Why “Needle” silts up or How to distinguish a correctly made well from a fake. How to make an Abyssinian well - making a homemade machine for drilling wells What kind of pipe is used for the needle well

Read also

Comfortable stay without clean water It's simply impossible. Regularly purchasing drinking water is expensive and unprofitable. Limited family budget does not allow you to use the services of well drilling companies? There is always a way out. The time has come to remember the technical structure that is accessible to everyone, and install an Abyssinian well at home with your own hands. This design was invented by the Americans, and in another way it is called a needle well.

At first, people called an Abyssinian well a shallow well with a hand pump pumping clean water from an aquiferous sand layer. The special design allows you to get water without spores, runoff or contamination.

Before you start drilling, you need to carefully study the geology of the area. You can find out from neighbors who have already provided their site with water, or from a geological survey conducted during the development of the site. The construction of a needle well is possible if the first aquifer is no deeper than 8 meters. For a lower layer, you need to drill a wide well and lower the pump into it.

Abyssinian well works great on an aquifer made of a mixture of sand and crushed stone or medium-grained sand. It will not be possible to install a needle well on a site if the geological map shows deposits of hard rocks, pebbles, and boulders. To reach the water flowing under such layers, you will need special equipment.

Advantages of using a needle well

- Simplicity of design and low price level.

- Possibility of installation without disturbing the landscape of the site.

- Large equipment is not used.

- Possibility of installing the pump indoors or directly on site.

- Drilling requires a maximum of 10 hours of working time.

- Installing a high-quality filter prevents silting of the well.

- The closed system does not allow contaminants to enter the well.

- High quality of produced water.

- Possibility of ensuring a constant supply of water in the required volumes.

- If necessary, the well can be dismantled and installed in another location.

Note! Due to the shallow depth of the Abyssinian wells, practically no dissolved iron gets into the water.

Well drilling

Not everyone can afford to buy special equipment to drill just one well or call in specialists. It is possible with the help of not too complex and expensive instruments make an Abyssinian well.

Tools required for work:

- Several pieces of gas keys.

- Grinder and drill.

- To slaughter a pipe, you need pancakes from a rod weighing 20 or 40 kg.

- Sledgehammer and hammer.

- Welding machine, pumping station.

- An inch pipe cut into meter pieces with short threads at the ends.

- One meter of ¾ inch pipe.

- Ten meters of ½ inch pipe.

- Garden auger, check valve.

- Bolts and nuts 10.

- Car clamps.

- A piece of mesh 16 by 100 cm of galloon weaving from of stainless steel.

- Cast iron couplings for connecting and slaughtering pipes.

- Wire with a cross-section of 0.2-0.3 mm - 2 m.

- HDPE couplings and pipes.

Making a filter

- Weld a cone-shaped tip onto an inch pipe 1.1 m long. If you were unable to buy such a tip, you can use a sledgehammer to flatten the end of the pipe.

- Using a grinder, carefully cut slots up to 2.5 cm long on both sides of the pipe every 2 cm. You need to do everything slowly, trying not to damage the strength of the pipe.

- Wind the wire onto the pipe and put a mesh on top, securing it with clamps every 10 cm. If possible, it is advisable to solder the mesh.

Note! Do not use solder with lead to avoid water poisoning. You need to work with tin solder and special flux.

Drilling technology

Using a garden auger, start drilling the soil, gradually building it up with prepared pipes. For this, ½-inch pipes are used, which are connected with couplings made from ¾-inch pipes and 10-point bolts through pre-drilled holes.

Continue drilling until wet sand begins to flow from the surface of the drill. There is no point in drilling further, the wet sand simply flows back into the well.

Installation of a pipe with a filter

Using couplings, connect the filter to the pipe sections. Be sure to wrap FUM tape around the thread. Ready design lower it into the hole until it reaches the sand. Screw a cast iron coupling onto the top of the pipe and place the prepared pancakes from the rod on it. The axis must be passed through the center of the pancakes, this is necessary for them to slide when clogging the pipe. For the axle, use ½ inch pipe 1.5 m long. There should be a bolt at the end of the pipe.

