Design and calculation of ventilation systems. Determination of local resistance coefficients of tees in ventilation systems Air duct side opening kms calculation

Read also

|

Purpose |

Basic Requirement | ||||

| Silence | Min. head loss | ||||

| Main channels | Main channels | Branches | |||

| Inflow | Hood | Inflow | Hood | ||

| Living spaces | 3 | 5 | 4 | 3 | 3 |

| Hotels | 5 | 7.5 | 6.5 | 6 | 5 |

| Institutions | 6 | 8 | 6.5 | 6 | 5 |

| Restaurants | 7 | 9 | 7 | 7 | 6 |

| The shops | 8 | 9 | 7 | 7 | 6 |

Based on these values, the linear parameters of the air ducts should be calculated.

Algorithm for calculating air pressure losses

The calculation must begin with drawing up a diagram of the ventilation system with the obligatory indication of the spatial location of the air ducts, the length of each section, ventilation grilles, additional equipment for air purification, technical fittings and fans. Losses are determined first for each individual line and then summed up. For a separate technological section, losses are determined using the formula P = L×R+Z, where P is the loss of air pressure in the design section, R is the loss per linear meter of the section, L is the total length of the air ducts in the section, Z is the loss in the additional fittings of the system ventilation.

To calculate pressure loss in a round duct, the formula Ptr is used. = (L/d×X) × (Y×V)/2g. X – tabular coefficient of air friction, depends on the material of the air duct, L – length of the calculated section, d – diameter of the air duct, V – required speed air flow, Y – air density taking into account temperature, g – fall acceleration (free). If the ventilation system has square air ducts, then table No. 2 should be used to convert round values to square ones.

Table No. 2. Equivalent diameters of round air ducts for square ones

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| 250 | 210 | 245 | 275 | |||||

| 300 | 230 | 265 | 300 | 330 | ||||

| 350 | 245 | 285 | 325 | 355 | 380 | |||

| 400 | 260 | 305 | 345 | 370 | 410 | 440 | ||

| 450 | 275 | 320 | 365 | 400 | 435 | 465 | 490 | |

| 500 | 290 | 340 | 380 | 425 | 455 | 490 | 520 | 545 |

| 550 | 300 | 350 | 400 | 440 | 475 | 515 | 545 | 575 |

| 600 | 310 | 365 | 415 | 460 | 495 | 535 | 565 | 600 |

| 650 | 320 | 380 | 430 | 475 | 515 | 555 | 590 | 625 |

| 700 | 390 | 445 | 490 | 535 | 575 | 610 | 645 | |

| 750 | 400 | 455 | 505 | 550 | 590 | 630 | 665 | |

| 800 | 415 | 470 | 520 | 565 | 610 | 650 | 685 | |

| 850 | 480 | 535 | 580 | 625 | 670 | 710 | ||

| 900 | 495 | 550 | 600 | 645 | 685 | 725 | ||

| 950 | 505 | 560 | 615 | 660 | 705 | 745 | ||

| 1000 | 520 | 575 | 625 | 675 | 720 | 760 | ||

| 1200 | 620 | 680 | 730 | 780 | 830 | |||

| 1400 | 725 | 780 | 835 | 880 | ||||

| 1600 | 830 | 885 | 940 | |||||

| 1800 | 870 | 935 | 990 |

The horizontal axis indicates the height of the square duct, and the vertical axis indicates the width. Equivalent value round section is at the intersection of lines.

Air pressure losses in bends are taken from table No. 3.

Table No. 3. Pressure loss at bends

To determine pressure losses in diffusers, data from table No. 4 is used.

Table No. 4. Pressure loss in diffusers

Table No. 5 gives general diagram losses on a straight line.

Table No. 5. Diagram of air pressure loss in straight air ducts

All individual losses in a given section of the air duct are summed up and adjusted with table No. 6. Table. No. 6. Calculation of flow pressure reduction in ventilation systems

During design and calculations, existing regulations It is recommended that the difference in pressure loss between individual sections should not exceed 10%. The fan must be installed in the area of the ventilation system with the highest resistance; the most distant air ducts must have minimal resistance. If these conditions are not met, then it is necessary to change the layout of air ducts and additional equipment, taking into account the requirements of the regulations.

Creation comfortable conditions staying in the premises is impossible without an aerodynamic calculation of the air ducts. Based on the data obtained, the cross-sectional diameter of the pipes, the power of the fans, the number and features of the branches are determined. Additionally, the power of heaters and the parameters of inlet and outlet openings can be calculated. Depending on the specific purpose of the rooms, the maximum permissible noise level, air exchange rate, direction and speed of flows in the room are taken into account.

