Finishing the facade with improvised materials. Recommendations for making furniture facades on your own. Types of facade finishing

One has only to change the cladding and the house itself will change beyond recognition. However, before delving into the design subtleties of facade design, it is important to understand the finishing materials, their properties, advantages and disadvantages. Do-it-yourself finishing of the facade of a house can be done using:

- siding,

- facade plaster,

- stone,

- brickwork,

- tiles

Each type of cladding has its own characteristics and requirements for surface preparation. This article will focus on the quality of the wall and the types of cladding materials.

Siding

Craftsmen have been sheathing houses with wooden boards for centuries, but only about 50 years ago a PVC analogue of this material was invented. PVC siding has a number of advantages, among which it is worth noting:

- The formation of a protective ventilated screen around the wall, which allows the walls to breathe.

- Vinyl siding does not require special care: to keep the facade clean, it is enough to wash it with water occasionally.

- PVC does not burn. Although it melts, releasing harmful substances, this does not in any way aggravate the situation of people inside the house during a fire.

- A house covered with vinyl siding looks very modern without losing its aesthetic properties over many years.

Resistance to color fading and service life depend on the manufacturer. Nicely low prices can be deceiving. Poor-quality house cladding will last only a few years, and then it will have to be replaced, which will entail additional financial costs.

Before buying material for finishing the facade, take measurements of the house. This will allow you to calculate the amount of siding and additional elements for its installation. It is very important to follow the installation technology. Calculate expansion and contraction ratio vinyl siding. This event will help you avoid rework due to expansion of the material during the hot season.

An equally common material for cladding is siding made of natural wood. Well, this structure looks really great. However, wood has a relatively short lifespan, so the expensive brilliance of wood siding may not be worth it. However, modern technologies have provided manufacturers with the opportunity to produce wood siding with an extended service life. By processing under high pressure wood density increases. This increases the resistance of the material to aggressive external environments.

The most durable, unpretentious, fireproof and resistant to mechanical damage counts metal siding. It is made from galvanized steel polymer coating. Main disadvantage material - limited palette of colors and types of textures. Grounding corrects the conductive properties of the metal. This event, by the way, prevents the penetration of radiomagnetic waves into the building. In this case, the house will have protective screen, But mobile connection It will be difficult to fish in it.

Classic approach - plaster

The plastered facade is also called wet. This is logical, because its arrangement cannot be done without wet processes. Nowadays for facade plastering funds developed different compositions plasters.

Mineral plaster. It is a bestseller due to its low cost. However, the material has the shortest service life and low ductility. Although, on the other hand, walls treated with mineral plaster “breathe”. It makes sense to apply “breathable” plaster only if the walls are also built from materials that allow air to pass through. Can be used as insulation mineral wool or basalt slabs. If your house is located near railway tracks or a busy highway, then mineral plaster for finishing the facade is inappropriate in this case. The fact is that it will crack and collapse due to constant vibrations. Typically the service life is about 10 years.

If your house has just been built, then you should not plaster it with this composition. The structure will shrink over the course of several years, causing the façade to crack and collapse. Simply put, such actions will lead to a waste of money.

The material is very plastic and resistant to moisture, “does not breathe.” However, if you chose polystyrene foam or foam glass as insulation, then this type of plaster will be indispensable. The façade can withstand high vibrations. This means that if your home is located close to railway or highways, then the wall cladding will last in its original form for a very long time!

Acrylic plaster absorbs dust, so if the house is located near a highway, its use should be as justified as possible.

The material is very durable, and the fact that it does not “breathe” can be compensated for by using forced ventilation. The service life is about 15–20 years.

Silicate plaster. The material has absorbed everything positive characteristics. It does not collect dust, is unusually plastic and allows air to pass through, that is, it “breathes”. However, silicate plaster is the most expensive. Its service life ranges from 20 to 25 years.

