Basic information about scroll compressors and their scope. Scroll refrigeration compressor. Operating principle and design Scroll compressor with perl and

Read also

Operating principle, design and features of COPELAND refrigeration scroll compressors. Increased energy efficiency and other advantages of COPELAND scroll compressors compared to other refrigeration compressors.

Learn more about Copeland scroll compressor models

Specifications and prices for hermetic medium-temperature scroll compressors Copeland Scroll ZR series (R407C)

Technical characteristics and prices for hermetic medium temperature scroll compressors Copeland Scroll ZP series (R410A)

Technical characteristics and prices for hermetic scroll compressors Copeland Scroll ZPD and ZRD series

Specifications and prices for Copeland ZH series hermetic scroll compressors

Specifications and prices for Copeland ZB series hermetic scroll compressors

Technical specifications and prices for Copeland ZF series hermetic scroll compressors

Technical specifications and prices for Copeland Scrol digital compressors of the ZFD and ZBD series

About scroll compressors in general and about COPELAND scroll compressors in particular

This simple type of compression was first patented in 1905. The movable spiral, moving in concert with respect to the stationary spiral, creates a system of crescent-shaped regions filled with gas between these spirals (see Fig. 1).

During the compression process, one helix remains motionless (fixed), and the second makes orbital (but not rotational) movements (orbital helix) around the fixed helix. As this movement develops, the areas between the two spirals are gradually pushed towards their center, simultaneously reducing in volume. When the area reaches the center of the spiral, the gas, which is now under high pressure, is forced out of the port located in the center. During compression, multiple areas are compressed simultaneously, allowing the compression process to occur smoothly.

Both the suction process (outer part of the spirals) and the discharge process ( inner part spirals) are carried out continuously.

1. The compression process is carried out through the interaction of the orbital and stationary spirals. Gas enters the outer regions formed during one of the orbital movements of the spiral.

2. As gas passes into the cavity of the spirals, the suction areas are closed.

3. As the moving spiral continues its orbital motion, the gas is compressed in two constantly decreasing areas.

4. By the time the gas reaches the center, discharge pressure is created.

5. Normally, during operation, all six gas-filled areas are in different stages of compression, allowing the suction and discharge processes to be carried out continuously.

Copeland scroll compressors first appeared on the refrigeration market in Russia and the CIS countries in the early 90s of the last century. Copeland scroll compressors are used in all major air conditioning systems, including split and multi-split models, floor-standing versions and in chillers, roof tops (rooftop air conditioners) and heat pumps. Typical applications are air conditioning in apartments, ships, factories and large buildings, also in automatic telephone exchanges, in refrigeration processes and in transport. Refrigeration scroll compressors are widely used in condensing units, supermarket "refrigeration" systems, industrial refrigeration and transport applications, including containers. The refrigeration capacity limits for scroll compressors are constantly expanding and are currently approaching 200 kW when using a multi-compressor station.

Copeland scroll compressors first appeared on the refrigeration market in Russia and the CIS countries in the early 90s of the last century. Copeland scroll compressors are used in all major air conditioning systems, including split and multi-split models, floor-standing versions and in chillers, roof tops (rooftop air conditioners) and heat pumps. Typical applications are air conditioning in apartments, ships, factories and large buildings, also in automatic telephone exchanges, in refrigeration processes and in transport. Refrigeration scroll compressors are widely used in condensing units, supermarket "refrigeration" systems, industrial refrigeration and transport applications, including containers. The refrigeration capacity limits for scroll compressors are constantly expanding and are currently approaching 200 kW when using a multi-compressor station.

