Finishing the veranda at the dacha. Methods for inexpensive cladding of an unheated veranda - nuances Finishing the terrace with clapboard

Finishing the veranda is creative process, because it is necessary to cover it according to the rules. Identical materials can be used to construct various types of verandas. Find out the secrets correct plating Some tips will help.

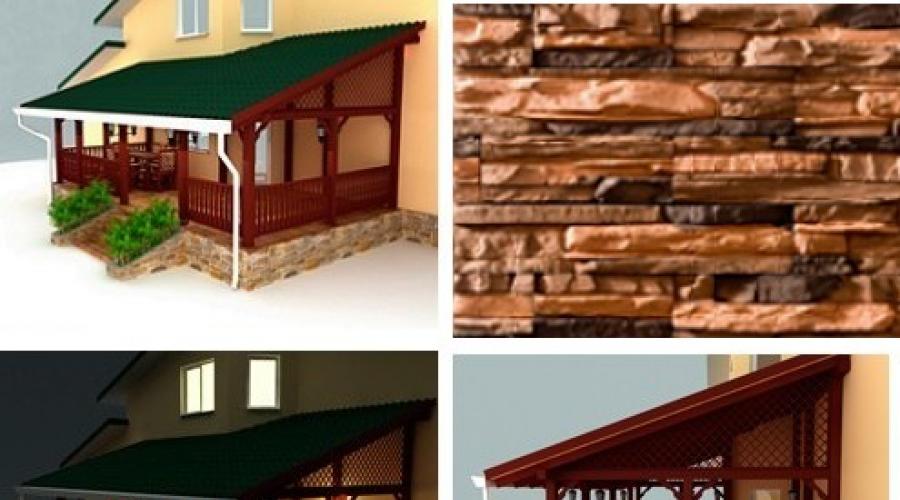

What type of veranda do you prefer?

Most owners of private holiday homes prefer a veranda - an extension that is adjacent to one of the walls of the building. When creating both a calm atmosphere and a comfortable mood of the veranda, its decoration plays a role.

The design of the veranda can be open or closed type. Naturally, the finishing of the veranda inside is carried out depending on its type. To design an open veranda (also called a terrace), you will need building materials that are not susceptible to atmospheric influence as high humidity(we advise you to pay attention to modern plastic panels for exterior decoration, perforated sheets, which can be used not only for decoration, but also for dividing into zones; perforated sheets can be used to decorate the ceiling of a terrace, etc.) and other interior items. There is no need for glazing for the summer veranda. This type of veranda is considered a seasonal space, so cabinet furniture or solid buildings are not appropriate on the veranda.

It is enough to decorate the summer veranda indoor plants and comfortable portable sofas and armchairs. This means that the decor of the outdoor veranda must not only be impressive, but also resistant to temperature changes or moisture.

Therefore, the interior decoration of the veranda begins with thermal and waterproofing of the lower part of the walls and ceiling. What materials can be used for this?

Options for interior and exterior decoration of an open veranda

lining, panels, plus fantasy

Traditionally, wood and stone are used as interior cladding for verandas. Before covering the veranda, all wooden structures must be treated with an antiseptic. The most common materials for covering the veranda inside and outside are:

Lining and plastic

Polystyrene tiles

PVC and MDF panels.

Of course, almost all the verandas of holiday villages and cottages in our vast Motherland are covered with these materials. Inexpensive and fast! But you always want to diversify your home, especially if a private house and its veranda is located in picturesque surroundings. You can help diversify the finishing inside and lining the veranda outside by using laminate and wood veneer.

Particularly interesting are the elements made from these materials for the verandas located on the upper floors of the house.

frame verandas

A simple option for creating and covering a veranda for a house is an extension made of planed pine beams. The structure will not require the construction of a complex and powerful foundation, so there will be no problems connecting with wooden structures and there is no subsequent finishing.

Light frame extension or you can build a veranda with your own hands. As roofing material good to use soft tiles, which, in terms of installation technology and performance characteristics, is successfully combined with the existing roofing of a private house.

What materials are used for the construction and cladding of an open veranda

An approximate list of materials required for covering a frame veranda:

Veranda foundation and frame

Concrete pillars for the foundation

Beam for frame

Lathing for the lower part of the veranda

Wooden lining or OSB boards

Brackets and corners for connecting beams

Self-tapping screws for fastening lining or slabs

Connecting anchors for frame

Roof

Beams and roofing material

Laths and boards for sheathing

Self-tapping screws for wood

Floor

Waterproofing

Floor boards or slabs

Logs and fastening elements.

In addition, it is necessary to consider the lighting option and finishing the lower part of the veranda with stone.

Useful tips

Experts believe that frame verandas are the cheapest and practical option construction of an additional building. The structure has less weight, which requires a lightweight foundation. The connecting connections of the main structure and the veranda are easily calculated and erected, always taking into account the junction of the veranda and the main structure of the house.

Open veranda connection points

When connecting an open veranda, the main attention should be paid to the connection points. It is recommended to take into account the difference in cladding and foundation materials, as well as the time of construction of structures.

Ideally, the connection points should perform the function expansion joint, compensating for the difference between linear and volumetric expansions. This process is inevitable over time and with temperature and humidity changes. It is preferable to use anchors as a connecting element for veranda walls.

Finishing a closed veranda

For warm veranda finishing options differ from finishing open type. In addition to the basic interior and exterior decoration, the owners are thinking about glazing and installing fireplaces.

The most common glazing option is the French veranda design, which uses metal-plastic windows large sizes.

glazing of a closed veranda

The French veranda is characterized by a design with glass walls. Installation of powerful double-glazed windows requires a solid foundation and reliable support pillars.

For this, experts recommend using metal frames or corners. When glazing, you can use one or two-layer bags. It is preferable to use tilt-and-turn structures that allow them to be opened.

French windows

“French” windows are a sliding structure with two sashes, one of which is movable. Such structures can withstand significant wind loads. Window frames are high-strength profiles with sealing and reliable fittings.

The windows can be closed from the inside and outside, providing access to the veranda. Therefore, windows can be successfully used as doors.

