The distance between the posts of the fence boards. The optimal distance between the fence posts from corrugated board. Mesh Fence Decor Ideas

Easy to build with your own hands. In order for the construction of the fence to pass without overlays, it is necessary to foresee all the technical points in advance. The basis of the fence - supporting pillars and logs, this is the most time-consuming part of the work. The maximum possible distance between the corrugated fence posts will significantly reduce the cost of the fence. At the same time, too long runs will make it difficult to install the corrugated board on the crate and reduce the strength of the structure. The optimal distance between the fence posts is approximately 2.5 meters. Depending on the design features of the fence, this figure may vary in one direction or another, but not more than 3 meters.

What materials are fence posts made of?

The distance between the fence posts depends on the material and method of mounting the supports. The stronger the pillars are installed, the greater the distance between them can be. Also, the distance is reduced if the height of the fence is 2.5 meters or more.

Brick supports for the fence have the greatest bearing strength. A fence is also erected using a metal pipe, a metal profile or on piles.

Pillars must be placed in the corners of the site and in places where the fence changes direction. The locations of the supports are marked with pegs, a rope is pulled between them, and if a straight line is violated, they are aligned. Plan the gate and gate.

brick supports

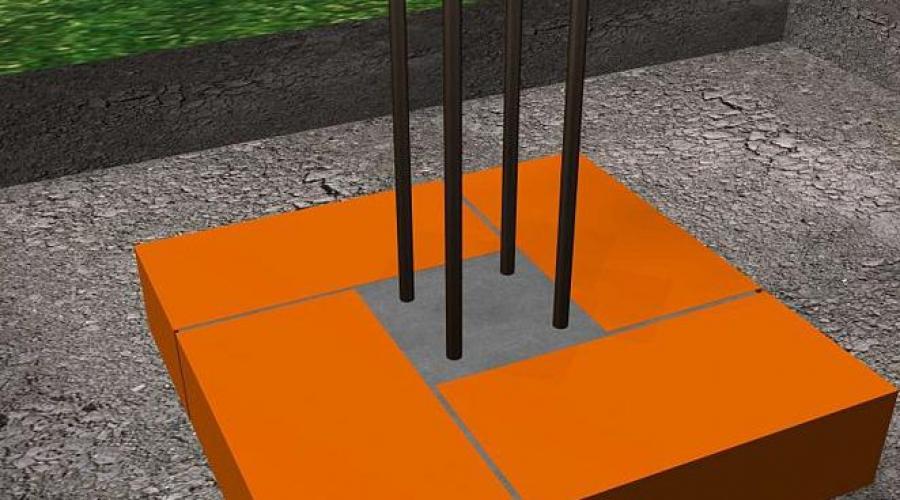

Brick columns as a support look beautiful, are not subject to corrosion, they do not need to be painted. This solid structure requires the construction of a solid foundation, otherwise the fence may be skewed.

For the base of the masonry, pipes with a diameter of 57 mm or 2-4 thick reinforcement bars are used. The distance between the finished corrugated fence posts will be 2.6 meters, and between the pipes - 3 meters. It is better to make supports from facing bricks - it looks more profitable. Expenses are planned based on the calculation of 80 pieces per column.

for brick pillars

A strip concrete foundation with a width of 0.6 m is equipped under it. Penetration into the ground is at least 0.5 m plus 20 cm sand cushion. The protruding part is 25-30 cm high. It can be made of concrete or laid out of brick, later lined with natural stone, tile, plastered or painted.

To protect the edges of the profiled sheet from below and from the sides, a groove is provided in the base and in the columns. It is more difficult to do this in columns. Can be used for laying half bricks. After installing the corrugated board on the logs, the grooves are sealed with cement.

They dig a trench, depending on how far metal pipes are installed between the fence posts (the usual figure is 3 meters). They are dug in to a depth below the freezing level by 25-30 cm. Then 2 layers of roofing material are placed in the trench to waterproof the foundation. A frame of reinforcement 10 mm thick is knitted at a distance of 5 cm from the edges of the pit. Formwork is installed, poured with M300 concrete. Plumb control supports.

If there are ground drops on the site, then the foundation tape is divided into segments with a height difference of 10 cm.

Construction of brick pillars

Brick pillars under the corrugated fence are laid one and a half or two bricks wide.

Their height is from 2 to 3 meters, from above the masonry is covered with metal caps or a cement ramp. During masonry, metal mortgages are installed for fastening the lags. The distance between the fence posts made of brick pillars in the final version is 2.6 meters. This is taken into account when cutting the profile of the crate and selecting the width of the sheet.