This model range has both a standard set of compressor properties and new additional functions. This set of capabilities has no analogues among other types of compressors. Copeland scroll compressors are available in the power range 2...15 hp. (by built-in electric/motor). Key features of these compressors include: wide operating range, efficiency comparable to semi-hermetic compressors and superior to hermetic models in low temperature applications, smooth operation allowing constant compression and reduced number of moving parts, high reliability achieved through the exclusive Copeland Scroll design ™. Size and weight advantage: Copeland scroll compressors occupy 1/3 of the supporting surface of an equivalent semi-hermetic compressor model, and their weight is 1/4 of its weight. Scroll compressors have fewer moving parts than piston compressors. This makes them more reliable and can be used over a wider operating range. Optimized for operation at low, medium and high boiling temperatures, the Copland series of refrigeration scroll compressors are increasingly replacing reciprocating compressors. Copland ZR series scroll compressors use 50 and 60 Hz electric motors. ZR scroll compressors are adapted for HFC and HCFC refrigerants and the full ZR range can be supplied with either mineral or synthetic oil.

It is believed that scroll compressors are only applicable in air conditioning, and only semi-hermetic piston or screw compressors are suitable for low-temperature applications. Yes, this statement is valid for most scroll compressors existing in the world. But not for Copeland compressors. Many distributors of products from competing companies draw everyone's attention to the fact that the scroll compressor is intended only for high or, in extreme cases, medium temperatures. They probably mean those compressors that they supply themselves, not being able to purchase equipment with more wide possibilities. Or, which is also likely, such statements are a simple trick in competition for the minds of those who are not yet privy to the details internal structure scroll compressors from various companies, and also knows nothing about their comparative advantages/disadvantages.

It is believed that scroll compressors are only applicable in air conditioning, and only semi-hermetic piston or screw compressors are suitable for low-temperature applications. Yes, this statement is valid for most scroll compressors existing in the world. But not for Copeland compressors. Many distributors of products from competing companies draw everyone's attention to the fact that the scroll compressor is intended only for high or, in extreme cases, medium temperatures. They probably mean those compressors that they supply themselves, not being able to purchase equipment with more wide possibilities. Or, which is also likely, such statements are a simple trick in competition for the minds of those who are not yet privy to the details internal structure scroll compressors from various companies, and also knows nothing about their comparative advantages/disadvantages.

The uniqueness of Copeland scroll compressors lies in the ability to painlessly inject liquid (or vapor) refrigerant directly into the spiral cavities approximately in the middle of the compression process. Most other scroll compressors do not have this capability due to significant design differences. Copeland, being a pioneer in the industrial development of scroll technology on a global scale (the world's first serial scroll compressors rolled off the assembly line of a new specialized Copeland plant in the USA in 1987), was the first to patent in a number of countries the most interesting technical solutions that allow liquid injection for intermediate cooling in low-temperature conditions directly into the compression zone, without reducing the operating life of the compressor. Thanks to this, the Copeland low-temperature scroll compressor is practically the only one in the world that can safely operate at boiling temperatures of minus 35...minus 40°C (R22 or R404A) and at normal condensation temperatures of +30...+50°C. Thus, the freezing process using a Copeland low-temperature scroll compressor is the reality of today. This technology has already been tested and successfully used in Russia, Ukraine and other CIS countries.

Those specialists who already have their own practical experience in operating Copeland low-temperature scroll compressors are well aware that no other compressor of any type (including piston, rotary, screw and even turbo compressors) reaches a given low-temperature regime as quickly as it does with a scroll Copeland compressor. So those consumers who require the fastest freezing rate can thank Copeland for their low-temperature scroll compressor.

The second generation of Copeland ZB and ZF series refrigeration scroll compressors with steam injection are designed for operation in medium and low temperature conditions with industry leading efficiency indicators throughout the year. ZB series with drive power from 2 to 30 hp. and ZF from 4 to 15 hp. designed to work with refrigerants R22, R134a, R404A and R407C. The presence of three times fewer moving parts in comparison with traditional semi-hermetic piston compressors, a built-in protection system and a spiral matching mechanism ensures significant tolerance to the ingress of liquid refrigerant, allowing us to speak about the excellent reliability of this range of compressors as a whole.

