The connection of a soft roof to a log wall. Connections between the roof and the wall - structure and features. Sealing the joint where the corrugated sheet meets the wall

Read also

In order for the roof of your house to successfully cope with its main task of protecting residents from moisture and wind, its roof must be one single monolithic product. Its elements, such as the junction of the roof to the wall and other roof structures, should be equipped only with the use of high quality materials, and this responsible work should only be performed experienced specialist. Chosen by you roofing material will dictate its methods for arranging junctions and the materials necessary for these purposes.

Vulnerability of junction nodes

The junction of the roof to a brick or monolithic wall is a rather vulnerable place. In such places, there is usually an accumulation of garbage brought here air currents. And where there is garbage, there is water, which in turn affects the entire area of the junction, disabling the waterproofing and roofing material.

So, due to the cyclical regimes of freezing and thawing of water, materials are first deformed and then completely deteriorated. The accumulation of snow in such places during the winter period contributes to the appearance of leaks.

Sealing the junction of the roof and wall structures is very important process, so this issue must be resolved at the design stage of your home. If you are planning to build a house made of brick, then the project should include a special canopy of half a brick, which will cover the future junction of the roof and the wall structure. Or another way - in the last rows of load-bearing walls, builders must leave a special recess, into which a sheet of roofing material is subsequently inserted to create a reverse corner.

There are two types of roof connections: side and top. In both the first and second options, it is permissible to use joint elements PS-1 and PS-2 (joint strip).

Roof connection unit made of profiled metal

Adjacency metal roofing to the wall is one of the simplest elements in roof construction. The main thing to remember is that there should always be a ventilation gap between the vertical elements, which ensures air circulation in the under-roof space.

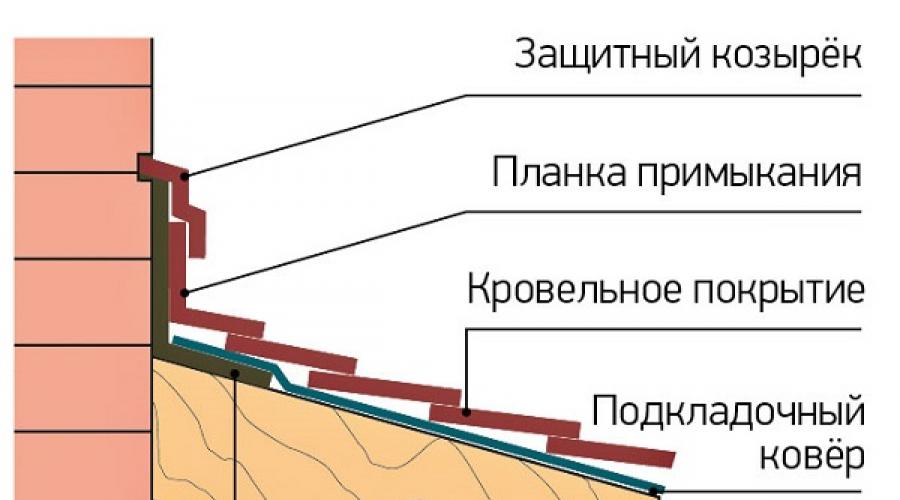

The connection between the roof and the wall is made using special elements made from sheet metal. To do this, at a height of about 200 mm in the wall, using an electric tool (grinder, for example), a groove no more than 3 centimeters deep is made. The upper part of the joint strip is treated with sealant and secured in the groove. The lower part of the PS is pressed to the roof surface with special fasteners, with the obligatory use of rubber or neoprene gaskets. These gaskets are necessary to increase the level of sealing of joints.

The use of double structure PS allows for a much higher degree of sealing of the connection. In this case, you can do without gating the walls, since the upper element of the PS is attached to the base using dowels, after which the lower fragment is placed under the base. It is equipped with a special lock that ensures a secure connection. Also on the lower element there can be clamps, with the help of which the lower element of the strip is secured to the roof. Do not forget to treat the contact areas with sealant before arranging the junction.

Joining roofs made of ceramic and soft tiles

If the roof is made of ceramic tiles, then according to SNiP II-26-76*, the connection is made using a special flexible tape made of aluminum alloy. During installation, such a tape takes the shape of the bends of the tile contour, thereby obtaining the most intimate contact with the roofing surface. Hot bitumen-based sealant is poured into the connecting seam; it reliably fills all cavities and allows for the highest possible level of roof sealing in this junction.

The connection is performed in the same way soft roof to the wall of the house. Flexible metal tape and hot bitumen sealant are used.

Roll roof junction unit

There are several methods available here.

First option. Roll roofing material is attached to the wall of the house using a wooden strip using self-tapping screws with a rubber seal.

The height of the junction of the rolled roofing to the wall of the house should be no more than 200 millimeters. The contact point between the plank and the wall must be treated before performing work. silicone sealant.

To prevent deflections of the roofing material and tears at the junction of the rolled material and the wall structure, an additional wooden element should be installed in the corner between the wall and the roof plane, and the junction should be thermally insulated.