Supports from a metal pipe

Use a round metal pipe with a diameter of 60 mm, metal thickness 2 mm. For a high fence, it is convenient to take pipes of 11 meters and cut them into three parts.

The length of the pipe section for the support is equal to the height of the fence plus half of it for the underground part. If the fence is 2 meters high, then 1 meter of the support goes underground, the total length of the pipe segment will be 3 meters. In this case, the distance between the fence posts from corrugated board can be made maximum - 3 meters, and even a little more (depending on the layout on the ground).

Installation of supports from a metal pipe

Previously, pipes from above must be welded or other plugs must be installed so that atmospheric precipitation does not get in. If a cross of reinforcement is welded onto the lower edge of the pipe, then the stability of the support will increase.

Install corner posts, stretch the twine at a distance of 30 cm from the ground and along the top. Mark out places for pits under the posts under the fence from corrugated board. Pits are made with a manual or electric drill to a depth of 1-1.5 m with a diameter of 30 cm. It is recommended to wrap the walls with roofing felt - this way the earth will not crumble. This will also protect the supports from deformation during soil subsidence: the soil will slide over the roofing material.

Crushed stone or gravel is poured at the bottom - 20 cm, a pole is installed (it should not pierce the pillow, otherwise corrosion is possible) and the concrete solution is poured to ¾ of the depth. Align the support on a plumb line, wedge it with pieces of bricks, top up to the top. If there is a slight skew, then it can be leveled until the concrete has hardened. They are concreted flush with the ground, and it is even better to make a formwork of 40-60 mm and raise the upper part above the ground.

Composition of concrete: 1 part cement, 4 parts sand, 4 parts gravel, 4 parts water.

The final solidification of the solution occurs within a week. Only after that proceed to the installation of the crate.

If there is little precipitation (annual norm up to 300 mm), the soil is sandy or loamy, then it is possible to do without concreting. The pipe is dug in by one third, wrapped with roofing material or doused with molten bitumen. The soil is poured in portions of 20-25 cm, thoroughly tamping each layer.

In the country version, it is possible to build a fence from corrugated board with pillars from a free-flow asbestos-cement pipe with a diameter of 100 mm. Its length is 3.95 m. Cut in half, two columns are obtained. The material is cheap but fragile.

Metal profile fence posts

Use a profile 60x60. Its length is 6 m or more, so you should take care of the delivery method in advance. Install supports from a metal profile in the same way as from a pipe. Its advantage is that it is easier to mount logs on it, you can make a butt joint. It is more aesthetically pleasing, the strength of this design is increased by attaching the profiled sheet to the pole.

Ready-made poles for profiled sheets from a local manufacturer are sold on the market: They already have a muffled top, a heel is welded (you can put it on a sand cushion), there are paws for lags with holes. The price is comparable to the price of the profile plus welding costs. The diameter of the pit for such supports will be two sides of the thrust bearing, and the distance between the fence posts can be 2.5-3 meters.

Installation of a fence from a profiled sheet on piles

Ready-made piles for the foundation are expensive: 2000-2500 rubles apiece. But if suddenly you got used material, then you won’t find the best supports. Their strength is very high, there are no costs for concreting and excavation. What is the distance between the fence posts on screw piles? Again, it all depends on the height of the structure. With a fence height of 2.5 m, too large runs should not be made, since the profiled sheet fence has a very large windage.

Option for craftsmen - homemade piles. The pipe of the required length is flattened at the end into a spear. From a sheet of steel with a thickness of 3 mm, an autogenous cut out a ring in three pipe diameters. Inside, a circle is cut out the size of the pipe diameter plus 15%, a groove is cut, bred into a screw and welded onto the pointed end of the pipe.

Lathing installation

After the concrete has hardened, the installation of the crate begins. Logs can be wooden or metal.

Logs made of wood are short-lived and have less strength. Therefore, we consider in more detail the crate made of metal. A profile 30x30 or 40x20 is used (attached with the flat side to the fence), metal thickness 1.5-2 mm. Sometimes a metal corner is used, but it is inconvenient to attach a profiled sheet to it.

If the height of the fence is up to 2 m, 2 lags are planned, above - 3 lags. is about 1.6 m, 20 cm recede from the upper and lower edges of the fence. If the distance between the fence posts from corrugated board is 3 m, then it is better to weld the profile not from above, but between the supports. This increases the strength of the structure and gives the fence a more aesthetic appearance.

Anti-corrosion treatment is also best done after cutting the lags, before welding. It is possible after, but it is more laborious. In any case, the welding spots are cleaned and painted. If you perform the installation of the crate without welding - screw it with bolts, then the strength of the structure will be lower.

