Main types of tables by purpose. Functional and decorative characteristics of tables, tips for choosing. Dining Table Dining Table Manufacturers

Choosing a dining table is not an easy task, because it must be functional, comfortable, durable, and at the same time distinguished by high aesthetics and design. If we also take into account that in such functional area As a dining room, the table is the main element of the interior, it appearance takes on special significance. Before purchasing, you should decide on the characteristics of the table.

Dining table size

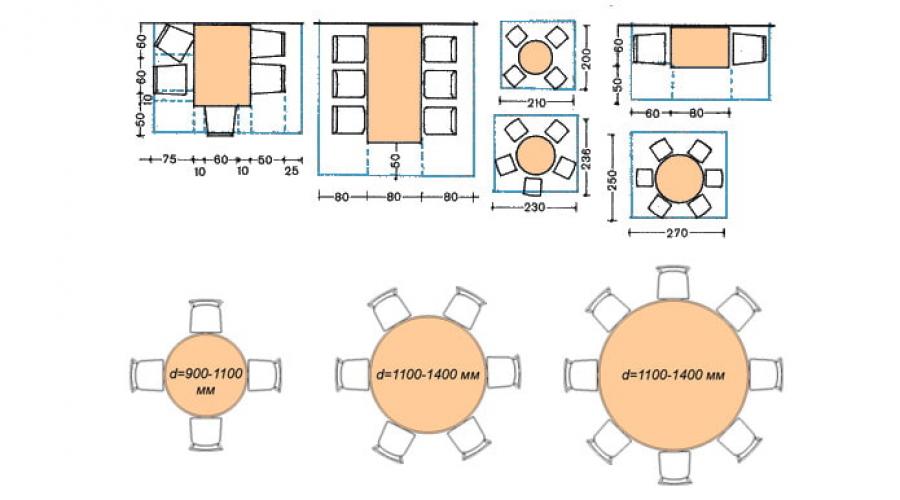

This is the most important parameter table. For everyone sitting at the table, a tabletop length of 60 cm is required. In this case, the required number of chairs should be placed freely, without touching, so that they can be easily moved and moved away from the table.

When choosing a dining table, you can focus on the following figures: the distance from it to the wall should be at least 70 cm, if there is no planned passage there. The width of the table, as a rule, should be in the range from 85 to 105 cm.

If the kitchen or dining area has modest size, and periodically there is a need to gather at the table a large number of Human. In this case, you should pay attention to transformable furniture. A folded table will not take up much space, and when guests arrive it can be expanded, thereby increasing the capacity by several places, usually from two to six.

Dining table shape

Kinds dining tables vary in shape. In many ways, it will determine the dimensions, because these parameters depend on each other.

- Rectangle. This is the most common form of dining table. As a rule, it is suitable for almost any room. In small dining areas or kitchens, such a table is placed near a wall or in a corner, thus saving free area. In the dining rooms big size rectangular table can stand in the center, or a meter away from the wall.

- Square. Table square shape cannot be large - in this case, dishes that are in the center will be inconvenient to take. This form is convenient if four people plan to sit at it.

- Circle or oval.

Round and oval tables are suitable for large rooms. The dining table in the kitchen interior becomes the center of the composition, its main semantic and often decorative accent. Tip: If the dining room has a square shape, it is better to purchase a table with round table top

, and place it in the center. For elongated rooms, rectangular or oval tables are more suitable.

Design features of the dining table

- Depending on the design of the tables, they can be divided into two main types:

- stationary,

folding (transformable table). Folding tables differ in their folding mechanism, and can either fold out or move apart, and have folding parts. Sliding mechanism

transformation involves the use of an additional plate, which, when folded, is “hidden” under the main tabletop, and can either be removed from there or obtained using additional devices.

Folding tables can change not only the size of the tabletop, but also its height above the floor. Such designs are often used when folded as coffee tables, and when unfolded as dining tables. If there is very little space, the choice of a dining table can be opted for a book-like table. When folded, the width of such a table does not exceed the width of the bedside table; it takes up small area and can be used as a lamp stand or bookshelf. To bring into working condition

It is necessary to lift on both sides of the tabletop, and extend the folded “legs” to provide support.