The second generation of Copeland ZB and ZF series refrigeration scroll compressors with steam injection are designed for operation in medium and low temperature conditions with industry leading efficiency indicators throughout the year. ZB series with drive power from 2 to 30 hp. and ZF from 4 to 15 hp. designed to work with refrigerants R22, R134a, R404A and R407C. The presence of three times fewer moving parts in comparison with traditional semi-hermetic piston compressors, a built-in protection system and a spiral matching mechanism ensures significant tolerance to the ingress of liquid refrigerant, allowing us to speak about the excellent reliability of this range of compressors as a whole.

Other important advantages of Copeland scroll compressors are operation at low temperatures ah of condensation, providing excellent annual operating efficiency, wide operating range and reduced size for better adaptability to the required application. Particularly suitable equipment for multi-evaporative refrigeration systems requiring controlled cooling capacity are the ZBD scroll compressor models for medium boiling temperatures and the ZFD with steam injection for low boiling temperatures.

The Copeland Digital Scroll Compressor provides infinitely variable capacity control from 10 to 100% using a simple mechanical system and guarantees precise control of boiling pressure and temperature at any load. The Copeland digital scroll compressor does not require complex electronic controls and is easily integrated into the refrigeration system. The compressor motor always operates at a constant rated speed, which ensures high reliability and guarantees efficiency internal system lubricants

Comparison with other types of compressors

|

Low temperature spiral Copeland compressors |

Other types of compressors of any known type global manufacturers |

|

High feed rate and coefficient of performance at optimum for this model range region boiling pressures (temperatures) combined with normal pressures (temperatures) condensation => at the same cooling capacity consumed power lower |

Most piston sealed and semi-hermetic (except for Copeland series models Discus), rotary, screw and centrifugal compressors have worse performance due to one or more of the following factors: “dead” volume, valve losses, large internal heat losses, high efficiency only in relatively narrow range of compression ratios, etc. => with the same cooling capacity power consumption is higher |

|

Possibility of using one model in wide range of boiling temperatures from minus 40oC to +7oC (for R22 or R404A) => for various applications only one model type required (low temperature!) => optimization warehouse stocks: fewer models - fewer spare parts |

Most other types of compressors have clear division into low and medium temperature models => for various tasks required several different types of models (2 or even 3 like!) => warehouse stocks are too large - more spare parts needed |

|

Relatively high drive power avoids overheating of the electric motor when exit to mode. Higher reliability. No need to protect the engine low temperature compressor at work at high pressures (temperatures) boiling => not required TRV with MOP function => technological problems are solved much faster rapid filling of the evaporator in the period of starting the compressor and reaching safe operating mode (for example, freezing of the product will take much longer faster; the finished product will be more high quality) |

Due to the relatively low drive power low temperature piston compressors artificial limitation required maximum boiling pressure (temperature), which is usually implemented using TRV with MOP function => requires expansion valve with MOP function MOP => due to low refrigerant supply to evaporator until the maximum maximum boiling pressure (individually for each compressor) refrigeration (freezing) installation reaches the set point very slow mode => loss of quality frozen products due to violation freezing speed |

|

The starting current is practically no different from worker (the compressor starts fully internally mechanically unloaded) => minimum => compressor contactors may have less power, and the protective electrical circuit breaker must be (!) less powerful. Saving energy during startup. |

Other types of compressors have increased or very high starting current even with use of mechanical unloading devices => adverse impact on neighbors electrical consumers; requires more powerful electrical installation equipment Increased power consumption during startup. |

|

The Copeland scroll compressor has one of the best indicators in terms of degree oil carryover into the system is one of the most low values => in many applications cases where an oil separator is used and other complex system components no lubrication required |

