and the boiler stops heating and turns off after 9 seconds. In such a situation, you will have to call a specialist.

Design and principle of operation of Mora boilers

Czech gas single-circuit and double-circuit Mora boilers are available in three modifications. Meteor - double-circuit flow wall-mounted boilers heating. The principle of forced air injection is used, as well as smoke removal - using a fan.

It has a modular burner, which makes it possible to adjust exactly the power required for operation. There is also a setting for the pressure of the hot water supply and the heating system - you can set limit values that will not allow the burner to ignite.

Gas boiler Mora Sirius

Gas boiler Mora Sirius

Titan - this model is equipped atmospheric burner and requires a traditional chimney. The water is heating up flow method, and gas and water pressure sensors ensure safety. There is a special function that prevents the coolant from freezing - heating is automatically turned on if the temperature drops to +5 degrees. Not sensitive to changes in the power system.

Sirius - this line includes both single-circuit wall-mounted flow devices and their double-circuit analogues. Models available with both open and closed camera combustion. They can be connected both conventionally and horizontal chimney. Consumes no more than 1-2 kW of electricity even at maximum load.

Our company offers its services for urgent repair of boilers for equipment located throughout Moscow and the Moscow region. We carry out troubleshooting professionally, quickly, efficiently, according to affordable prices, with a guarantee. The AIS company currently has more than 10 years of experience in boiler repair and can offer not only simple boiler repairs, but also annual maintenance and repair of breakdowns of any complexity.

Our engineers and craftsmen have a wealth of knowledge and skills, as well as professional tools without which boiler repairs cannot be carried out professionally.

We offer boiler repair:

Specialists top class with extensive work experience;

- Processing your call regarding boiler repair in the shortest possible time;

- You will immediately find out over the phone the price for the repairs being carried out; we answer openly and honestly from the very beginning;

- Quick departure for boiler repairs in Moscow and throughout the Moscow region;

- Diagnosis of faults is carried out using only professional tools;

- Boiler repairs are carried out using original spare parts;

- Boiler repairs are carried out necessarily with a subsequent guarantee for the work done and spare parts.

Our specialists service center will repair any faults; for them there are no difficult tasks that cannot be solved.

The professionals of our company will repair the boiler as quickly as possible, 90% in one visit.

Common causes of malfunction leading to boiler repair:

Installation heating system was carried out unprofessionally, without complying with the conditions;

- failure to comply with the manufacturer’s recommendations for the operation of heating equipment;

- the necessary technical manipulations are not carried out service which must be carried out annually;

- additional ones are not used protective equipment for example a voltage stabilizer.

Common boiler malfunctions and repairs:

The flame in the burner goes out when the unit starts;

A lot of soot is formed;

Loud popping noises are heard when the equipment is operating;

The boiler does not turn on and does not respond to the reset button;

The pressure in the heating system constantly drops.

If you have problems with the operation of your boiler equipment, call us, the specialists of our company will come to you urgently in order to repair heating boilers from any manufacturer as soon as possible. Specialists constantly improve their knowledge and increase their experience by going out to repair heating boilers of any degree of complexity.

AIS company always strives for fruitful cooperation with its clients. Personal approach to each client, discounts, competently performed complex work, guarantees for work.