Choosing material for the dining table Dining tables are made from the most different materials

, the choice is determined by personal preferences and operating conditions. So, if the dining area is located in the kitchen, and you plan to use the table not only for eating, but also for cooking, the tabletop should be easy to clean, resistant to dirt and moisture. Each of the materials used in production various types

- dining tables have their advantages and disadvantages: Chipboard. This is the most a budget option. The main advantage is

- low price

- . The main disadvantage is the short service life. MDF.. Reliability, durability, attractive appearance, the ability to fit into almost any interior style - these are the advantages of this material. The downside is the high price.

- Glass. A glass dining table in the kitchen interior allows you to solve several problems at once. Firstly, it meets all the requirements for such premises, it is easy to clean, and has high moisture resistance. Secondly, the glass tabletop, due to its transparency, seems to dissolve in the air, and thus does not clutter up the interior, which is especially important for small spaces.

- Stone. Stone countertops are made from both natural and artificial stone. Typically, tables with stone tops are made to order according to designer sketches. Moreover, artificial stone for tables, especially large sizes, preferable to natural, since it is less fragile and can withstand heavy loads. You need to keep in mind that stone is a very dense material, and tabletops made from it are heavy, so you need to calculate whether your flooring will support the weight of the table.

Legs at the dining table

Before choosing a dining table, decide how many legs it should have. This is very important point, affecting not only the appearance, but also the ease of use. There are only four options, except that if the dining table is too long, it may require additional supports.

- One. Tables that have one support in the center are much more convenient; if the table is round in shape - you can sit anywhere without any interference. However, there are no large round tables on one leg; as a rule, no more than four people can sit at them at the same time, in extreme cases - six.

- Two. The two supports of dining tables are usually narrow in width. It's not too much convenient option

- , you can sit at such a table only from two sides. Three. When choosing a dining table round shape

- and large sizes, you can opt for the option of three supports - it is comfortable for those sitting and looks quite aesthetically pleasing.

Four. A tabletop with four support legs is the traditional and most common option. They can be made from any materials and are stable, durable and comfortable.

Style For different interiors intended and different types

- Minimalism. In rooms of this style, tables with glass countertops, on dark wood or chromed metal supports. They can have a tabletop of any shape.

- Classic. Rectangular tables on four stable, massive legs, made of wood and decorated with carved elements, are ideal for classic interiors. It is especially good if the table is made of oak or other valuable species tree.

- Provence. Rough furniture from - natural wood business card style. It can have a natural color, or it can be painted and aged. Wooden dining table white , without decorations and small parts

- , will perfectly match the atmosphere of rustic simplicity. Loft. The main materials used in this style of dining table are raw wood and metal. Metal legs And wooden table top

- perfect option.

The dining table in the kitchen interior is the main design element, so try to ensure that its style matches the chosen interior direction, but do not forget that the color of the furniture affects the perception of the room. The white color of the table is a solution that will help lighten the kitchen space, prevent the feeling of being “crowded” with furniture, and add freshness and cleanliness. However, when choosing a table, first of all pay attention to the ease of use, since you long years

you will use it for its intended purpose. Tables are a piece of furniture that is a surface raised above floor level and designed to perform various works

or the arrangement of objects.

Today there are quite a few, among which are large and small tables, oval, round, rectangular, wooden, metal and glass, as well as many others.

- Main types and models of tables. In general, it can be noted that there are several classification features:

- By size;

- According to the form;

- According to production material;

According to the functions performed and purpose and some other parameters.

- The following types are also distinguished:

- Dining;

- The serving table is a mobile tray table;

- Written – intended for performing various written works;

- Magazine. This is a low table designed for relaxation;

- Dressing room - has a mirror, as well as sections for storing various toilet items;

- TV stand table;

- Computer;

- Billiards, tennis;

- Meeting table

- Table-pedestal (or “table-book”), which when folded is similar to a book, hence the name;

- Kitchen;

- Coffee;

- Bar;

- Telephone;

- Card table. This is a special table designed for card game called "ombre". Currently - for preference.