Profiled sheet installation

The distance between the fence posts from the corrugated board should be taken into account when choosing the corrugated board. For the fence, they take a wall profiled sheet C8, C10, C20, C21. Sheet C15 is most in demand - it is cut off without an upward wave, so it is convenient to combine it. The width of standard rolled products is from 800 to 1850, the most popular is 1100 - 1180, the length (height) is 1440-3000, you can order up to 4500 - it will cost more.

The height of the lower edge of the fence from the ground is 15 cm. If the surface of the site is uneven, then differences of 10-15 cm are made. Sheets are mounted with an overlap in one wave, fastened after 1-2 waves (if less often, it will rattle in the wind), or 20- 25 cm, in the hollow of the profile.

Installation is carried out with self-tapping screws for metal using a screwdriver or rivets (pre-drill holes), using identical self-tapping screws, only gray, but this design cannot be disassembled.

How to extend the life of a corrugated fence

To protect against corrosion, a metal profile is additionally installed from below and from above. It, as well as the metal crate and supports, will have to be painted about once every 3-5 years. Otherwise, corrosion will make itself felt. Alas, the only way not - brick pillars. Not only fences are made of corrugated board, since it is an inexpensive and fairly durable material.

By being careful when installing the sheet, you will save yourself from the need for preventive work in the future. Use self-tapping screws with an EPDM gasket to protect the sheet coating from damage. During the installation process, paint over the scratched areas with spray paint. Also in the future, regularly treat scratches that have arisen during operation.

A fence made of corrugated board, built taking into account all the recommendations, does not require special care in the future and will last for decades.

Street lighting is very different from the usual home lighting for all of us. Here everything follows pragmatism, functionality and durability. After all, if all this is not respected, then the street type of lighting will be of little use.

street lighting

One of the most important outdoor lighting parameters is the correct calculation of the distance between street poles. Moreover, if in the city center this issue is not so scrupulous, then in the private sector and on the outskirts, as well as in the village, certain difficulties may arise in terms of implementation. Our article will tell you what you need to know about such a concept as the distance between lighting poles.

Features of outdoor lighting

For many years, lampposts have been actively used for outdoor lighting in cities and villages. Today they can be made in various ways and from different materials (concrete, reinforced concrete, metal).

The purpose of the street lighting option is to create a full-fledged luminous flux for various parts of the city:

- the carriageway of highways, highways;

- sidewalks and pedestrian roads;

- parks and squares;

- territories of state, public and educational buildings;

- parking lots;

- gas stations, etc.

Wherever there is a need to install an outdoor type of lighting, a fair question always arises - what should be the distance that will be between two adjacent pillars.

To understand why this distance is so important, you need to know what a street lighting support is. This support consists of two parts:

- Light source. Lighting fixtures are always placed at the top of a lamppost. What lamps the support will be crowned with depends on the place where it is placed. Powerful spotlights should be used to illuminate roads, but decorative lights are suitable for parks and squares;

Note! Street risers with decorative lanterns can be used both by the city authorities to illuminate parks, and by private individuals when installed in the garden. With such pillars and lamps, you can decorate the entire backyard area around the perimeter.

Decorative lamp post

- actual pole. It may have a different height depending on where it will be placed. In the city and in the country, such poles are usually high enough for the incident light from the lamps to form intersecting lighting cones.

Note! If you have a dacha, then you can install lampposts on it in the garden with your own hands to illuminate any height.

In order for street lighting to fully illuminate certain parts of the city, village or homestead territory, the distance between the pillars must be such as to form intersecting cones of light.

In addition, the supports themselves can be used to not only hold lamps at the right height, but also power wires. In such a situation, the distance for supports, in contrast to poles with lamps, may not be so small.

Features of the distance between the supports

The distance that will be between adjacent pillars is called the span. For such spans, the regulatory documentation (GOST, SNiP) has its own rules and regulations. An example of such spans is shown below.

spans between pillars

At the same time, each case of installing poles for outdoor lighting in a city, village or cottage will be regulated by different points and have different points of implementation, including the distance that exists between the poles.

According to the regulatory documentation, the calculation of the length of the span (the distance between two adjacent pillars) should be based on the following parameters:

- the level of illumination set for a particular area (city, village, cottage);

- type of lamp (especially its power), which will act as the main element of the backlight;

- the height at which the lantern will be placed;

- light source option: LED, fluorescent and other light bulbs.

It is worth noting that the optimal distance that can exist between the supports will be 35 m. This applies to both lighting poles and power transmission towers.

Additional nuances to consider

When installing poles that will be placed along streets, squares and roads (in a city or in a village), it is important to consider not only the distance between the poles, but also their distance from other architectural and / or road elements.