After each impact, the pipe is immersed in the ground by several centimeters. The tip with the filter should penetrate 50 cm into the sand layer. After this, it is necessary to pour a large number of water into the pipe.

Pumping water

First of all, it is necessary to install a check valve, and then a pumping station.

Note! The entire structure must be sealed.

Fill the pumping station with water and connect a hose to the outlet. Start the pump. At first, air may come out of the well, and then dirty water. After a certain period of time, good clean water will appear. To check the quality of the water, take it to the sanitary and epidemiological station for analysis.

It is better to do around the Abyssinian well concrete platform to ensure the outflow of precipitation. Now there will always be clean water on your site, and you will be able to grow your own vegetables and flowers.

The needle well, also known as the Abyssinian well (AK), is a pipe with a diameter of 40-70 mm submerged to a depth of 8-10 meters, at the end of which a conical sieve-shaped tip is installed. Water is drawn from such a well using a pump or a hand pump mounted at its mouth.

In this article we will tell you how to make an Abyssinian well with your own hands. You will learn the advantages and disadvantages of this design, receive recommendations for choosing a pump and driving a pipe, and also be able to familiarize yourself with diagrams that explain in detail the process of constructing a needle well.

1 Device, advantages and disadvantages

The first Abyssinian wells were used in the 70s of the last century during the British military campaign against Ethiopia. In the dry climate of the African country, the soldiers desperately needed a universal source of water supply, the arrangement of which would not take much time. It was possible to make such a source by punching a hole in the ground using a Norton projectile, which yielded almost 2 buckets drinking water in a minute.

The Abyssinian well is widely used to this day, remaining one of the simplest in the world. The cost of equipping a turnkey needle well varies between 15-20 thousand rubles, another 5 thousand will need to be spent on a simple surface pump. If, then the final costs can be reduced to 10 thousand. Low price installation is key advantage from this source, for comparison, prices for the construction of a conventional well start at 40 thousand.

Installation Abyssinian well does not require the use of expensive equipment. The pit is made through conventional percussion-rope drilling, which requires the efforts of two adult men. You can also do the installation of the UDC yourself or rent it. The depth of the aquifer in the central part of Russia is 5-10 meters; it is possible to drill a well to such a depth in one working day.

The advantages of AK also include:

- long service life, which can reach 30 years;

- the minimum dimensions of the well allow it to be made directly in the basement of a house or cottage;

- subject to installation technology - clean water;

- no need to obtain permits, as is the case with the installation of deeper wells.

This water source also has its drawbacks. First of all, let us highlight its situational nature - it makes sense to build such a structure only in coarse-grained sands and bedrock; in all other types of soil it will have insufficient flow or will quickly silt up.

It is also worth considering that the quality of water obtained from surface soil layers varies greatly in different places. Such a well must be located at a sufficient distance from any sources of pollution, as well as from natural bodies of water. (at least 5 meters).

1.1 How to make an Abyssinian well with your own hands? (video)

1.2 Tools and materials for AK installation

To build an Abyssinian well with your own hands, you will need the following set of materials:

- A needle is a cone-shaped tip that is placed on a pipe string, due to the sharpness of which the casing is more effectively driven into the ground. To the strength of the needles extend increased requirements, so it makes sense to buy it in a ready-made form, however, if available lathe and welding equipment, you can do it yourself. The length of the needle should be 15-20 cm, the diameter should be 20-30 mm larger than the diameter of the pipes. The needle is fixed to the pipes using a threaded connection.

- A water intake main is a column of interconnected casing pipes through which water is supplied. Most often, pipes with a diameter of 40-70 mm are used, joined together using threads or couplings, the joint is sealed rubber seals or flax tow.

- Filter - perforated pipe, installed on the lower section of the highway. The filter removes mechanical impurities and sand from the water entering the column. The pitch of the holes is selected based on the specific diameter of the pipe, the average distance is 5 mm. On the outside, the section is wrapped with a special filter mesh for wells, which is attached to the pipe using wire.