Modern requirements are specified in the Code of Rules SP 60.13330.2012. Normalized parameters of microclimate indicators in premises for various purposes are given in GOST 30494, SanPiN 2.1.3.2630, SanPiN 2.4.1.1249 and SanPiN 2.1.2.2645. During calculation of indicators ventilation systems all provisions must be taken into account.

Aerodynamic calculation of air ducts - algorithm of actions

The work includes several successive stages, each of which solves local problems. The obtained data is formatted in the form of tables, and schematic diagrams and graphs are drawn up on their basis. The work is divided into the following stages:

- Development of an axonometric diagram of air distribution throughout the system. Based on the diagram, a specific calculation methodology is determined, taking into account the features and tasks of the ventilation system.

- An aerodynamic calculation of air ducts is performed both along the main routes and all branches.

- Based on the data received, it is selected geometric shape and cross-sectional area of the air ducts are determined technical specifications fans and heaters. Additionally, the possibility of installing fire extinguishing sensors, preventing the spread of smoke, and the possibility of automatically adjusting the ventilation power taking into account the program compiled by the users are taken into account.

Development of a ventilation system diagram

Depending on the linear parameters diagram, the scale is selected, the diagram indicates the spatial position of the air ducts, the points of connection of additional technical devices, existing branches, air supply and intake points.

The diagram indicates the main highway, its location and parameters, connection points and specifications branches. The location of air ducts takes into account the architectural characteristics of the premises and the building as a whole. During compilation supply circuit The calculation procedure begins from the point furthest from the fan or from the room for which the maximum air exchange rate is required. During compilation exhaust ventilation The main criterion is the maximum air flow rate. Common line during calculations, it is divided into separate sections, and each section must have the same cross-sections of air ducts, stable air consumption, the same materials of manufacture and pipe geometry.

The segments are numbered in sequence from the section with the lowest flow rate and in increasing order to the highest. Next, the actual length of each individual section is determined, the individual sections are summed up, and the total length of the ventilation system is determined.

When planning a ventilation scheme, they can be taken as common for the following premises:

- residential or public in any combination;

- industrial, if they belong to group A or B according to the fire safety category and are located on no more than three floors;

- one of the categories industrial buildings categories B1 – B4;

- category industrial buildings B1 m B2 are allowed to be connected to one ventilation system in any combination.

If the ventilation systems completely lack the possibility of natural ventilation, then the diagram must provide for the mandatory connection emergency equipment. The power and installation location of additional fans are calculated according to general rules. For rooms that have openings that are constantly open or open when necessary, the diagram can be drawn up without the possibility of a backup emergency connection.

Systems for suctioning contaminated air directly from technological or work areas must have one backup fan; turning the device into operation can be automatic or manual. The requirements apply to work areas of hazard classes 1 and 2. It is allowed not to include a backup fan in the installation diagram only in the following cases:

- Synchronized stop of harmful production processes in case of malfunction of the ventilation system.

- IN production premises Separate emergency ventilation with its own air ducts is provided. Such ventilation parameters must remove at least 10% of the volume of air supplied by stationary systems.

The ventilation scheme must provide a separate possibility of showering on workplace with increased levels of air pollution. All sections and connection points are indicated on the diagram and included in general algorithm calculations.

It is prohibited to place air receiving devices closer than eight meters horizontally from garbage dumps, car parking areas, roads with heavy traffic, exhaust pipes and chimneys. Receptionists air devices subject to protection special devices on the windward side. Resistance indicators protective devices taken into account during aerodynamic calculations common system ventilation.

Calculation of air flow pressure loss Aerodynamic calculation of air ducts based on air losses is done with the aim of the right choice sections to ensure technical requirements system and selection of fan power. Losses are determined by the formula:

R yd - value specific losses pressure in all sections of the air duct;

P gr – gravitational air pressure in vertical channels;

Σ l – the sum of individual sections of the ventilation system.

Pressure losses are obtained in Pa, the length of sections is determined in meters. If the movement of air flows in ventilation systems occurs due to a natural pressure difference, then the calculated pressure reduction is Σ = (Rln + Z) for each individual section. To calculate the gravitational pressure you need to use the formula:

P gr – gravitational pressure, Pa;

h – height of the air column, m;

ρ n – air density outside the room, kg/m3;

ρ in – indoor air density, kg/m3.