The material is elastic, breathable, does not absorb chemical compounds, including salts, antistatic. If silicone plaster is applied correctly, it will be a durable decoration of the facade for 25 years, or even more. The material is so reliable that it can be used to cover a façade even near a busy highway.

Monumental facade finished with tiles or stone

It's very easy to do with tiles. Beautiful design Houses. However, in order for such a facade to last for a long time, it is very important to follow the installation technology. The first thing to consider is that brick walls must first shrink. In addition, in order for the tiles to adhere well to the walls, for each type of tile it is necessary to use the appropriate adhesive composition. By the way, tiles can be clinker, ceramic, made from natural or artificial stone, made on a sand-cement base.

Tiles can transform a flat, unremarkable wall into an exquisite architectural masterpiece. Finishing the facade with tiles is done seriously and for a long time. The tiles you use must be designed for outdoor use!

If you decide to make a ventilated facade, then the walls insulated in this way can be finished with tiles. The method of fastening and the thickness of the skin are calculated in accordance with the upcoming loads. Ventilated facades are made of brick. After this, you can finish the walls with tiles.

If you decide to cover your house with tiles that imitate chopped stone or brick, then leave 5 mm gaps between the parts for subsequent grouting. To make the imitation masonry look more attractive, choose a matching grout color.

When combining tile textures, it is important to consider their size. To cover the base, choose large elements. Smaller tiles are better for walls. This way the house will look more stable. The top edge of the finish should be protected from moisture penetration. For this purpose, use protective cornices or canopies.

As for facing the facade with natural stone, the technology is as follows:

Cladding the external walls of the house with brickwork

Brick is a symbol of good quality construction. To make the house more respectable, it is best to use clinker bricks. As a rule, facing walls with bricks is done already at the stage of laying walls. This move is usually calculated by architects in advance. What if the building has already been built? In this case, facing the facade with clinker bricks - perfect solution to improve the attractiveness of the home.

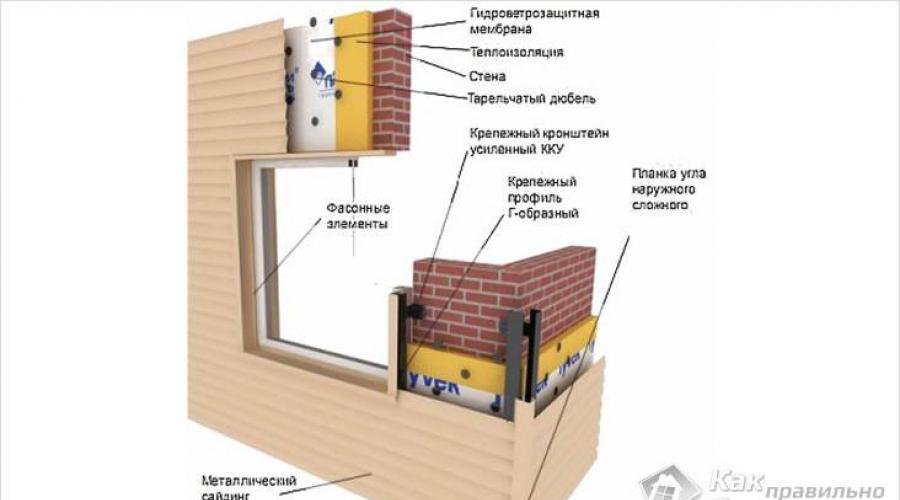

If you have wooden house, then finishing it with brick is advisable only if a ventilated façade is installed. Otherwise on wooden wall Condensation will form, quickly destroying it.

Thickening a wall with brickwork will not increase it thermal insulation properties. To make the house warmer, you need to make a ventilated facade with wall insulation basalt slab or mineral wool. Brickwork cannot be started unless the foundation of the house is strengthened and expanded. This is due to the fact that brick absorbs moisture. In addition, a waterproofing layer should be laid on the foundation.