You will also need a pump to supply water from the Abyssinian well. Here it is necessary to use a surface-type pump, since the diameter of the water intake column will not be enough to accommodate submersible pumps.

An interesting fact is that even powerful modern surface pumps cannot lift water from a depth of more than 9 meters - this imposes a limit on the maximum depth of the needle well. We recommend buying a centrifugal pump with a capacity of 30-40 l/min and a head of 20-30 m. Give preference to equipment from trusted manufacturers - Grundfos, Gardena, Hitachi. The cost of such equipment varies within 10 thousand.

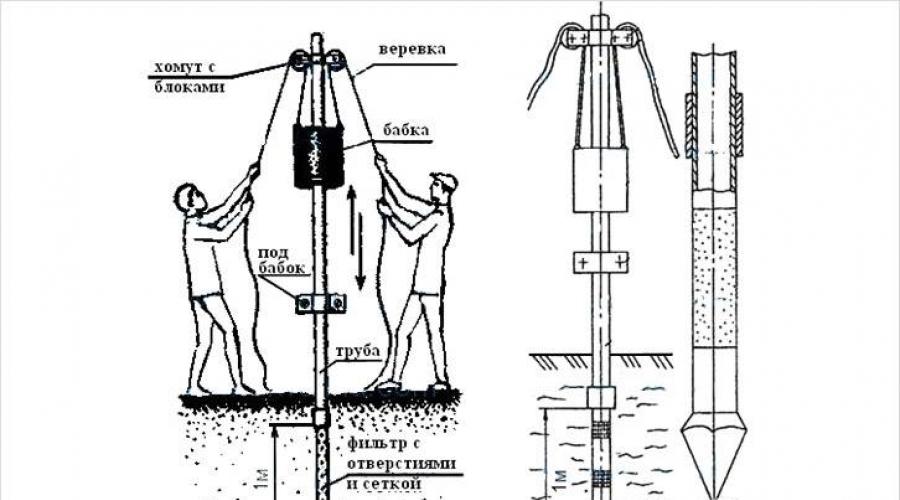

A special headstock is used to drive pipes. You can buy it, rent it, or make it yourself. At self-production From a square steel profile you need to weld a tripod about 2 meters high. At the top of the tripod there should be a block with rollers for hanging the weighting material (headstock) using cables.

The headstock itself can be made from a concreted pipe with a diameter of 10-15 cm. It is also recommended to weld handles to the headstock, which will make it possible not only to drop the weighting agent onto the pipes being driven, but also to help the process manually.

2 What is the technology for driving a needle hole?

Work on developing the Abyssinian well begins with searching for a drilling site. It is impossible to hammer a needle on slopes and sloping terrain, since when groundwater is withdrawn, the risk of landslides sharply increases. It is also necessary to maintain a distance of at least 15 meters from sources of pollution - compost and sewage pits, septic tanks, toilets, etc.

Next, the place of driving is marked and the tripod with the headstock is deployed. Relieve initial stage driving can be done using hand drill by developing a well of the maximum possible depth. Next, the first section of the column (with the tip installed on it) is inserted into the cavity, its verticality is checked and driving begins - the cable holding the headstock is pulled, the projectile rises and from the top point is lowered onto the pipe, which sinks into the ground from the weight of the falling projectile.

After driving the first section, it is fixed on the pipe coupling, the next section is screwed into it and the driving is repeated. During the immersion process, it is important to constantly monitor the vertical position of the column using a level; at the slightest deviation, it is necessary to install spacers and try to straighten the line.

You may encounter that different stages driving column will be immersed with at different speeds. This is due to the fact that it passes through soil layers of different densities. To soften the progress, you can water the soil around the pipes.

After water appears in the well (you can check this by using a strip wrapped in paper lowered on a cord inside the column), it is necessary to rinse the main filter with a strong stream of water to remove clogged soil from the perforations. Do not be alarmed if the Abyssinian well at first produces muddy water- this is possible within the first day after completion of its installation.