There is comparatively new option arrangement of the junction of the roof to the wall structures. IN in this case the surface junction is treated with an elastic sealant, reinforced with a layer of geotextile, and a layer of sealant is applied again. This method allows you to create the most sealed and durable junction unit. This work can be done by the developer himself.

Flashing method

This technology was developed not so long ago and involves treating the joint with several layers of sealant and reinforcement with several layers of geotextile.

The main thing is to give each layer time to dry; depending on the type of sealant, it can range from 3 to 24 hours. If the technology has been followed, you will receive as a result: - maximum tightness of the junction unit;

Elasticity and flexibility; -high degree resistance to temperature changes;

High degree of resistance to natural factors;

Long service life;

Considerable strength.

Using this method, you can easily and quickly connect a pitched or flat roof made of rolled material of any type to a wall made of any material.

Junctions of pitched and flat roofs to the wall

If an armor layer is used in a soft roof, then inclusions of mineral chips must be removed along the entire length of the junction seam, this is necessary to obtain reliable adhesion of the material to the wall.

If this method is used to arrange the junction of a brick wall structure with a roof, then you first need to look at the quality of the masonry material. If the wall has significant damage and is quite old, then it would not be a bad idea to apply a layer of plaster.

All installation work, which are associated with waterproofing contact points, should be carried out only after the plaster has completely dried. Before starting work with sealants and reinforcing compounds, it is better to apply a layer of primer material and also wait for it to dry. Then you can begin work.

If we're talking about about reinforced concrete wall structures and the adjoining flat roof, you should first make sure the integrity of the surfaces. Very often, over time, cracks and chips appear in such structures. If such problems are found, you must fill them out construction sealant and wait for it to dry.

If there are some unevennesses, they should be sanded or filled. cement mortar. After this, it is necessary to treat the surface with a special primer based on bitumen resins. This operation will significantly reduce throughput material, and will also increase surface adhesion for closer contact of the wall with the mastic.

Contact points between the wall and roofing pie are considered potentially hazardous areas. Any violation technological process during their arrangement will inevitably entail premature destruction of the waterproofing layer. Subsequently thawed and rainwater will freely penetrate into the roof cavities. Wet cotton insulation loses up to 60% of its thermal insulation ability.

In addition, a humid environment leads to the formation of fungi and rotting. wooden elements. As a result, you will have to pay a significant amount for major renovation roofs.

For reliable protection Roofs should be properly covered against weather. It must be made as airtight as possible. The connection of the roof to the wall should be done using techniques and materials that correspond to the type of coating. This will ensure long-term operation of the roof as a whole. It is also important to consider the type of connection - top or side. Depending on this condition, different strips for fastening the roof are selected.

The need to seal the junctions

The junction of the roof covering to the wall is one of the most vulnerable parts of the roof. This is where garbage regularly collects. The wind blows him onto the roof. Garbage, in turn, has the ability to accumulate moisture, which has a destructive effect on the roofing material. Waterproofing may also suffer - the water will constantly thaw and freeze. The risk of leaks near the walls of the building increases the most.

To ensure reliable sealing of the roof, it is necessary to know the principles of arranging joints and take them into account during the design of the house. For example, in the case of brick building you can make a canopy over the future joint in half a brick. Also, when laying, you can leave a recess into which the edge of the roofing material will later be inserted.

A variety of materials can be used to seal junctions. The technology for performing the work is determined taking into account the type of roof. You can distinguish the top and side abutments. In each case, joint strips PS-1 and PS-2 are used.

Corrugated sheet roofing

The installation of a metal roof is much easier than with other materials. The profiled sheet is a simple and reliable coverage. The main thing is to remember that the vertical elements must be at a certain distance from each other (there must be a gap between them). This space will ensure air circulation in the roof cavity.

Any junction of the roof to the wall is arranged using a certain technology. Most often, metal elements are used as a repair agent. The wall apron is carried out after the wall has been chipped. To do this, a trench 3 cm deep is made at a height of 20 cm.

The edges of the element are treated with sealant. After this, it can be installed in the groove. Bottom part the element is pressed to the roof using fasteners. The screws that secure the apron are equipped with rubber gaskets, which prevent moisture from getting under the waterproofing. After installing the apron, the groove is sealed with concrete mortar.

Sometimes you can do without a recess in the wall. To do this you need to install a double apron. Its upper part is attached to the wall with dowels. After this, the lower element is placed under the base. This apron is equipped with a special locking device, ensuring maximum connection reliability. In addition, at the bottom there are clamps that secure the part to the roof.

Important! All areas that will be in contact with each other should be treated with sealant.

When choosing as a roofing material ceramic tiles the junction points must be constructed from tape. It is most often made on the basis of aluminum. During installation soft material able to take any shape, which ensures reliable contact with the roof surface. Hot bitumen sealant must be poured into the joint. After it hardens, all cavities and cracks will be firmly sealed. To equip a passage through the roof, you will need elastic corrugation and bitumen mastic.