Oil carryover in most piston engines compressors (except for models with ventilation valve in the crankcase, for example, for Copeland - model series Discus or S-series) are higher, and screw ones are several times higher => additionally expensive ones are required oil return system components (and sometimes cooling), plant control system becomes more complicated and its reliability decreases |

|

Possibility of temporary work in conditions intermittent (lean) oil return thanks to Teflon plain bearings => high working life even in heavy conditions operating conditions (for example, reduced viscosity due to high oil temperature or high amount of dissolved refrigerant; intermittent (portioned) return compressor oil) |

Almost all other compressors in the world (except model series Discus or S-series from Copeland), in which sliding bearings are used, have a bronze or similar coating (babbits, etc.) in friction pairs => at improper lubrication conditions increased wear of friction pairs => rapid failure compressor |

|

High feed rate per throughout the entire service life due to free self-adjusting seal between spirals – radial matching => constant cooling capacity |

Most types of compressors have a coefficient flow rate decreases with use compressor due to wear of the mating parts in compression cavities => reduced end cooling capacity standard service life |

|

Increased resistance to “wet” course" thanks to the radial agreement |

Low resistance to “wet running” for all types of compressors (including scroll models where there is no radial matching), except screw compressors |

|

High resistance to mechanical contamination due to radial agreement |

Mechanical particles entering the compression zone almost always leads to failure all types of compressors, including scroll models without radial matching |

Comparison with other types of scroll compressors

| Copeland scroll compressors | Other scroll compressors |

|

We have the most complete line scroll compressors, including low temperature models up to minus 40 boiling oC: * air conditioning (R22, R134a, R407C) ZR * air conditioning (R410A) ZP * high temperature heat pumps ZH * high and medium temperature cooling / chillers ZB * medium temperature cooling ZS * ZF low temperature cooling * ultra-low temperature (cryogenic) cooling ZC * horizontal models: ZBH – high and medium temperature cooling ZSH – medium temperature cooling ZFH – low temperature cooling * models with stepless and stepless performance regulation |

Most of the companies producing spiral compressors have in their arsenal only models for air conditioning (at least case, for medium-temperature cold), because low temperature models are too complex and require radical changes in internal designs |

|

There is an internal mechanical Spiral overload protection: medium and temperature models ZS and ZF – when the pressure ratio is exceeded discharge/suction 20:1 high and medium temperature models ZR and ZB – when the pressure ratio is exceeded discharge/suction 10:1 thanks to axial alignment |

Most manufacturers have mechanical protection of the spirals themselves from overloads absent (no axial alignment) => Possible destruction of the spirals when overloaded |

|

When starting, the spirals do not touch each other its lateral surfaces (due to axial coordination) => unloaded start => increased motor life and reduced Energy consumption |

Most scroll compressors have design with a rigidly fixed trajectory movement of the rotating spiral (no axial coordination) => start under load => increased energy consumption |

|

Direct contact between spirals in end direction without using end gaskets => high service life and ability to work at high compression ratios |

Many manufacturers use end gaskets to ensure proper seals => reduced service life and difficulties in working with large differences pressure (low temperature modes) |

Copeland Digital Scroll™ compressors

The design of Copland Digital Scroll™ compressors is based on unique technology Copeland Compliance™ spiral block approval. Performance control is achieved by spreading the spirals axially for a short period of time. It's simple and reliable mechanical method for smooth performance control, precise temperature control and increased system efficiency.

The design of Copland Digital Scroll™ compressors is based on unique technology Copeland Compliance™ spiral block approval. Performance control is achieved by spreading the spirals axially for a short period of time. It's simple and reliable mechanical method for smooth performance control, precise temperature control and increased system efficiency.

The Copeland Digital Scroll™ compressor is a solution that can be integrated into existing system. It is quick and easy because no other components are required. To make implementation easier, Dixell and Alco have developed two controllers with Copeland to control Copeland Digital Scroll™ compressors.