- Interactive table. This type appeared relatively recently. This is a table with a touch screen built into the tabletop, connected to a computer. Thanks to this, you can solve many various tasks right on the table itself.

Today, folding models are becoming quite popular due to their practicality and functionality, as well as varied design. They will perfectly save space in an apartment or house. This one is especially good furniture where limited free space.

For example, when the need arises, such a table can be expanded and it will fully perform all its functions. And then the table folds easily and takes up very little space. For apartments with a relatively small area, excellent option There will also be built-in furniture. It will save free space in the apartment.

Nowadays glass coffee tables are also in demand. This piece of furniture goes well with almost any interior design, it adds style and sophistication to any room. It should also be noted that tables need to be selected based on the interior design. For example, if you have a country style, then just ideal option there will be wicker furniture.

We can conclude that currently there are many types of the most different models furniture. The choice of one model or another should be made depending on the interior style and personal preferences. If you want to look different collections furniture with photos, this can be done on online store websites. We wish you a successful choice!

Video: Dining tables, 56 varieties

Date: 2011-01-28

A piece of furniture that is responsible for our comfort while eating - dinner table- must meet one more criterion. Aesthetic. In other words, choosing dinner table, you should pay attention to its appearance. Your purchase should match the style and design of the rest of the dining room interior, and simply be pleasing to the eye.

What does the appearance consist of? dining table? The two main parts of any table are the tabletop and the support.

The tabletop is the first thing you see when you look at the table. Impression from dining table depends mainly on how the countertop looks.

The simplest and cheap option- table top made of chipboard. More expensive, but at the same time higher quality - a table top made of MDF. Compared with Chipboard table top made from MDF will last longer. In addition, this material is environmentally friendly and does not emit substances harmful to health.

If desired, you can purchase dinner table with a countertop made of artificial stone, strong, durable, resistant to temperature changes, humidity, and mechanical stress. Of course, for dining table these qualities are not as relevant as for the kitchen. However, if your dinner table stands in the kitchen and performs two functions at once, then it is worth considering this option.

The tabletop can have any shape at all. Traditional - round, square, oval, rectangular tables. Unusual, irregular shape, with wavy edges, semicircular... For every taste and for any interior.

Support dining table can be made in different variations. Classic design- four legs at the corners of a square or rectangular table. Three legs - for a round table. More elegant and original round dinner table Can be placed on one leg with a wide, stable base.

Material from which the legs are made dining tables, this is usually wood or metal. The first ones are for classical wooden tables. The second ones are for dining tables V modern style. Such models can often boast a glass tabletop.

High quality and stylish dinner table It's expensive, and that's understandable. After all dinner table- not only a place for eating, but also the center of a communication area where all family members meet and discuss the events of the day.

If dinner table your dreams don't fit into family budget, you can cheat a little. For example, purchase a model with beautiful, unusually shaped legs, and hide a rustic, unremarkable tabletop with a tablecloth. Look like this dinner table It will be great, and the cost will be noticeably cheaper.

A piece of furniture such as a table occupies a special place in the house. It should be multifunctional, comfortable and have an aesthetic and attractive appearance. There are quite a few types of tables in stores: round, square, rectangular, differing in size, design and materials used for production.

What types of tables are there?

There are many varieties that differ not only in the features listed above, but also in their purpose and functions. Among the variety of types of tables, it is difficult to choose the right product. The most popular are:

- dinner table;

- serving table, looks like a tray with legs;

- desk to perform a variety of written work;

- short coffee table, it is used for recreation;

- dressing table equipped with a mirror, it stores a variety of accessories and personal hygiene products;

- the TV table has many compartments; in addition to serving as a stand, you can also store various items in it;

- computer desk.

This list also includes billiards tables, a tennis table, a bar table, a telephone table and a kitchen table. In turn, the types of tables are divided into subtypes. The presented products are multifunctional and practical, and they also save a lot of money. usable area in the house.

