Painting the roof from ondulin. What is the best way to paint ondulin on a roof - selection and comparison How to paint a roof made of ondulin

When choosing materials for roofing, developers give preference to inexpensive and durable ones, such as ondulin. It is in high demand, but it also has certain disadvantages. One of them is gradual fading in the sun. As a result, the question arises of how to paint ondulin if it is faded.

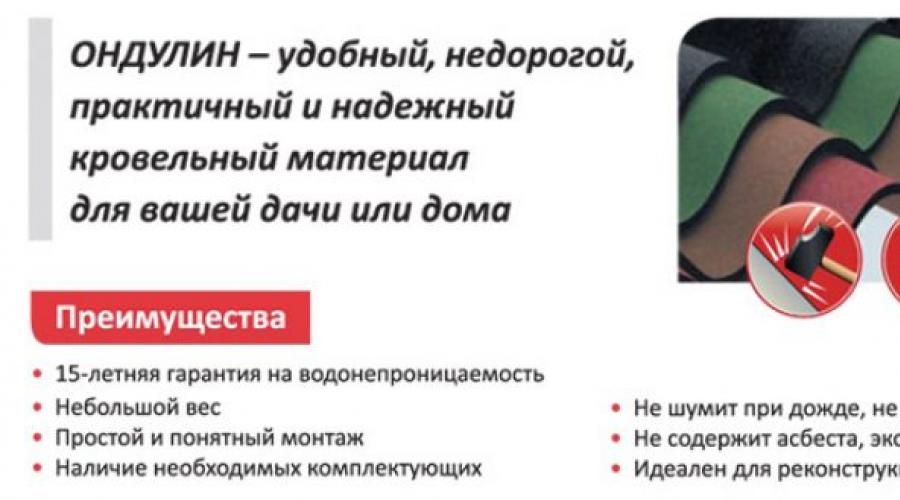

Sheets attract with a variety of shades and saturation color range. Different from others brands quality and high performance characteristics. On the front side there is a marking in the form of the inscription Onduline.

According to the specifics of production, after production corrugated sheets they are painted using a palette of 4 colors, and then “sealed” by treating them with a bitumen composition with the addition of polymers.

- For economy class additional outer layer, allowing to protect and preserve color is not provided. Ondulin fades over time and its color fades. It becomes especially noticeable after 5-6 years of operation.

- Lux after coating with bitumen composition is repainted. This maintains brightness for up to 15 years, but significantly increases the cost.

Possibility to paint roofing material secondly, it gives a chance to protect it from subsequent burnout and leakage. This allows you to renew the roof, change its color, give it the desired degree of dullness and decorativeness, and increase its service life by several years.

Overview of suitable paints

The manufacturer produces roofing sheets using a four-color range: red, brown, green and black. When onduline begins to fade, it becomes dull and unsightly. Over time, bitumen stains may appear on its surface.

The paint was developed by the same company that made the sheets.

- The basis of this high-tech product is an acrylic-silicone composition with additives that make the paint resistant to UV rays and weathering.

- Ondulin sheets can only be painted at air temperatures from +5 to +30°C.

- It is sold completely ready for use, but when thickening it is diluted with water.

- For achievement desired result At least 2 coats must be applied. The second time the treatment should be performed 4 hours after the first layer.

- The consistency allows you to apply the mixture with a brush, roller or spray. In the latter case, the need does not exceed 130-150 g/m2.

If you follow the rules specified in the instructions, the manufacturer provides a 5-year warranty.

The Finnish company Tikkurila produces acrylate paint. It can be applied to sheets that contain bitumen.

Highly valued for its elasticity at temperatures below zero degrees and big choice colors. Service life guarantee – 6-7 years.

3. Chief technologist.

Rubber alkyd-urethane paint produced by the domestic company Novbytkhim is designed for protective and decorative painting. Has a wide scope of application. Before use, stir and adjust to the desired consistency by adding water.

- Resistant to negative environmental influences, cracking, wear-resistant, does not fade.

- Has a fairly large selection of colors.

- Withstands temperature regime from -50 to +60°C.

- Careful preparation of the area and cleaning it of contaminants is required. Sand previously painted areas until matte.

- Painting can only be done in dry weather, with humidity not exceeding 80% and temperatures from +10 to +30°C.

- Application is possible in any way available to the performer. It takes 2-4 hours to dry completely, 2-3 layers are needed. Drying the layer is 60 minutes, consumption is 250-300g/m2.