There is no point in installing expensive multi-layer PVC windows. It is better to consider the option of insulating the floor and walls of the veranda. To insulate the walls, floor and ceiling of a closed veranda, it is better to use such traditional insulation materials.

In the case of budget and inexpensive finishing, you can install ordinary windows, which are recommended to be installed at a height of at least 80 cm from the floor.

Drywall and plasterboard can be used to cover the walls of an enclosed veranda. Before covering the walls of a warm veranda, it is necessary to waterproof the walls from the inside and outside.

The following are suitable as insulation:

Mineral wool

Extruded polystyrene foam.

On the veranda room side, the insulation is “covered” with a vapor barrier film and covered with plywood, plasterboard, clapboard or wall panels.

How to cover a closed veranda is presented in the video.

A modern country house is designed to provide best conditions living in it. Currently, all conditions have been created for this - abundance constructive solutions in house construction, a variety of traditional and new proven materials.

One of the elements of private buildings is currently a terrace - in whole or in part open area equipped with a roof. It allows you to fully feel like a part of nature, practically without leaving your home. What materials and in compliance with what requirements can be used to finish the terrace will be discussed further.

Structurally, an extension to a house, called a terrace or veranda, is a podium raised above the ground on one of the types of foundations, and a roof made of some material, supported by several support beams. According to their design, such structures are divided into:

This view is good when located on the leeward sunny side. Due to the absence of fences, there are practically no boundaries between the veranda and the space surrounding it. It is better if the floor height of such a structure is low. This is especially true when living in country house children.

This option requires minimal construction costs. And finishing the veranda will not require large expenses. But its quality must be met maximum requirements, since structural elements will be under constant influence of excessive moisture, frost, winds, and temperature changes.

Such a terrace retains its airiness and openness, but ensures high safety for household members and their guests. The main difference from the previous version is the presence of fences made of timber in the form frame structure from lumber, as well as from blocks or bricks, followed by finishing the walls of the veranda from the outside and inside.

Due to the lack of complete isolation from the atmosphere, the operation of structures of the first and second types is possible only in the warm season. It is impossible to properly insulate them due to the design features, and it is quite difficult to completely protect visitors to such a terrace from the wind and raindrops flying inside.

This type is most suitable for year-round use as additional space. Even in the winter cold, closed from the wind and frost, you can enjoy hot tea while admiring the beauty of nature. In this case, it is better to combine the interior decoration of the veranda with insulation of all its walls. This will minimize heating costs for the house as a whole.

The manufacturing process of the described structures is not complicated and is quite accessible with your own hands, as is finishing the veranda inside or outside. Since the topic of the article requires a more detailed acquaintance with the second part of the works, we will consider them, focusing on possible options, their features, advantages and disadvantages.

Currently, the interior of the veranda is covered using the following materials:

- wooden lining;

- plastic panels;

- MDF panels;

- cement plaster and cement-based artificial stone.

The classic option is the use of natural wood materials for wall decoration not only interior spaces houses, but also outbuildings. The lining is distinguished by its good appearance, ease of installation and low requirements for the quality of base preparation.

Its installation is carried out on a lathing made of 40x40 mm bars using special fasteners - clamps, which grab the panels by the groove and securely fix them. Finishing parts can be placed vertically, horizontally or at an angle to the floor.

When finishing the exterior, you can sheathe the veranda only by installing the lining parallel to the soil with the ridges up to prevent the accumulation of water in the grooves.

Also quite a common option. It is better to decorate a closed veranda with such panels. In this case, temperature changes are less sensitive to the material, which helps to increase its service life.

Unlike wood materials, plastic is practically not afraid of water. Modern retail chains offer many options for both color and texture design of plastic panels.

Installation plastic trim easier than wood. Thanks to the significant width of the panels, the process is faster.

It is convenient to attach finishing parts to the sheathing using construction stapler, driving staples into a wide shelf along the edge of the products. Plastic panels do not require further finishing with paintwork, they can be easily washed with a damp cloth, and dust does not settle on them.

Another common finishing material for interior work– MDF panels. Like previous version, they are distinguished by a large working width, which allows plating to be carried out quite quickly. For fastening to wooden sheathing, clamps are used, similar to those used when installing wooden lining.

Thanks to a large number of colors imitating natural wood, stone and even skin, such interior decoration the veranda will have a very high quality look. With all its advantages, MDF also has a significant drawback - very low moisture resistance. In this regard, it is better not to use them for finishing open terraces. Otherwise you will need additional protection in the form of varnishing all sides of the panels.

In the case of using cement-containing building materials - blocks with one or another filling, or bricks - to make a terrace, it is better to finish the walls with mixtures or parts that are similar in composition.

Please note that the plaster on gypsum base and gypsum artificial stone are not suitable for covering the walls of open verandas.

Often home owners are stopped by the high cost of cement finishing materials. At the same time, it is not difficult to produce the required amount of original artificial stone yourself in a home workshop. By adding aniline dye, you can get a unique interior in the room being finished.

As already noted, the materials listed above, used in finishing the interior space of verandas, have certain disadvantages that limit their use. IN last years increasingly wider external walls and the roofs of the terraces are covered with polycarbonate - an artificial transparent material that allows you to create a closed space while maintaining visual contact with the surrounding nature.

There are two main types of this plastic – cellular and monolithic. The first is distinguished by minimal weight, high light transmittance, and durability, so it is often used for roofing terrace roofs.

The second one is close in its properties to real quartz glass, but unlike it, it does not have such high fragility. This determined its use in vertical frame structures - windows, doors, transparent walls.

Modern manufacturers are not limited to producing colorless sheets. To create a soft shadow, we recommend using green, blue, red, yellow cellular polycarbonate for the roof. You can combine several colors, giving the entire design brightness and uniqueness.

Covering veranda walls with cellular polycarbonate is quite easy to do yourself. To work you will need a minimum set of tools:

- cutting knife - any construction knife will do;

- screwdriver

The polycarbonate installation technology involves the following list of works.