The surface pump can be installed in any convenient place not far from the well, but keep in mind that using a pump you can pump out water only in the warm season, since this technique cannot be used when sub-zero temperatures. If you plan to operate the well in winter time, then it is rational to install a mechanical pump (manual piston pump), which can be purchased for 4000-6000 rubles.

Connect a small country estate to central water supply very often impossible due to the remoteness of the water main. Digging a well or drilling a well is sometimes not affordable, but for the construction autonomous system you need your own water source.

In such cases, you can equip an Abyssinian well with your own hands - the technology for organizing such a source of water intake is quite simple. Agree, before starting to implement the idea, it is necessary to understand the design and operating principle of the system.

We will tell you how to plan an Abyssinian well, what equipment you will need and how to make an igloo well yourself. Special attention should be given to the type of soil on the site.

An Abyssinian well is a simplified version of a well that allows you to obtain water from the first or second aquifer lying on top. Its design is extremely simple. It is a column of interconnected gas pipelines steel pipes with a primitive filter and a metal tip at the bottom.

The thin trunk of the excavation looks like an ancient sewing device. Hence the second name: needle well.

The classic method of immersing an Abyssinian well into the ground is done by banal driving - the most in a simple way, actively used in the environment independent masters. They hammer until the lower pipe with the tip opens the aquifer.

Sometimes the column is partially buried by auger drilling, but renting a manual or mechanical drilling rig significantly increases the work budget.

The Abyssinian well was invented and tested during the war between colonial England and Ethiopia in 1867-68. Proposed American engineer Norton's design tirelessly provided the British troops with water during their movements across the desert.

Image gallery

There are two main components in the design of an Abyssinian well:

- drill bit, including a tip that cuts the soil and a barrel that grows during the process of penetration into the ground. The trunk also serves as a channel for lifting water from the depths. Therefore, it is assembled from pipe sections, and not from a steel circle or rod.

- Koper, consisting of a metal tripod and a heavy woman playing the role of a hammer. At the top of the tripod there are two blocks with ropes stretched through them, to which the woman is tied.

When the ropes are pulled, the woman rises to the top of the installation. When weakened, it rapidly falls onto the headstock, rigidly fixed on the section of the trunk being driven in. The latter performs the function of an anvil, thanks to which the trunk is consistently immersed in the ground.

An alternative option for adapting the water intake needle to an unsuitable level groundwater consists in the construction of a pit. Before driving the column into the ground, a hole is dug about a meter deep, the width of which is convenient for working with a shovel in it. Driving the rods then begins from the bottom of the hole. In such situations, the pump is installed in a pit.

For those who decide to make an Abyssinian well with a pit, information is needed about the structure and condition of the soil layers lying at the depth of the pit. If the section is composed of sandy loam, loam or their alternating layers, it is not necessary to strengthen the walls of the pit.

Loose, unstable walls of the pit should be strengthened so that the wellhead of the needle and pump equipment did not fall asleep with non-cohesive soils

If the pit is dredged in sand, the walls should be reinforced with boards or concrete. Sandy sides are unstable and can collapse and cover the water intake point along with the pumping equipment.

Questions about upper layers soil is also needed by those who plan to go through the upper part of the excavation with an auger. Auger drilling will significantly speed up the process, but may not bring the planned result. For work, use a simple device - purchased or.

With collapsing sand walls, an installation will be required, due to which the economic priorities of the Abyssinian well will be reduced.

Installation and operation of the Abyssinian well is the simplest and cheap method obtaining water from upper aquifers. To construct a water intake shaft, no equipment is required; all stages of the work can be easily completed with your own hands.

The invested efforts and small funds will quickly pay off; the Abyssinian well will last no less than traditional water sources. It is important to get excited and implement the idea, armed with the information we present.

Do you have practical skills in constructing a needle well on your site? Please share your accumulated knowledge or ask questions on the topic in the comments below.

Availability on summer cottage water - necessary condition his existence. If the owner has a limited budget, then you can use the construction of a low-cost technical structure, which is available to most summer residents.