Roll roofing

Places where the wall and roll material roofs can be sealed in several ways. One of them is the use of a wooden plank. It is used to press the rolled material tightly and then fasten it with special self-tapping screws equipped with rubber tips.

The junction of the roof to the wall should not be higher than 20 cm. The junction of the plank and the wall must be sealed with silicone sealant. To avoid depressions and breakthroughs, install in the corners between the wall and roof additional element made of wood, and then thermal insulation.

The result is something like a roller. Such a product is able to preserve the integrity of the rolled roofing, which increases its service life. Also, due to this device, the joints are additionally insulated. When settling in warm roof all layers of the pie extend onto the wall. Then they all get covered finishing material. The chimney passes through the roof using elastic rubber elements.

Today, a relatively new method of arranging the junction of the roof and the wall is often used. The surface is treated with a sealant, a reinforcing geotextile layer and, additionally, a sealant. Using this method creates the strongest possible connection. Anyone can install such a connection. The main thing is to choose the right materials.

Flashing

The method is relatively easy to use. Its essence is as follows:

- first, mastic is applied to the surface;

- after that geotextiles are glued onto it;

- the junction on top is again treated with mastic.

To get a high-quality result, you will have to follow several rules:

- Before starting work, clean each surface of any debris and dust. If there is roofing coating on the material, clean it off in places where mastic is applied.

- Brick walls It is worth plastering and waiting until the applied layer is completely dry. Concrete walls treated with bitumen primer.

- Any unevenness on the surfaces to be glued should be removed, and chips should be repaired using sealant.

This method of arranging the junction increases the durability of the roofing pie and rafter system.

Universal method

The use of new roll materials makes it easier and faster to seal joints. The amount of labor costs is also significantly reduced. The result is an absolutely tight connection, regardless of the configuration of the roofing. Such materials are often made of aluminum foil or corrugation, onto which an adhesive composition is applied.

Such materials are used both for connecting devices both during the construction of new objects and during the renovation of old ones. They are produced in the form of strips, which are easy to paste over the desired areas.

The composition from which such materials are made can withstand a temperature range from -50 to +100 degrees. The upper edge of the tape is attached to the wall using a special Vaka strip, which is made of painted aluminum. The strobe is not performed. The upper edge of the strip is insulated with sealant.

Flat roll roofs

Waterproofing of junctions of flat roofs, which are covered with rolled material, has to be done quite often. This is due to the strong impact of precipitation on the roof. Today, liquid rubber is increasingly used for this purpose. It can be applied either by hand or by cold airless spray.

This material is successfully used both for newly constructed roofs and as a repair agent. During application work liquid rubber It is worth monitoring the thickness of the coating. After drying, a rubber-like membrane is obtained, which is characterized by increased wear resistance.

The passage through the roof is often equipped with an elastic penetration. It is made of rubber. This product is a round pyramid with several steps. Flexible penetration can be installed on any roof covering. In addition, it can withstand significant temperature changes (from -50 to +130 degrees) and exposure to precipitation.

Results

The choice of materials and method of arranging the connection between the roof and the wall depends on the type of roofing. For example, in the case of a profiled sheet, it is necessary to make a groove in the wall. If the roof is covered with rolled material, it is enough to secure it at the joint wooden plank and seal with sealant. Also, special self-adhesive tapes are used as a repair agent. They perfectly withstand temperature changes and do not allow moisture to pass through. The passage in the roof is equipped with elastic rubber elements. You can do all the work on connecting the roof to the wall with your own hands - the main thing is to choose high-quality material.

The junction of the roof to the chimney pipe is a rather complex roofing element from a technical point of view, the correct execution of which largely determines not only the service life of the rafter system, but also the comfort of living in the building. If you don't have any personal experience performing roofing and tin works, then it is better to use the services of professionals - mistakes become the reason big problems, eliminating them requires a lot of time and money. In the most severe cases You will have to do unscheduled repairs to the premises and rafter system.

There are a great many options for solving the problem of roof abutment, each professional master makes changes taking into account specific features and his skills. But there are several factors that have a critical impact on the technology of work.

The passage of the chimney through the roof - the main nuances of the arrangement

Roofing type

To cover roofs, soft roofing materials, profiled sheets, piece natural or artificial tiles, and asbestos concrete sheets are used. Each coating has its own nuances in the manufacture of junctions; both standard components produced by coating manufacturers and home-made ones from galvanized steel can be used for them. steel sheets or rolled soft materials.

| Roofing material | Minimum slope angle, degrees |

|---|---|

| Corrugated sheeting | 20 |

| Ruberoid | 3-4 |

| Metal tiles | 25 |

| Asbestos cement slate | 20-35 |

| Ceramic, concrete tiles | 25 |

| Euroslate (ondulin) | 6 |

| Bituminous soft tiles | 11 |

Roofing materials - types and photos

Prices for metal tiles

Metal tiles

Type of rafter system

Depending on the architectural parameters, the roof can be flat, inclined, domed, etc. Depending on the type, the slope of the rafters, the type of base and sheathing for roofing materials, and the location change load-bearing elements designs. All these features must be taken into account when choosing materials and technology for connecting the roof to the chimney pipe.