Installation is carried out in the same way cellular polycarbonate on the roof of the terrace. If there is a ridge - the junction of two roof slopes, use a special ridge profile, sold in organizations that sell sheets.

If you have no cutting experience, cut sheets according to required sizes can also be performed by workers at construction bases.

As follows from our review, the amount of materials for covering terraces is sufficient to create a unique structure. Before finishing your veranda with any of them, carefully study all the operating features in a particular case.

External works

When choosing what to cover the outside of the veranda with, you need to focus on the appearance of the house, otherwise the room will stand out from the overall picture. Universal materials can be combined with almost anything. The following are called universal:

- tree;

- plastic;

- stone and brick.

Wood

Wood is difficult to work with. Without proper care, this material quickly deteriorates. Its positive aspects include the following features:

- An attractive look, which is achieved through a variety of textures.

- Thanks to wood, you can implement veranda projects in any style. From Old Russian, decorating the corners of the room with carved pillars, to modern modern with a slightly processed wooden surface. It looks great with glass, stone, brick, wood and forged elements.

- Environmentally friendly.

The disadvantages include:

- High exposure atmospheric phenomena. Various impregnations and coatings protect against influence environment, but do not guarantee complete protection of the veranda. In addition, procedures to protect the tree will have to be done regularly, which takes time and effort.

- Wood is a fire hazardous material.

- Financial component. The tree is expensive. Add to this the cost of regular board maintenance and you get a pretty substantial amount.

Bricks and stones

Usually, not the entire veranda is made of stone or brick, but only the foundation and several pillars that support the roof of the structure.

Let's look at the positive aspects:

Disadvantages of the material:

- Stone and brick are expensive materials.

- They are not compatible with wooden houses, which can be a problem if you are building a veranda in your country house.

- Labor intensity of construction.

Plastic

Plastic is one of the most popular materials. Its advantages include:

- Low price.

- Ease of operation and installation of the casing.

- Wear resistance and resistance to weather conditions. High-quality plastic can withstand extreme heat and frost.

- High sound absorption and excellent thermal insulation properties.

- The material can withstand high loads.

- Under the influence of the sun and temperature changes, the material loses its decorative properties over time.

- This is an artificial material.

Internal arrangement of walls

The interior decoration of the veranda is carried out with the following materials:

- lining;

- decorative plaster;

- PVC panels;

- MDF panels.

They all have their own installation specifics.

Lining

Interior finishing of the veranda with clapboard - classic version registration

For a veranda, standard thin lining 5-10mm is usually used. As a rule, this is a board made of wood, wood processing products or plastic. There are differences depending on the profile. There are:

- Standard profile. The option features beveled edges that create noticeable gaps between the panels.

- Calm. It features relatively soft transitions due to the small angle of edge stitching.

- Europrofile. Once the coating is assembled, it forms a specific pattern.

The boards are connected using special system consisting of tenons and grooves. But keep in mind that working with lining is very difficult. Wooden panels they shrink or swell, but plastic ones are not so whimsical.

For installation you will need the following tools:

- screwdriver;

- clasps (special metal latches).

The lining can be positioned horizontally or vertically. You can also try installing it at an angle. It depends on your skill, imagination and the characteristics of the room. And one more tip - do not try to squeeze the tenons into the grooves all the way.

Decorative plaster

To decorate the veranda from the inside, plaster is often used. This is a mixture that, after being applied to the wall, turns into a finished coating. There is a huge variety of different coatings:

- plaster, which contains colors to give the walls the desired color;

- plaster imitating stone;

- Venetian, which repeats the texture of marble.

The appearance of the veranda also depends on the technique of applying the material. Different results can be achieved by simply using a little more plaster or making different types strokes. In addition, with the help of plaster you can create sgraffito - stucco paintings on the walls.

MDF and PVC panels

MDF panels (Medium Density Fiberboard) are wood fibers that were obtained by processing solid blocks of wood. After this, the chips are pressed under high pressure and temperature. The veranda can be sheathed with slabs up to 10 millimeters thick. Ready block has the following qualities:

- has high sound absorption rates;

- withstands high and low temperatures;

- convenient to use.

But the material also has a minus - it reacts poorly to moisture (swells and disintegrates). If condensation often appears in the veranda, MDF panels will not be suitable.

For ease of use, several formats of MDF panels are made:

- separate sheets;

- lining, etc.

They just need to be secured to the wall with screws.

PVC panels are a material made from polyvinyl chloride. It's very comfortable. Since the panels are plastic, they can be bent to fit any room shape.

PVC panels have the following positive aspects:

- light weight;

- high resistance to contact with water;

- resistance to high temperatures;

- low cost.

But there is also a minus - the material cracks in the cold. So if winters are harsh and the temperature often reaches -15, it is better not to use PVC panels in an unheated veranda.

If you do all the work yourself, it is advisable to choose a material with pins and grooves for quick installation. The working process is as simple as with MDF.

Special fasteners are used for installation. You need to screw the panels in place with a screwdriver. To avoid damaging the material, perform the operation on low power. If you bought a kit ready for installation, then you can do without a screwdriver at all, using only clamps and screws.

Improvement of ceilings

The ceiling is the part of the structure that bears the heaviest load. It is constantly exposed to moisture due to seasonal precipitation, and in winter it must also withstand the weight of snow. Pick up the right material not easy. It must be at the same time: durable, lightweight, and moisture resistant.

Two materials meet these parameters:

- polycarbonate;

- weaving.

They are easy to install and do not require special maintenance.

Polycarbonate

Polycarbonate – transparent modern material. It is very reminiscent of glass, but without its disadvantages. In particular, polycarbonate is durable and very lightweight.

It has several types:

- Monolithic. It is a solid material produced in the form of plates. Externally it resembles glass. It can withstand loads and is therefore better suited for roofing.

- Cell phone. Inside, this polymer has a honeycomb division. It is less transparent, but has the same high light transmittance. This polycarbonate retains heat much better and is much lighter than its monolithic counterpart.

Polycarbonate can be transparent or colored. It is easy to secure the material. To do this, create a frame on which you need to install the sheets. They are fastened using galvanized self-tapping screws with thermal washers to prevent leakage.