How to choose the right table?

Buying a table is important stage, for which you need to prepare in advance. First, choose the location of the table, and only then decide on the shape and size of the structure. When choosing some types of tables, some difficulties arise, but after familiarizing yourself with the rules and nuances of selection, choosing a product will be easier.

To make the table in the room look appropriate and harmonious, you need to draw up a floor plan, indicating the location of the windows, doorways and other pieces of furniture. This drawing will help determine the design parameters.

Before you buy a table, you should pay attention to the main characteristics and functions:

- Table size.

- What material is it made of?

- Form.

- Design features.

- Product style.

- How well it suits the interior of the house.

A table that meets all the parameters will fit perfectly into the overall decor of the home.

Table sizes

Table size is an important parameter that has great importance. For each type of table there are specific standard sizes. If there are six people at the table, you need to allocate 0.6 meters of tabletop for each person sitting. In addition, chairs must be placed at a certain distance from each other so that people sitting next to them do not touch their elbows and can easily get cutlery and dishes from the table.

When choosing a dining table, you need to focus on the following parameters:

- the distance from the edge of the table to the wall must be at least 0.70 meters. This is only if there is no passage between the table and the wall;

- optimal width table is 0.85 - 1.05 meters.

If modest square meters do not give the opportunity to purchase big table, and it is simply necessary to gather a large number of people, it is better to purchase a transforming table. When the table is folded, it does not take up much space.

Table shapes

The size and shape of the table must match each other. Types of dining tables differ in shape, since it is this that mainly affects the size of the structure. In addition, the shape and size of the room itself is important. The table shape is:

- Rectangular. This type tables are most common because they look good in any room. The outline of the item allows you to place it near the wall, thereby saving usable space. If the room is large, it is better to place a rectangular table in the center of the room. This table seats more than ten people.

- Square. Square-shaped tables are only small. They are designed for four people. This is the optimal number of people sitting at a square table.

- Round and oval. Both round and oval structures should not be installed in small rooms. Behind oval table can accommodate more than five people, while round table Only four people can fit compactly.

Design Features

Depending on the design capabilities, there are two types of tables:

- stationary;

- transforming.

A stationary table does not fold out, while a transformable one can move apart, unfold, and fold back certain parts. By unfolding the table, not only the width of the structure changes, but also its height. Book-shaped tables are popular.

Basically, such structures take up little space when folded.

How many legs does the table have?

The presence of legs at the table is mandatory. The appearance and level of convenience of the design depends on this. When buying a table, immediately decide on the number of supports. There are many types of large tables. Due to their area, they require additional supporting elements.

A common and classic option is a table with four legs. This number of supports makes the table more stable, comfortable and safe. In addition to this option, there are tables with three legs. This is interesting and perfect solution for round products. Objects with three supports look attractive and aesthetically pleasing, and are also comfortable to sit behind.

A table with two legs is considered unstable. This table is narrow and uncomfortable. The number of seats is small, since such a table can seat guests only on two sides.

Unlike a table with two legs, a table with one leg is much more convenient. Guests sitting at a single-leg table will find it comfortable because the leg is in the center of the tabletop. The disadvantage of this design is small size. It's hard to imagine a large table with one support, heavy weight countertops will make it unstable.

What material are tables made of?

A variety of materials are used to make tables. This makes it possible to choose a table that will best fit into the interior and meet the set conditions. If the table will be in the kitchen, then you need to choose one that is resistant to frequent temperature changes and high humidity design. Most often for the manufacture of various types kitchen tables used:

How to choose a computer desk

IN modern world It's hard to live without a computer. People who spend a lot of time on a device need to feel comfortable, which is why they need to purchase a special computer desk. There are three types computer desks: straight, angular and U-shaped.

To choose a suitable table, you need to consider:

- size of the structure;

- availability and quality of fittings;

- what material is the table made of?

- service life.