Chimney parameters

Chimneys are made of brick, concrete blocks, metal or asbestos cement pipes. Structural differences affect not only the technology for carrying out adjoining work, but also the choice of materials. Additionally, during the manufacture of the junction, the location of the chimney must be taken into account.. If it is close to the ridge, then you need to use one technology; if it is closer to the drainpipes, then you should work taking this factor into account. This applies not only to the method of water drainage, but also to the materials used for sealing.

There is one more feature. Brick chimneys can have smooth side planes or with special steps for water drainage. Depending on the method of laying the chimney, a specific algorithm for making the roof connection is selected. Some types brick chimneys do not require gating.

Connection installation time

Work on waterproofing the junction can be carried out during the installation of the roof or after. There are ways to seal a chimney without the need to dismantle the installed coverings; all elements are laid on top of the existing roof.

As an example, consider three options for manufacturing junctions on various types roofing materials: brick chimneys over soft tiles and metal tiles, and round over finished roofing. These are the options that are most often encountered during the construction of private houses. The algorithm for performing the work allows you to perform it yourself without the involvement of expensive specialists. But only under one condition - you have experience covering roofs, necessary materials and tools.

Important! All work on roofs should be carried out only in good weather; the temperature cannot be lower than +5°C.

Step-by-step instructions for connecting a chimney to soft roofs

To create the junction you will need pliers, a medium-sized flat spatula, a mounting knife, a hammer, a screwdriver, scissors for cutting metal, a hair dryer, measuring instruments and devices. A mastic based on modified bitumen is used as a waterproofing agent; for the sealant, you can use a special mastic in a tube or any other material based on impact-resistant external environment polymers. If you have an air gun, great, it will be easier to work. If for some reason you do not have special device, then the nails can be driven in manually.

Practical advice! There is no need to buy expensive tools to make one or more connections. They are used only professional builders on an ongoing basis.

Installation technology flexible tiles involves installing a fillet, plinth or diagonally spread 50x50 mm beam near the chimney. The elements are fixed to the sheathing, pressed tightly against the planes of the chimney and screwed in this position. A waterproofing layer (underlayment) is installed on top of the elements, and individual pieces are glued with bitumen. Chimneys made of piece masonry materials must be plastered, allowed to dry and primed with any bitumen-based material. It is advisable to install the junction unit simultaneously with the installation of the soft roof - this not only simplifies the work, but also guarantees tightness.

Prices for underlay carpet

Underlay carpet

Step 1. Install the shingles in the usual manner until they meet the fillets. If one edge extends onto the surface of the element, it must be cut off with a mounting knife. Make a vertical cut along the corner of the chimney, and a horizontal cut along the bottom line of the fillet. To prevent damage to the underlayment when cutting soft tiles, always place a piece of plywood under the knife blade. Guide the tip of the knife exactly along the fold line of the roof. Cutting soft tiles is quite difficult; use strong and sharp knives.

Step 2. Additionally, seal all corners of the chimney with patches. How it's done?

It is recommended to seal the chimney passage unit using patterns from the remaining pieces of the valley carpet. In terms of its performance indicators, it responds better modern requirements. In extreme cases, it is allowed to use patterns from the lining carpet.

Step 3. Place a piece of carpet at the bottom of the chimney and mark it the width of the chimney. The length of the pattern must correspond to the sum of the height of the sealing on the chimney and the length of the material under the soft tiles. Practitioners recommend taking with a reserve; a large length will not pose a problem for further work, and too short a pattern can cause leaks. Put it in place, bend it and use your finger to find the connection points between the fillet and the slope and chimney. You need to cut the pattern at these points.

The vertical height of the establishment must take into account climatic conditions location of the house and maximum height snow cover, but be at least 30 cm, extending beyond the horizon - at least 20 cm. To these dimensions you need to add the length of the fillet. The width of the pattern depends on the parameters of the pipe; the length of the side parts of the envelope is at least 20 cm.

Practical advice! If it is difficult for you to immediately make a pattern on the valley material, then prepare a template using thick paper. This will make it possible to get practical experience and avoid annoying mistakes in the future. You will find out in which places you need to make bends and which ones to cut off completely, you will see optimal width hems, etc.

A more accurate pattern can be made on a flat surface, transferring the location of the points of the cutting lines and bends using a square and an ordinary nail.

Step 4. Gently coat reverse side each pattern with a special mastic, do not leave gaps. Layer thickness is approximately 0.5–1.0 mm. Modern mastic will reliably glue the pattern to the chimney pipe, allowing it to withstand wind loads, will prevent water from coming under protection.

Prices for mastic for tiles

Mastic for tiles

Patterns must be glued taking into account the direction of water flow. The front one is installed first; its lower part should cover the top of the shingles. All the water from the chimney will subsequently flow onto this element. Next, the side patterns are fixed; later they will be covered finishing coat. The last thing to cover is the back surface of the chimney.