The Copeland Digital Scroll™ compressor offers the widest range of capacity control in the industry and allows capacity to be infinitely varied from 10% to 100% without changing the operating range of a standard Copeland Scroll™ compressor. As a result, suction pressure and temperature are maintained very precisely and compressor cycling is reduced to a minimum. This ensures optimal system efficiency and long service life of equipment and components.

The ability to operate Copeland Digital Scroll™ compressors at condensing temperatures down to 10°C also ensures the best seasonal efficiency in the compressor market. Refrigerant flow rates in systems with Copeland Digital Scroll™ compressors are identical to standard compressors, even at low capacity.

The Copeland Digital Scroll™ compressor runs at full speed all the time, never reducing oil return to the compressor. The Digital Scroll™ compressor provides similar high level reliability, just like systems with standard compressors. The compressor motor does not overheat and there are no resonant oscillations during operation, as often happens in systems with an inverter.

High efficiency Copeland ZF EVI scroll compressors

Copeland Scroll TM offers the most effective solution for low temperature applications in supermarkets. Three years ago, with the introduction of the ZB series of scroll compressors for refrigeration applications operating in the medium boiling range, Copeland launched its second generation of scroll compressors. Today this generation has expanded new series highly efficient scroll compressors, which will undoubtedly have a significant impact on the subsequent development of refrigeration systems. The new ZF EVI scroll compressor, specially designed and optimized to maximize the benefits of liquid subcooling and vapor injection technology, is a key component for the design of highly efficient low temperature central refrigeration plants.

ZF EVI scroll compressors are characterized by higher cooling capacity and coefficient of performance (COP) compared to models available on the market, which ensures additional benefits during operation and makes this compressor the most preferred solution for food storage systems. This article describes the concept of the EVI scroll compressor, gives its main characteristics and application aspects of use in refrigeration systems. Steam injection. Refrigeration cycle with a scroll compressor, EVI is similar to a two-stage intercooled cycle, but using one single compressor (see Fig. 1). This concept is much simpler and eliminates the additional losses that exist in a conventional two-stage compression system. Operating principle of the stage high pressure consists in selecting part of the condensed liquid and its subsequent evaporation after the expansion valve in a counter-flow heat exchanger-subcooler (economizer). Next, the superheated steam enters through the intermediate injection ports into the cavities of the spiral block.

Additional subcooling increases the cooling capacity of the evaporator, lowering the enthalpy of the refrigerant at the inlet, while maintaining a constant mass flow. The additional mass flow required for injection depends on the location of the port and creates an additional load, which slightly increases the energy consumption of the scroll compressor. Therefore, the injection port design has been optimized to maximize performance while minimizing compressor energy consumption. It is well known that the efficiency of a two-stage compression cycle is higher than that of a single-stage one (with equal volumetric productivity).

The increase in compressor cooling capacity is achieved due to deeper subcooling of the liquid in the economizer with a slight increase in energy consumption for compressing a small portion of gas from intermediate pressure to discharge pressure. Interstage steam cooling reduces the discharge temperature, allowing the scroll compressor to operate at a higher pressure ratio. Previously, steam injection was traditionally used only in large commercial screw and multi-stage centrifugal compressors (but not in small hermetic ones). Today Copeland presents new compressor with steam injection, part of the spiral family. It is specifically designed for low temperature applications and provides efficiency levels comparable to the Copeland Discus series semi-hermetic compressor, which last years was recognized as the most efficient in the world among compressors of all types.

Rice. 2. 26. Performer scroll compressor (Danfoss). 1 – movable spiral; 2 – fixed spiral; 3 - terminal box; 4 – electric motor protection; 5 – sight glass; 6 – suction; 7 – oil pump; 8 - electric motor; 9 – injection; 10 – reverse rotation protection; 11 – check valve.