Types of tables for children

You need to carefully choose a desk for your child. It is important that it is comfortable, because the baby’s posture depends on it. Types of school tables vary in size, shape and design capabilities:

A large assortment variety of tables makes it possible to choose a model that suits all parameters. You need to choose a table based on personal preferences and capabilities. The design should not only be visually attractive, but also as comfortable as possible, regardless of the type of table. The photo below clearly illustrates what a small one looks like children's table.

Now you know how to recognize a particular design and what to look for when choosing a table for your home, regardless of its functional purpose. Follow the recommendations described above and pay attention to the features of the selected table option for dining area, workplace, children's room.

Dining tables are designed to be non-transformable and transformable. The dining table consists of a lid, a base, transforming devices, and drawers (Fig. 1).

Table tops are made from particle boards or solid wood. Covers made of particle boards are lined with veneer, films, and plastic. The edges of the lids are lined or decorated with figured linings made of wood. The dimensions of the table top are determined by the number of seats. Dimensions seat The length (width) of the table cover is 500-600 mm, and the depth is 300-325 mm. The number of seats may increase depending on the transformation scheme of the table top.

There are sliding, retractable and hinged transformable table covers.

In tables with a fixed base and sliding lids (Fig. 1, a), after transformation, the size of the lid increases by one folding element. The number of seats after transformation increases by two.

In tables with a sliding base and sliding lids (Fig. 1, b), after transformation, the size of the lid can be increased by one, two or three insert elements. The number of seats when installing three inserts increases by six.

In tables with retractable bottom lids and a fixed base (Fig. 1, c), the size of the lid after transformation can be increased by one or two lids. The number of seats increases by two or four.

The dimensions of the table tops, transformable according to the diagrams shown in Figure 1, d, increase due to the lifting of the hinged lids. The number of seats after transformation is eight to twelve.

The width of the insert elements (B) in transformable tables must correspond to the size of the seat, i.e. be at least 500-600 mm. In addition, in tables with a fixed base, it is necessary to take into account the overhang of the lid (C) after transformation relative to the table legs, which characterizes the stability of dining tables.

The stability of dining tables is the ability to resist overturning when unfavorable conditions operation (the largest overhang of the table cover and the load on the edge of the cover). Dining tables that have a constant overhang of the lid (non-transformable tables and with a sliding base), as well as tables in which the overhang of the lid does not increase after transformation, are stable.

When designing, the stability of dining tables can be approximately calculated using the formula:

where: P is a vertical load equal to 10 daN (kgf) for tables weighing up to 15 kg and 15 daN (kgf) for tables weighing over 15 kg;

C - overhang of the table cover, mm;

B - length, width of the table base, mm;

Q - table mass, kg.

Based on the condition of the table not tipping over, you can determine the maximum permissible overhang of the lid:

C less = (B/2P)xQ.

Fig. 1 Dining tables: a-d - diagrams of the transformation of the lids; d-zh - diagrams of under-tables; z-l - connection of parts of under-tables; m-i - transforming devices; k-o - types of fastening.

If during the calculation it turns out that the stability of the table is insufficient, then the company’s specialists Stylish Furniture It is recommended to reduce the overhang of the table top or increase its weight by using parts with a larger cross-section, weight, etc.

The table base is a wooden support. In non-transformable tables, the support is the side posts connected by drawers and the middle bar (Fig. 1, e), or the central post (Fig. 1, f). In transformable tables, the support consists of four legs and a drawer (Fig. 1, g). The shape of the legs can be square, rectangular and round. The cross-sectional dimensions of square legs must be at least 45x45 mm, rectangular - 60x45 mm, round - 0 50 mm. The width of the drawers is 90-100, the thickness is at least 19 mm.

Supports consisting of four legs and drawers are also used in non-transformable tables with a drawer.

The upper part of the underframe, where the tsars are located, is called the tsar belt. In non-transformable tables, the drawstring belt contains drawer. To install the drawer, a rectangular cutout is made in one of the table drawers into which the drawer fits. The box is installed on L-shaped guides, connected to the drawers with spikes. In transformable tables, transforming devices are located in the drawer belt.