Lighting poles along roads

- there must be a distance of at least 1 m from the support to the curb. This requirement is relevant for high-speed highways. For other roads, this distance is reduced and is 0.5 m;

- for roads where large trucks do not drive, the distance is 0.3 m;

- in the absence of a curb, the distance from the road to the support must be at least 1.75 m.

These parameters, albeit indirectly, can affect the distance between the pillars. Any change in the position of the post will affect the cone of light produced by the lantern. If it is not possible to meet such requirements for the placement of supports, then the spans between them will need to be reduced in proportion.

Within the city limits, the height of lighting poles should be 20 m. But this parameter should be economically and technically justified, as well as convenient to maintain.

How the desired parameter is determined

Any installation of lighting poles always begins with accurate calculations of the following parameters:

- optimal placement of poles with lanterns. Here it is necessary to indicate at what distance from neighboring objects each specific column will be located;

- span to be formed between adjacent supports.

Street lighting plan

If everything is relatively clear with the first paragraph, since there are specific rules that must be obeyed. Then, with the determination of the distance between adjacent supports, difficulties may arise, since this parameter depends on:

- the number of lighting fixtures that will be placed on the pole;

Note! A wide variety of lighting installations can be used here as an outdoor type of lighting: searchlights, lanterns, lamps, etc.

- the height of the fixtures;

- their powers.

Using the above indicators, as well as special tables specified in the relevant sections of the regulatory documentation.

Street lighting standards

As can be seen from the table, using specific parameters, it is quite easy to calculate the distance between the supports, which should be formed in a particular case.

Within the city limit, the optimal distance between the lamps will be 35 m. But if necessary, the distance may vary depending on the situation.

Note! In the city, the definition of this indicator, just like in the countryside, should always be based on the three parameters given above.

Street lighting in the village

At the same time, it must be remembered that the ratio of the pitch of the lighting device to the height at which it is placed for roads and streets is in the ratio 5:1 for one-way traffic, as well as for rectangular and axial placement of lamps. This figure will be already 7:1 when using a checkerboard layout of fixtures.

It should also be noted that the data given in the table are indicated as maximum. They are calculated taking into account the necessary illumination of the road.

Based on this data, you can correctly calculate the required span in any possible situation. This will help you not only determine how accurately utility workers adhere to established rules and recommendations, but also do everything yourself. This knowledge will not be superfluous if you decide to make outdoor lighting in the country.

What is it for

The correct definition of the span between the lighting poles will achieve:

- creation of a full-fledged lighting supply on the entire section of the roadway;

- high-quality illumination of sidewalks, squares and parks;

- creating conditions for the safe movement of vehicles on the roads, as well as people on sidewalks and pedestrian crossings;

urban street lighting

- reducing the level of illegal actions that, according to statistics, are committed in poorly lit sections of streets, parks and squares;

- maintaining the infrastructure of the city at the right level.

If at least somewhere an error has crept in, then the outdoor lighting system will not be able to perform its direct functions at the proper level.

Conclusion

To determine the distance between the lighting poles, you do not need to carry out complex mathematical calculations. It is enough just to find out all the necessary criteria and use them to find out the desired value from the table. Everything is simple and clear here.

Solving the problem of flickering LED strips in the on state

Solving the problem of flickering LED strips in the on state

In recent years, sheet corrugated board has taken a leading position among the materials used for fencing.

Low price, easy installation and durability. These three factors are decisive in his choice.

The stability and strength of the metal fence is provided by pillars. They are the most critical element of the design.

If the step and depth of their installation is incorrectly chosen, mistakes are made when attaching the skin, then the owner of the estate will soon have to deal with repairs.

In this article, we will talk about what kind of posts are needed for a corrugated fence and how to install them correctly. Having received useful information, you will avoid annoying mistakes and unjustified spending on restoration work.

Which poles are suitable for corrugated fencing?

Strictly speaking, any. However, we are interested in a material that is as durable and strong as possible. Wood is the least suitable option. Its service life is much less than that of metal.

Having installed corrugated board on pine racks treated with an antiseptic, you will have to remove it after 6 years and start work again. The use of larch or oak prolongs the life of the frame, but increases. Therefore, wooden posts are most often used for temporary fences.

You can eliminate the contact of wood with the ground by making a metal adapter and concrete it in the foundation. However, this option is not suitable for high fences experiencing intense wind loads. Another similar option is to use a piece of a profile pipe as a steel sleeve into which a post is inserted and then concreted.

The next contender for the title of the supporting structure is asbestos-cement pipes. They are inexpensive, do not rot and are quite durable. Their disadvantages include the fragility and difficulty of fastening the runs.

It is impossible to leave asbestos-cement pipes open. Rain water, falling into them like a well, freezes in winter and breaks the walls. Therefore, after installation, they are filled with cement mortar, or before the start of work, plugs are placed on both ends.