Weaving

If you want to original ceiling on the veranda, then the cheapest alternative to design solutions can be a wicker option. Externally, it looks like the walls of a basket, but it looks stylish. Typically used for weaving:

- thin moisture-resistant plywood;

- veneer.

The installation procedure in the house is quite simple:

- Saw the sheet into several even strips. To do this, you can use a machine so that the cuts are neat, otherwise the weaving may be fragile.

- On flat surface weave the fabric. Weave in a checkerboard pattern, tapping the protruding edges with a rubber mallet.

- Hide the “tails” of the stripes on the wrong side of the weave.

- Since the structure is quite heavy, it is impossible for one person to lift it. To make the job easier, use ropes around the edges. It is better to lift from the door side.

- The material can be secured with slate nails.

To hide the joints, install skirting boards. For greater aesthetics, coat it with varnish.

Flooring

The final chord in the design of the veranda is the choice of flooring. The options may be the following:

- terrace board;

- tile;

- rubber;

- linoleum;

- cement.

To finally make your choice, think about whether you will walk on the veranda barefoot or in shoes. In addition, you can lay a carpet or rug on the floor in the veranda.

Terrace board

Deck board is essentially treated lumber. This is a three-layer design:

- Bottom layer. This is a covering with ventilation slots.

- Middle layer. There are cavities here that allow the wood to expand without deforming the overall structure.

- Upper. This is the front part of the board, so it is smooth.

This material has many advantages:

- the board is easy to install;

- the floor is not much different from wood;

- The coating is durable and heat-intensive.

To prevent the floor from deteriorating, it is better to give preference to boards that are varnished. Installation must be done on a frame with lag through it. Moreover, the logs need to be placed perpendicularly with an interval of 40-60 cm. After this, the board can be fixed. It is better to use nails or screws as a fastener.

Tile

The slab is a difficult material to install. But the difficulties are worth it, since the tiles have the following positive qualities:

- it is impact resistant;

- easy to clean and withstands precipitation;

- differs in a variety of designs.

Installation of tiles is carried out according to the following steps:

- First, the surface needs to be leveled.

- Next comes the screed.

- Preparation of materials. You will need special tile adhesive.

- The tile is leveled. You need to install special crosses between the corners to even out the dimensions of the seams.

- Next, mask the joints with a special grout. If grout gets on the tiles, don't worry. It will wash off the surface, but will remain in the gaps.

But there is one difficulty - cutting. This must be done if the premises non-standard sizes. This operation is almost impossible to do without a tile cutter, although you can try replacing it with a grinder.

Linoleum

If the classic wall decoration in the veranda is lining, then for the floor it is linoleum. The coating is made from polyvinyl chloride in combination with polymers. The advantages of the material include:

- waterproof (but only if attached in one piece);

- impact resistance and wear resistance;

- ease of installation and maintenance;

- huge assortment;

- low cost.

Even a non-professional can install the material. The main thing is that the floor surface is fairly level. Next you need to roll out the roll, level it and secure it near the baseboard. If the linoleum has been cut, individual sections can be fastened together using a special strip. But due to the fact that the material allows cold to pass through, insulation must be used.

Rubber

Rubber coating is the rubber that covers the floor. On the market it is presented in slabs or monolithic blocks. From positive aspects materials can be distinguished:

- impact resistance;

- absolute waterproofness;

- resistance to temperature changes;

- phenomenal wear resistance;

- wide choice of design solutions.

It is important here that the floor is level. To connect the boards together you need polymer glue.

The installation procedure is similar to working with regular tiles. But in this case, crosspieces are not needed, because the plates fit more tightly. If rolled rubber is used, the joints are sealed using a soldering iron or a hair dryer.

Cement mixtures

You can finish the floor in the veranda in the standard way using cement. Despite the banality, the option remains the most labor-intensive. At the same time, you can lay such a floor even on monolithic foundation. As a result, you will get a coating that is different:

- impact resistance;

- waterproof;

- resistance to temperature changes.

It does not require careful care. True, after cement mixture installed, it needs to be polished to a shine with a special machine.

There are many other versions of finishing materials such as OSB boards or self-leveling flooring, but all of them are in less demand among consumers.

The choice of material for finishing the walls of the veranda

The materials chosen for finishing the walls of the veranda must meet practical and aesthetic requirements. The peculiarity of their choice is the lack of heating in the closed type extension and the serious impact climatic conditions on the open veranda structure. Therefore, the material used for decoration must not only be visually attractive and match the design, but also withstand exposure to the sun, high humidity and temperature fluctuations.

The veranda walls can be covered with many finishing materials that are used for interior and exterior work:

- Wooden lining. It belongs to the classics of the genre, as it is the most popular material for wall cladding due to its environmental friendliness, excellent appearance and pleasant aroma, exuded by natural wood.

- Plasterboard sheets (GKL). For verandas, their moisture-resistant version is suitable. Such products differ from ordinary gypsum boards in their green color. The material is environmentally friendly, easy to install and can be easily processed in numerous ways. It can take almost any shape, and this is important when decorating walls. This type of cladding is used in closed verandas.

- MDF panels. This material imitates natural wood. It is quite durable, but a humid environment is not for it. Therefore, MDF can be used to cover the walls of a closed veranda.

- PVC panels. This is a durable and inexpensive moisture-resistant material. It is presented in a rich assortment of various shades and colors, can have different textures, is very easy to work with and is not particularly demanding to care for. Suitable for cladding walls of any type of extension.

- Siding panels. They are practical to use and affordable. Often imitate wood and come in a variety of colors. The material does not rot, is resistant to temperature changes and fire, easy to care for and durable. Most often used for exterior wall decoration on the veranda.

Preparatory work before finishing the walls on the veranda

If the veranda has glazing, it is better to finish its walls after installing thermal insulation under the windows. In this case, the room can be used almost until frost sets in.

