Pedestrian paths in the park. Construction of pedestrian and automobile paths and platforms. Paths, stairs and platforms

Roads, paths, trails, platforms are some of the most important planning elements of a facility landscape architecture. Analysis of design solutions and field surveys of garden and park areas show that the road network and sites occupy 10-20% of the total area of the facility, and the relative length of roads is 300 - 400 m per 1 hectare.

Technology for constructing paths and platforms .

When installing a garden park paths and sites with various types of coatings, a number of general construction norms and rules are observed.

First, the entire road and path network with platforms is laid out in accordance with the project and layout drawing using geodetic tools and instruments.

The routes of the main roads are plotted along their axes with reference to the main baselines. Then the longitudinal slopes are checked in accordance with the vertical layout project, and the points of intersection of paths, turns and radii of curvature, as well as relief fractures are fixed in nature. Subsequently, a complex of earthworks is carried out to cut out the “trough” and level the road surface in accordance with the required slopes.

After preparing the road surface and trough for the sites, it is again necessary to check the longitudinal slopes of the surface.

Then the boundaries of the structures are marked out, marked in kind with pegs and stretched twine.

An important point is the creation of a cross-section of roads. The transverse profile of small tracks is created manually using a specially cut template from thick plywood with a given profile.

All microrelief changes on the surface of the canvas are leveled, construction waste is removed or can be partially used when constructing the base.

The surface of the canvas is compacted by motor rollers. The soil surface of a road or site is considered ready and well compacted if thin round objects - nails, wire, etc. - are pulled out of the soil without violating its integrity.

The coverings of paths and areas in gardens and parks, in landscape architecture of urban centers, residential and industrial buildings are given great importance in connection with the overall compositional solution of the object.

Coatings should be varied in their design, color, and materials. The surface of paths and platforms is perceived by the visitor from various points - from the viewing platform, from flat roofs buildings or from terraces. A variety of types of coatings on a small object can create the illusion of scale and, as it were, increase its area. The size and dimensions of alleys, roads, paths, platforms, the design of their coverings, the shape and proportions of their elements, the material from which the coverings are made must correspond to the general compositional design of the object and the laws of landscape construction.

The road and path network, platforms, alleys are usually divided into classes depending on their functions and classified according to types of coatings. There are 6 classes of roads, paths, alleys:

1 class -main roads and alleys, by which the main flows of visitors to the facility are distributed; they are usually provided as the main routes of movement around the site and carry heavy loads from visitors. The design of this type of road must be very durable, made of low-wear materials.

2nd grade -secondary roads, paths, alleys, are designed to connect various nodes of the facility and more evenly distribute visitors, leading them to the main traffic routes, recreation and sports areas, viewing points of the facility and other planning elements.

The intensity of traffic on secondary paths, their capacity is lower than on the main ones. However, the coverings of such paths should be decorative, since their functions fulfill an important planning role.

3rd grade -additional roads, paths, trails, serve to connect secondary planning elements of the object, play the role of transitions, approaches to structures, to flower beds, and are “branches” from the main and secondary traffic routes. The traffic intensity on additional tracks is reduced compared to the tracks of the first two classes. The designs and coatings of such paths are simplified.

4th grade -bicycle recreational roads and trails;

5th grade -horse riding roads;

6th grade -utility roads and driveways;

Each class of roads has its own dimensions - length and width. The width of the garden and park road plays a significant role, since it is related to the attendance of the site and the intensity of visitor traffic.

The capacity of garden and park alleys and roads, especially class I and II, is important due to the intensity of visitor traffic. Therefore, it is important to calculate the dimensions of roads and sites.

Areas in gardens and parks have a specific purpose, are used by visitors for various purposes and are divided into the following categories:

Areas for quiet relaxation, group, single, for quiet games for visitors of different ages, including for contemplating landscapes;

Areas for active recreation, family or collective, group, playgrounds, for picnics, shows, public events;

Playgrounds for various age groups: primary, for preschoolers, for junior schoolchildren, for high school age and youth;

Sports grounds: football fields, golf fields, volleyball and basketball fields, tennis fields, special fields for playing chess and checkers;

Utility areas intended for the installation of mobile office premises, change houses, locker rooms, storage of equipment and inventory; areas for waste containers; areas for storing compost and fertilizers; areas for storing planting material; areas occupied by greenhouses, etc.

All sites have Various types structures and coatings depending on surface loads, attendance, traffic intensity, and frequency of events.

Types of coatings For paths and platforms

Coverings made of concrete tiles. Covering paths and platforms with concrete slabs is one of the most common in garden and park construction.

Concrete slabs are manufactured industrially in a factory and therefore are the cheapest material for covering paths and platforms. Concrete tiles are produced using the following methods:

Pressing;

Vibrocompression;

Vibration rolling;

Vibrations.

Possible production of slabs manually in special forms, however this leads to an increase in price by 60% of the cost.

The shapes of concrete tiles and their sizes are extremely varied. They are made in shape: square, round, hexagonal, trapezoidal, triangular, irregular polyhedron.

In addition to the variety of shapes and sizes, tiles are made in different colors and shades, which is achieved by introducing dyes or additives into the concrete in the form of colored cements or colored sand,

The surface of the tiles can be treated with special matrices, with the help of which a decorative pattern is applied. The texture of the tiles becomes extremely varied.

There is a great variety of tiles with exposed aggregate, which is used as pebbles and gravel of various fractions. Such tiles are manufactured in factories and are widely used in gardening construction.

Paths and areas covered with special mixtures

When constructing paths and platforms with bulk (rammed-in) structures, great importance is attached to the arrangement of supporting edges along the boundaries and contours.

The edge is arranged along the borders of the path by adding a roller of plant soil. The height of the roller should be at least 15 cm. The roller of earth is tightly compacted, and a strip of turf is spread over its surface with an inclination towards the path or site.

Instead of a supporting edge, a curb or garden curb made of stone or concrete is built from the ground. On the main paths and platforms, a permanent installation of curb stones is carried out.