Important! To improve the quality and reliability of gluing, professional roofers recommend using a hair dryer. All joints are carefully bent, heated and re-glued; due to this operation, adhesion between surfaces is significantly increased, the mastic hermetically covers the stone chips located on the material.

Step 5. Insert the upper metal strip to fix the position of the pattern. The planks are sold complete with the roof; if you do not have them, then the elements can be made independently from any galvanized and color-painted coating metal profile. The strips are fixed with dowels; they not only increase the tightness, but also eliminate the possibility of the patterns being torn off from the surface of the chimney.

Step 6. Carefully seal the junction of the strip with one-component polyurethane sealant. Try to fill the cracks to the full depth; remove excess with your finger.

After gluing all the parts to the chimney, you can continue laying the flexible tiles. The shingles are cut evenly at a distance of 5–8 cm, not reaching the lower edge of the fillet. The side cut of the tiles must be coated with mastic, the same operation must be done in all places where there is no self-adhesive layer. The edge of the cut shingles serves as a groove that directs rainwater in the desired direction. The last tiles to be laid are on the back side of the chimney, then work continues on the entire roof.

Bypass of a chimney pipe on a metal profile roof

Initial data: unplastered chimney sand-lime brick, galvanized steel is used for the work.

Practical advice! For the connection, it is better to buy a standard sheet profile for the groove with dimensions of 15x23 cm, the width of the shelf for the groove is 2 cm, the width of the bend of the drainage grooves is 1.6 cm. The profile is galvanized, the zinc thickness is at least 20 microns.

Step 1. Place the profile against the pipe with the side on which there is a curved shelf for entering the groove. Using a construction marker, draw lines around the entire perimeter of the chimney.

Step 2. Using a grinder with a diamond blade, cut a groove at least 2 cm deep. Work carefully, try to make the cuts as even as possible.

Important! Follow safety precautions when working with a cylindrical grinder. Never delete protective cover, work with glasses. Remember that the disk should rotate towards the worker, and not vice versa. If the direction of rotation is not observed, then during biting the tool will be thrown onto the worker, this can cause very serious injuries.

Step 3. First install the galvanized sheet from the bottom junction of the chimney and the base of the metal tile deck to the eaves. It will drain all the water around the perimeter of the pipe. The chimney can also be lined at the bottom; if this is difficult to do, then place it close to the brickwork.

The first element is galvanized sheet

Step 4. Place the bottom joint on top of this sheet. This order must be observed for any method of draining water from the chimney. When installing sheets along the perimeter, one sheet is folded under the other, which prevents moisture from entering the junction areas. How to take sheet dimensions and prepare a pattern?

This completes the cutting process.

Step 5. Place the cut piece in place, bend its side tabs so that they are pressed as tightly as possible against the surface of the pipe. To do this, you need to bend the profile shelves on the folded tabs, which are inserted into the groove. Make sure that the metal fits as tightly as possible to the surface of the chimney, and do not allow gaps to appear. The reason for their occurrence is wrong taken dimensions. If the gap does not exceed 2–3 mm, then there is nothing to worry about, just take into account errors in the future. If the gap is large, you will have to repeat the measurements and cutting the profile.

Step 6. Proceed to form the side junction. Align it with the bottom one, make similar markings for bending and cutting the sheet. Remove excess areas.

Step 7 Attach finished part to the pipe and secure with dowels. Dowels must have rubber gaskets for sealing.

Step 8 Carefully bend the protruding elements onto bottom part bend, use a wooden or metal hammer to press them together as firmly as possible.

Practical advice! Experienced roofers coat the joint line with sealant before bending. This operation does not take much time, and the reliability of sealing increases significantly. We recommend that all beginners use this technology; they do not yet have enough practical skills in working with metal sheets. As a result, the joints are uneven and water can flow into the cracks.

Install the connection on the opposite side of the chimney in the same way.

Step 9 Proceed with the installation of the closing upper abutment element. It is done according to the same principle as the first one. The only difference is that the bend angle of the profile must be reduced, and in the side bends at the angle of the roof, the upper part, rather than the lower part, must be cut off.

At this point, the fixation of the metal abutment elements is completed; proceed to filling the grooves with sealant. Be careful that there are kinks at the edges. metal sheets performed their function and directed the flow of water downwards.

Connecting a round chimney to the finished roof

We have already mentioned that this is not the best option construction, but life often dictates its own rules, you have to solve problems as they arise. Initial data: pitched roof with bitumen shingles, round chimney.

Step 1. Find the exact location of the chimney pipe exit on the roof. To do this, you need to attach a plumb line to the flooring, align it with the center of the stove pipe and make a mark. Drill a through hole according to the mark; working from the roof is much easier.

Step 2. Using a spatula, carefully pry up the shingles and unscrew the screws. If the soft roof is fixed with nails, then the work will become somewhat more complicated. Dismantle the roof using the same method; the dimensions of the freed section of the roof should be 30–40 cm larger than the diameter of the pipe. Carefully stack soft tiles in free space; all of them are reusable.