To insulate a closed veranda, you can use mineral wool or polystyrene foam. To begin with, waterproofing should be secured to the walls; you can use a moisture-proof polyethylene film as it. It is laid with an overlap of 150-200 mm, the joints of the canvases must be glued with metallized tape.

After this, it is necessary to install lathing on the walls. The material for it can be a wooden beam, pre-treated with an antiseptic. The cross-section of the beam should be selected according to the thickness of the insulation, and the size of the sheathing cell should correspond to the width of the insulation.

Then the insulation, in particular mineral wool, should be packaged in waterproof material and placed in the cells of the sheathing. Wrapping the insulation will protect it from moisture and maintain its functionality for many years.

After this, a foil membrane should be secured to the sheathing on top of the insulation and its joints should be taped. During the insulation process, it plays the role of a heat-reflecting screen. At this point, the thermal insulation of the walls can be completed.

Veranda wall finishing technology

Having chosen what to cover the walls on the veranda with, you can begin finishing them. Below we will look at several of its options.

Decorating veranda walls with PVC panels

This finishing method is inexpensive, but it can make an ordinary room cozy and interesting. The panels are not afraid high humidity air and sudden changes in its temperature - they are not capable of causing deformation of this material. Installation of the panels is easy and without any tricks.

The disadvantage of the material is its fragility, although currently you can purchase “armored” panels, the cost of which will be twice as much as usual. Therefore, after installing such cladding, you should be more careful when moving chairs towards it or leaning on the wall. To minimize risks, there is such a construction trick: the first plank of the panel sheathing is mounted at the level of the knees, the second - at the pelvis, and the third - at the shoulder.

The frame for plastic panels is made of wooden slats or a profile that is used when installing gypsum boards. The slats can have a cross-section of 30x10 or 30x20 mm; before use they should be treated with an antiseptic.

The sheathing slats should be fastened in a perpendicular direction relative to the installation of the panels. For example, if the plastic on the wall needs to be placed vertically, then the slats for attaching it should be placed horizontally on the wall, the step between them should not exceed 50 cm.

After making the sheathing in the corner of the room, you need to secure the mounting angle with screws or nails or starting profile. The corner will allow you to join the panels to each other. The starting profile is installed if the adjacent wall will be sheathed with a different material. You need to install a mounting strip for the baseboard on the ceiling.

The first panel is inserted into the guide profile with the tenon facing towards the installation. Then it needs to be fixed to the sheathing using a self-tapping screw with a press washer. Then the tenon of the next PVC panel must be tightly inserted into the groove of the previous one and secured. All other cladding panels are installed in the same way.

Due to the fact that plastic has thermal expansion, a gap of 20-30 mm should be left at the bottom and top of the wall to compensate for it, masking it with a plinth.

Important! Panels with a pattern when covering walls are installed from left to right. Plain panels can be mounted starting from any side.

Decorating veranda walls with MDF panels

This material is quite popular among adherents self-finishing. MDF panels are stronger than plastic, but are not resistant to moisture. Therefore, they should only be used on closed verandas.

The installation process of MDF panels is similar to the previous one. Only in this case their fastening is done using metal special devices- clamps, which are fixed to the material with small nails or a construction stapler. This must be done through a guide; it will prevent damage to the edge of the panel.

Decorating the walls of the veranda with clapboard

They call it lining wooden board up to 22 mm thick, having special grooves with the help of which the installation and joining of cladding elements is carried out. If the material is treated with an antiseptic, its service life can be extended to 20 years.

According to the production method, the cladding board can be solid or spliced. In the latter case, the pieces quality wood connected to each other in a special way. Such products do not have flaws in the form of knots or cracks, but are not suitable for covering the walls of an open veranda.

The reason for this is the formation of cracks in the places where the boards meet at high humidity, which spoil the appearance of the finished cladding. The most expensive lining is almost always spliced. It has an “extra” class, and products of classes A, B and C are made from solid wood.

Before finishing the walls on the veranda with cladding boards, the material must be left to adapt in a closed room for several days, and then the lining must be treated with a protective compound. Installing boards on veranda walls is similar to installing PVC and MDF panels.

There are several ways to attach it:

- The simplest of them is fastening using galvanized nails. In this case, they are driven in along the center of the planks, and the caps are recessed into the wood using a punch.

- Fixing the sheathing board with self-tapping screws is more labor-intensive, but the fastening points are not visible. A hole with a depth of about 10 mm is drilled in the board on the tenon side. The diameters of the drill and fastener heads must match each other. Then the plank is screwed to the sheathing batten, and the screw is recessed into the hole and closed with a dowel on top. The fastening area is then sanded.

- The board can be attached to the sheathing using mounting brackets. For this, a pneumatic or mechanical construction stapler is used.

- Another method is to fasten wooden sheathing with clamps. In this case, it is first attached to the rear wall of the mounting groove of the first strip. Then it is fastened with nails to the wall and only then the clamp is fixed. The same clamp is installed on the second board, its tenon is inserted into the groove of the previous plank and the clamp is secured to the sheathing batten. With the help of such fasteners, only interior lining walls

After completing the installation of wooden wall cladding, you need to cover all corners and joints near doors and windows with a corner and begin finishing coverings. To give its surface a certain shade, you can use colored varnishes and wood stains.

Before painting the walls on the veranda, it is recommended to apply the selected varnish to a sample of the material and let it dry. It happens that after drying the shade of the coating changes, and it is quite difficult to remove a layer of varnish that does not correspond to the design. Therefore, it would be better to buy a small container with a painting composition for testing, and if it suits, purchase the rest.

If there is a need to leave the cladding wood in its original form, a colorless glaze containing an ultraviolet filter can be applied to it. It will help prevent the walls of the veranda from fading from exposure to the sun.

Exterior wall decoration of the veranda

It can be done using lining or siding. Wood cladding in this regard, it is somewhat capricious. Despite the treatment of its elements with various antiseptics, when exposed to precipitation, sunlight and seasonal temperature changes, the cladding may lose its original appearance if it is not taken care of.

Therefore, every year you will have to carry out various measures to preserve it: impregnation, painting, etc. But if the choice to use wood has already been made, it is important to remember that the horizontal fastening of the outer cladding boards should be done with the tenon upwards, fixing them in 2 rows on each side of the key joint.