Regardless of what material the walls are made of, they must be connected to the masonry with flexible connections. For 1 m2 there are 7 flexible connections. The height of the masonry together with the pediment cannot exceed 7 m. Otherwise, it will be fragile. To liven up the texture of a wall, install on it decorative elements, such as cornices, fillets and arch molding.

In addition, you can combine bricks of several colors. Such a facade will look very original and unusual. If you add the appropriate dye to the solution, the masonry will look even more elegant.

If you have already decided how to decorate the facade of the house yourself, then purchase the material and start doing the work. If you have any questions on the topic, then write your comments to the article. The specialists working on the site will advise you, clarifying all the details of the facade finishing or the choice of materials.

Photo

Important components depend on the facade of the furniture: appearance, functionality and cost of the entire product. The area of the parts of the external front side of cabinet furniture, relative to the entire product, is small. But despite this, production furniture facades requires a lot of time and effort. This is the front side of the design, every flaw will be evident.

In order to independently make a furniture facade that does not differ in quality from the factory product, you need to purchase the necessary tools in advance:

- Boards from which frames will be cut - it is important to select elements with a smooth surface, without knots or chips;

- Sheets of plywood, plastic or glass, no more than 6 mm thick - they are needed to create a panel - important element decor;

- Metal ruler with 30-40 cm markings;

- Pencil;

- Electric jigsaw with a set of wood files;

- Roulette;

- Wood glue;

- Brush for glue work;

- Discs for cutting boards, it is convenient to use a milling cutter.

To maintain order while working, prepare a bucket of water and a rag.

Manufacturing technology

The manufacturing process of furniture facades is complex. You can create neat and suitable doors on your own if you strictly follow the steps of work.

Carrying out calculations

First stage technological process– calculations. The dimensions of future doors are easy to make: just use a tape measure to check the parameters doorways. For the calculations to be correct, it is necessary to clarify the details:

- The size of the facade should differ from the height of the opening by 3 mm in a smaller direction. If this point is not observed, the finished doors will not close and open freely;

- The parameters for the width of racks and crossbars do not have specific standards. However, their dimensions on one piece of furniture should be the same;

- The difference in the width of the product and the doorway should be 3 mm. If you need to make 2 doors, then you need to make the following calculations: divide the width of the opening in half and subtract 1.5 mm;

- The length of the crossbar is calculated according to the following scheme: the sum of the width of the two racks is subtracted from the width of the facade and 2 cm is added;

- The dimensions of the panels are determined as follows: width - 2 cm greater than the crossbar, height - width multiplied by 2, minus the height of the door and plus 2 cm.

Having dealt with the calculations, you can begin to select materials.

What materials are best?

The furniture facade is responsible for aesthetics and functionality. Therefore, much attention is paid to doors on cabinets and furniture. What material to use as a basis, what to make the panel from, how to decorate it and other questions are asked by the craftsmen at the first stages of work. Everyone decides for themselves what to choose.

The most common materials for making furniture facades with your own hands:

- Plastic;

- Aluminum;

- Glass;

- Wood.

Each material attracts with its advantages and repels with its disadvantages. The color of wood changes under the influence of the sun, but glass is not affected sun rays. Glass door can break from a blow, but the tree retains its strength for a long time. It is difficult to work with certain materials at home, so only professionals use them.

The easiest way is to make a furniture facade with your own hands from wood. When using carpentry tools, the material becomes pliable. Less pliable materials - plastic, glass - are used for finishing facades.

Aluminum

Sawing elements

On the base (board or plastic), the parameters for the location of the crossbars and racks are noted. Then the parts are cut out. Columns are made in double quantities. After this, special notches need to be cut out on the crossbars, through which they will be attached to each other. Upon completion, each part must be carefully sanded.

To ensure that the panels are securely in place, you need to cut special grooves. Using prepared disks, it is necessary to cut holes, the width of which should be 5 mm and the depth -10 mm. Before cutting grooves, you need to check the disk for functionality waste material so as not to spoil quality workpieces.