The guaranteed operational period, subject to storage and use conditions, is from 2 to 4 years.

Paint for ondulin will increase its durability several times, but you need to take into account that subsequently this action will have to be performed at least once every three years.

1. The selected mixture must have performance characteristics the same as roof covering, not only improving appearance, but also increasing moisture resistance.

2. The paint should dry no more than 3-5 hours. When applying several layers, the next one is placed after the previous one has completely dried. The exception is special conditions manufacturers.

3. To obtain a specific color, you need to mix the mixture with a color scheme. It is advisable to use ingredients from the same manufacturer.

4. Before treatment, ondulin roofing must be cleaned, dried, and, if necessary, primed.

5. Primers are selected in accordance with the instructions for the specific composition and are applied in 1-2 layers.

6. Depending on the type of coating, sheets are:

- matte, rough to the touch, painted with acrylic composition;

- glossy, with a bright surface obtained by adding silicone.

7. Ondulin is made using bitumen, so it is better to choose paint with a bitumen base.

The color scheme used by the manufacturer was not chosen by chance. Red, brown, green and black shades harmonize with almost any surface shade.

Before starting the process, you must read the instructions, since failure to follow the technology can cause swelling and premature shedding of the paint.

Popular roofing materialondulinsuccessfully replaced traditional slate.RooffromondulinaIt is absolutely environmentally friendly, as it is made from cellulose fibers pressed and impregnated with bitumen. One of the advantages of ondulin coating is the wide palette of colors offered by its manufacturers. Thanks to this material, any design task for home decoration can be solved.

Unfortunately, such roofing material tends to fade, fade and lose attractiveness over time. In addition, having a natural basis, ondulin does not have high biological resistance. Already in the third year after installing the roof, moss and fungal colonies begin to multiply on its surface. And this leads to the formation of stains on the roof, the appearance of which becomes unpresentable.

Preparatory work, choice of paint

The paint, thanks to bitumen impregnation, does not crack on the surface of ondulin, but tends to fade in the sun. This happens especially quickly if the home owner decides to save on cost. construction work and purchased cheap roofing material. To prevent the painted surface of the roof from swelling, it must be absolutely dry and clean.Roof paintingproduced in spring or autumn, when solar activity subsides, and during mild bitumen roofing you can move freely. If it is necessary to apply a primer or putty on the surface of ondulin, it should be allowed to dry for several days.

Experts recommend using paint on the surface for acrylic base. If the roof surface is covered with real French ondulin, then for its treatment you should purchase branded acrylic paint or analogues recommended by the manufacturer.

Ondulin roof painting

Roofingfromondulinaafter preparatory work and applying patches, as well as good drying, can be painted.Roof paintingIt is made in two layers, and if the process is performed for the first time, then the ondulin roof must be primed. The viscosity of the first layer should be lower than the finishing layer. Such shading is necessary for better wetting of the surface and penetration of paint into all irregularities. Painting the patches is done without sharp pressure on the brush, so as not to disturb the integrity of the edges of the restored roof area.

Processpainting ondulinIt is recommended to start with the ridge and slopes, gradually going down. During the painting process, a hard bristle brush should be rotated periodically to ensure even abrasion. To form an even and high-quality layer of paint, the brush is held in the hand in such a way that the pile is perpendicular to the roof surface. It should be remembered that after painting, each layer must dry thoroughly. The first layer dries for at least 5-7 days, the second - about 10 days.

Order painting of an ondulin roof in Moscow

To perform professionally and reliably:paint the rooffromondulina, just contact the specialists of our company. Our craftsmen have extensive experience and approvals to perform hazardous work at a high level, and can perform high-quality painting of an ondulin roof of any complexity. To do this, you can use the contact numbers listed on the website and get advice at our company office.

Experienced roofers often prefer ondulin, a roofing material that is lightweight and durable. But he has one significant drawback– over time, it begins to fade under the influence of ultraviolet radiation. Painting ondulin allows you to preserve the appearance of the roofing surface.

Characteristics of ondulin

In 1944, a French company began producing ondulin. Initially this material intended for eliminating leaks in roofs covered with slate, tiles or corrugated sheets. Over time, ondulin from the manufacturer of the same name became an independent product. This type of euro slate is inexpensive, practical, and looks quite attractive on the roof.