Step 3. Proceed with installation of the passage element at the chimney outlet; it must be fireproof and airtight. Elements are sold in specialized stores; it is much more profitable and reliable to use factory products than to invent them yourself various devices. The kit includes a pass-through element made of high-strength polypropylene, heat-resistant rubber and a metal clamp.

Step 4. Cut a hole in the heat-resistant rubber to fit the diameter of the chimney. To facilitate work, rings with specified diameters. Pierce a small hole with a knife, and then you can cut it with scissors.

Step 5. There are special lines on the penetration that indicate different slope roofs. Find the mark with your slope and cut the hole. The plastic is very hard; use metal scissors for cutting. Due to this placement, the chimney will be in a vertical position.

Step 6. On the base of the roof, find a hole pointing to the center of the chimney, place the penetration on continuous sheathing and install it in such a way that the centers are located on the same vertical line. Mark the diameter of the hole to be cut for the pipe using electric jigsaw cut out the slab.

Step 7 Place the passage element in place and secure it with self-tapping screws to the continuous sheathing.

Step 8 Install the chimney, put a rubber sealing casing on it. Pay attention to the location of the technological mark; it should face forward. Place the metal clamp and tighten it. There is no need to apply much effort, the rubber compresses easily, and too much load can cut it. Assemble the chimney and install all the special elements on it.

A strip of lining layer is inserted into the gap

Step 10 Replace the shingles and trim off any excess. To guarantee, coat the joints with a high-quality compound.

Prices for popular models of screwdrivers

Screwdrivers

This completes the installation work. To check the reliability of the seal, it is recommended to pour several buckets of water onto the roof.. If leaks are detected, they should be repaired immediately. Doing this in a timely manner is much more profitable than later dealing with unscheduled repairs to the rafter system or roof.

Video - Joining flexible tiles

Video - Chimney. Adjacency

Video - Bypassing a chimney pipe on a metal roof

The content of the article

The junction of the roof with the wall, chimney pipes, and other structural elements of the roof are areas of increased risk for leaks and often cause water to penetrate into the under-roof space.At the junctions, debris blown by the wind accumulates to a greater extent; a large layer of snow most often accumulates here, resulting in rafter system pressure increases and the sealing of the roofing may be disrupted.

Such problem areas are sealed in several ways, depending on the type of roofing. Even at the project development stage, the junction of the roof and the wall should be provided. In the case where the wall is made of brick, during the laying of the walls a protruding canopy of half a brick is made, which should subsequently cover the junction of the roof and the wall and protect it from precipitation. Or a recess is left in the wall for a quarter of a brick so that roofing material can then be inserted into this recess.

Connecting a metal profile roof to a wall

Any profiled metal covering in the area adjacent to the wall, skylights, parapets are made leaving the minimum gap necessary for ventilation of the under-roof space.

If the vertical surface to which the connection is made is concrete or brick plastered, then a recess 2-3 cm deep is made on it, parallel to the roof.

An apron made of steel of the same type as the roof covering, treated with silicone sealant, is inserted into the recess. There are special ready-made strips or aprons. The underside of the strip is attached to the roofing using self-tapping screws .

An apron made of steel of the same type as the roof covering, treated with silicone sealant, is inserted into the recess. There are special ready-made strips or aprons. The underside of the strip is attached to the roofing using self-tapping screws .

The junction of the roof to the wall can be made from two aprons using the overlay method. In this case, the wall is not grooved; the upper apron is attached to the wall with dowels. A lower strip is placed under it, which engages with the upper one with a locking connection. There are special clamps on the bottom strip, which are screwed to the roofing with self-tapping screws. All joints are coated with silicone sealant.

When installing connections tiled roof A tape made of corrugated aluminum is used to the wall. It allows you to repeat the profile of ceramic tiles, and hot bitumen poured into the seam will create reliable waterproofing. Aluminum tape can be used for soft tile roofs.

Soft roof connection device

The junction points of a roof made of rolled materials are made in several ways. In one case, the rolled material is pressed against the wall wooden slats, which is fastened with self-tapping screws.

The height of the roofing felt on the wall is approximately 15-20 cm. The junction of the strip and the wall is coated with silicone sealant. To prevent a depression from forming at the junction of the roofing felt and the wall and subsequently a gap to appear, a triangular block is inserted into the corner between the wall and the roof surface or an additional layer of thermal insulation is made.

Thus, a roller is obtained that protects the roofing material from breaking through and promotes better insulation junction points. When an insulated roof is being made, all layers of the roofing cake, except for the insulation, are placed on the wall along with the finishing coating.

Thus, a roller is obtained that protects the roofing material from breaking through and promotes better insulation junction points. When an insulated roof is being made, all layers of the roofing cake, except for the insulation, are placed on the wall along with the finishing coating.