Having the finished parts in hand, you can begin assembly. The process consists of two steps:

- The posts are inserted into the cuts on the panel;

- Crossbars are fixed along the top and bottom.

All design details must fit together perfectly. If inconsistencies appear during assembly, they must be eliminated using sandpaper.

Making the markings

Sawing the material

Grinding the surface

Cutting the grooves

Making recesses

Connecting the elements

Clean with sandpaper

Finishing

The decoration of facades depends on the desires and capabilities of the person. Most often, three options are used in the manufacture of facades.

| Material | Description |

| Solid wood | This option is considered classic and is used for finishing furniture of any type (kitchen, bedroom, living room). Usually it is chosen when the furniture must correspond to one of the expensive styles - Empire, Baroque, classicism. To reduce the price of the facade, you can make the base from MDF and cover the front part solid wood. Such doors will look good on furniture in a classic or modern style. |

| Painted MDF | Smooth and bright facades are most often used in creating kitchen sets and wardrobes. Glossy panels will look equally good in modern style or futuristic design. They cannot be classified as cheap options, but they are no different in practicality: the smallest stains immediately become noticeable, chips and scratches form with minor impacts. If you want to have original and bright furniture, then this option fits better Total. |

| Frame facades made of aluminum profiles | Aluminum is used as the frame. To fill the space, plates made of MDF, glass or plastic are installed. The option is not the cheapest, but very practical. The advantage of such facades is their neat appearance and durability. It’s easy to keep such facades clean: just wipe them with a damp cloth and detergent from time to time. Furniture is usually decorated in this way. different styles. For minimalism, it will be enough to make inserts from glass or transparent plastic. The same option will fit into the loft style. Glass is used for kitchen units and façade decoration. For modernism, brightly colored plastic is more suitable. |

There are other, less popular types of facade finishing. Not all of them will fit into ordinary interior, therefore they are considered non-standard. Combination of different materials when creating a furniture façade, select originals. This may include various variations with MDF, which is taken as a basis. Glass and plastic are used as a supplement. Often the facade consists entirely of wood material, and decorative film is used as protection and decoration.

Solid wood

Aluminum

Varnishing and painting

Before painting, you need to prepare all materials. It is recommended to paint facades with a brush. If you plan to use a spray can or spray gun in the process of decorating furniture, then you need to cover nearby objects with film in advance so as not to stain them with paint.

The coloring workflow consists of several stages:

- Cleaning the surface from dust and small debris;

- Degreasing with an alcohol solution;

- Putty. This stage is not always necessary, but only if there are chips and irregularities on the facade;

- Primer. Each material uses its own version of grout. It can be applied with a brush or aerosol. To increase efficiency, you need to apply at least two layers;

- Applying paint. To ensure that there are no gaps left on the surface, apply 2-3 layers.

Painted surfaces will look more impressive if they are covered with glisal. The composition must be diluted with water according to the instructions and applied to the facade with a clean brush. . For a mirror shine and extended service life, painted doors are coated with several layers of varnish. Before applying, you need to wait time for the paint to dry.

To obtain glossy facades, acrylic varnish is used. It is applied in two cases: after painting and instead of paint. If you plan to leave the natural color of the base material for the facade, then it must be varnished. It is usually used for wooden surfaces. Varnish improves the appearance of furniture, increases strength and extends service life.

Before varnishing, it is necessary to apply a layer of primer to the surface of the facade. After that, the unevenness is covered with putty. When the surface is dry, you need to sand it with emery cloth. After which a layer of primer is applied again. The last step is to apply varnish with a brush to the joints of the facade and the main part. For getting mirror surface you need to coat it with several layers of varnish. At least 5 hours must pass before each coating.

Cleaning the coating

Apply primer

Seal cracks with putty

Degrease with alcohol

Painting the surface

Creating beautiful inserts

When making furniture facades, you can use your imagination and create unique design. There are several options on how to make facades beautiful and unusual.