This material is sold in the form of rectangular sheets with a size of 205x305 centimeters and a wavy profile. It is produced exclusively from natural raw materials:

- purified cellulose fibers;

- petroleum bitumen;

- natural pigments;

- various modifiers.

Advantages of an ondulin roof

The popularity of using ondulin is explained by a number of its characteristics:

- Light weight. A sheet of material weighs only 6 kilograms, which makes it lighter compared to other types of roofing products, so installation requires a simple rafter frame and sheathing. The weight of ondulin makes it possible to lay a new coating without dismantling the old one.

- Strength. This property is due to the presence of a fibrous structure in the material. Ondulin is able to withstand snow load size 300 kg/m².

- Waterproof and low water absorption. The material is resistant to water. It does not absorb moisture due to the presence of bitumen impregnation.

- Long service life. Ondulin is able to withstand 25 cycles, during which it is first frozen and then thawed, without changing its structure or losing its original properties. According to the manufacturer's warranty, the service life reaches 15 years. If the coating is properly cared for, it will last at least 30-40 years.

- Resistance to microorganisms. As you know, ondulin is impregnated with petroleum bitumen, which is a powerful antiseptic and for this reason a roof with such a coating cannot be damaged by fungus and mold.

- Environmental Safety. The components used for the production of ondulin do not adversely affect human health and environment, and this circumstance distinguishes it from other roofing products, which may contain harmful impurities.

Negative effects of ultraviolet radiation - loss of color

A significant disadvantage of ondulin is its instability to ultraviolet radiation. When sunlight hits the roofing surface of this material, the pigment that gives color to the coating begins to deteriorate.

As a result, ondulin becomes dull and faded, but the most unpleasant thing is that this process occurs unevenly. As a result, the destruction of the pigment leads to a decrease in the decorative qualities of the coating - the appearance of the roof deteriorates. But is it possible to paint ondulin?

Two types of this material are produced, which differ in coloring technology:

- Economy class. When manufacturing roofing products, sheets are painted before being impregnated with bitumen. This method allows you to hide under protective layer destructible pigment. As a result, ondulin retains its color for 6–8 years and is much cheaper.

- Luxury class. During the production process, products are subjected to a dyeing procedure 2 times. The first time paint is applied to them before treating ondulin with bitumen, and the second time after. The material is able to maintain color saturation for 10-15 years, but the use of an additional layer of paint increases the cost of the product.

Another disadvantage of ondulin is the small number of options color design. The material is made in only four shades - black, brown, red and green. Limitation color palette forces many owners of private houses to think about solving the problem of how to paint an ondulin roof.

Choosing paint - what is better to paint

Such a problem as color loss by ondulin can be easily dealt with. When the roofing covering finally loses its color and becomes dull, its sheets are coated with special coloring compounds that improve its appearance and at the same time increase the moisture resistance of the roof.

Ondulin paint must have properties similar to those of the coating in order to withstand adverse climatic influences throughout its entire service life. But there is little in the construction market suitable options.

As a result of the limited supply of coloring compositions for ondulin, the following are used:

- "Ondupaint". The paint is produced specifically for painting this material based on silicone and acrylic. After drying, a durable film is formed on the roof surface. Since this paint is produced by the ondulin manufacturer, compatibility is guaranteed. But the Ondupaint color palette is also limited to 4 standard shades. On complete drying The paint takes only 4 hours, and its service life is at least 5 years. The disadvantage of this option is high price, this paint is more expensive than similar compositions.

- Acrylic paint. It is made on the basis of water-dispersed polyacrylate. When dry after application acrylic paint a film is formed on the roofing surface, insoluble in water and similar in properties to bitumen. Its cost is cheaper than Ondupaint, but it lasts only a few seasons. The advantage of this option is the huge choice color solutions. Usage acrylic composition allows you to paint the roof in any color.

- Bitumen mastic. She is also called " liquid rubber" Due to the compatibility of the compositions, mastic is best choice How to paint ondulin if necessary to renew the roofing. When applied, a durable film is formed on the surface of the material that resists atmospheric influences. Coloring composition bitumen-based paint is more expensive than acrylic paint, but cheaper than Ondupaint. Its service life is approximately 3 years. All shades included in the color palette bitumen mastic, matte. The composition dries quickly, only 2-3 hours.

To obtain optimal results, the roofing surface must be properly prepared. First, the stingray is cleaned using water, sometimes this requires a brush with plastic bristles. After drying, the ondulin surface is primed and painted in one or two layers.