The technology for installing an Abyssinian well with your own hands is quite simple. This type of well or well needle was invented by the Americans back in the 19th century. The article suggests familiarizing yourself with the basic rules of its design.

What geological conditions are needed to construct a well?

- a shallow well into which it is installed hand pump. With its help, water is pumped from the aquiferous sand layer.

This structure differs from a conventional well in the presence of very clean water. It is not clogged by dust, dirt, drains and water.

Before you begin to implement your plan, you need to get acquainted with the geology of your area. Usually, neighbors who have owned plots nearby for a long time can tell about this.

They know where the soil layers are located and the depth of the aquifers.

Advice: An Abyssinian well can only be constructed if the upper aquifer is located no deeper than 8 m from the ground surface. From greater depths, lifting water using surface pump may prove problematic. If the aquifer lies lower, a sand well should be drilled with a larger diameter or the pump should be buried, rather than using a surface pump.

Soil requirements for constructing a well:

- The aquifer for which the well will be constructed must contain medium-grained sand or a mixture of crushed stone and sand. Such soil allows water to pass through well and will be easy to pump out.

- The condition for the upper layers is only their permeability. Otherwise, you will need special equipment.

What are the advantages of such water supply?

Advice: If your dacha neighbors already have similar wells, then there won’t be any special problems constructing one on the site.

Advantages of the Abyssinian well:

- Simplicity and low cost of design.

- It does not require much space for its arrangement: the structure does not disturb the composition of the landscape.

- There is no need to use equipment, no access roads are needed to deliver it to the site.

- The pump can be installed on site or indoors.

- The work will take no more than 10 hours, which depends on the hardness of the soil and the depth of the water carrier.

- Siltation is prevented by quality, which allows the structure to be used for a long time.

- No contaminants enter the device from the surface of the earth.

- The quality of water from such a well is similar to that of a spring.

- The needle water well provides a constant supply of water volume. It is enough to water the plot and for household needs: for an average well, the debit is from 0.5 to 3 cubic meters per hour.

- The device can be easily dismantled and installed in another location.

- Such wells are shallower than traditional sand wells, which reduces the likelihood of dissolved iron entering structures. This eliminates the need to install filters, which are quite expensive.

Equipment design features

The functioning of any well and Abyssinian well depends on the quality of the pipe and its size:

- For construction, it is best to use inch or one and a half inch pipes made of metal or plastic, cut into pieces one to two meters long.

- As the pipe is immersed, the pipe is built up to the required length. Their connection is made with threaded connections.

- Silicone, plumbing flax, and oil paint are used for sealing.

- Special couplings are also used for connection.

Tip: It is necessary to ensure that the pipes are connected securely enough. A leak in the seal can damage the entire structure.

- To advance the device through the soil, the diameter of the tip must be slightly larger than the diameter of the pipe.

- The end of the pipe ends with a special needle filter. This facilitates the passage of the pipe in the ground, protects the well structure from silting, and ensures the purity of the incoming water.

Tip: It is best that the needle for the Abyssinian well is made of the same material as the main pipe, which will prevent the occurrence of electrochemical corrosion.

For the manufacture of a filter needle from galvanized metal pipe, necessary:

- Holes with a diameter of 5 to 8 mm are drilled in the pipe; they must be placed in a checkerboard pattern.

- A stainless steel mesh is soldered on top. If there is no mesh, you can use wire; it is wound around the perforated end of the pipe, leaving a gap between the turns.

- The wire is also soldered.

- A spear-shaped tip is welded to the end of the pipe, the diameter of which is slightly larger than the pipe. This is necessary for the free movement of the structure following the needle.

Tip: For solder you need to use only pure tin. The presence of lead in it is unacceptable for an Abyssinian well; this can cause severe water poisoning.

Suitable for such a well reinforced pipe made of polypropylene.

To make a filter needle from PVC pipes need to:

- Insert a filter mesh inside the pipe.

- Secure it using the fusion method.