- Combination - With You can make an insert into the furniture façade from any material. By combining two dissimilar materials, you can get unique style. It is important to understand that unusual materials on the facades should be at least slightly in harmony with the decor of the room. Most often they combine wood and textiles, plastic and aluminum, leather and glass. Bamboo and rattan inserts look very unusual, but look beautiful;

- Drawings – original way furniture facade decoration. It is suitable if the insert on the door is glass or plastic. You can draw by different means, but most often used acrylic paints. With their help you can draw anything you want. For accuracy, you can use a stencil. After completely dry The patterned surface can be washed with water and detergents. Making furniture facades has become very popular, so new methods of decoration are being created. The sandblasted image is one of the latter. It’s difficult to create something like this at home, because the process requires special equipment. As a result, a neat matte pattern appears on the mirror surface. If you lack the desire and ability to draw, then you can stick a self-adhesive film over the glossy surface. You can also use ready-made stickers for furniture;

- Stained glass and mosaics - do-it-yourself furniture facades that use glass as inserts look very beautiful and expensive. With imagination and patience, you can create original design. To do this you will need several multi-colored sheets of glass, glue gun and glass cutter. In the process, it is necessary to cut the glass into pieces so that when sticking to the facade there are no gaps between them. And if you try really hard, you can create a small picture like a mosaic from small parts on the surface of the facade.

By showing imagination, perseverance and accuracy, you can independently create furniture that will look more beautiful than models from magazines. The main thing is to think through the project well and select all the necessary materials according to color and texture.

How to make a house facade with your own hands: Photo + Video. Every homeowner wants their home to be unique and suit their taste. To do this, you can use the services of professionals, but it will be many times more expensive, and besides, it will be nice to invest a piece of “yourself” in the construction, so that in the future you can tell your grandchildren that you took part in the construction of the house.

We will tell you in detail how to make the facade of a house with your own hands using the specified building materials.

Options

Facade cladding can be done using:

- Siding.

- Facing brick.

- Thermal panels.

- Artificial and natural stone.

Plastering

This is an excellent way to finish a facade, it is also called wet method. It makes it possible to perfectly hide even the biggest flaws that could appear during the operation of the house:

- Cracks.

- Convexities and depressions.

- Holes that were made to attach something but were not used.

- Defects that occurred during the construction of walls.

To do this, you need to use special solutions. They are applied to a certain thickness to obtain an ideal surface.

Sometimes this happens when a large layer is required and then we recommend stick to a few rules:

And now that we are talking about the types of mixtures, let's look at what they are for exterior finishing. Please note that the compositions for interior work It cannot be used for the façade in any way. The fact is that if you make the facade of a house using compositions for interior work, the solutions simply will not be able to withstand the load that the façade cladding will be subjected to.

And the second point– it’s better to buy already ready-made mixtures for plastering, since manufacturers add special chemical components during production that help extend the service life of the finished coating.

Types of mixtures for facade plaster

So, what mixture should you choose so that you can do all the work yourself and also get a great result? It should be noted that in order to get a perfectly even layer, you will need to put in a lot of effort and practice. If this is your first time plastering, it is better to do small area, approximately 1 m 2, for any flat surface. Then you look at the result to understand whether the mixture, the method of application and the ability of the solution to level are suitable for you.

Let's get back to the lineups:

Let's talk separately about decorative compositions. With their help, you can create an unusual texture, or vice versa, smooth surface. To ensure that the coating is textured, use rollers, improvised means or special components (for example, bark beetle plaster contains special small granules).

Brick

If you want to make the facade of your house with your own hands, and at the same time make it look reliable and respectable, use brick. Everything will look especially good if you choose an original laying method and different shades of material. But there are some here too subtleties worth knowing about:

- If you use solid bricks, you should further strengthen the foundation so that it can withstand such a load.