Reinforced concrete is also suitable for making posts. The only requirement that needs to be taken into account at the pouring stage is the installation of metal embedded plates to which the runs will be attached.

The technology of industrial casting of concrete in recent years has stepped far forward. Therefore, instead of labor-intensive "home needlework", we recommend buying aesthetic prefabricated structures.

Metal is the undisputed leader in the field of "fence construction". It goes well with corrugated board, holds wind loads well and retains strength for 50 years. The only thing that is required from the owner is to update the anti-corrosion protection once every 3-4 years.

The cross-sectional shape of standard steel posts is round, square and rectangle. A profiled pipe is more convenient to install and for this reason is used more often than a round one.

Purlins can be fastened in various ways using welding, additional elements and threaded connections. This is another advantage of steel racks.

Pillars for a fence made of corrugated board are often made of brick. However, even in this case it will not be possible to do without metal. It is required for the manufacture of embedded parts to which the logs are fixed, and to give the structure sufficient rigidity.

The basis is reinforcing bars or a profile pipe. The space between the masonry and the metal is filled with mortar.

The disadvantages of brick racks include the high price, the laboriousness of the masonry and the heavy weight, which requires pouring a solid foundation. In terms of aesthetics and durability, they are superior to other types of fence supports.

To install a fence made of corrugated board, it is advantageous to use screw posts. These are hollow steel pipes of a square or round profile, equipped with a wide blade.

Using them, you can assemble a solid frame without excavation and concrete. The pile rack is screwed into the ground to a depth of 0.8-1.2 meters and is firmly held in it due to wide blades. On soft soil, screw posts can be placed manually using a special mechanism for gripping and rotating.

The main points of installation

In order to properly install the poles, it is necessary to choose the best way to fix them in the ground. To do this, take into account the composition of the soil. If it is sandy and dense enough, then the racks can be placed without concreting in prepared wells or by driving.

The main danger for any fence supports is the forces of frost heaving, pushing them out of the ground and warping the frame. On sand, which passes moisture well, deformation of the fence does not threaten. Concrete in this case is used to increase the contact area of the support with the ground.

On dense sandy soil, it is recommended to deepen the posts by at least 1/3 of their length. On loose and heaving soil, the embedment depth remains the same, but the well should be drilled with a diameter of 100 mm more than the width of the column and always below the depth of seasonal freezing of the soil.

Having done this work, the bottom of the pit is covered with rubble and sand to the level of the installation of racks. After mounting the support around it, a mixture of crushed stone and sand is poured in layers with tamping. By letting water through, it will prevent the pole from being pushed out by frozen soil.

Concreting can be done in one of two ways:

- Traditional (digging a hole, lowering a support into it and pouring it with concrete);

- Combined (a well is drilled to a depth of at least 80 cm, a stand is placed and a wide hole 40 cm deep is dug around it for concreting).

Note that the second option is more economical than the first in terms of concrete consumption, although it is more difficult to implement.

Fence posts can be tied together with a shallow tape grillage. It increases the rigidity of the fence and improves its appearance.

For a fence made of steel pipes, you can use different sections of the profile. More often, the supports are made of a square pipe 60x60 mm with a wall thickness of 3 mm or a rectangular pipe 60x40 mm (3 mm wall). Racks made of round pipes are less convenient when installing girders. Therefore, they are used less frequently.

The second issue that should be resolved before starting work is the distance (step) between the pillars. Profile pipes are supplied in the form of 6-meter whips, therefore, to reduce losses, it is more profitable to cut them into 3-meter pieces.

The optimal size of the section of the runs (lag) is 40x20mm, the wall thickness is at least 2 mm.

The distance between the lags depends on the height of the fence and ranges from 1.2 to 1.6 meters. From the bottom of the sheet to the ground or to the upper mark of the foundation grillage, a gap of 5 to 10 cm is left.

Installation of metal poles and frame

The first stage is marking the contour of the fence with a tape measure and a cord. In the course of this work, pegs are driven into the ground, marking the places for digging holes.

First they put, level and concrete the pillars at the corners of the site. After that, they dig holes for ordinary racks. A cord is pulled between the extreme supports and ordinary posts are placed along it.

Attention! To protect against corrosion, the lower part of the support must be welded with a steel plate and coated with a protective compound. The top covers are welded to the racks after their installation is completed or special plastic plugs are placed in them.

Double control of distances during installation is necessary. When drilling and digging holes, there is a deviation from the intended installation points for the supports. Metal does not forgive mistakes, so the distances between the centers of the racks must be maintained with an accuracy of 1 cm.