After installing the curb and preparing the canvas, a layer of crushed stone is scattered over the surface. The crushed stone layer is leveled in accordance with the transverse and longitudinal profile of the path.

Sand-gravel and soil-cement mixtures are laid on a previously prepared and profiled soil base.

Area lighting.

The lighting is designed to ensure the safe movement of pedestrians in the evening along paths and alleys, thereby creating comfortable conditions for evening walks.

When lighting park areas, one should distinguish between lighting installations that perform utilitarian And decorative functions.

Installations of utilitarian value provide illumination of pedestrian movement paths.

Decorative installations are intended for highlighting buildings, sculptures, fountains, ponds, trees, shrubs, and flower beds.

Lighting should play one of the important roles in creating the landscape and architectural appearance of the evening park. At the same time, all lighting elements must be aesthetically attractive during the daytime.

When lighting park areas, a variety of light sources are used. Sodium lamp fixtures produce golden-orange illumination of the subject and create “warm” tones. Mercury vapor lamps illuminate objects with a bluish-green color and create “cool” tones.

For lighting flower beds, it is important to select the spectral composition of light sources, taking into account color range plants.

To illuminate trees and shrubs, incandescent lamps of 300, 400, 500 W, mercury lamps of 250 W, located at a height of 1-1.5 m, are used.

It is recommended to illuminate steps of stairs, areas of lawns, flower beds, groupings of trees and shrubs with low-lying lamps. Such lamps can have the shape of mushrooms, balls, cylinders of various heights and configurations. During the daytime, such lamps play the role of small architectural forms. The lighting of the garden and park facility is developed according to special project

and is created using a system of electrical cables connected to the lamps and laid in a trench.

The choice of light source is based on cost-effective installation and correct color rendering. Supports for park lamps can be metal or reinforced concrete. They are installed on lawns in the same row as trees. The lighting network is laid, connected to a power source and handed over to the customer for switching on by a special construction and installation organization.

The purpose of alleys, roads in parks, gardens, public gardens is to provide convenient pedestrian connections of entrances with all functional areas, structures, devices and individual areas, to reveal the aesthetic advantages of green spaces and the natural landscape when moving.

Straight-line alleys add solemnity to the site, winding paths are appropriate when organizing walking routes with viewpoints, alleys laid along the shortest path connect objects. Paths are often laid along existing trails.

In the overall balance of the park's territory, 8-15% is allocated for roads and alleys, sites - 5-10%, outside the city - 2-4% and 1-2%, respectively. Their relative length is assumed to be 300-400 m/ha in the city, 50-100 m/ha outside the city. In sports parks these standards are increasing. The main pedestrian alleys and roads connect the main entrances to the most visited sites, connect functional areas

Secondary pedestrian alleys and roads serve as intra-zonal connections, connect secondary entrances with objects of attraction, and distribute visitors throughout the territory. The designed width is 3-12 m with a longitudinal slope of up to 60% and pedestrian traffic with an intensity of up to 300 people/hour. Transport is possible.

Additional walking roads and trails lead to separate park devices. They are designed with a width of 0.75-3 m with a longitudinal slope of up to 80% and low-intensity pedestrian traffic.

Bicycle paths for walking are designed 1.5-2.5 m wide with a longitudinal slope of no more than 50%, and a transverse slope of 15-25%.

Roads for walking on horseback, in carriages and sleighs are designed with a width of 2.5-6.5 m, a longitudinal slope of up to 60% and an improved ground surface.

Parking lots are designed at the rate of 2-3 parking spaces per 100 one-time visitors to the park in the first place and 5-7 in the second phase. settlement period. Forest parks have 2-4 and 7-10 parking spaces, respectively. Parking lots are divided into sectors by green spaces.

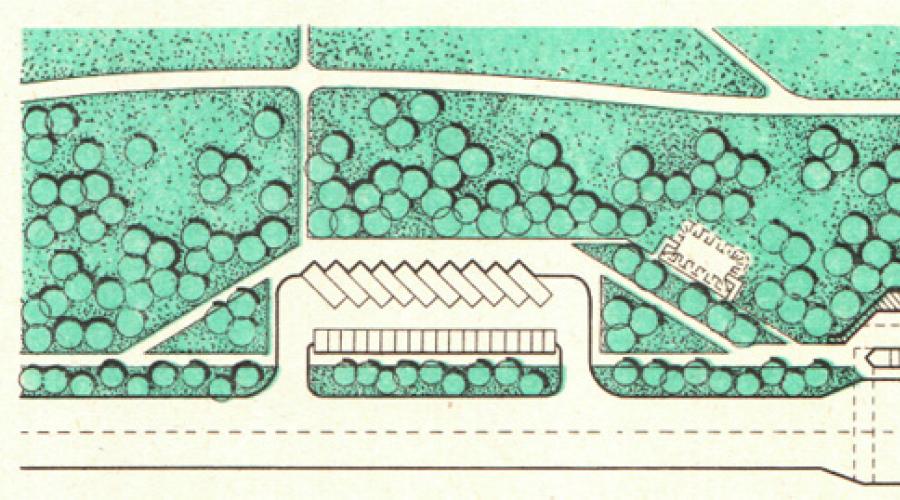

| Layout of park alleys and roads: a, b - main pedestrian alleys; c - embankment alley; d - intersection of the alley with the bicycle path; d - horse road and trail; 1 - main lane of the main road; 2 - additional lane; 3 - minor road; 4 - additional road or trail; 5 - bicycle path; 6 - road for horse riding; 7 - flower garden; 8 - lawn; 9 - plantings |

|

|

| Examples of track junctions. 1 - trampling zone |

Intra-park passenger transport (vehicles with electric motors, aerial cableways and monorails, funiculars, elevators, moving sidewalks, narrow-gauge railways) is created in parks with an area of over 300 hectares, and with complex terrain - more than 100 hectares. It can be used for sightseeing and serve as an attraction at the same time. For cable cars, the maximum longitudinal slope is 80%, travel speed is up to 14 km/h, transportation in one direction is up to 1200 people/hour. The speed of movement on monorail roads is 10-40 km/h, and the capacity is 20-25 thousand people/hour.