- There must be a space between the finishing and main walls.

- Separate two walls must be connected by flexible connections.

These processes are labor-intensive and costly, so before purchasing the material, first calculate whether such an investment will be advantageous material Or would it be better to choose something more practical? You can replace facing brick to clinker, since with this option no additional strengthening of the foundation is required, but the walls must be strong. Clinker brick in appearance it resembles small tiles with the properties of a standard brick, so the installation process will be lengthy. But keep in mind that such finishing is considered durable and perfectly protects the house from humidity and temperature changes. Moreover, such a coating does not require complex care, because rain will wash away all the dirt and dust.

Siding

The facade finishing option is ideal for those who have an old house and the walls are not very strong. Panels separately and general design not very heavy, so they will practically not create a load on the base. It is very important that the panels and additional elements, without which installation will be impossible, are selected from the same manufacturer and made in the same batch, otherwise you may encounter such an unpleasant problem as discrepancies in shades and sizes.

Most affordable option finishing - vinyl siding. But this does not mean that manufacturers have saved on the quality of this type of material. Well-known companies produce panels High Quality, which will serve for a long time and without changes. The installation process is extremely simple, but we recommend that you read the manufacturer’s instructions and follow everything that is written there as accurately as possible. Also be sure to leave some room for thermal expansion. The panels will expand greatly under the influence of high temperatures, and if the fasteners are too tight, then in the first summer you will see the formation of cracks and the presence of deformations.

Artificial and natural stone

Before you start finishing with natural stone, you should check whether the base can withstand such a load. The fact is that natural materials They are quite heavy and are not recommended to be installed on an old base.

There is another option, but then you will need to strengthen both the foundation and the walls. Naturally, natural stone perfectly protects walls from any type of impact:

There is another option, but then you will need to strengthen both the foundation and the walls. Naturally, natural stone perfectly protects walls from any type of impact:

- Mechanical.

- Atmospheric.

- Chemical.

But installation requires special skills. For this reason, it is better to replace the finishing material with artificial analogue. Thanks to modern technologies stones that are obtained under production conditions have the same technological characteristics, like natural ones, but at the same time they weigh and cost less.

In order for the artificial stone finish to last as long as possible, it should be coated with a hydrophobic compound. This is the only drawback. But the installation can be completed without outside help.

Thermal panels

Thermal panels are also used to make the facade of the house.

This finishing method helps solve two problems at once.:

- Updated appearance.

The panels are made in such a way that they have two surfaces. The top one is facing material. This may be imitation brickwork, wooden board or natural stone. The bottom side has insulation that will help keep the house warm. Also pay attention to the fact that moisture will not escape from the room. But in order for it not to accumulate in the rooms, arrangement is required additional ventilation. The second solution to the problem would be to install panels like a ventilated facade.

Results

This type of finish will help protect against temperature changes. environment. Even mechanical damage is not scary. A beginner can handle the installation, even alone. As you can see, there are quite a lot of options for finishing the facade, and you can choose the one that you like and can afford.

The question of how cheaper it is to decorate the facade of a house is relevant for almost all owners of private buildings. After all, on the one hand, you want the cladding of your home to be of high quality and aesthetically attractive, but on the other hand, it is obvious that there is no need for unjustified expenses in pursuit of “exclusive” and stunning appearance. Rare are those families who can afford any solution without regard to its cost.

But also to go to extremes, stopping at the very budget option, without an objective assessment of the ability of the selected material to “resist” an aggressive outdoor environment - wind, rain, frost, snow, etc., it is definitely not worth it. Perhaps you want to verify in practice the effectiveness of the saying “the miser pays twice.”

Of course, it won’t be possible to decorate the façade of a house cheaply, but choose optimal material, which, with all other performance characteristics being equal, will have a lower price, is quite realistic.

Criteria for choosing wisely

In order to decide what is the best way to decorate the façade of a house and not lose financially, it is very important to clearly define the criteria that will help identify the advantages and disadvantages of one or another option.