There is an option for connecting the roof to the walls using the flashing method. The essence of this method is to apply elastic mastic, a reinforcing layer of geotextile and another layer of mastic. This method is distinguished by obtaining a strong and sealed joint between the roof and different surfaces. Using these materials, anyone can make airtight joints themselves.

Before connecting the roof to the parapet using the flashing method, the surface is cleaned of debris, dust and dirt. If roofing felt with a coating is used, it is cleaned off in those places where the mastic will be applied.

Before connecting the roof to the parapet using the flashing method, the surface is cleaned of debris, dust and dirt. If roofing felt with a coating is used, it is cleaned off in those places where the mastic will be applied.

PVC membrane materials are cleaned of dust and degreased. Brick walls are plastered if necessary, after which the layer of plaster must dry. Concrete surface Before use, mastics are treated with a bitumen-based primer. All irregularities on surfaces to be covered with mastic and geotextile must be removed, chips and cracks must be sealed with sealant.

Connections to chimneys and pipes

When connecting the roof to the pipe, a layer of mastic is applied to the prepared surface using a brush or roller, after which the geotextile is immediately laid. A second layer of mastic is applied on top of the geotextile. Drying time for each layer is from 3 to 24 hours depending on the ambient temperature.

When connecting the roof to the pipe, a layer of mastic is applied to the prepared surface using a brush or roller, after which the geotextile is immediately laid. A second layer of mastic is applied on top of the geotextile. Drying time for each layer is from 3 to 24 hours depending on the ambient temperature.

If necessary, you can apply several layers of mastic, but each previous one must dry.

The mastic contains polyurethane, which is a plastic material that is resistant to both high and low temperatures. The range of application of such mastic is from -40 to +75 degrees. The durability of waterproofing mastic is estimated at at least 20 years.

The connection of the roof to a chimney or parapet occurs using a slightly different technology than to a wall. The chimney pipe passes through the ceiling and the roof itself. Therefore, in each case it is necessary to seal the pipe passages. Connecting the roof to the chimney pipe is probably the most complex, responsible and painstaking task in roof construction and therefore requires special care.

1- soft roof, 2 - lining carpet, 3 - base, 4 - sheathing, 5 - timber 50 to 50, 6 - waterproofing, 7 - rafters, 8 - insulation, 9 - timber 50 to 50, 10 - vapor barrier, 11 - edged board, 12 - hemming, 18 - junction strip, 19 - pipe, 23 - valley carpet

- On the upper side, the sheathing near the pipe is laid horizontally.

- fits on it waterproofing material, both edges of which extend onto the pipe on one side and under the roofing on the other.

- In addition, at the junction of the sheathing bar or board to the pipe, a triangular wooden block under waterproofing material.

- Where the waterproofing extends onto the vertical surface of the pipe, its edge is coated with sealant and covered with a metal wall strip on top.

- The strip can be attached with dowels to the pipe or go into the groove and be filled with sealant.

Features of repair work

It is easier to repair roof junctions with roof structural elements using the flashing method, the technology of which is described above. The basis of this method is the one-component mastic Hyperdesmo - RV-1K, consisting of bitumen-polyurethane substances. Its advantage is that it can be applied to any surface of a wide variety of shapes, creating reliable waterproofing everywhere that will serve for many years.

The interface between the roofing covering and the vertical surface of the wall is always considered an area of increased risk for the flow of rain moisture and melt water. Often, when laying material on the roof sheathing, workers simply blow out the junction of the roof to the wall with polyurethane foam and cover it with a decorative canopy. And after a couple of months of windy weather, the first signs of leakage appear. And the longer the line along which the roof joins the wall, the faster the imperfections will appear.

How to properly seal the junction of the roof and the wall

The most problematic is the end connection of the vertical brickwork and the edges of the sheet of roofing material. The joint line is exposed to more intense rain and melt water than the rest of the roof. Even a little rain most often leads to water flowing down the vertical wall and collapses onto the line where the roof meets the wall of the building.

Most often, the junction is sealed in the following ways:

- Decorative overhead canopy with fairly wide overlap fields;

- If soft roofing material is used, the edge is folded over the wall and sealed with mastic;

- Use special seal made of corrugated aluminum, this option is often used for corrugated slate or metal profiles if it is necessary to work with a high “wave”.

Important! The main reason why the arrangement and sealing of the junction must be carried out especially carefully is the temperature deformation of the wall and roof.

The vast majority of roofing and walls are made of different materials, therefore, even the most durable and rigid seam in the area where the roof meets the wall will inevitably collapse due to temperature stresses.

Options for sealing the junction of the roofing material and the wall

Due to microscopic movements, the main material for sealing the abutment line is considered to be:

- Silicone sealants and sealants based on organosilicon. They have excellent adhesion and provide high elasticity to the seam; in the absence of exposure to ultraviolet radiation from the sun, a silicone seam in the roof junction area can last at least ten years;

- Bitumen and polyurethane mastics are used for gluing soft roofing and joint tapes, when correct use give a very dense and flexible connection;

- Polymer and rubber seals do not tolerate high temperatures well and Sun rays, but in some cases they are indispensable for sealing canopies at the junction of the roof on the wall;

- Composite aluminum or copper tapes that can withstand relatively high temperature. They are a specially developed material for sealing a section of the chimney wall and the junction of the roofing material.