Having exposed the supports, they are temporarily fixed with wedges or pieces of brick and once again check the verticality and step. After that, you can pour concrete or fill the pits with a sand-gravel mixture.

After giving the concrete 7 days to gain strength, you can proceed with the installation of the log (runs). They are attached by welding or threaded connections. Welding technology is used more often because it is simpler and faster. Having aligned the run on the level, it is grabbed to the rack, the “horizon” is checked again and fixed with a working seam.

Having assembled the metal frame, you can proceed to attach the corrugated board to it using special self-tapping screws.

It has always been believed that a fence made of corrugated board is a simple structure that any owner of a personal plot can put up. When building a fence, it is very important to choose the right fence posts from corrugated board.

Mounted iron fence posts

The material for the supports of such a fence can be:

- brick;

- pipes;

- wood.

brick supports

Brick fences, as well as, the price of which is quite high, are considered to be buildings of the elite category. However, such fences differ in price and quality.

It looks like a fence made of corrugated board with brick pillars

Significantly reduce the cost of poles for a corrugated fence, while maintaining a beautiful appearance and attractiveness, perhaps if you use ordinary facing bricks, most often red.

Such a fence can be made of any size, which, by its appearance, as well as the quality of workmanship, will not yield to natural materials in any way. The price of brick pillars for a corrugated fence is always higher than. However, a brick has an undoubted advantage over a metal support. decorate any site, they emphasize the good taste and solidity of its owner.

In addition to decorative properties, brick pillars are highly durable, they are not afraid of strong winds, they endure atmospheric influences. Usually, brick pillars, when corrugated board becomes the material of the fence, are built from facing bricks, which perfectly imitate stone.

Scheme with dimensions for mounting brick pillars

The height of such a column reaches a maximum of 2.5 meters. The step between the supports should not exceed three meters. Brick supports are usually built in conjunction with the plinth. To install them. Special brick supports protect. These decorative details add a unique look to the fence.

Pillars for corrugated metal pipes

According to practice, in order to make the construction of the fence more durable, both and are used. Their price is quite affordable for every owner of a summer cottage. To install the pipes into the ground, no additional work is required. The size of the walls of such pipes for poles must exceed two millimeters. The cross section of the pipe is selected individually.

The length of the posts depends on the height of the fence. Moreover, the length of the pipe should be one meter longer than the height of the fence.

An example of the height of a fence made of corrugated board and poles

The upper part of the support is welded or a plug is placed on it to prevent moisture from entering the metal supports.

In some cases, when a reinforced concrete foundation is poured, asbestos-cement pipes are installed. The price of such a support is quite low, so they are often used for fences blocking a summer cottage or a utility yard.

Asbestos-cement pipes have not become very popular, since it is very difficult to attach logs and mortgages to them. This material is distinguished by increased fragility, water constantly accumulates in the pipes. With the onset of cold weather, the water freezes, the pipe begins to crack. A fence made of corrugated board is too heavy for such supports.

wooden poles

It became less and less common when the fence is built from corrugated board. To increase the life of a wooden pole, especially when it is located on the street, its special processing is required. As a result, the price of the pillar increases sharply, and a positive result is not always obtained.

When wood is used for poles, a wooden beam is used for corrugated board, the size of which exceeds 100 x 100 mm.

This makes it possible to achieve a high strength of the support so that it can withstand strong wind loads. The lower part of the pillar, before being buried in the ground,. As a result, the tree becomes resistant to a variety of, including aggressive, environments:

- alkalis;

- acid;

- water.

To obtain greater reliability, two bituminous layers are made, which are applied one after the other after 24 hours.

Bituminous impregnation of a wooden pole for a corrugated fence

Such a break is necessary for the bituminous impregnation of the first layer to completely harden. Wooden poles must be well dried before installation, their moisture content should not exceed 15%.

Pole installation

Profiled sheeting has always been used by builders to cover the roofs of industrial premises. It was also used to install fences for a variety of construction areas. However, after profiled sheets with a multi-colored protective coating appeared, they were increasingly used to fence private buildings.

Each building should have a finished look, which usually gives it a beautiful fence. The pillars are the backbone of any fence. When the installation of corrugated fence posts is done in accordance with all building rules, it can stand for many decades. Therefore, during the construction of the fence, very important questions remain relevant: what kind of poles are required, what material is needed for their manufacture?

Scheme of installation of posts for a fence made of corrugated board

Requirements for modern fences

Strength comes first. Any fence should protect from gusts of wind, from the penetration of intruders and prying eyes. When choosing a fence for do-it-yourself construction, the scales tilt towards external attractiveness. In this case, the fence made of corrugated board will be the most accurate and correct. To make the base of the pillars with your own hands, you can use several types of material.