First of all, you should pay attention to the appearance of the finished facade. Of course, the “presentability” of the cladding is a very, very subjective concept, directly depending on the personal tastes of the owners. However, such parameters of the materials used as:

- number of color variations and textures offered,

- resistance to fading and other visual defects,

- similarity to natural raw materials (if an imitation product is considered)

Under no circumstances should it be ignored. They will help you form an objective impression of the product.

The next quite obvious criterion is the durability of the material. Agree, it will be very sad if an inexpensive house facade turns out to be a real headache with the need for annual reinnovation work. If the type of cladding you like good timing services - know you are on the right track.

It's no secret that façade material is not enough to simply choose. It also needs to be installed. The complexity of the task, the presence of seasonal restrictions, the volume of auxiliary elements and materials - all these factors must be taken into account.

And finally, the total cost external cladding. This should include:

- cost of material per kilogram or square meter;

- price of components, tinting, necessary equipment;

- cost of installation (and, if necessary, preparatory work).

All other things being equal, you can safely focus your choice on the final cost of finishing the facade.

Popular options for exterior home decoration

Most often, owners of private houses prefer facade cladding:

- siding;

- facade plaster;

- block house;

- facing bricks - ceramic or clinker;

- facade tiles.

Siding - a good choice or not?

The main types of siding used for cladding the facades of houses are vinyl and basement. Aluminum in residential construction used extremely rarely. The key advantages of the material are safety, relative ease of installation, and ease of maintenance.

And the most obvious drawback is the artificial appearance. And, we can say that this fact practically negates all the advantages. In Europe, for example, siding is used exclusively when it is necessary to clad outbuildings or temporary buildings. And although basement siding, unlike vinyl, and imitates natural brick or stone, it still has a plastic feel to it.

As for the service life, siding manufacturers claim that their “brainchildren” can serve faithfully for 40-50 years. But in practice, this figure is usually much less, since the material is fragile in severe frosts, unstable to deformation, and prone to fading. Cases when siding is sad to look at after only 5 years of use are, unfortunately, not uncommon.

When installing siding in the cold season, it should be taken into account that the material has a high rate of thermal expansion.

average cost

Vinyl siding will cost you about 200 rubles/sq.m. m. The total cost of such cladding, taking into account installation and the necessary auxiliary elements, is about 1,500 rubles/sq.m.

Basement siding is a more expensive pleasure. The material itself costs on average 400-500 rubles/sq.m. The actual cost of finishing a house with it is 3000 rubles/sq.m.

Advantages and disadvantages of plaster

Plaster is a coating that can provide the facade with a decent appearance; moisture-resistant, breathable. Depending on the connecting link, facade plasters are:

- mineral (base - cement);

- acrylic (base - acrylic resins);

- silicate (based on liquid glass);

- silicone (based on silicone resins).

Variety of textures and color range at of this material very limited. In the vast majority of cases, such cladding must be additionally painted. And the texture can usually be chosen either rough or rustic.

The service life of a façade finished with plaster is 7-10 years. And although plaster becomes stronger over time, it is not resistant to mechanical damage.

Installation subtleties

It takes 6-8 weeks to decorate a house with an area of 150-200 square meters with facade plaster. The surfaces must be primed first. “Wet” processes make the installation of facade plaster very dependent on weather conditions and season.

Note! Low vapor permeability acrylic plaster makes it impossible to use it in tandem with insulation such as mineral wool.

Only mineral plaster is “suitable” for aerated foam concrete base.

average cost

- Mineral plaster. The cost of the material is about 40 rubles/kg. Plaster consumption per square meter is 3 kg. Total cost per square meter including installation fees and all necessary materials- 2000-2200 rubles.

- Acrylic plaster. The cost of the material is 50 rubles/kg. Consumption - 1.5 kg/sq.m. Total cost - 2500.