The electric motor is located in the lower part of the compressor; the shaft, with the help of an eccentric, ensures the ellipsoidal movement of a movable spiral inserted into a stationary spiral installed in the upper part of the compressor. The sucked gas enters the compressor through the suction pipe, flows around the electric motor casing and enters it through the holes in the lower part of the casing (Fig. 2.26). The oil contained in the refrigerant vapor is separated from it as a result of rotation of the refrigerant-oil mixture under the influence of centrifugal forces and flows to the bottom of the compressor crankcase. The steam passes through the electric motor, ensuring complete cooling of the compressor in all operating modes. After passing through the electric motor, the steam enters the compressor scroll elements, which are located at the top of the compressor above the electric motor. The working cycle is completed in three revolutions of the shaft: the first revolution is suction, the second revolution is compression, the third revolution is discharge. There is a check valve immediately above the outlet of the fixed volute. It protects the compressor from backflow of gas after it is turned off. After passing the check valve, the gas leaves the compressor through the discharge pipe.

The efficiency of scroll compressors is largely determined by the magnitude of internal radial and axial gas leaks during the compression process. Radial leaks occur between the touching side surfaces of the spirals, axial leaks - between the upper end of one spiral and the base plate of the other (Fig. 2. 24). Leaks lead to an increase in compressor power consumption, reducing its cooling capacity and operating efficiency.

The main difference between this compressor and other scroll compressors is the principle of compaction of the scroll elements. A common way to ensure radial sealing is to create tight contact by pressing the movable spiral onto the stationary one under the influence of centrifugal force. However, freshly manufactured compressors only create an effective, uniform seal after a “break-in” period during which the necessary contact is established between the surfaces. Touching the side surfaces of the spirals is a prerequisite for such compressors.

Danfoss uses the so-called “controlled orbiting principle” in Performer brand compressors, which implies the movement of the scrolls along a fixed path without contact between the moving and stationary scrolls under any operating conditions of the compressor.

Performer controlled rotation compressors must have ultra-precise profile scrolls to achieve a guaranteed seal. The lateral surfaces of such spirals never touch each other, but thin film oil, sealing the gap, ensures lubrication of the spirals without friction and wear of their surface.

When creating an axial seal, some compressor manufacturers press a moving scroll against a stationary one to seal using compressed gas pressure.

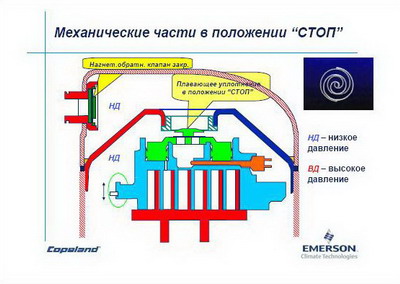

On Performer compressors, dynamic contact between the top end of the moving scroll and the fixed scroll base plate is maintained by a floating seal (Fig. 2.27).

Rice. 2.27. Performer Rotation Controlled Scroll Floating Seal:

1 - base plate; 2 - the gap between the end and the base plate; 3 - floating seal; 4 - spiral; 5 - oil film preventing seal gas leakage; 6 - high pressure gas

This sealing element is located in a groove cut into the upper end of the movable spiral (Fig. 2.27). Gas under pressure presses on the floating seal from below and forces it to press against base plate spirals, creating dynamic contact during compressor operation. The pressing forces are very small, which in combination with small area contact reduces friction and increases compressor efficiency.

A characteristic feature of these compressors is that they start idle, even when the pressure in the system is unbalanced. This happens due to the installation check valve on the discharge line, which closes when it stops. Under these conditions, only the gas compressed in the compressor to the valve installation location returns to the crankcase, passing through the spirals. This ensures alignment internal pressure. When the compressor stops, the two spirals open both vertically and horizontally. When restarted, the compressor does not experience a load, since the pressure increases gradually. The scroll compressor is equipped with a safety valve that opens when the pressure exceeds 28 bar and bypasses the refrigerant from the discharge cavity to the suction cavity.