Wood

Such supports for corrugated board are distinguished by low cost. However, wooden poles are not very durable compared to their counterparts.

Brick

Always looks attractive and majestic. A fence with brick pillars is characterized by increased strength and can be used for more than a dozen years.

Option of brick pillars for a metal fence

The disadvantages of such a brick fence can be called:

- High cost;

- Labor intensity of work;

- Long construction period.

metal pipes

Usually a round profile is used. Some for the manufacture of pillars choose between steel and asbestos-cement pipes. In any case, the fence turns out to be reliable and affordable for making with your own hands.

Such supports are slightly more expensive than wooden poles, however, their reliability is much higher.

Choice of distance between supports

Installing a fence using corrugated board is quite simple with your own hands. To eliminate errors, it is necessary to adhere to the correct technology of work.

The basis of each fence is made up of logs along with pillars. Their installation is considered the most time-consuming work.

To reduce financial investments in the construction of the fence, it is necessary to maintain the maximum distance between the pillars.

The scheme of the distance between the fence posts

However, a very large distance will complicate installation work with corrugated board. It will be difficult to make a crate, the strength of the entire fence will decrease. The best is the distance between the pillars, equal to 2.5 meters. Of course, this value is subject to change. It all depends on the complexity of the design and technological features of the structure. But in any case, the distance between the pillars should not be more than three meters.

Choice of poles

What supports to choose so that the fence is beautiful, durable, reliable and attractive? This question is asked by everyone who decides to build a fence with their own hands. Today, supports are widely used:

- wooden;

- brick;

- profile;

- steel;

Technological features of the installation of pillars

In order to install the supports with your own hands, several types of technological operations are used:

Let's consider each of these methods separately.

In order for the fence to be reliable, before installing it, you must first take into account all the nuances. The basis here is the fence posts made of corrugated board and lintels, and the installation of supports is the most time-consuming and responsible part of the work. Therefore, it is so important to follow all the rules for building a fence. and one of the first questions that can be omitted is what distance between corrugated fence posts is considered acceptable.

Fence brick posts

Advantages of a corrugated fence

Fences from profile sheets have proven themselves and, of course, have their own dignity:

reliability;

universality;

low price;

pleasant appearance;

guaranteed fire safety;

a large selection of types of corrugated board;

various colors of the polymer coating;

long term operation.

Various premises, garages, pavilions are mounted from this material, as well as profile sheets are used to protect private household plots.

Finished profiled fence

The use of fence posts

Fencing posts are installed into the ground at the desired depth and play the role of supporting the entire structure. In order for the fence to be reliable, you need to know which posts are needed for a corrugated fence, while racks of different materials are allowed:

-

asbestos cement;

reinforced concrete supports.

Let's consider some of them in more detail.

Pillars for corrugated metal pipes

When installing a fence made of profiled sheets, metal pipes are reliable supports, while they can be either rectangular or round.

Thus, let the cost of new pipes be higher, but they will last longer, guaranteeing the reliability and durability of the fence. Profile supports are much more convenient to use because of their square configuration: it is easier to attach crossbars to such a surface by welding. Therefore, they do not need additional fastening.

Frame for a fence from a profile pipe

Pillars from asbestos-cement pipes

Supports made of such material are an alternative to wood and metal racks. And for this they have their own Benefits:

Low cost.

Are not subject to rotting and corrosion.

They do not require maintenance (painting, antiseptic treatment).

The disadvantages of these pillars include their relative fragility, laboriousness during installation and unattractive appearance.

Installed asbestos pipes for the fence

On our site you can find contacts of construction companies that offer the service of building fences and fences. You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

Wooden poles for corrugated board

Wooden supports have been used less and less in recent years. In order for them to last longer, the supports must be specially processed or poles made of larch or oak must be selected. But all this will be expensive, require additional costs and does not guarantee a 100% result.

If wooden poles are used, then they must be at least 100 mm in cross section. It is with this thickness that the supports will be relatively strong and will be able to withstand the wind loads that act on the fence.

Corrugated fence with brick posts

Today there are many options for fencing structures, but recently fences made of corrugated board with brick supports have become more common.

This fence has an attractive appearance and looks solid, unlike other types of fences. After planning and marking such a fence, a part of the soil is first removed and the strip foundation is poured.

When the mortar hardens, support pillars of brick or concrete are installed, imitating fireclay masonry. In the latter version, the fence is attached to reinforced concrete pillars, but ceramic slats with imitation of bricks are used, which are attached to the support plane with cement mortar.

The cost of such poles is lower, and their installation requires less effort and time, in connection with this, this option is becoming more and more popular with customers.