Further calculations for systems natural ventilation are performed according to the formulas:

Definition cross section air ducts

Determination of the speed of movement of air masses in gas ducts

Calculation of losses based on local resistances of the ventilation system

Determination of friction loss

Determination of air flow speed in channels

The calculation begins with the longest and most remote section of the ventilation system. As a result of aerodynamic calculations of air ducts, the required ventilation mode in the room must be ensured.

The cross-sectional area is determined by the formula:

F P = L P /V T .

F P – cross-sectional area of the air channel;

L P – actual air flow in the calculated section of the ventilation system;

V T – speed of air flow to ensure the required frequency of air exchange in the required volume.

Taking into account the results obtained, the pressure loss during the forced movement of air masses through the air ducts is determined.

For each air duct material, correction factors are applied, depending on the surface roughness indicators and the speed of movement of air flows. To facilitate aerodynamic calculations of air ducts, you can use tables.

Table No. 1. Calculation metal air ducts round profile.

Table No. 2. Values correction factors taking into account the material of the air ducts and the air flow speed.

The roughness coefficients used for calculations for each material depend not only on its physical characteristics, but also on the speed of air flow. The faster the air moves, the more resistance it experiences. This feature must be taken into account when selecting a specific coefficient.

Aerodynamic calculations for air flow in square and round air ducts show different flow rates for the same cross-sectional area conditional passage. This is explained by differences in the nature of vortices, their meaning and ability to resist movement.

The main condition for calculations is that the speed of air movement constantly increases as the area approaches the fan. Taking this into account, requirements are imposed on the diameters of the channels. In this case, the parameters of air exchange in the premises must be taken into account. The locations of the inflow and outlet flows are selected in such a way that people staying in the room do not feel drafts. If it is not possible to achieve the regulated result using a straight section, then diaphragms with through holes are inserted into the air ducts. By changing the diameter of the holes, optimal regulation of air flow is achieved. The diaphragm resistance is calculated using the formula:

The general calculation of ventilation systems should take into account:

- Dynamic air pressure during movement. The data is consistent with the technical specifications and serves as the main criterion when choosing a specific fan, its location and operating principle. If it is impossible to ensure the planned operating modes of the ventilation system with one unit, installation of several is provided. The specific location of their installation depends on the features schematic diagram air ducts and permissible parameters.

- The volume (flow rate) of transported air masses in the context of each branch and room per unit of time. Initial data - requirements of sanitary authorities for cleanliness of the premises and features technological process industrial enterprises.

- Unavoidable pressure losses resulting from vortex phenomena during the movement of air flows on various speeds. In addition to this parameter, the actual cross-section of the air duct and its geometric shape are taken into account.

- Optimal air movement speed in the main channel and separately for each branch. The indicator influences the choice of fan power and their installation locations.

To facilitate calculations, it is allowed to use a simplified scheme; it is used for all premises with non-critical requirements. To guarantee the required parameters, the selection of fans in terms of power and quantity is done with a margin of up to 15%. Simplified aerodynamic calculations of ventilation systems are performed using the following algorithm:

- Determination of the cross-sectional area of the channel depending on the optimal speed of air flow.

- Selecting a standard channel cross-section close to the design one. Specific indicators should always be selected upward. Air channels may have increased technical indicators; it is prohibited to reduce their capabilities. If it is impossible to select standard channels in technical conditions It is envisaged that they will be manufactured according to individual sketches.

- Checking air speed indicators taking into account real values conventional cross-section of the main channel and all branches.

The task of aerodynamic calculation of air ducts is to ensure the planned ventilation rates of rooms with minimal losses financial resources. At the same time, it is necessary to achieve a reduction in labor intensity and metal consumption of construction and installation work, ensuring reliable operation installed equipment in various modes.

Special equipment must be installed in accessible places, it is provided with unhindered access for routine technical inspections and other work to maintain the system in working order.

According to the provisions of GOST R EN 13779-2007 for calculating ventilation efficiency ε v you need to apply the formula:

with ENA– indicators of the concentration of harmful compounds and suspended substances in the removed air;

With IDA– concentration of harmful chemical compounds and suspended substances in the room or work area;

c sup– indicators of contaminants entering with the supply air.

The efficiency of ventilation systems depends not only on the power of the connected exhaust or blower devices, but also on the location of the sources of air pollution. During aerodynamic calculations must be taken into account minimum indicators on the efficiency of the system.

Specific power (P Sfp > W∙s / m 3) of fans is calculated using the formula:

de P – power of the electric motor installed on the fan, W;

q v – air flow rate supplied by the fans during optimal operation, m 3 /s;

∆ p – indicator of the pressure drop at the air inlet and outlet of the fan;

η tot - overall coefficient useful action for electric motor, air fan and air ducts.