Exterior decoration of veranda walls with siding is more good option. This type of cladding got its name in the 19th century. Planed and painted boards were attached at an angle to the plane of the wall so that each subsequent horizontal element slightly overhangs the previous one. This position of the boards allowed water to roll down the cladding without delay. Nowadays, siding performs two functions - protective and aesthetic.

Most often for outdoor wall cladding used vinyl siding. Its popularity is due to ease of installation, practicality and affordable price. Externally, the material looks like an ordinary board that is used for cladding facades.

However, vinyl will not lose its appearance even after a couple of decades, despite seasonal temperature fluctuations, bitter frosts and heavy rainfalls. In addition, dirt does not stick to this material and maintenance is minimal - just wash off the dust from the cladding with a garden hose. Thanks to a huge number of shades, siding can be matched to any home exterior; it will fit perfectly into the overall ensemble.

Installation of vinyl siding panels is carried out in the following order:

- First, you need to make and install sheathing for cladding the walls of the veranda. This will require unedged board 30 mm thick or wooden beam with cross-sectional dimensions 40x50 mm. It needs to be fixed in vertical position in increments of 400-500 mm over the entire surface of the walls. Additional wooden blocks should be installed around the windows, at the corners of the veranda, along the upper and lower edges of the future cladding.

- From below, along the perimeter of the walls in a strictly horizontal position, it is necessary to secure the starting profile to the sheathing using self-tapping screws.

- After this you need to install corner profiles around openings, as well as in all corners of the building. The lower edge of the corner profile should be located 5-6 mm below the level of the starting strip.

- Then you should cut the panels. Vinyl is easy to cut with scissors, a hacksaw or electric jigsaw. Due to the fact that vinyl panels have thermal expansion, each of them must be made 5-7 mm shorter than the wall.

- After this, the prepared panel must be slightly bent in the center, and its edges inserted into the grooves of the profiles located at the corners of the wall. Then the panel should be aligned and its lower edge should be inserted into the starting profile. The upper edge must be secured with self-tapping screws to the sheathing through special holes.

- Pressing the screw heads tightly against the panel material is unacceptable. The oval shape of the fastening holes is specially designed for free movement of material relative to the screw part of the fastener when air temperature changes. There should be a distance of 1.5 mm between the screw head and the sheathing.

- The next panel must also be inserted into the corner profiles, snapped into the groove of the previous element and secured to the wall sheathing.

- Before installation last panel It is necessary to level the finishing profile on the sheathing. Then you need to cut the panel to the required width and snap it into the previous paneling element, simply inserting the free edge of the product into the finishing profile. This completes the covering of the veranda walls with siding.

How to cover the walls of the veranda - look at the video:

A beautifully decorated building, located near the house or in the garden, always serves as an excellent place for relaxation and casual conversation. Carefully and tastefully executed interior decoration can create a feeling of home comfort on the veranda and become excellent designer decoration. editors of TutKnow.ru

Your country house will become even more comfortable and beautiful if an extension is added to it, located along one of the walls, which is called a veranda. Practically, this is another one of the premises, but located on clean air, where you can enjoy the aromas of flowers in the summer and the smell of rotten leaves in autumn period. Even if there is a downpour outside the window, you can enjoy a cup of coffee on the veranda. Enclosed veranda can be converted into a summer dining room where the whole family can gather.

Sheathing the veranda

Since the veranda is used only in summer time, then it is not necessary to carry out communications and heating there, so very often such construction is done with one’s own hands. Just like the facade of the house, the veranda needs additional finishing that will help you feel an atmosphere of comfort and warmth. You should know that a house with a veranda covered with siding in the same style will look more beautiful, look at the photo.

The veranda is finished with siding even when the house itself is lined with brick or special plaster. Due to the precisely selected color of the panels, the result will be the most harmonious.

Why siding?

When compared with other finishing materials, the use of siding provides the following opportunities:

- ease of maintenance - to make the cladding look clean and beautiful, you should sometimes spray the surface of the panels with water from a hose;

- has a low cost.

This material is simple and easy to install, so if you have a little construction experience, covering the veranda with siding after carefully reviewing the recommendations is quite a simple task.

Wall decoration

Before you start covering the veranda with panels, you should develop a plan that will enable you not only to calculate the cost of installing the panels, but also to prepare the exact amount of material. When the drawing with the indicated dimensions is completed, the lathing is attached to the facade, which is required for the correct installation of the building material. For the frame, a metal profile or even wooden slats are most often used. Surface preparation is also an important work process, as is the installation of the siding panels themselves. Siding only highlights all the obvious irregularities and distortions of the walls, therefore, when installing the frame, the possibility of such errors should be completely eliminated.

The lathing is installed vertically along the entire plane of the wall, at a distance of about fifty centimeters. Additional bars are attached around window openings, at the corners of the veranda and along the top and bottom edges of the trim. All fasteners and screws that are used to install the frame must be long to fit into the tree, no less than thirty millimeters. The caps should be about eight millimeters in size.

A starting profile is installed from below, which is attached to the frame with self-tapping screws. It should only be positioned horizontally. Then corner profiles are attached in all corners, as well as around window and door openings. In this case, it is necessary to strictly ensure that the lower edge of the corner profile is several millimeters below the first rail.

When the sheathing is ready, you should begin cutting out the panels. You can cut the plank with a regular hacksaw with small teeth or a jigsaw. The finished plank is slightly bent in an arc and the edges are inserted into the grooves of the corner profiles. The aligned strip is inserted with one edge into starting bar, after which it is fixed with self-tapping screws into pre-prepared recesses. It is not recommended to decorate the veranda with siding without ready-made holes; if necessary, you can use special tool or a knife. It is not recommended to fasten siding tightly to the frame; there should be a small gap between the head of the screw and the surface of the board to allow expansion and deformation of the panel. In areas where frequent cold weather occurs, it is better to place a special nylon washer under the self-tapping screw.