The width of park alleys depends on the number of visitors and is taken as a multiple of 0.75 m - the width of one traffic lane. TsNIIP of Urban Planning recommends that the capacity of a 1 m wide pedestrian lane be no higher than 400 people/hour, which ensures comfort and continuity of movement of visitors. To accommodate the most public events, the width of the main alley is increased due to side lawn strips that allow for one-time loads. When forming the main alley from three pedestrian lanes, the width of the middle lane should be taken with a coefficient of 0.8 from the sum of the extreme ones.

In large parks, the main alley is designed in the form of an esplanade 25-50 m wide, having a rectilinear or curvilinear outline with a large turning radius. When passing through areas with complex terrain, the esplanade is divided into alleys. The esplanade laid along the reservoir should follow coastline and have an asymmetrical profile. Landscaping is carried out in such a way that middle lane was illuminated, the outermost areas alternated between illuminated and shaded areas, and the walking path was shaded and protected from the wind.

In health-improving parks, health paths are laid - special pedestrian roads for treatment with dosed walking. According to difficulty, such roads are divided into easy sections 500-600 m long without climbing; medium - 1500-2000 m long with a rise of 50-100%, difficult - 3000-3500 m long with a rise of 100-150% and steeper. Ascents alternate with horizontal sections, rest areas with benches are placed on short routes every 30-50 m, on long routes - every 100-200 m.

The radii of curvatures at intersections and junctions of roads and alleys are no less than half the width of the main road, and for driveways no less than 7 m. When constructing intersections, the corners are smoothed along the line of natural pedestrian movement to prevent trampling. In cases where several tracks are connected in one node, their junction points are expanded.

It must be durable, resistant to atmospheric influences and loads, provide drainage of surface, storm, and melt water and be convenient to use. The surface is intended for pedestrians, so it should be smooth, but not slippery. An important role in creating harmonious landscape compositions is given to the decorative characteristics of coatings, which are chosen based on the purpose of the site, landscape features and the architectural and planning solution of the territory. The existing classification of coatings is based on the nature of the application and the material. The type of coating must meet the intended purpose, sanitary, hygienic, aesthetic and economic requirements.

Coverings can be solid, panel and tiled. Continuous coatings are divided into soil, crushed stone or gravel and asphalt. Ground coatings are the most imperfect. In the practice of constructing garden and park alleys and roads, improved soil surfaces are used - cement-soil, lime-soil and sand-gravel. Crushed stone is more durable. The crushed stone is covered with a layer of fine sifted chips (brick, granite, tuff) and rolled with rollers. Resulting colors bright coatings goes well with greenery, but in windy conditions hot weather dusty, when wet they become soaked and carried away by streams of water, especially on slopes, and become overgrown with grass.

In coastal cities, river or sea pebbles are used to cover paths. It is advisable to lay 1-2 layers under the coating polyethylene film, roofing felt, roofing felt, which will get rid of weeds. Pebbles are an excellent background for ornamental plants: carpet, creeping, coniferous and deciduous shrubs, ivy. Asphalt pavements are more durable, but when heated by the sun they soften, emit heat even in the evening, and have low artistic performance. decorative qualities. After each opening of the surface, traces remain.

|

|

|

|

|

|

| Coverings: 1 - monolithic concrete coverings; 2 - coverings made of natural stone; 3 - brick coverings(a, b - tied; c - braided; d - mesh; e - herringbone); 4 - wood covering; 5 - coverings made of concrete slabs (a - without rupture; b - with rupture); 6 - laying slabs at corners and turns |

Panel concrete covering can be prefabricated and monolithic, can have different shapes with curvilinear or rectilinear outlines and different sizes. Large slabs (e.g. 1.5x1.5; 1.0x2.0 m) require mechanisms for laying on a pre-prepared base. By introducing aggregates into concrete, a variety of textures, patterns, and colors of the coating are achieved, and its decorative qualities are enhanced. Monolithic concrete pavements are made on site using compacted crushed stone. They can have a pattern due to artificial seams, which are also necessary for extinguishing temperature changes. Inserts made of pebbles, crushed stone, gravel or carpet plants are used.

Natural stone coatings are durable and beautiful, they retain their decorative properties for decades, they are widely used to create interesting compositions for landscaping around monuments, fountains, etc. For these purposes, slabs of hard rock (granite, gneiss, basalt) or soft, sedimentary (sand, tuff, limestone-shell rock). In the southern regions, mosaic slabs of regular geometric shape are made from fragments of polished marble slabs.

Stone is used taking into account its architectural expressiveness and color. Stone slabs of various sizes and shapes create a picturesque pattern against the background of a green carpet. Mosaic coverings are created from cubic stone blocks measuring 3-7 cm. The checkers are laid on a sandy base 6-8 cm thick. The resulting seams are filled with sand. Such coatings are successfully used on paths with a significant slope. Small stone blocks are also used in the construction of concrete slab coverings to fill uneven areas around the perimeter of the paving, at corners and in seams, near water intake wells, and stairs. In paths made of natural stone there is no correct form the seams are filled with mortar and filled with pebbles, gravel or vegetable soil.

Clinker brick coverings. The bricks are laid in a cage, herringbone pattern, flat or on edge on a sandy base 5-10 cm thick, which is given a slight slope to drain water from the paving surface. When laying the bricks, they are compacted, and the seams between them are filled with sand.

Wood coverings are picturesque, but short-lived, quickly become dirty and cannot be cleaned. It can be recommended for rarely visited areas of green space or for decorative purposes. Wooden coverings are common in cities located in forested areas, where industrial wood waste is used for these purposes. They use round timber of hardwood that does not rot (usually coniferous), cut into cylinders of equal height 12-16 cm with a diameter of 10-50 cm, from which the mosaic covering is assembled. A geometric pattern can be obtained using square, rectangular, hexagonal checkers. The seams are filled with vegetable soil and sand.