During calculations we take into account following types air flows according to the numbering in the diagram:

Diagram 1. Types of air flows in the ventilation system.

- External, enters the air conditioning system from the external environment.

- Supply. Air flows entering the duct system after preliminary preparation(heating or cleaning).

- The air in the room.

- Flowing air currents. Air moving from one room to another.

- Exhaust. Air exhausted from the room to the outside or into the system.

- Recirculation. The portion of the flow returned to the system to maintain the internal temperature within the specified values.

- Deletable. Air that is removed from the premises irrevocably.

- Secondary air. Returned back to the room after cleaning, heating, cooling, etc.

- Air loss. Possible leaks due to leaky air duct connections.

- Infiltration. The process of air entering indoors naturally.

- Exfiltration. Natural air leakage from the room.

- Air mixture. Simultaneous suppression of multiple threads.

Each type of air has its own state standards. All calculations of ventilation systems must take them into account.

With this material, the editors of the magazine “Climate World” continue the publication of chapters from the book “Ventilation and air conditioning systems. Design guidelines for production

water and public buildings.” Author Krasnov Yu.S.

The aerodynamic calculation of air ducts begins with drawing an axonometric diagram (M 1: 100), putting down the numbers of sections, their loads L (m 3 / h) and lengths I (m). The direction of the aerodynamic calculation is determined - from the most distant and loaded area to the fan. When in doubt when determining a direction, consider all possible options.

The calculation begins with a remote section: determine the diameter D (m) of the round or the area F (m 2) of the cross section of the rectangular air duct:

The speed increases as you approach the fan.

According to Appendix H, the nearest standard values are taken: D CT or (a x b) st (m).

Hydraulic radius of rectangular ducts (m):

where is the sum of the coefficients local resistance on the air duct section.

Local resistances at the border of two sections (tees, crosses) are assigned to the section with lower flow.

Local resistance coefficients are given in the appendices.

Diagram of the supply ventilation system serving a 3-story administrative building

Calculation example

Initial data:

| No. of plots | flow L, m 3 / h | length L, m | υ rivers, m/s | section a × b, m |

υ f, m/s | D l,m | Re | λ | Kmc | losses in the area Δр, pa |

| PP grid at the outlet | 0.2 × 0.4 | 3,1 | - | - | - | 1,8 | 10,4 | |||

| 1 | 720 | 4,2 | 4 | 0.2 × 0.25 | 4,0 | 0,222 | 56900 | 0,0205 | 0,48 | 8,4 |

| 2 | 1030 | 3,0 | 5 | 0.25×0.25 | 4,6 | 0,25 | 73700 | 0,0195 | 0,4 | 8,1 |

| 3 | 2130 | 2,7 | 6 | 0.4 × 0.25 | 5,92 | 0,308 | 116900 | 0,0180 | 0,48 | 13,4 |

| 4 | 3480 | 14,8 | 7 | 0.4 × 0.4 | 6,04 | 0,40 | 154900 | 0,0172 | 1,44 | 45,5 |

| 5 | 6830 | 1,2 | 8 | 0.5 × 0.5 | 7,6 | 0,50 | 234000 | 0,0159 | 0,2 | 8,3 |

| 6 | 10420 | 6,4 | 10 | 0.6 × 0.5 | 9,65 | 0,545 | 337000 | 0,0151 | 0,64 | 45,7 |

| 6a | 10420 | 0,8 | Yu. | Ø0.64 | 8,99 | 0,64 | 369000 | 0,0149 | 0 | 0,9 |

| 7 | 10420 | 3,2 | 5 | 0.53 × 1.06 | 5,15 | 0,707 | 234000 | 0.0312×n | 2,5 | 44,2 |

| Total losses: 185 | ||||||||||

| Table 1. Aerodynamic calculation | ||||||||||

The air ducts are made of galvanized sheet steel, the thickness and size of which correspond to approx. N from. The material of the air intake shaft is brick. Adjustable grilles of the PP type with possible sections: 100 x 200; 200 x 200; 400 x 200 and 600 x 200 mm, shading coefficient 0.8 and maximum speed air outlet up to 3 m/s.

The resistance of the insulated intake valve with fully open blades is 10 Pa. The hydraulic resistance of the heating unit is 100 Pa (according to a separate calculation). Filter resistance G-4 250 Pa. Hydraulic resistance of the muffler 36 Pa (according to acoustic calculation). Air ducts are designed based on architectural requirements rectangular section.