- Perforate the pipe. To do this, slits are made on its surface with a hacksaw.

How to build an Abyssinian well

To make a structure, you can use one of two methods:

- Scoring. To drive structures into the ground, a “driver” is usually used. In this case, you need to constantly add water to the pipe. After a sudden drop of water into the soil, the structure is deepened another half a meter, then installation can begin.

The driving method for creating an Abyssinian well is excellent, but there are a number of dangers. The main one is the probability of passing by the aquifer.

In addition, if a stone is encountered at great depths, the structure may be completely damaged.

- Small diameter drilling. This method guarantees the presence of water in the well, but its use requires special equipment.

Advice: It is better to pour one or two bags of marble chips into the well to create an additional filtration circuit and prevent siltation of the structure.

To build a well you need to purchase:

- Drill and grinder.

- Hammer and sledgehammer.

- A pair of gas keys.

- Pancakes from a bar from 20 to 40 kg, for clogging a pipe.

- Welding machine.

- Garden drill with a diameter of 15 cm.

- Pipes: From 3 to 10 meters - ½ inch, 1 meter - ¾ inch.

- 1 inch pipe for a well, in pieces of 1-1.5 m with a short thread on each side.

- Bolts and nuts 10.

- Mesh made of stainless steel galloon weaving P48, 1 m long and 16 cm wide.

- Car clamps 32 sizes.

- Couplings: steel, for connecting pipes and cast iron, 3 - 4 pieces, for clogging pipes.

- Wire two meters with a diameter of 0.2 - 0.3 mm.

- Pumping station, HDPE pipes, check valve and couplings.

How to make a filter

To make a filter, you need an inch pipe approximately 110 cm long; a cone-shaped tip is welded to it - a needle for an Abyssinian well. If you don't have one, you can simply flatten the end of the pipe with a sledgehammer.

Next you need to do:

- Using a grinder, slots are cut on both sides of the pipe at a length of 80 cm every 1.5 - 2 cm, the size of the slot is from 2 to 2.5 cm. In this case, the overall strength of the pipe should not be compromised.

- A wire is wound onto the pipe.

- After this, a mesh is placed on it and fixed with clamps every 8 - 10 cm. The photo shows ready-made filters for the Abyssinian well.

In America, unlike the Russian Federation, for example, a filter for such a well is made with an internal mesh and wire located above and below the mesh.

Drilling technology

The instructions indicate that the drilling process is as follows:

- The soil is drilled using a garden auger.

- The structure is built up from pipes: meter-long ½-inch pipes are connected to each other using couplings from pipes with a diameter of ¾-inch and 10-inch bolts. Holes must first be drilled at the fixation points.

- The process continues until wet sand appears flowing from the surface of the drill. Further drilling makes no sense - wet sand will return back into the well.

- The pipe with the filter is clogged.

- The pipe sections are connected to the filter using couplings. FUM tape is screwed onto the thread.

- Then such a structure with a pipe filter is lowered to the sand, and a cast iron coupling is screwed onto it on top.

- Pancakes are placed on this coupling from the bar. An axis is passed through their center, along which the pancakes will slide and clog the pipe. The axle is made from a piece of pipe 1.5 meters long and ½ inch in diameter with a bolt at the end.

- With each blow from the pancake, the pipe plunges several centimeters.

- After passing half a meter from the sand level, you need to pour some water into the pipe. If she disappears, the sand has accepted her.

How to pump a finished well

The process of pumping a well is as follows:

- A check valve is installed.

- A pumping station is being installed. It is necessary to ensure the tightness of the entire structure.

- Water is poured into the alluvial station.

- A piece of hose is connected to the outlet.

- The pump starts. Initially, air will come out of the well, and then muddy water.

- After this, clean water will appear. You can verify its quality after carrying out tests (see) or simple boiling.

How water is extracted at the dacha using a well needle can be seen in detail in the video. This article suggests brief information about the stages of device construction.