Factory-made concrete tiles are durable and hygienic, and are the most effective coating for landscaping green areas. They are varied in shape (square, rectangular, hexagonal, round, etc.), color and texture. Strength is achieved through high grades of cement, a good mixture of concrete and compaction. The tiles are laid on a sand cushion (for sandy loam soils 14-16 cm, on waterproof soils up to 25 cm), and when weak soils- on a crushed stone or gravel base with a slope for water drainage.

The most commonly used tile sizes for pedestrian paths, cm: 20x20; 25x25; 30x30; 40x40; 50x50; 75x75; 20x40; 40x60; 25x50; 50x75; hexagonal slabs with side sizes from 20 to 50 cm, round slabs with a diameter of up to 50 cm. The thickness of the tiles is within 4-8 cm, and for the roadway 15-20 cm. Concrete tiles with a rough, corrugated surface, with exposed filling are widely used (pebbles, gravel of various fractions) and from sand or silicate fine-grained concrete. The tiles are laid closely (with seams of 6-10 mm) or at intervals of at least 5 cm, which can be filled concrete mortar, cover with gravel, pebbles, sand or fill with plant soil.

The monotony and monotony of the paving is broken by the arrangement of green islands, interspersed with slabs that differ in color or texture, as well as from other materials. The use of rectangular slabs with an aspect ratio of 1:2 also contributes to a greater variety of patterns; combinations of slabs of different sizes and masonry without continuous longitudinal and cross-shaped seams are also interesting. Paving begins from the structure with seams parallel or perpendicular to the facade. At the turning junctions of paths, trapezoidal, conical, triangular slabs are used, or “sawtooth” paving along the edge is used.

The tiles are quickly and easily made into rectilinear or curved paths of any pattern, of the required dimensions in one or several rows. If you need to change directions, they can be easily moved to a new location.

In places with heavy pedestrian traffic, the surface of tree holes is covered with pebbles, which facilitates the penetration of air and water into the soil.

Prefabricated concrete and lawn pavements improve hygienic and decorative properties coverings. Water does not linger on them, they do not generate dust, and do not overheat in the sun. The grass cover in the spaces between the slabs and in empty cells reduces the air temperature and increases its humidity. By including a lawn in the surface, the path is combined with the surrounding landscape, creating a harmonious natural composition.

In a pass-pied covering, the slabs are laid on the lawn with breaks corresponding to a person’s step. Round slabs laid in two rows in a checkerboard pattern are called the “elephant” path.

Ceramic tiles (20x20 cm) 1.5 cm thick have become widespread, from which they create durable decorative coverings. Abroad, coatings made of colored asphalt, plastics, and rubber tiles are used.

Find wide application decorative coatings, including several materials: concrete plates in combination with gravel, pebbles, cobblestones, paving stones, natural stone slabs, wood, brick; monolithic concrete with gravel, brick, natural stone, slabs. In these cases, the track design should be as uniform as possible to facilitate execution.

A drainage system is installed to drain surface water from the paths. With an open system, water is discharged through trays. Closed system it is arranged at a high level of improvement of the territory or in the event that an open drainage system cannot protect the coating from erosion. The more advanced the coating materials, the easier the water flow.

For coatings made of concrete, asphalt, tiles, the transverse slope is taken to be 0.015-0.02, for coatings made of small crushed stone - 0.03-0.06. Paths are arranged with a convex gable or single-pitch profile. The longitudinal slope is taken from 0.5 to 5-6%. In central areas, paths are arranged at the same level as the surrounding area and open trays are created along their boundaries.

Edge stones are laid at the same level with the pedestrian part or raised above the adjacent areas by 10-12 cm. Coverings made of slabs and natural stones without edge stones enhance the connection with the green area. In the southern regions the paths are made slightly higher surrounding area and without trays. Water is diverted to lawns.

For park roads with heavy traffic, the lower base (10-15 cm) is made of crushed stone, gravel, and broken bricks. On sandy soils, coarse sand is used for these purposes. In damp places, drainage of up to 10 cm is provided (fine gravel, slag, sand). The leveling layer for this type of path is made of sand stabilized with 10% cement. The seams are also filled with sand and filled with cement mortar. On paths and walking paths with light loads, the slabs are laid on a sand layer. The thickness of the slabs is greater than for coatings with a solid base. The seams are sealed with sand. On wet soils 5-10 cm of fine gravel, slag or crushed stone is poured under the sand layer.

K category: Landscape construction

Construction of garden paths and playgrounds

Classification of tracks and platforms

Paths and platforms are one of the main elements of the planning of a landscaping facility. The paths are used for walking, and visitors can relax on the platforms. Paths and platforms are also designed to drain surface storm and melt water.

Types of garden paths. The dimensions and length of the road and path network are determined by the purpose of the landscaping object. There are only five classes of garden paths.

The first class includes the main paths along which the main flows of visitors are distributed, the second class includes secondary paths designed for a more even distribution of visitors throughout the facility and connecting the main paths with each other. The third class is additional paths that seem to “penetrate” the entire territory, connecting individual planning elements with each other (platforms, view points, etc.). The fourth class includes trails intended for single movement of visitors. Fifth class - economic roads along which traffic flows for the purpose of transporting materials and equipment for the repair of plantings or structures, as well as food for canteens, cafes, etc.

City parks and forest parks are characterized by all five classes of roads and paths. On the boulevards, in the squares, small gardens they arrange tracks for the first three classes. In microdistrict territories, secondary-third and fourth-class paths are laid, which play the role of connection individual elements plans with each other. In the general balance of distribution of the territory of the object, alleys and paths can occupy from 5 to 20% of its area.

In accordance with the purpose of certain sections of the facility and its attendance, the class of paths, as well as the types of their structures, are determined. An important indicator is the load from the movement of visitors, which are far from evenly distributed throughout the facility. Main paths with heavy traffic should be reasonably wide and have durable, low-wear and durable designs. In addition, they must meet aesthetic and sanitary-hygienic requirements. It is very important (even at the design stage) to determine the sufficient width of the track. Often, too narrow a path provided in the visited part of the property leads to trampling of the edges of the lawn and damage to plantings.