The cross-sections of brick channels are taken according to table. 22.7.

Local resistance coefficients

Section 1. PP grid at the outlet with a cross section of 200×400 mm (calculated separately):

| No. of plots | Type of local resistance | Sketch | Angle α, deg. | Attitude | Rationale | KMS | ||

| F 0 /F 1 | L 0 /L st | f pass /f stv | ||||||

| 1 | Diffuser |

|

20 | 0,62 | - | - | Table 25.1 | 0,09 |

| Retraction |

|

90 | - | - | - | Table 25.11 | 0,19 | |

| Tee-pass |

|

- | - | 0,3 | 0,8 | Adj. 25.8 | 0,2 | |

| ∑ = | 0,48 | |||||||

| 2 | Tee-pass |

|

- | - | 0,48 | 0,63 | Adj. 25.8 | 0,4 |

| 3 | Branch tee |

|

- | 0,63 | 0,61 | - | Adj. 25.9 | 0,48 |

| 4 | 2 bends | 250×400 | 90 | - | - | - | Adj. 25.11 | |

| Retraction | 400×250 | 90 | - | - | - | Adj. 25.11 | 0,22 | |

| Tee-pass |

|

- | - | 0,49 | 0,64 | Table 25.8 | 0,4 | |

| ∑ = | 1,44 | |||||||

| 5 | Tee-pass |

|

- | - | 0,34 | 0,83 | Adj. 25.8 | 0,2 |

| 6 | Diffuser after fan |

|

h=0.6 | 1,53 | - | - | Adj. 25.13 | 0,14 |

| Retraction | 600×500 | 90 | - | - | - | Adj. 25.11 | 0,5 | |

| ∑= | 0,64 | |||||||

| 6a | Confusion in front of the fan |

|

D g =0.42 m | Table 25.12 | 0 | |||

| 7 | Knee | 90 | - | - | - | Table 25.1 | 1,2 | |

| Louvre grille | Table 25.1 | 1,3 | ||||||

| ∑ = | 1,44 | |||||||

| Table 2. Determination of local resistances | ||||||||

Krasnov Yu.S.,

1. Friction losses:

Ptr = (x*l/d) * (v*v*y)/2g,

z = Q* (v*v*y)/2g,

Permissible speed method

Note: air flow speed in the table is given in meters per second

Using rectangular ducts

The head loss diagram shows the diameters of round ducts. If rectangular ducts are used instead, their equivalent diameters must be found using the table below.

Notes:

- If there is not enough space (for example, during reconstruction), rectangular air ducts are chosen. As a rule, the width of the duct is 2 times the height).

Table of equivalent duct diameters

When the parameters of the air ducts are known (their length, cross-section, coefficient of air friction on the surface), it is possible to calculate the pressure loss in the system at the designed air flow.

Total pressure loss (in kg/sq.m.) is calculated using the formula:

where R is pressure loss due to friction per 1 linear meter air duct, l - length of the air duct in meters, z - pressure loss due to local resistance (with a variable cross-section).

1. Friction losses:

In a round air duct, pressure loss due to friction P tr is calculated as follows:

Ptr = (x*l/d) * (v*v*y)/2g,

where x is the coefficient of friction resistance, l is the length of the air duct in meters, d is the diameter of the air duct in meters, v is the air flow speed in m/s, y is the air density in kg/cub.m., g is acceleration free fall(9.8 m/s2).

Note: If the duct has a rectangular rather than a round cross-section, the equivalent diameter must be substituted into the formula, which for an air duct with sides A and B is equal to: deq = 2AB/(A + B)

2. Losses due to local resistance:

Pressure losses due to local resistance are calculated using the formula:

z = Q* (v*v*y)/2g,

where Q is the sum of the local resistance coefficients in the section of the air duct for which the calculation is being made, v is the air flow speed in m/s, y is the air density in kg/cub.m., g is the acceleration of gravity (9.8 m/s2 ). Q values are presented in tabular form.

Permissible speed method

When calculating the air duct network using the permissible speed method, the optimal air speed is taken as the initial data (see table). Then the required cross-section of the air duct and the pressure loss in it are calculated.

Procedure for aerodynamic calculation of air ducts using the permissible speed method:

Draw a diagram of the air distribution system. For each section of the air duct, indicate the length and amount of air passing in 1 hour.

We start the calculation from the areas farthest from the fan and the most loaded.

Knowing the optimal air speed for of this premises and the volume of air passing through the air duct in 1 hour, we will determine the appropriate diameter (or cross-section) of the air duct.