Prerequisites and basics for calculating the distance between fence posts

When building a fence from a profiled sheet, it is important to observe the distance between the posts for a corrugated fence, as it is deaf and experiences heavy loads during strong winds.

And if the distance between the fence posts from the corrugated board is chosen more than the permissible one, then this will soon be expressed in the structure in the form of leaning pillars, sagging sheets and other troubles. Moreover, negligence in calculations can lead to serious financial losses, for example, alteration of brick and concrete supports.

The size between the racks directly depends on their cross section. The higher the fence will be, and the greater the distance between the fence posts, the stronger and with a large cut the pipes will be installed.

What determines the distance between the pillars

When constructing a fence, optimal gaps between support points should be selected. With large spans, there is a possibility of bending and tilting of the entire structure. And if the pillars are often installed, then - a large consumption of material and time.

In this case, the size between the racks is influenced by several factors:

The size of the pillars and sheets of corrugated board. Its stability in strong winds directly depends on the height of the fence: the higher the fence, the more often it is necessary to install poles.

The number of jumpers. The rigidity of the structure depends on this parameter. At a height of more than two meters, it is recommended to use three jumpers.

When calculating the distance between the posts for the fence, you must keep in mind the length of the horizontal bars.

What determines the installation depth of the pillars

It would seem that the deeper the pipe is dug, the more reliable the fence, but on the other hand, with a recess for every 10 cm, the cost of work increases. Here you need to choose the best option.

Support installation depth depends on the following parameters:

height and weight of the fence;

on the type of construction (solid or transparent);

soil features (composition, freezing depth, groundwater level).

Important to remember! The poles are affected by the size, weight of the structure and the force of the wind. Together, these two guides form a torque that reaches a peak at the point where the support leaves the soil.

Fence post installation steps

After the optimal installation method is chosen, it is decided which posts to use for the fence from the profiled sheet, the necessary tool is prepared. Workers will need: a drill, a shovel, a sledgehammer, a plumb line and a level, a cord, a container for mixing the mortar or a concrete mixer, cement and crushed stone.

Then the place of the future fence is marked. The installation of jumpers and sections of the profiled sheet largely depends on this layout, since when the pillars are displaced from the specified parameters, additional adjustment of these elements will be required.

The division of the site is as follows stages:

along the perimeter at the place of supports in advance pegs are driven in;

establish corner end posts according to the hydraulic level and fill them with a solution;

after cement curing pull the cord without sagging top and bottom;

successively installation and pouring of racks is carried out at a distance of 2.5-3 meters. (this size depends on the length and width of the sheet, weight, soil, as well as on the total length of the profile jumpers - if the size is 9-12 meters, then it is better to divide into 3 or 4 parts without a trace, and in the case of a 10-meter length - into 4 segments);

after assembly, the welding seams are cleaned and coated with an anti-corrosion compound, primed, and only then painted to match the color of the profiled sheet;

fastening of the corrugated board is carried out no earlier than 4-5 days from the pouring of the supports, in order to allow the mortar to fully set and harden; the profiled sheet is fixed with the placement of the previous product on the same wave with self-tapping screws with rubber washers.

On a note! To maintain the correct geometry of the fence during the installation of support posts and the construction of the fence, a team of two or three people is needed.

At different ground levels, one more support is installed and a stepped fence is made, and the distance between the fence posts from the profiled sheet can be significantly reduced. Also, additional reinforced pillars are mounted at the locations of the gates and gates. When pouring a support with a solution, its vertical level is checked with a plumb line, and the line is visually checked relative to other pillars.

Video description

For more information about the fence device, see the video:

How to extend the life of a corrugated fence

The reliability of the steel profile sheet allows the fencing to operate for at least 25 years. But sometimes, with a careless attitude and improper care, the structural features of this material can noticeably change for the worse. Therefore, it is important to know the factors influencing material change and how to increase the service life.

If the foundation begins to collapse, then it can be strengthened with cement clips around the base, leveling chips and cracks with a concrete mixture and proper drainage.

In the event of a violation of the protective layer of paint on the frames of such fences, it must be periodically updated.

Sometimes there are defects on the outer layer of profiled sheets due to improper cut, careless transportation, installation or operation. In such cases, it is necessary to clean the damaged surface from rust and paint it with enamel of a suitable color for metal.

Video description

About ordering the construction of a turnkey profiled fence in the following video:

Conclusion

Fences from a professional flooring are beautiful, steady and durable. They protect the territory from uninvited guests with a guarantee, they are easy to install, and have a budget cost.

This material looks great and is an attractive option for exterior cladding of the adjacent area. And the durability of the entire fencing structure largely depends on how the supports are installed correctly.