Having made an Abyssinian well with your own hands, it will be possible to extract water from the soil layer closest to the surface - sand. In most cases, the water passing through the porous structure is of sufficiently high quality (this parameter must be tested in a laboratory), so there is no need to drill deeper and, accordingly, pay more.

Before drilling, you can ask your neighbors about the quality of water, and after the well is installed, its suitability for drinking and cooking is determined in a laboratory. At the same time, the Abyssinian well (needle well) has design differences and certain advantages when compared with a classic well, which, in accordance with its depth (to the sand layer), is called a sand well.

To determine which is best for you, an Abyssinian well or a sand well, pay attention to the following:

- One of the main differences should be considered well size. Diameter casing pipe the Abyssinian well is much smaller - most often 1 inch. Due to this, it is also called a needle hole.

- Is different water pumping principle– liquid enters the “needle” according to the principle of suction and is often under pressure. At the same time into the well large diameter water flows according to the principle of arrival.

Basic specifications Abyssinian well:

- well depth usually no more than 8-10 meters, although in certain cases it can reach 12-20 meters. But if the water level in it is lower 8-9 meters, there will be problems with water supply using a surface pump,

- performance– 0.5-3 m3/hour.

The needle well design is quite simple. For ease of immersion, the casing pipe consists of sections connected by couplings. The submersible end is equipped with a cone with a slot for water intake and a filter in its upper part.

Well components parameters:

- pipe diameter for the Abyssinian well – from 2.5 to 7.5 cm,

- the length of each segment is about 2 m,

- length of the cone-shaped tip – 20-30 cm,

- the cone diameter is selected 1-1.5 cm larger than the corresponding casing pipe parameter.

The pump for an Abyssinian well can be an external electric one, and in some cases (for periodic use, for example, only for watering a small garden), it is practiced to install a cheaper hand pump.

Advantages and disadvantages of needle well

Abyssinian wells have a number of advantages, which have led to their widespread use.

- With a smaller diameter, the Abyssinian well, made by hand, is not inferior to its larger counterparts.

- The source is equipped with surface pumps (more convenient for inspection and repair than submersible models).

- An Abyssinian well installed with your own hands, thanks to its features, can become practical and convenient option where the use of a conventional well is not practical or even impossible.

- With a small thickness of the sandy aquifer, it is easier to “catch” it with a thin casing pipe (in some cases, a do-it-yourself needle well is the only option).

- The construction of an Abyssinian well does not require much space, so it is often done right in the house, in the basement.

- The immersion of the casing pipe of an Abyssinian well with a large thickness of the aquifer is arbitrary, while a classic well must be drilled to the aquitard - the clay layer located after the sand. This eliminates the possibility of water being drawn from the lower part of the sand layer, which often contains a large amount of impurities, including dissolved iron. Thus, mineral composition The water in an Abyssinian well, built according to all the rules, is usually better than in a large-diameter well.

- An igloo well, built and equipped with your own hands, silts up less, including due to the presence of pressure and intense water flow. In addition, it is easier to clean the “needle” casing.

For any owner of a house or cottage it is important low cost Abyssinian well and the ability to drill and equip an “igloo” in one day.

You will learn more about what types there are by reading our separate article. The depth from which it can lift water also depends on the type of pump.

What is it like? artesian well and the features of its structure are described in the material.

The main disadvantage of the Abyssinian well should be considered the possibility of contaminants entering the water from the surface due to the shallow depth of the intake. Because of this, you should carefully choose a place to install a needle well, ensuring maximum distance from landfills, latrines, cesspools and septic tanks, drainage ditches, showers, in which water goes directly into the soil under the booth, etc.).

Unfortunately, the Abyssinian well cannot be built on any soil, since hard rocky layers will be difficult to penetrate, and aquifers on a loam rather than a sandy layer will not provide water for such a design.

Ways to create an Abyssinian well yourself

The services of specialized companies performing water drilling and even renting special equipment are quite expensive. At the same time, there are several ways to make an Abyssinian well with your own hands.