The next plank is also inserted into the corner profiles, after which it snaps into the groove of the previous one and is also fixed to the frame.

Before installing the final panel, a finishing profile is mounted, which is fixed level, and the panel of the required width is inserted into the previous strip with one edge, the other edge into the profile and snaps into place.

When installing antennas and other walkable parts to the panels, these elements should not in any way resist the expansion and shrinkage of the panels.

Finishing the veranda with siding is carried out at a temperature of at least ten degrees. If installation is necessary in the cold season, small gaps are left between the panels.

In order to get a veranda covered with siding in the photo, you just need to follow the recommendations. If you have any difficulties while working, you can watch the video.

Material requirements

Because we're talking about about covering the outside of the veranda, it is important to understand the seriousness of the choice of material. It must meet some requirements. For example, have you seen someone wallpapering a house or veranda? No? But why? The thing is that the material is simply not made for outdoor use. The wallpaper will fade in a few days, peel off, or get wet in the rain. From this example, you can understand that the material for covering the veranda must meet certain requirements. Here is the list:

- Withstand precipitation in the form of rain, fog or snow.

- Resist the influence of ultraviolet rays, do not fade or warp.

- Be resistant to sudden temperature fluctuations.

- Be frost-resistant and durable.

- Withstand various physical and mechanical damage.

- Be bioresistant and not susceptible to mold, mildew or insects.

- Be aesthetically attractive.

Only such materials for covering the veranda can serve you well, remaining durable, reliable and beautiful for many years. What can you choose from? Let's look at the list suitable materials, and video installation instructions for each of them.

Wooden lining

One of the most popular materials for finishing both inside and outside. The lining is made of wood, therefore it is environmentally friendly. In addition, the appearance of the products is simply magnificent. As for the plating process, it is simple. It all comes down to creating a wooden frame and fixing the lining to it. Due to the locking connection, no seams are visible. The connection points are hidden. But you can fix punks in different ways. Often, clamps, nails, screws or staples are used for this.

Here are the advantages of the products:

- Great looks.

- Ecological cleanliness.

- Easy to install.

- With proper processing, the material will be protected from moisture and other atmospheric influences.

- The lining is strong and durable.

- Thanks to the classification of products, you can choose products according to the price category for yourself, ranging from inexpensive to luxury.

- Possibility of laying insulation under the lining.

- Versatility. Can be used both outside and inside.

The installation process itself is simple. You can see the technology from this video:

Siding for covering the veranda

This is a unique material that is created for outdoor use. It has all the advantages that we talked about above. There are several types of siding:

- metal;

- cement;

- wood;

- vinyl.

Most often, the last two options are used in finishing verandas. The installation technology is somewhat reminiscent of lining, since here you also need to build a frame and fix the siding to it. But there are some details and subtleties in the work that are different. The material itself is very worthy and is widely used for cladding not only verandas, but also houses in general.

Here are the benefits of siding:

- Long service life (50 years minimum).

- It has a beautiful appearance and a different range of colors.

- Easy to use, easy to clean, no need to paint or repair.

- It is lightweight and flexible.

- It is universal, you can choose the material of manufacture yourself.

- Installation is quite simple.

- Copes well with temperature changes and harsh weather conditions.

- It has holes for ventilation and condensate drainage.

- The material for covering the veranda will not rot or be attacked by insects.

- Durable, practical and does not fade.

Due to its advantages, siding takes a leading position among other cladding materials. Although, like everything, it has some disadvantages:

- the material cannot be called environmentally friendly, although this is not so important for cladding the outside of the veranda.

- vinyl products burn very well, emitting harmful and toxic smoke;

- vinyl products for the veranda become brittle at low temperatures;

- metal siding is easy to damage. By bending it once, you will not return it to its former appearance;

- Wood siding has a short service life.

You can see siding installation in this video:

Other popular materials for covering verandas

Most often, the materials described above are used for cladding. Although, there are other options that are also in demand. One of them is facing brick. If your house is completely covered with this material, then it would be foolish to use any other material for the veranda. Facing brick is quite expensive, but has its advantages. We can note reliability, strength, external beauty, durability, resistance to precipitation and temperature fluctuations. The material is not afraid of impacts and ultra-violet rays. Therefore, we can say that this option is a guarantee of reliability.

If we are talking about wooden house, then the veranda for him can be made in exactly this style. Many people sheathe the veranda with wood; this includes lining. However, a block house or imitation timber (false timber) is often used for these purposes. These are some of the types of lining that differ in appearance and characteristics. A block house is a lining that imitates rounded timber. The material has a convex shape, so after covering the veranda it may seem that it is entirely made of wooden beam. But imitation timber creates the effect of an ordinary timber and has a rectangular shape. Take a look at the photo to understand the difference in appearance materials.

You can decorate the veranda in one way or another. It's up to you to decide. It all depends on desire, preferences and financial capabilities.

It is not always possible to sheathe a veranda. There is another finishing option, which is plastering. Often the house itself is finished using plaster, so the veranda can be made like this. At the same time, you have the opportunity to insulate it from the outside. It is enough to sheathe the veranda with insulating material. plaster the surface using reinforcing mesh, and then perform finishing putty or plaster. At the same time there appear various options plastering. This can be bark beetle plaster, fur coat, structural, decorative or textured plaster. There are plenty of options, and the choice is up to you. At the same time, the material will resist perfectly external influence and protect the insulation inside. So, you can kill two birds with one stone at once. Look at the photo to see what the bark beetle looks like on the surface.

It should be as comfortable and aesthetically pleasing as the entire building. This could be the front entrance, which gives the first impression of the interior, or an extension intended for recreation or household needs. One way or another, one of its main purposes is to serve as decoration, without which the house would not look so elegant. It can be designed in the same style as the main building, or differ from it, creating an interesting composition with it and successfully complementing the facade. The walls and ceiling will require a durable and fireproof finish, so we’ll tell you what you can use to cover an unheated one outside and inside.