Sealing the joint where the corrugated sheet meets the wall

Most difficult situation A scheme is considered in which the roofing material is adjacent to the vertical surface of the wall with the side edge of the corrugated sheet or metal tile. To seal the seam, use an overhead cornice, fixed to the wall with one shelf, and the second shelf pressing the edge of the roof. Arrangement of the junction site is carried out in the following order.

At a height of 10-15 cm above the roof level, a gutter with a section of 3x2 cm is cut out in the wall using a hammer drill or grinder with a stone circle installed. Accurate marking of the gutter line can be obtained by laying a cornice with a rubber gasket on the roof in the area adjacent to the wall. The lower edge of the gutter must be carefully rounded or sloped. The gutter runs along the entire length of the laid roof. The cut groove will be needed to secure the upper edge of the corner cornice along the entire length of the roof. This simple technique will allow you to hide the seam between the cornice flange and the wall into the thickness of the stone. Water flowing down the wall, and even slanting rain will not be able to flow into the space between the stone and metal.

To secure the cornice, you will need to use a hammer drill to punch holes every 30 cm for installing plugs, wooden or plastic. After performing this operation, it is necessary to prepare the surface of the roof adjacent to the wall for installing the cornice. The most in a simple way is the laying layer cement-sand mortar and carefully leveling the wavy surface with a plank. If the edge of the flooring in the area adjacent to the wall has a flat surface, this operation can be abandoned.

We lay a rubber gasket on the surface of the corrugated sheet and install a corner cornice. Using the marked places for plugs in the wall, we drill a hole in the metal wall for self-tapping screws. On last stage We glue the gasket onto the edge of the corrugated sheet using sealant and apply a thin strip of silicone to the surface of the gutter, after which we install the cornice at the junction and fix it with self-tapping screws.

The bottom flange of the curtain rod is usually not attached to the rubber gasket. This allows you to avoid breakage of the glued gasket and depressurization of the joint when the roof is deformed; under load, the shelf simply slides over the rubber surface. At correct execution installation of pressing force metal corner enough to provide protection from moisture.

Sealing the junction of the soft roof

Arrangement of the junction of the soft roof to the wall can be closed and sealed using several simple operations. Laying of a soft roof should be done with an overlap on the wall. The overlap is glued to the wall, if possible with part of the roofing sheet placed on the parapet. The laid roof is secured along the surface of the parapet using a strip. Gluing is carried out using hot bitumen mastic.

When sealing a joint in the case of a soft roof adjoining a wall with a side edge, the size of the overlap of the panel on the wall is chosen such that the folded edge is equal in size to the height of the cornice that will cover the joint. The use of a decorative overlay measuring 10-15 cm significantly improves appearance. If the latter is not of particular importance, or the sealing of the junction zone must be done on a concrete slab, on the roof, it is easier and more reliable to seal the joint with a geotextile plaster laid on bitumen mastic or glue. Most often, 3-4 patches are used with the obligatory procedure of rolling the adhesive coating using a rubber roller.

Sealing the joint of the roof edge at the junction with the surface of the chimney

The chimney passage through the roof especially requires careful sealing due to temperature fluctuations of the pipe itself and the structures partially in contact with it. The sealing scheme is chosen depending on the material of the pipe, the roof and the method by which the passage through the roof is implemented.

If the upper section of the pipe is made of brick, and the roof is covered with non-flammable materials- slate, corrugated sheeting or metal tiles, in this case it is easiest to seal the junction of the roof according to the diagram shown in the figure, with minor additions. First of all, the passage through the roof must be supplemented with thermal insulation in the form of a belt on a pipe made of sheet asbestos, 10-12 mm thick. Waterproofing at the point of contact with the hot surface of the brick can be sealed with high-temperature sealant without the use of traditional bitumen or polymer mastics and films.

According to the norms fire safety, the distance of flammable materials from the chimney elements must be at least 35 cm. In addition, between the walls wooden box a layer of basalt fiber insulation is installed on the rafters under the chimney outlet.

It is easier to seal the junction for a cement-asbestos pipe. In this case, a circular blind area is made from a piece of corrugated sheeting around the pipe, and the joint is sealed with cement mortar with the addition of asbestos or basalt fiber.

Nozzles made of heat-resistant silicone can also be used for metal chimneys, but only on condition that the temperature of the pipe wall does not exceed 230 o C. This is the temperature at which dry pine chips begin to char if they are applied to a metal surface.

A more reliable way to seal the junction would be to use a special metal nozzle on the chimney. Good heat dissipation from the metal surface allows the adapter to be installed directly on corrugated sheets or metal tiles with a high-temperature silicone gasket. For roofing from polymer materials and soft roll coverings It is better not to use this option, even if there is thermal insulation, it may not be enough, and the nozzle will melt the coating.