Rice. 1. Types of profiles garden paths and their designs: a - single-pitched, with a concrete open tray; b - gable

In large parks, the width of the main paths, depending on attendance, can be 15-20 m or more, the width of secondary, walking paths is usually taken within 4.5-15 m, and additional paths - 2.5-5 m. The width of the paths can be from 0.5 to 1.5 m depending on the planning features of the areas.

Since the paths play the role of drainage, their surfaces are given certain slopes depending on the materials from which the coverings are made. The more advanced the materials from which the covering is made, the easier it will be for water to drain from the path and the smaller the transverse slope should be. So, for coatings made of hard materials - concrete, asphalt, tiles - the slope is taken in the amount of 0.015-0.02, for coatings made of small crushed stone - in the amount of 0.03-0.06 (depending on the width of the path). All paths are constructed with a convex gable or single-pitch profile. A convex gable profile is usually made on walking paths of the first and second classes. A single-slope profile is provided for paths designed on slopes (Fig. 1).

When constructing paths, longitudinal slopes are important. The maximum permissible longitudinal slope of the path is 0.07 (i.e., for every 10 m of the length of the section, the relief difference is 70 cm). For slopes greater than 0.07 (for ease of movement), garden stairs are installed.

The connection of paths with surrounding areas of plantings is important. In the northern, northwestern and central regions of the country, where significant amounts of precipitation fall, paths are usually arranged lower or at the same level with the surrounding territory, while open trays are installed along the paths along their borders to collect water. This is necessary to drain areas and collect excess surface moisture, which promotes better growth and development of vegetation and prevents waterlogging in areas.

In the southern and southeastern regions of the country, where there is relatively little precipitation, paths are arranged slightly higher than the surrounding area and without open trays. This allows atmospheric water to be drained from the surface of the path to areas of plantings that need moisture. In both cases, the paths must have a convex gable or single-pitch profile.

Types of gardening areas. The venues are important elements layouts of the landscaping facility and are intended for recreation, public events and household needs. All gardening areas can be divided into two categories: recreational areas and utility areas. In a special category are allocated sports grounds(see below).

Recreation areas, in turn, are divided into several types depending on their use by various age groups visitors. Thus, the following types of playgrounds are distinguished: children's playgrounds, playgrounds for quiet recreation for adult visitors, playgrounds (or clearings) for mass games and celebrations.

Areas for quiet recreation for the adult population are characteristic of all landscaping facilities. Utility areas are located at various landscaping sites.

It is recommended to arrange all playgrounds, especially children's ones, on dry, slightly elevated places. The surface of the sites must be flat and have a slope in one or two directions of no less than 0.006 and no more than 0.03. Such biases, firstly, create favorable conditions for surface runoff of rain and melt water, and, secondly, they are convenient for movement and recreation. It is believed that slopes steeper than 0.03 are already unfavorable for constant movement and stay on the site.

In some cases, in areas with high level When groundwater stands, drainage of the sites is provided. Surface drainage is organized so that water is quickly drained into rainwater wells and then into storm sewers.

The main types of construction of paths and platforms. Landscape paths and sites consist of subgrade, pavement and drainage (Fig. 1).

A subgrade is a depression prepared by excavating soil in accordance with the dimensions of paths and platforms and the thickness of the pavement. The roadbed is the support of all elements of clothing and absorbs the loads from pedestrian traffic, transferring them to the earth's surface. Road pavement consists of a base layer, a base and a covering. The underlying layer is made of sand and serves to reduce the loads arising from pedestrian traffic, and also acts as drainage, especially on soils with low permeability to water.

The base is the main structural element of clothing, which is the main load-bearing part and determines the degree of durability and strength. The base serves to uniformly distribute loads from clothing and external loads on the subgrade. As a rule, the base is made of crushed stone, which is used as broken brick, crushed granite or metallurgical slag.

Covering is the upper structural element of clothing that directly absorbs loads from movement; Important qualities of coatings are their durability, decorativeness, lack of dust in dry weather, and lack of soaking during rain.

Depending on the materials, the coverings of roads, paths and playgrounds can be improved or simple. Improved coatings include coatings made of stone, concrete and ceramic slabs, as well as clinker, brick and, in some cases, made of monolithic concrete or asphalt. The simplest coatings are crushed stone, gravel, and soil mixed with cement powder. In Fig. Figure 2 shows the designs of paths with a simple coating of crushed stone materials.

Improved coatings are usually provided on paths and areas in the most visited and critical parts of the landscaping facility. Currently, coatings made from prefabricated or “piece” elements are widely used in gardens and parks (Fig. 3). Such coatings are very convenient and economical to use. The use of industrially produced slabs of various shapes and sizes makes it possible to create the necessary decorative effect(Fig. 4, 5). The advantage of prefabricated coverings made from concrete and ceramic slabs is that the slabs do not soften like asphalt in hot weather, the coverings made from them do not generate dust, and do not become slippery during rain.

Rice. 2. Designs of garden paths: a - with the simplest type of coating and an edge made of soil; b - the same, c curb stone

The tile covering is not continuous, like asphalt, and through the gaps between the tiles, air and moisture enter the soil, thereby improving the microclimate of the area.

Currently, in the USSR, slabs of various shapes and sizes are produced, used both for road surfaces and for covering playgrounds, paths in gardens and parks. A state standard for concrete slabs has been established. The standard provides the following sizes of slabs: square 25X25, 37.5X37.5, 50x50 cm; rectangular 37.5X25, 50X25, 50×37.5, 75×37.5, 75×50 cm; hexagonal 25X43.2, 37.5×64.8, 50×86.5 cm. The thickness of the slabs varies depending on the nature of the load and the thickness of the base and is 5-6 cm. For secondary park paths, it is allowed to produce slabs measuring 20X20 cm and thickness 3.5 cm. Tiles are produced for squares, boulevards and areas in public centers different colors- with dyes.