How to cover an unheated veranda inside and outside

Material requirements

One of the main tasks is to create a coating that does not allow heat to pass through and protects from drafts. At the same time, the walls must breathe, otherwise in the cold season it will be stuffy and uncomfortable inside, especially when it is turned on. The problem can be solved ventilation valve. Such devices are usually used in city apartments where impenetrable plastic double-glazed windows are installed.

If the house is intended for living all year round, the coating will be required to have good thermal insulation properties. It is advisable to put a layer of thermal insulation under the finishing, covering it with a film that does not allow moisture to pass through. Without such protective measures, water will penetrate into the voids and begin to destroy the material, expanding when it freezes. There will be a smell of dampness in the room, and there may be a smell in the corners.

If the building is garden plot used only in summer, the outer finishing layer must still have good waterproofing properties and reliably protect brick, concrete or wood from getting wet.

One of the most important requirements- fire safety. For a log house or structure made of timber, relaxation can be allowed, but it is still worth making a choice in favor of a non-combustible coating. In the event of a fire, it will retard the flames and may save the lives of people in the building.

Non-toxicity is also important. The coating should not cause allergies. If it has a pronounced chemical smell, it must not be used under any circumstances. Even in open space It will be impossible to get rid of such a “flavor”. When burned, the material will likely release toxic gas. Unscrupulous manufacturers try to sell their goods as quickly as possible. It is usually sold in markets where no one monitors quality, and is very cheap, so it is better to purchase it in construction stores, where the quality of the product is beyond doubt. Price serves as one of the indicators of quality.

The cladding is required to maintain its properties despite frost, rain and exposure to ultraviolet radiation. If you plan to paint it, it is better to choose the most durable compounds.

How to sheathe the outside of the veranda

Lining

In the case of open verandas, no protective measures are required.

It is most often used for cladding. It's environmentally friendly pure material. It is not expensive and has everything necessary properties. To protect the boards from exposure to microorganisms, they are treated with an antiseptic. To protect against moisture, use varnish and. It may contain antiseptic substances. Each board has a small protrusion on one edge that extends beyond the next one. This is necessary to close the voids at the joints. If necessary, the covering is cut and attached to the sheathing with nails, clamps, staples or self-tapping screws.

Wood looks great with any material. If, for example, the question arose - how to cover the pillars open veranda- it’s better to choose a lining.

Siding

In second place in popularity is. It comes in four types:

- polymeric;

- metal;

- cement;

- wood.

It is more resistant to rain and frost, does not fade in the sun and does not require additional processing. Its service life is several times longer.

There are also disadvantages. Polymer products burn well, emitting acrid toxic smoke. Metal ones are fireproof, but they are easy to damage. If you bend one part or make a dent in it, it will no longer be possible to straighten it.

Installation is carried out on the lathing using special fittings and baguette.

Brick

It has the highest strength characteristics. He is not afraid of impacts and scratches. He doesn't care about rain and snow. The service life of a brick is not limited.

Plaster

If the building is built reliably and the load-bearing structures do not “walk”, its outer part can be covered with plaster. Exist decorative compositions, mixtures with improved technical characteristics. You can add any color dye to the composition.

Polycarbonate

Walls and roofing can be made transparent using polycarbonate plates. They are monolithic and hollow. Products can have any color, smooth or textured surface. The material transmits light perfectly and is highly durable. This allows it to withstand loads from more than a meter layer of snow. It weighs a little. To install it, you do not have to assemble massive structures. The slabs are attached to a frame or sheathing.

OSB

For rough finishing, you can use oriented strand boards (OSB). In terms of technical characteristics, they are superior to natural wood finishes. On open terraces They are used to make not only enclosing structures, but also floors.

How to sheathe a cold veranda from the inside

On the inside, you may also need heat and waterproofing. It is done in the same way as with the external one. The exception is open and semi-open structures.

How to cover the walls

Regardless of what the finishing will be, it is better to protect the load-bearing structures with heat and water insulators. Used for insulation mineral wool, expanded polystyrene foam, polyurethane foam. To protect this layer, polyethylene-based waterproofing is laid on top. Polyurethane foam is applied by spraying using special equipment. In other cases, the work can be done with your own hands. Porous slabs are laid on wooden sheathing. The seams between them are filled polyurethane foam, the excess is cut off with a knife. Polyethylene is nailed to the top of the sheathing. The joints are sealed with metal tape.

For a comfortable stay on the terrace during the cold season additional insulation not required if the walls are made of thick logs or aerated concrete blocks. The thickness of the masonry in this case should be at least 25 cm.

Most often, lining is used for finishing. This is the rare case when construction material has a pleasant natural smell that is good for health. If the terrace serves as the entrance to the home, polyvinyl chloride panels are suitable as cladding. They are easy to wash and are not afraid of moisture. They do not look as elegant and colorful as natural wood, but unlike it, they hold their shape well when the temperature changes in unheated room.

Have proven themselves well MDF boards. They look like solid wood, while devoid of most of the disadvantages inherent in birch or pine. The vulnerable point is the edges, which must be closed during installation, having previously been treated with an antiseptic. Otherwise they will crumble.

How to cover the ceiling on the veranda

In first place in popularity is again lining. She is not required to withstand heavy loads, and nothing threatens her at the top.

PVC panels, MDF and OSB boards are also used for ceilings. Weaving and bamboo surface look good.

When choosing plaster, it is better to focus on compositions for facades. They are not afraid of humidity and temperature changes.

You can assemble a transparent polycarbonate roof. In this case, a ceiling will not be required, but even cellular coatings will not be able to create the required level of thermal insulation.

How to finish the floor

Floors have the highest strength. A dye can be added to the solution, but the main advantage of this solution is its reliability.

If durability and high decorative characteristics are required from the coating, tiles would be the best solution. There are a huge number of tiles that differ in price, properties and composition. The material is environmentally friendly and is not afraid of water. There are special coatings that are characterized by increased strength and abrasion resistance.

At low humidity, you can lay linoleum, rubber, even, but it’s better not to risk it. Too much condensation accumulates in an unheated room. It is better to use floor boards coated with varnish, paint and treated with antiseptics.

- Material prepared by: Artem Filimonov