- Silicate plaster. The cost of the material is 100 rubles/kg. Consumption - 2.5 kg/sq.m. Total cost - 2800.

- Silicone plaster. The cost of the material is 100 rubles/kg. Consumption - 3 kg/sq.m. Total cost - 3000.

Features of a block house

Block house is a subtype of lining whose front surface imitates a rounded log. This material is natural and environmentally friendly, but quite expensive and short-lived. Not fire resistant. Defects in appearance include knots, cracks, wormholes and other defects characteristic of wood.

When purchasing a block house, you should make sure that it is not “raw” - otherwise there is a high risk that the material will rot.

Important! Block house, like any other wooden surface, located on outdoors, needs periodic updating - covering with special protective compounds etc.

average cost

The price of a block house largely depends on the type of wood. Price square meter can range from 400 to 1000 rubles (including installation work and necessary processing - 3000-4000 thousand)

Facing brick - quality and durability

Facing ceramic bricks are environmentally friendly pure material from natural raw materials (clay), made according to special technology. It is frost-resistant, durable, exhibits low moisture absorption and good sound insulation. Facing clinker bricks are produced in exactly the same way as ceramic ones, but are fired at a higher temperature. high temperature, due to which there are no voids left in it. Compared to ceramic, it has even better physical characteristics.

Facing bricks have a wide range of textures, shapes and colors. With it, your facade does not risk fading. The only possible external drawback is the appearance of efflorescence.

A house finished with face brick will look luxurious for decades. Clinker brick is an example of durability; it can withstand more than 150 freeze-thaw cycles.

The cladding of a building with bricks should be taken into account at the design stage (the material is laid on the main foundation). Otherwise, additional strengthening of the foundation will be required.

average cost

The range of prices for the material is quite wide, but, naturally, having the status of a leader in durability and quality, facing brick simply cannot be cheap. Professional brick laying is also quite expensive. Therefore, the average Russian rarely chooses this option for façade finishing.

Square meter ceramic bricks will cost 1200-3000 rubles, clinker - 3600-4000. Square meter of finished, beautiful and insulated brick facade in general it will require up to 6,000 rubles.

Facade tiles: pros and cons

Facade tiles are a modern and reliable building material. Not afraid of moisture, strong, durable. At high-quality installation- provides an excellent appearance of the house. Service life of a finished façade ceramic tiles may be tens of years. True, a lot depends on the quality of the adhesive solution.

Installation facade tiles, as a rule, is not easy. The process becomes more difficult:

- the need for careful preliminary surface preparation;

- the difficulty of achieving straightness of the seam;

- high fragility of the material before installation.

average cost

Facade tiles, in comparison with bricks, demonstrate no worse quality and aesthetics of the final result, and are much cheaper. The price per square meter of material is 1000-1500 rubles, but the actual cost per square meter of such cladding usually does not exceed 3000.

Really inexpensive finishing the facade of the house can only be created if you make it yourself. As you can see, some materials, at first glance, seem extremely cheap, but in practice, taking into account the cost of all the auxiliary elements and the entire scope of work, it turns out that this is not the case. And only if you decide to take on this rather difficult work yourself can you talk about significant savings.

This video will introduce you to the rules for installing vinyl siding:

When choosing materials for facade cladding, it is very important to objectively assess their “prospects” - how long they will last, how often they will need maintenance and renewal, what investments and how soon they may require.

It would be a good idea to look at the photos on the Internet. various types facades, feel which “execution style” you prefer. You should not just like the appearance of the house - you must be in love with it. It has been proven that this moment directly affects the psychological comfort of staying inside or near housing.

Understand how cheaper it is to decorate the facade of a house photo various options facings are unlikely to help, but they will clearly contribute to a clear idea of what awaits you in the end when turning to this or that material.

Having thoughtfully weighed all the nuances, we are confident that you will be able to accept correct solution, which will be optimal for your family, both from a financial and aesthetic point of view.