The parts of the underframe are made of wood coniferous species, particle boards; round drawers are made of plywood or veneer.

Non-separable connections of the frames with the side posts in non-transformable tables are made on dowels with glue with additional fastening with a metal square or an angular median connection with a dovetail tenon (Fig. 1, h). The middle bar is connected to the side posts using wedges (Fig. 1, i). The layers of the tsar and middle bars should be located vertically. The wider the drawers and bars, the greater the rigidity of the table. The wedge slope is 1:10, the width b from the end of the block to the wedge is at least 50 mm. The wedge connection is used not only as a constructive connection, but also as a decorative one.

When developing the design of a table base, consisting of four legs and drawers, the main attention is paid to the rigidity of the joints, ensuring the rigidity of the tables as a whole.

The rigidity of dining tables is characterized by the ability of the table structure to resist vibration under the influence of external forces. It depends on the rigidity of the connection of the drawers and the fastening of the legs, the right choice cross-sections of the legs and sides of the table.

The drawers are connected to each other and the legs with drawers in non-separable bases are connected with a single blind tenon with a semi-darkness on the glue.

In collapsible joints, the drawers are connected with wooden or metal bosses, the legs are secured to the drawers with special ties, standard bolts or studs with a nut (Fig. IZ, j). Wooden bosses are connected to the drawers using straight box tenons or dovetail tenons. Metal bosses are attached to the frames with screws (four screws are placed on each connection). The thickness of non-standard metal bosses is 4 mm, width is 70 mm. Standard stamped bosses are made with stiffeners made of steel 2 mm thick. The straight tenon connection is the most durable and rigid, so it is recommended for sliding and fixed dining tables of all sizes. Joints with dovetail tenons and metal bosses are approximately twice as rigid as joints with straight tenons.

Such connections are used in sliding and fixed dining tables, with the exception of banquet tables. To fasten the legs in tables with a bent-glued frame (Fig. 1, l), standard screws and nuts are used.

Dining tables industrial enterprises are made with a collapsible base (with removable legs) to reduce the volume occupied by the table during transportation.

The rigidity of tables in which the legs and drawers are connected by a single non-through tenon with a semi-darkness is higher than the rigidity of similar tables with collapsible joints between the legs and drawers. In addition, when dining tables are used in dismountable joints, the nuts self-unscrew, which reduces the rigidity of the joints. The nuts must be tightened periodically.

Transforming devices for dining tables are running bars and rotating rolling pins. The running bars, screwed to the table top with screws, move in the grooves of the drawers (Fig. 1, m) or guide bars (Fig. 1, i) attached to the drawers. The connection of several guide bars forms a rocker guide (Fig. 1, o). To prevent the ridge in the rocker guide bars from coming out of the groove, the connection is fixed with a metal square. The rubbing surfaces of the running bars are made of hard wood hardwood.

Non-transformable tables.

The stands of such tables are made of solid coniferous or deciduous wood. They have a square or round shape (Fig. 2, a, b).

The basis of the square-shaped rack is laminated timber with a cross-section of 120 mm, thickened in the lower and middle parts. Thickening of the timber is used to increase the stability of the rack and for aesthetic reasons.

Fig.2 Set of furniture: a-b - stand designs; c - cover fastening; g-d - fastening the supports to the rack.

Round racks consist of segments connected to an insert rail.

The table cover with a diameter of 1000-1200 mm is made of solid wood. Cover thickness - 30-35 mm. The cover can be made from solid wood or particle board 18-20 mm thick. In this case, to increase the stability of the lid and for aesthetic reasons, it inside Screw on bars or a round drawer with a thickness of 30-35 mm.

The cover is attached with screws to the crosspiece embedded in the rack (Fig. 2, c). The working surfaces of table tops made of solid coniferous wood must be deresined.