We calculate the pressure loss due to friction P tr.

Using the tabular data, we determine the sum of local resistances Q and calculate the pressure loss due to local resistances z.

The available pressure for the following branches of the air distribution network is determined as the sum of pressure losses in the areas located before this branch.

During the calculation process, it is necessary to sequentially link all branches of the network, equating the resistance of each branch to the resistance of the most loaded branch. This is done using diaphragms. They are installed on lightly loaded areas of air ducts, increasing resistance.

Table of maximum air speed depending on duct requirements

Constant head loss method

This method assumes a constant loss of pressure per 1 linear meter of air duct. Based on this, the dimensions of the air duct network are determined. The method of constant pressure loss is quite simple and is used at the stage of feasibility study of ventilation systems:

Depending on the purpose of the room, according to the table of permissible air speeds, select the speed on the main section of the air duct.

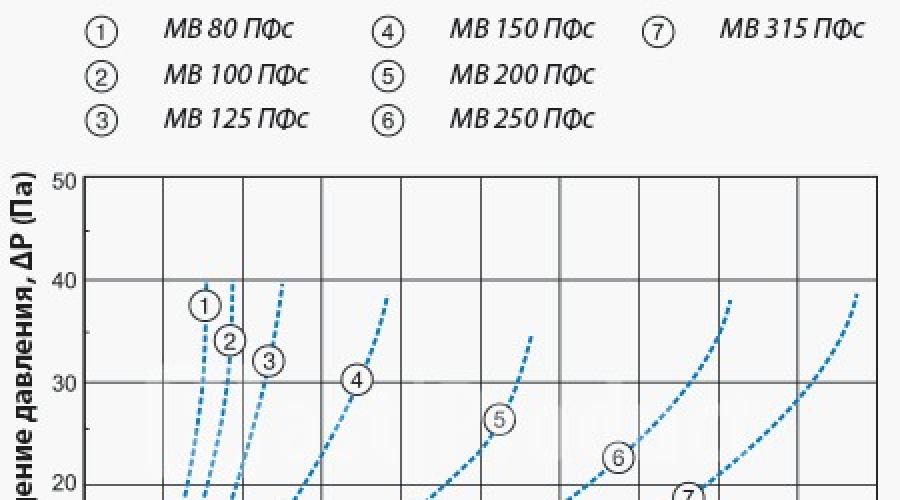

Based on the speed determined in paragraph 1 and based on the design air flow, the initial pressure loss is found (per 1 m of duct length). The diagram below does this.

The most loaded branch is determined, and its length is taken as the equivalent length of the air distribution system. Most often this is the distance to the farthest diffuser.

Multiply the equivalent length of the system by the pressure loss from step 2. The pressure loss at the diffusers is added to the resulting value.

Now, using the diagram below, determine the diameter of the initial air duct coming from the fan, and then the diameters of the remaining sections of the network according to the corresponding air flow rates. In this case, the initial pressure loss is assumed to be constant.

Diagram for determining pressure loss and diameter of air ducts

The pressure loss diagram shows the diameters of round ducts. If rectangular ducts are used instead, their equivalent diameters must be found using the table below.

Notes:

If space allows, it is better to choose round or square air ducts;

If there is not enough space (for example, during reconstruction), rectangular air ducts are chosen. As a rule, the width of the duct is 2 times the height).

The table shows the height of the air duct in mm along the horizontal line, its width in the vertical line, and the cells of the table contain the equivalent diameters of the air ducts in mm.

The aerodynamic calculation of air ducts begins with drawing an axonometric diagram M 1:100, putting down the numbers of sections, their loads b m / h, and lengths 1 m. The direction of the aerodynamic calculation is determined - from the most remote and loaded section to the fan. When in doubt when determining the direction, all possible options are calculated.

The calculation begins with a remote area, its diameter D, m, or area is calculated.

Cross-sectional area of a rectangular air duct P, m:

Start of the system at the fan

Administrative buildings 4-5 m/s 8-12 m/s

Industrial buildings 5-6 m/s 10-16 m/s,

Increasing in size as it approaches the fan.

Using Appendix 21, we accept the nearest standard values Dst or (a x b)st

Then we calculate the actual speed:

Or———————— ———— - , m/s.