Rice. 3. Types of layout of slabs on garden paths

Rice. 4. General form garden path made of tiles with seams filled with soil and sown with grass seeds

Rice. 5. General view of the site with lawn tiled covering

Ceramic tiles measuring 20X20 cm and 1.5 cm thick are also becoming widespread. These tiles can be used to create durable decorative coatings of various colors and patterns.

Coatings made from slabs made from natural stone are highly decorative and durable. They are common in areas where stone is a local, readily available building material.

Brick chips in their pure form cannot be used for coatings, since the coating turns out to be “movable”, generates dust, and stains the shoes of pedestrians.

An important auxiliary element of paths and platforms are drainage structures. An open gutter of the simplest type is a structure designed to collect and drain surface water into storm water inlets and consisting of a side stone and part of the pavement or platform. Open trays more complex types can be made of bricks laid flat along the borders of the path, or from special concrete products. Trays of the simplest type are arranged on most secondary and additional paths, and more complex types - on paths with pronounced relief, on slopes, near slopes and retaining walls and so on.

Regularly shaped stones, cut from granite or made in special concrete forms, are used as borders. On the simplest paths, instead of a curb, edges made of soil and turf are installed. The side stone and the edge are elements of the interface between the path or platform and adjacent areas of the lawn.

Technology of construction of paths and platforms

The construction of the track surface is carried out using motor graders or bulldozers (Fig. 7). The bottom of the canvas is given a convex profile with transverse slopes. The profile of the bottom of the trough is checked using a special wooden template, and the longitudinal slopes are checked with geodetic instruments.

The bottom of the trough is compacted with a roller weighing up to 5 tons, starting from the edges to the middle of the sheet, overlapping the roller track by 20-30 cm. Sandy and sandy loam soils are compacted while moistened (watering at the rate of 5 liters per 1 m2 of surface).

An underlying layer of sand (10-20 cm) is scattered along the bottom, then it is leveled and compacted with a roller. It should be taken into account that the compaction coefficient of sand is 1.1-1.15, so the layer being laid should be thicker (about 4-5 cm) than the design one, taking into account future compaction. After this, they begin to install the edges or borders.

Rice. 7. Work on the construction of the garden path

When constructing the main paths, a side stone or curb is installed along their edges. Secondary and additional paths are arranged without a border, but with edges. When transferring the project to nature, it is necessary to clearly mark the boundaries of the paths and sites. The edges are arranged strictly along the cord along the borders by adding a layer of plant soil. The ground is evenly spread and leveled. Then the soil is compacted using tampers and the edge is trimmed along the border line with a shovel. The height of the edge is set by the project and must be at least 10 cm above the surface of the coating. The finished earthen edge is covered with turf.

Before installing the edge stone, sections are divided along the boundaries using special metal pins and a cord. After breaking, they dig grooves with a width and depth depending on the size of the side stone. Cement mortar or concrete mixture is placed in the grooves. Following this, a side stone is placed on the mortar or mixture. Laying is carried out strictly in accordance with the breakdown. The edge stone is sunk into the mortar or mixture and “settled” using wooden tampers (Fig. 8). To firmly connect the side stones, the seams are filled with mortar, and concrete mixture is poured from the sides at the base and compacted. After laying the side stone, they begin to construct the base.

The device is operated in a certain sequence. First, crushed stone is delivered and laid layer by layer, leveled and checked for transverse slopes. Then the laid crushed stone is rolled with a roller. After rolling, it is necessary to check the slope again.

Rice. 8. Work on installing curb stones a - installation on concrete base; b - “sedimentation” using wooden tampers

It should be taken into account that first a layer of crushed stone with large fractions is laid, and then a second layer. Each layer is rolled 8-10 times, passing along one track and overlapping it by 0.2-0.3 of the width of the roller cylinder from the edges to the middle. When rolling, you should simultaneously water the walkway at a rate of 5 liters per 1 m2. A sign of the end of rolling is the absence of a noticeable mark after the roller passes, as well as the absence of mobility of the crushed stone. If crushed stone grains 3-4 cm in size thrown under the rear cylinder of the roller are easily pressed into the base, then rolling should be continued. Then they begin to install the coating.

Slab coverings can be built on a base of crushed stone or sand to which dry cement has been added (cement to sand ratio 1:10); the sand-cement base is made in a layer of 10-12 cm. When laying the slabs, they are “settled” with special wooden tampers and sunk into the sand-cement mixture to approximately 1/3 of their thickness. Subsequently, when the base is moistened, the cement “seizes” the slabs, and the coating becomes durable. Small tiles are laid by hand, large slabs are laid using a truck crane. To avoid erosion of tile joints by rainwater, tiled paths should always have a one-way slope without any breaks in their profile. When laying the slabs, you should ensure that the coating is even and the slabs do not protrude with their edges above the surface. To do this, they are laid using a special strip or wooden template, which is used to check the correctness of installation and the slopes of the surface of the entire coating in different directions.

Coatings made from special mixtures (seeding construction waste, granite and brick chips, slaked lime, soil and sand, etc.) are laid in one layer on a crushed stone base, planned and checked with a template. Then the surface is watered and after drying, after about 2-3 days, it is rolled with a light roller weighing 1-2 tons. Sprinkle a 1 cm layer of sand on top and roll it again with a light roller.

Soil cement coatings are installed directly on the compacted subgrade using the same principle. In this case, one part of cement is added to 10 parts of soil. Then the surface of the paths and platforms is moistened, carefully profiled and rolled.