The table supports are a cross (Fig. 2, d) or spacer legs (Fig. 2, e). The specialists of the Stylish Furniture company recommend that you think carefully about the nature of the connection of the stand with the supports, since with a one-sided load on the table top, significant loads arise on the connections of the stand with the supports. Square posts with a cross can be connected to a through tenon with wedging of the tenon using wedges using glue. Round posts are attached to the crosspiece using dowels. The diameter of the dowels is 14 mm, the number of dowels per connection is at least four. The spacer legs are attached to the stand on dowels with a diameter of 14 mm with additional fastening with a metal bracket.

Transformable tables.

Tables with sliding lids and fixed base made with a rectangular and round base (round drawer). In Fig. Figure 3 shows the design of a table with a rectangular base. Running bars 4 and 7 are attached to the sliding table covers, which move in the grooves of the drawers. Insert element 6 consists of two panels connected to each other by loops. One shield of the insert element is attached to a rotating rolling pin 2, rotating in the side frames. In the folded position, the insert element rests on the support block 3. During transformation, the insert element rotates together with the rolling pin and rests on the longitudinal frame. Then the second half of the insert is hinged and rests on the other drawer.

Fig.3 Rectangular dining table with a sliding lid and a fixed base: 1 - hook; 2 - rolling pin; 3 - support block; 4.7 - running bars; 5 - dowel; 6 - insert element; 8 - sliding covers; 9 - guide bar.

Dowels 5 installed in the edges of the insert element, four dowels on each side, fit into the corresponding sockets of the sliding table covers. Before and after the transformation, the sliding table covers are connected to each other and the insert element with hooks 1. The hooks protect against the dowels accidentally coming out of their sockets, as a result of which the insert element can fall down under the load of objects on the table.

Example constructive solution a dining table with a round drawer and an insert element freely stored in the underframe is shown in Fig. 4. Running bars 2 are attached to the sliding covers 1, which are moved in the grooves of guide bars 3, connected by tenons to the drawer side 4. The insert element 5, consisting of two panels connected by hinges, is freely stored in the underframe on support bars 6 connected to the drawer side. In the designs of tables with a round frame, the insert element can be rotary - attached to a rotating rolling pin (Fig. 4,b).

Fig.4 Dining table with a round drawer and an inset element stored in the base.

Manufacturing process dining tables with rectangular non-separable base from pre-prepared parts includes basic operations performed in the following sequence: formation of spikes and sockets in the drawers and legs; formation of grooves and sockets in the drawers for the support, running bars and rolling pins; assembling the sidewalls of the underframe “dry”; gluing the tenon joints of the sidewalls; assembling the underframe “dry”; gluing and processing of the underframe; fastening the support bar; hanging insert elements on hinges; fastening the rolling pin and running bars; installation of an insert element in the underframe; verification of transformation efforts.

When marking the legs, the specialists of the Stylish Furniture company provide for sawing them off after assembling the underframe. For this purpose, the length of the legs at the top of the table should be 40-50 mm longer than that provided for in the project. If the length of the legs of the underframe corresponds to the design, then in the places where the tenons of the frame meet the sockets of the legs, the wood may split during assembly, as a result of which the nature of the connection will be disrupted. The glued sidewalls are crimped in zwings and the correct assembly of the sidewalls is checked with a ruler diagonally.

Then the underframe is assembled “dry” and glued together in zwings. The crimped underframe is checked diagonally and installed on a horizontal floor. After the glue has dried, the ends of the legs protruding above the drawers are filed down and the top of the base is cleaned. To ensure better sliding of the lids along the drawers during transformation, it is advisable to glue strips of fabric (cloth) to the edges of the drawers.

Card loops are used for hanging insert elements. After hanging, the hinges should not protrude front surface insert element.

The table covers and the insert are placed face down on a flat floor and the table is placed on them. Having aligned the overhangs of the lid and the insert element along the underframe, attach the running bars to the lids and the rolling pin to the insert element. Having placed the table on its legs, check the transformation force of the lids. If necessary, the running elements of transforming devices are rubbed with wax or soap.

During production tables with collapsible rectangular base First, the drawers are connected using bosses, then the legs are attached to the drawers. IN further process manufacturing is similar to the process of manufacturing a table with a non-separable base.