FACT 3660*(a*6)st

For further calculations, we determine the hydraulic radius of rectangular air ducts:

£>1 =--,m. a + b

To avoid using tables and interpolating specific friction loss values, we use a direct solution to the problem:

We define the Reynolds criterion:

Rae = 64 100 * Ost * Ufact (for rectangular Ost = Ob) (14.6)

And the coefficient of hydraulic friction:

0.3164*Rae 0 25 at Rae< 60 ООО (14.7)

0.1266 *Nе 0167 at Rе > 60 000. (14.8)

The pressure loss in the design area will be:

Where KMR is the sum of the local resistance coefficients on the air duct section.

Local resistances lying on the border of two sections (tees, crosses) should be attributed to the section with lower flow.

Local resistance coefficients are given in the appendices.

Initial data:

Air duct material is galvanized sheet steel, thickness and dimensions in accordance with App. 21.

The material of the air intake shaft is brick. Adjustable grilles of the PP type with possible cross-sections are used as air distributors:

100 x 200; 200 x 200; 400 x 200 and 600 x 200 mm, shading coefficient 0.8 and maximum air outlet speed up to 3 m/s.

The resistance of the insulated intake valve with fully open blades is 10 Pa. The hydraulic resistance of the heater installation is 132 Pa (according to a separate calculation). Filter resistance 0-4 250 Pa. The hydraulic resistance of the muffler is 36 Pa (according to acoustic calculations). Based on architectural requirements, air ducts are designed with a rectangular cross-section.

|

Delivery L, m3/h |

Length 1, m |

Section a * b, m |

Losses in the area p, Pa |

|||||||

|

PP grid at the outlet |

||||||||||

|

250×250 b =1030 |

|

|

|

With this material, the editors of the magazine “Climate World” continue the publication of chapters from the book “Ventilation and air conditioning systems. Design guidelines for production

agricultural and public buildings“. Author Krasnov Yu.S.

The aerodynamic calculation of air ducts begins with drawing an axonometric diagram (M 1: 100), putting down the numbers of sections, their loads L (m 3 / h) and lengths I (m). The direction of the aerodynamic calculation is determined - from the most distant and loaded area to the fan. When in doubt when determining a direction, consider all possible options.

The calculation begins with a remote section: determine the diameter D (m) of the round or the area F (m 2) of the cross section of the rectangular air duct:

The speed increases as you approach the fan.

According to Appendix H, the nearest standard values are taken: D CT or (a x b) st (m).

Hydraulic radius of rectangular ducts (m):

|

where is the sum of the local resistance coefficients in the air duct section.

Local resistances at the border of two sections (tees, crosses) are assigned to the section with lower flow.

Local resistance coefficients are given in the appendices.

Diagram of the supply ventilation system serving a 3-story administrative building

Calculation example

Initial data:

| No. of plots | flow L, m 3 / h | length L, m | υ rivers, m/s | section a × b, m |

υ f, m/s | D l,m | Re | λ | Kmc | losses in the area Δр, pa |

| PP grid at the outlet | 0.2 × 0.4 | 3,1 | — | — | — | 1,8 | 10,4 | |||

| 1 | 720 | 4,2 | 4 | 0.2 × 0.25 | 4,0 | 0,222 | 56900 | 0,0205 | 0,48 | 8,4 |

| 2 | 1030 | 3,0 | 5 | 0.25×0.25 | 4,6 | 0,25 | 73700 | 0,0195 | 0,4 | 8,1 |

| 3 | 2130 | 2,7 | 6 | 0.4 × 0.25 | 5,92 | 0,308 | 116900 | 0,0180 | 0,48 | 13,4 |

| 4 | 3480 | 14,8 | 7 | 0.4 × 0.4 | 6,04 | 0,40 | 154900 | 0,0172 | 1,44 | 45,5 |

| 5 | 6830 | 1,2 | 8 | 0.5 × 0.5 | 7,6 | 0,50 | 234000 | 0,0159 | 0,2 | 8,3 |

| 6 | 10420 | 6,4 | 10 | 0.6 × 0.5 | 9,65 | 0,545 | 337000 | 0,0151 | 0,64 | 45,7 |

| 6a | 10420 | 0,8 | Yu. | Ø0.64 | 8,99 | 0,64 | 369000 | 0,0149 | 0 | 0,9 |

| 7 | 10420 | 3,2 | 5 | 0.53 × 1.06 | 5,15 | 0,707 | 234000 | 0.0312×n | 2,5 | 44,2 |

| Total losses: 185 | ||||||||||

| Table 1. Aerodynamic calculation | ||||||||||

The air ducts are made of galvanized sheet steel, the thickness and size of which correspond to approx. N from . The material of the air intake shaft is brick. Adjustable grilles of the PP type with possible sections: 100 x 200; 200 x 200; 400 x 200 and 600 x 200 mm, shading coefficient 0.8 and maximum air outlet speed up to 3 m/s.