Rice. 9. Work on laying slabs on garden paths and platforms a, b - laying the slab on the base; c, d - laying and compaction, checking the slope and leveling the surface with a template

Gravel-sand paths are arranged in cases where appropriate materials are available required quality, for example, if there is a quarry with gravel and sand next to the object,

When constructing dirt paths, the fertile layer of soil is cut off, and barren soil is poured into the resulting “trough”. Then, in accordance with the project, profiling and subsequent rolling of the web are carried out. If the soil is infertile, then the path fabric is loosened within its boundaries, and then profiled and rolled. Dry crushed clay should be added to loose sandy soil at the rate of 0.2 m3 per 1 m2 in order to increase the cohesion of particles, and sand or gravel should be added to heavy clay in the same amount to reduce slipping.

Coverings made from the ends of wood or clinker are placed on a well-prepared and planned sand-cement base 10-15 cm thick. The ends or brick are sunk into the base, lightly tapping with a sledgehammer. Alignment is carried out wooden slats. The ends are placed close to each other, the seams are covered with cement. The bricks are laid on edge close to each other and the seams are filled with cement mortar.

- Construction of garden paths and playgrounds

1.Basic provisions

2. Arrangement of tracks

3.Types of tracks

4.Types of coating

Bibliography

1. Basic provisions

Paths are the main element of the garden composition; they create perspective and close the visual perception of the site. For the coating, natural stone, bulk materials (gravel, pebbles, crushed stone, marble or brick chips, sand), and concrete are used. On surface layer concrete paths are sometimes painted with a metal brush or wooden float, or by sinking pebbles, multi-colored stones, ceramic chips, etc. into the still wet mass. The most popular coating is concrete paving slabs various sizes and flowers. There are also ceramic paving slabs. In a landscape garden, paths made from transverse cuts of wood, buried in the ground, between which are filled with fine gravel or sand, look good. Coating from decorative concrete can imitate masonry from natural stone or wood, vary in color and texture. This material is durable, resistant to temperature changes, exposure to light and chemically aggressive substances. If desired, you can also make lawn paths by sowing them in the cells of a special plastic lattice. lawn grass. You can not only walk on this surface, but also drive a car.

The paving of each path must correspond to its functional purpose. Narrow, winding paths winding through the garden will benefit from a modest surface of crushed stone, gravel or cobblestones. The path running along the lawn can be laid out with slabs that run one step at a time. The front entrance to the house can be paved with paving stones. The combined effects should also not be forgotten. Modern paving materials such as concrete tiles combined with traditional brick or marble chips create a very pleasing appearance. Recently, paving with natural stone, in harmony with the rest, has become increasingly popular. landscape gardening plot.

2. Arrangement of tracks

Track arrangement - necessary element landscaping of the garden. The paths separate and at the same time connect the functional zones of the site. It is with the application of the road and path network that site planning begins. Like any other element of the garden, the design of the path is completely subject to the general style decision plot. When regular layout the paths are straight, forming small platforms at the intersections, often decorated with small architectural forms. Winding paths that smoothly go around a lawn, flower garden or landscape group of ornamental shrubs correspond to landscape planning. Paved areas should not occupy more than 10% of the dacha territory; there is no need to permeate it all with scattering different sides paths and cover with stone slabs.

For example, a fairly wide front path is usually laid from the entrance to the site to the area near the porch of the house. It is necessary to construct a path from the porch to the gazebo or barbecue area, summer kitchen, bathhouse or some other outbuildings. You should not make a path leading to a garden or green lawn with a hammock. And the construction of a path to flower beds, a pond or a rock garden is necessary, since these objects are pleasant to view at close range. When designing paths, it is important to be guided not only by utilitarian, but also by aesthetic considerations.

Many people think that paths should be laid in a straight line, that is, the shortest distance between objects. In a number of cases, this solution is not very suitable for constructing garden paths. It is much more interesting and convenient to lay a main closed path that runs around the entire garden area. It is important that the path does not cross the space of the central lawn; it should offer a view of the most decorative corners garden If one path is not enough, then additional branches can be made to approach specific objects. In this way, you will get rid of the numerous corners that inevitably form in the crossroads of paths and are inevitably trampled down due to the ineradicable habit of people taking shortcuts. Of course, it will not be possible to do without corners completely, but reducing their number is quite possible. In order not to trample existing corners, they are decorated with corner flower beds and decorative groups woody plants, low borders, bosquets. For greater guarantee behind the flower bed or decorative group lay tiles at a distance of a step, on which you can walk, if desired, without damaging the lawn.

Depending on the intensity of the load and functional purpose when constructing paths, paths use a hard covering of paving stones, bridge stones, tiles on a concrete or sand base, or soft covering from gravel, granite stones or brick chips. The most simple tracks- ground, sprinkled with sand. Another type of covering is garden parquet or wood flooring - usually in the form of square panels, but the most common different designs, up to wooden circles. However, wood quickly rots even with special treatment, so it is recommended to dry the panels for the winter and put them in a non-damp room.

A separate type of paths are paths with non-continuous coverage. Sometimes such paths are very convenient; they are laid in those places where a path is needed, but they are rarely used. For example, from time to time it becomes necessary to go to a flower garden, pond or alpine hill to plant a new plant, weed out weeds or trim a faded perennial. Obviously, a permanent track is not needed in this case. It is better to place separate tiles, flat stones or round timber - cuts of thick logs - at a distance of one step in place of the removed turf. A layer of gravel and a layer of sand are poured under the tiles, so that the path is slightly below the level of the lawn, then it will not interfere with mowing. Another advantage of such a path is that, when no longer needed, the tiles can be easily and quickly removed, the remaining depressions can be filled with plant soil and sown with lawn grass mixture seeds. After some time, not a trace of the tiles will remain.

Some variety and unusualness are given to the garden by combined coverings that combine different types materials. For example, gravel goes well with colored tiles, flagstone and garden parquet; clinker brick - with natural boulders and paving stones, mosaic ceramic tile- with breccia or flagstone. Color should not be overlooked either. road surface. In addition to the traditional gray or reddish-burgundy color, the bridge stone can also be black or green. River pebbles, which are heterogeneous in composition, are usually variegated, and fine gravel has shades from white to yellowish. The color of flagstone depends on the rock from which it is made, and is also very diverse: from almost black, burgundy to light with a pinkish or yellowish tint. The main thing is not to be afraid to combine. When choosing a material for building a path, you should think about the intensity of its use. Soft surfaces (gravel, sand, brick chips) are intended only for pedestrian paths; even a heavily loaded wheelbarrow or baby stroller can leave a rut on such a path. Tiles with sand backing are more reliable, and when laid on concrete or dry cement mixture, they will also withstand light garden equipment.