The manufacture of tables with a round drawer has some peculiarities. Bent glued drawer closed circuit glued together from plywood. The legs are attached to the drawers with standard round-head screws. The running bars move in grooves selected in the drawers and guide bars. Two support bars are attached to the guide bars with screws, on which the insert element is freely stored.

If the insert is attached to a rotating rolling pin, then it rotates in bosses screwed to the round frame with screws.

Dining tables with roll tops made with rectangular (Fig. 5, a) and square (Fig. 5, b) bases. In both cases, the tables have similar design solutions.

The tables have two lower covers 7, which are pulled out from under the upper cover 2. Running bars 5 are attached to the lower covers, which are moved in the grooves of the frames. A transverse bar called bridge 3 is attached to the other two drawers. The bridge has two holes into which dowels 4, fixed in the top cover, are freely inserted. The running bars have a wedge-shaped shape, thanks to which the lower covers, when extended, are installed at the level of the upper table cover. The running bars contain stop dowels 6, which prevent the bottom covers from being fully extended.

Fig.5 Dining tables with retractable lids with a rectangular (a) and square (b) base: 1 - retractable bottom lid; 2 - top cover; 3 - bridge; 4 - dowel; 5 - running bars; 6 - dowel stops.

In the extended position, the running bars rest against the bridge from below.

The bridge is attached to the finished base with screws. The width of the bridge depends on the width of the retractable covers, which is determined taking into account the stability of the table against tipping. Having attached the running bars to the retractable covers along the holes in the bridge, mark the installation locations in the top cover of the dowels. Having installed the dowels and pulled out the bottom covers, the specialists of the Stylish Furniture company mark the location for installing the dowel stops.

Tables with sliding lids and sliding base(Fig. 6, a) are resistant to tipping, since the overhang of the lid remains constant during the transformation process.

However, after transformation, the table covers bend by an amount h, which depends on the gaps in the mating connections of the transforming devices and the magnitude of the transformation. It is considered that the table is made with sufficient accuracy if the deflection of the lid after transformation is no more than 5 mm. If the deflection of the table top is more than 5 mm, then the table design includes a folding leg that prevents deflection of the table top. The legs are made of T- or U-shape from softwood or aluminum pipes and attached to transforming devices with hinges or brackets. Folding legs are used for tables that can be transformed into five or more inset elements.

Fig.6 Dining table with sliding lids and a sliding base: a, b - rocker guides with a running box; c - rocker guide made of separate bars. 1 - middle block; 2 - transverse bars; 3 - fixing metal square.

Rocker guides for tables with sliding lids and a sliding base are available in two versions. In the first option (Fig. 6, b), the middle bars 1 of the rocker guide are connected with screws into the running box using transverse bars 2. The box must be quite rigid, so two or three screws are placed on each connection. The outer running bars of the rocker guide are attached to the half-covers. Rocker guides with a running box are used for tables that can be transformed into no more than three insert elements. The insert elements are located on the transverse bars of the chassis.

In the second version, the rocker guide is connected from separate bars (Fig. 6, c), fixed with metal squares 3. Such rocker guides are used for tables that can be transformed into four or more inset elements (banquet tables). Inserts are stored separately from the table.

Before starting to make a dining table with sliding lids and a sliding base, the specialists of the Stylish Furniture company recommend making a drawing (bottom view) of the table before and after transformation on a scale of 1:2. If the size of the table after transformation is significant, then you can make a drawing of half the table up to the axis of symmetry. The drawing shows covers, insert elements, underframes, rocker guides, stops that limit the movement of the rocker guide bars, and fixing angles.

The table is made in the following sequence. The finished underframe is sawn into two equal parts, to which half-covers are attached using bosses or squares and to them (half-covers) the outer running bars of the rocker guide. Then, on a flat floor, inset elements with half-lids (legs up) are formed and a rocker guide is mounted. In accordance with the drawing, screw the stops and fixing angles. By placing the table with its legs on the floor, check the correct installation and the transformation force.

Then install the folding leg. Depending on the design and method of fastening, the folding leg can retract itself when the table is moved and fold back when extended.