Drilling

This method is often used to pass the soil to the quicksand, as a sandy layer saturated with water is called, which, due to its looseness, can crumble immediately after the drill moves through it. To avoid this, drilling a well is combined with immersing the casing.

Drills for the production of Abassinian needles can be welded in a home workshop. It is optimal to use two modifications:

- frame drill, which is a U-shaped structure, and is used to pass through a dense clay layer,

- a frame drill with a cylinder, which is installed inside the frame and serves to collect and subsequently evacuate soil from the canal.

The width of any type of drill must correspond to the diameter of the casing pipe.

The drilling technology is quite simple - the passage of soil layers is carried out sequentially, with a gradual increase in the working part using rods. At the stage of drilling with a drill with a cylinder, it is better to use a winch (purchased or assembled independently from a starter and cable, equipped with limit washers and installed on a stand). Such a device will make it easy to remove the drill, rods and soil accumulated in the cylinder from the channel, which together add up to considerable weight.

Hammering with a headstock and a headstock

The headstock is a cone-shaped element fixed to the rod using a thrust washer. The simple design allows for maximum efficiency.

The headstock sliding along the bar, falling after lifting, transfers energy to the headstock, due to which the bar enters the ground. In order to avoid destruction, the headstock cone must be made of more durable material than grandma. The thrust washer prevents the cone from flying off the rod even under very strong blows. On the contrary, at this time it “sits down” even more firmly.

Headstock driving with plug

To implement this method, they use an end headstock rather than a sliding one on the rod. To protect the threads of the rod, a plug is installed in the upper part. It is recommended to use headstocks of 30 kg or more.

Barbell hammering

Equipment for driving with a rod - hexagonal rods, the diameter of which allows them to be placed in the column. Each of them is equipped with a thread for increasing the length (internal on one side and external on the other). For reliable fastening, the length of the threaded sections must be at least 2 cm. The process of driving a casing pipe immersed in a drilled well involves throwing a rod into the cavity of the rod.

Necessary equipment

For self-construction An Abyssinian well will require tools and materials, which in most cases are available to most home craftsmen. What you need is easy to acquire.

Electrical equipment for the Abyssinian well:

- welding machine,

- Bulgarian,

- drill.

Hand tools:

- gas keys,

- sledgehammer,

- hammer.

Materials:

- casing pipe in sections of 1-2 meters,

- steel couplings for connecting them,

- wire with a diameter of 0.2-0.3 mm and stainless steel galloon mesh for making a filter,

- FUM tape or other material for sealing threaded connections.

Well equipment:

- check valve,

- manual or electric pump.

May be useful:

- discs for rods up to 40 kg as an alternative to the driving headstock,

- car clamps,

- nuts and bolts,

- thrust washer (when using a headstock).

Making a tip with a filter

Making a filter for an Abyssinian well with your own hands is quite simple. A piece of pipe (approximately 80 cm) with a cone-shaped tip is perforated - thin cuts are made or round holes are drilled. After this, wire is wound around the perforated area and a braided mesh of stainless material. The latter is fixed with clamps or soldered using special non-toxic tin solder.

Sequence of work

IN general view construction of an Abyssinian well borehole type is performed in the following sequence:

- A hole is dug out.

- The well is clogged.

- The required sound depth is determined (in clay soils advancement occurs silently, a grinding sound is heard in coarse sand, and a rustling sound in fine sand).

- After the sound appears, a control check is carried out - water is poured into the pipe, if it leaves quickly, then the depth is optimal, if it is slow, then the pipe must be immersed another 0.5 meters.

- A manual or electric pump is installed in the well.

- The well is pumped until clean water appears (if the characteristics electric pump do not allow it to be used for dirty water, pumping is performed with a manual or drainage unit).

All work can easily be completed in part-time work, so, having started creating a well in the morning, by the evening you can enjoy clean and tasty water.

There is information on what it is, its types and materials of manufacture on our website.

You can talk about the technology of drilling another type of well, in sand. Necessary equipment and sequence of work.

Video

How to make an Abyssinian well with your own hands - a video that demonstrates the process of creating a needle well.