The surface of footpaths should not be slippery in wet weather, so there is no need to use smooth tiles or fragments of polished granite or marble for paving. All paths for better drying and to prevent the appearance of puddles are made with a slope of 2% from the middle to the edges and 0.5 - 1.5% along the path for each meter. When designing, paths are drawn on the plan in accordance with the scale. It is better to make several options and choose the most suitable one. In a low-rise suburban construction when constructing paths they are often used latest materials and more modern technologies. For example, electric heating of the road surface. In this case, the paths dry out quickly after rain, and in winter snow and ice do not accumulate on them. Currently, not only the well-known road tiles are used for road surfaces, but also special ceramic mosaic tiles, which look especially good in patios and on open terraces. Decorative concrete technology is used to construct garden paths. Its essence lies in the fact that the concrete sheet is covered with a special polymer material, on which, using a matrix, one or another pattern is imprinted, imitating various types of natural stone. The polymer can be painted in one color or another at the request of the site owner. The technology is quite expensive, but it pays for itself.

3. Types of tracks

There are two types of paths: transport and walking. Depending on the expected load, different methods of constructing underlying layers are used when preparing the base of the path, as well as when choosing materials for paving.

The width of the tracks also depends on their purpose. The path leading to the house is between 1 meter and 1.5 meters wide. Two adults should separate on it without interfering with each other. For paths of secondary importance, for example from a house to a garage, or from a house to a recreation area, a width of 80 centimeters to 1 meter is sufficient, step by step paths and the paths between the beds in the garden are approximately 50-60 centimeters wide.

In the second case, the paths themselves can serve to drain water from the site, located below the level of the lawn. The use of this option requires strict adherence to the design heights when constructing paths and other coverings to avoid blocking the flow along the paths.

4. Types of coating

path garden pedestrian drainage

Today, there are a huge number of coating materials that can make the path not just durable, but also truly beautiful.

Hard coatings

Traditionally, hard surfaces are used in areas that need to be cleared of snow in winter. They are made of tiles, stone or concrete, clinker bricks, etc. They have a hard surface and are divided into monolithic and paving.

Monolithic coatings are made from hot or cold mixtures laid on a prepared base. When solidified monolithic coverings form a homogeneous surface.

Paving is made from individual elements, laying them on a prepared base. Properly executed paving is not inferior in strength to monolithic paving.

Soft coverings

In most cases, soft surfaces suffer during winter cleaning, regardless of its type. Soft coatings traditionally include:

Ground coatings

Coatings made of bulk materials (gravel, pebbles, bark, etc.)

Rubber coverings

Wood coverings

Grass (lawn) coverings

Combined coatings

This type of coating is especially decorative. Combined coatings involve the use of solid elements laid with gaps, filled with lawn or bulk inert materials.

Strengthening the edge of the path

Strengthening the edges of the road surface increases its stability, prevents the edges from slipping, and prevents the pavement from becoming overgrown with vegetation. For paths and areas with soft and combined surfaces, securing the edges is mandatory!

Path drainage

Drainage is of particular importance in severe clay soils, poorly permeable to water. The accumulation and further freezing of water in such soil leads to a significant expansion of the soil volume, which entails damage to the paving.

When constructing paths, it is advisable to use a linear drainage system. This will avoid the formation of puddles and, as a result, the rapid destruction of paths. Linear drainage systems consist of drains, gratings and other special elements of different sizes and strength characteristics.

Depending on the intensity of the load and the functional purpose, when constructing paths, a hard covering of paving stones, bridge stones, tiles on a concrete or sand base, or a soft covering of gravel, granite stones or brick chips are used. The simplest paths are dirt, sprinkled with sand. Another type of covering is garden parquet or wood flooring - usually in the form of square panels, but there are a variety of designs, even wooden circles. However, wood quickly rots even with special treatment, so it is recommended to dry the panels for the winter and put them in a non-damp room. A separate type of paths are paths with non-continuous coverage. Sometimes such paths are very convenient; they are laid in those places where a path is needed, but they are rarely used. For example, from time to time there is a need to go to a flower garden, pond or alpine hill to plant a new plant, weed out weeds or trim a faded perennial. Obviously, a permanent track is not needed in this case. It is better to place individual tiles, flat stones or round wood pieces - cuts of thick logs - in place of the removed turf with the plant. A layer of gravel and sand is added under the tiles so that the path is slightly below the level of the lawn, then it will not interfere with mowing. Another advantage of such a path is that the tiles can be easily and quickly removed as they are no longer needed, the remaining depressions can be filled with plant soil and sown with lawn grass mixture seeds. After some time, not a trace of the tiles will remain.

Soft surfaces (gravel, sand, brick chips) are intended only for pedestrian paths; even a heavily loaded wheelbarrow or baby stroller can leave a rut on such a path. Tiles with sand backing are more reliable, and when laid on concrete or dry cement mixture, they will also withstand light garden equipment.

Combined coatings.

Combined coverings that combine different types of materials give the garden some variety and unusualness. For example, gravel goes well with colored tiles, flagstone and garden parquet; clinker bricks- with natural boulders and paving stones, mosaic ceramic tiles - with breccia or flagstone. The color of the road surface should not be overlooked. In addition to the traditional gray or reddish-burgundy color, the bridge stone can also be black or green. River pebbles, which are heterogeneous in composition, are usually variegated, and fine gravel has shades from white to yellowish. The color of flagstone depends on the nature from which it is made, and is also very diverse: from almost black, burgundy to light with a pinkish or yellowish tint.

Bibliography

1.www.abies-landshaft.ru/tropinki/