The modern building materials market offers roofing coverings for every taste and budget. Thanks to high competition, the consumer receives high-quality products for reasonable money, which are constantly being improved by the manufacturer. Recently, experienced roofers have “introduced fashion” to ondulin, a lightweight and durable roofing material for roofing. But it has one unpleasant property - such a coating fades over time under the influence of ultraviolet rays. In this article we will tell you how to paint ondulin in order to preserve the aesthetic appearance of the coating and extend the life of the roof.

Material trait

Ondulin is the name given to the products of the French company of the same name, which began producing this practical roofing material back in 1944. It was conceived as a means of quickly repairing and eliminating leaks in roofs made of corrugated sheets, slate or tiles without dismantling the structure, which over time turned into an independent covering. Ondulin is a rectangular sheet with a wavy profile, the size of which is 205x305 cm. The composition of this roofing material includes only natural ingredients: purified cellulose fibers, natural pigments, modifiers and petroleum bitumen. The use of this material has the following advantages:

- A light weight. One sheet of ondulin weighs only 6 kilograms, which makes this material lighter than other roofing coverings. That is why quality, it is mounted on the most simple rafter frame and lathing. The lightness of ondulin allows you to lay a new coating without removing the old one.

- Strength. The fibrous structure provides ondulin with greater strength; it can easily withstand a snow load of 300 kg/m2. A large load under which an ondulin roof is deformed amounts to 600 kg/m2, but in most cases it is not the roof covering that is destroyed, but the sheathing and frame.

- Waterproof and low absorbency. Ondulin is highly resistant to melt or rain water; it does not absorb moisture due to bitumen impregnation.

- Long term operation. Ondulin can withstand 25 cycles of freezing and thawing without transforming the structure or losing properties. The service life of the material, guaranteed by the manufacturer, is 15 years. With proper care, a roof with such a coating will last at least 30-40 years.

- Microbial resistance. The petroleum bitumen with which ondulin is impregnated is a strong antiseptic, so a roof made of this material will not be damaged by mold, mildew or moss.

Note! The main advantage of ondulin is the safety and environmental friendliness of this material. All components included in the composition do not have any negative influence on external environment or human health. This property distinguishes ondulin from other roofing materials that contain harmful impurities.

Effect of ultraviolet

Perhaps the only drawback of ondulin, which sellers and manufacturers constantly warn customers about, is the instability of this material to ultraviolet radiation. At a time when the corrugated roof gets hit Sun rays, the natural pigment that gives color to the coating, begins to slowly deteriorate. As a result, ondulin fades over time, and the destruction of the pigment occurs unevenly. This process significantly reduces decorative qualities coating, spoils the appearance of the roof. There are 2 types of material, differing in the coloring method:

- Ondulin "economy" class. During the production of roofing sheets, the pages are coated with paint before being impregnated with bitumen. This technology allows you to “hide” the easily destructible pigment under a protective layer. Ondulin "economy" class is less resistant to ultraviolet radiation, so it retains color for 6-8 years, but it costs an order of magnitude cheaper.

- Luxury ondulin. During the production of luxury roofing, the painting procedure is performed 2 times. The pages are painted first before being soaked in bitumen, and a second time after finishing. Thanks to the double layer of pigment, the material retains its rich color for more than 10-15 years, but for this additional layer paint will need to be paid.

Fundamentally important! Another problem with working with ondulin is the limited range of colors in which this material is produced. The manufacturer produces roofing coverings in 4 shades: dark, brown, green, red. The scarcity of the color palette forces many homeowners to paint ondulin themselves using special compositions.

Choice of colors

Fortunately, the problem of ondulin fading is quite easy to deal with. To do this, at a time when the roofing material completely loses its color, the pages are painted with special compounds. This coating enhances the appearance and at the same time increases the moisture resistance of the roof. Paint for ondulin must have properties similar to it in order to withstand negative weather conditions throughout the entire service life. But, construction market doesn't offer many suitable options. For staining ondulin use:

Skilled roofers say that in order to achieve optimal results when painting, it is fundamentally important to properly prepare the surface to be treated. First of all, the roof slope is cleaned of dust and dirt using water. From time to time alone " water procedures“is not enough, then a brush with plastic bristles comes into motion. After drying, the ondulin is primed, and then paint is applied in 1 or 2 layers.

Video instruction