The resistance of the insulated intake valve with fully open blades is 10 Pa. The hydraulic resistance of the heating unit is 100 Pa (according to a separate calculation). Filter resistance G-4 250 Pa. The hydraulic resistance of the muffler is 36 Pa (according to acoustic calculations). Based on architectural requirements, rectangular air ducts are designed.

The cross-sections of brick channels are taken according to table. 22.7.

Local resistance coefficients

Section 1. PP grid at the outlet with a cross section of 200×400 mm (calculated separately):

| No. of plots | Type of local resistance | Sketch | Angle α, deg. | Attitude | Rationale | KMS | ||

| F 0 /F 1 | L 0 /L st | f pass /f stv | ||||||

| 1 | Diffuser |

|

20 | 0,62 | — | — | Table 25.1 | 0,09 |

| Retraction |

|

90 | — | — | — | Table 25.11 | 0,19 | |

| Tee-pass |

|

— | — | 0,3 | 0,8 | Adj. 25.8 | 0,2 | |

| ∑ = | 0,48 | |||||||

| 2 | Tee-pass |

|

— | — | 0,48 | 0,63 | Adj. 25.8 | 0,4 |

| 3 | Branch tee |

|

— | 0,63 | 0,61 | — | Adj. 25.9 | 0,48 |

| 4 | 2 bends | 250×400 | 90 | — | — | — | Adj. 25.11 | |

| Retraction | 400×250 | 90 | — | — | — | Adj. 25.11 | 0,22 | |

| Tee-pass |

|

— | — | 0,49 | 0,64 | Table 25.8 | 0,4 | |

| ∑ = | 1,44 | |||||||

| 5 | Tee-pass |

|

— | — | 0,34 | 0,83 | Adj. 25.8 | 0,2 |

| 6 | Diffuser after fan |

|

h=0.6 | 1,53 | — | — | Adj. 25.13 | 0,14 |

| Retraction | 600×500 | 90 | — | — | — | Adj. 25.11 | 0,5 | |

| ∑= | 0,64 | |||||||

| 6a | Confusion in front of the fan |

|

D g =0.42 m | Table 25.12 | 0 | |||

| 7 | Knee | 90 | — | — | — | Table 25.1 | 1,2 | |

| Louvre grille | Table 25.1 | 1,3 | ||||||

| ∑ = | 1,44 | |||||||

| Table 2. Determination of local resistances | ||||||||

Krasnov Yu.S.,

„Ventilation and air conditioning systems. Design recommendations for industrial and public buildings”, chapter 15. “Thermocool”

- Refrigerating machines and refrigeration units. Example of designing refrigeration centers

- “Calculation of heat balance, moisture intake, air exchange, construction of J-d diagrams. Multi-zone air conditioning. Examples of solutions"

- To the designer. Materials from the magazine "Climate World"

- Basic air parameters, filter classes, calculation of heater power, standards and regulatory documents, table of physical quantities

- Selected technical solutions, equipment What is an elliptical plug and why is it needed?

The Impact of Current Temperature Regulations on Data Center Energy Consumption New Methods for Improving Energy Efficiency in Data Center Air Conditioning Systems Increasing the efficiency of a solid fuel fireplace Heat recovery systems in refrigeration units Microclimate of wine storage facilities and equipment for its creation Selection of equipment for specialized outdoor air supply systems (DOAS) Tunnel ventilation system. Equipment from TLT-TURBO GmbH Application of Wesper equipment in the deep oil processing complex of the KIRISHINEFTEORGSINTEZ enterprise Air exchange control in laboratory premises Integrated use of underfloor air distribution (UFAD) systems in combination with chilled beams Tunnel ventilation system. Selecting a ventilation scheme Calculation of air-thermal curtains based on a new type of presentation of experimental data on heat and mass losses Experience in creating a decentralized ventilation system during building reconstruction Cold beams for laboratories. Using double energy recovery Ensuring reliability at the design stage Utilization of heat released during the operation of a refrigeration unit at an industrial enterprise - Methodology for aerodynamic calculation of air ducts Methodology for selecting a split system from DAICHI Vibration characteristics of fans New Standard for Thermal Insulation Design Applied issues of classification of premises according to climatic parameters Optimization of control and structure of ventilation systems CVTs and drainage pumps from EDC New reference publication from ABOK A new approach to the construction and operation of refrigeration systems for air-conditioned buildings