The oil in scroll compressors serves only to lubricate the bearings and the floating seal ring. Lubrication of the spirals is not required due to the low rotation speed and friction force at each contact point. The oil content in the refrigerant oil mixture is sufficient to provide the necessary lubrication, so the oil is not exposed to high temperatures, which can lead to deterioration of the oil's characteristics over time. Another positive feature is a high ability to resist oil carryover during startup.

Questions for self-control in Chapter 2.

What is the difference between direct-flow and indirect-flow compressors? 2. What is the design difference of the compressor? simple action from a double acting compressor? 3. What water hammer protection device is included in the compressor? 4. What is the difference between a piston seal ring and an oil seal ring? 5. How is the compressor seal lubricated? 6. What is the purpose safety valve in the compressor? 7. How does the oil carried away by the refrigerant vapor return to the compressor crankcase? 8. Why does a compressor running on ammonia have greater cooling capacity than when running on R22? 9. How can you change the cooling capacity of a refrigeration compressor? 10. How does compression occur in a screw compressor? 11. Why do energy losses occur in a screw compressor when the pressure at the end of compression does not coincide with the discharge pressure? 12. Why does the refrigeration capacity of a screw compressor change when the spool moves? 13. What are the advantages and disadvantages of a screw compressor compared to a piston compressor? 14. What are the advantages of scroll compressors? 15. Seals for scroll compressors. 16. Operating principle of scroll compressors. 17. What is the “pinched” volume in screw compressors?

Readings for Chapter 2.

1.Baranenko A.V., Bukharin N.N., Pekarev V.I., Timofeevsky L.S. Refrigerating machines - St. Petersburg: Politekhnika, 2006.-944 p.

2. Quick selection automatic regulators, compressors and compressor-condensing units. Catalog. Danfoss. 2009.-234s

3. Ladin N.V., Abdulmanov Kh.A., Lalaev G.G. Marine refrigeration units. Textbook. Moscow, Transport, 1993.-246 p.

4. Shvetsov G. M., Ladin N. V. Marine refrigeration units: A textbook for

universities - M.: Transport, 1986. - 232 p.

Scroll compressors are single-shaft machines of the positive displacement principle. As is known, machines of this operating principle are reversible, i.e. can operate practically without changing the design, both as compressors and as motors (expanders or expanders.

The idea of such a machine has been known for more than a hundred years, but it was only possible to realize it and bring it to industrial production and widespread use in the 80s of the twentieth century. The reason is the same as during the development of screw compressors, there was not sufficiently accurate equipment to produce such a part shape as a spiral.

Currently, in refrigeration technology, scroll compressors are used in household and transport air conditioners, heat pumps, and low- and medium-power refrigeration machines up to 50 kW. But calculations show that the refrigerating power of scroll compressors can be increased to 100 kW or more as their design and manufacturing technology are improved.

28 Classification of scroll compressors

Scroll compressors are classified as follows: oil-flooded; with injection of drip liquid (for example refrigerant); dry compression.

And, naturally, one- and two-stage with different arrangements of stages in relation to the engine.

Depending on the type of gas, power and other conditions: sealed, sealless, stuffed.

According to the type of spirals used: with involute spirals, with Archimedes spirals, with piecewise-circular ones, etc.

It is important to divide scroll compressors into vertical and horizontal. In the latter, shaft 1 is located horizontally (see Figure 65). In horizontally located scroll compressors, for example in a transport air conditioner with a parallel shaft arrangement and the longitudinal axis of the vehicle, it is more difficult to ensure reliable operation of the compressor lubrication system.

29 Advantages and disadvantages of scroll compressors

The main advantages of scroll compressors are:

1.High energy efficiency; their effective efficiency reaches 80-86%;

2.High reliability and durability, determined by the durability of the bearings;

3.Good balance; slight change in torque on the compressor shaft; low gas speeds in the car - all this ensures the machine runs with a low noise level.

4. Speed - the number of revolutions of the compressor shaft is from 1000 to 13000, and this range is expanding.

5. No dead volume, low leakage rate, and, therefore, higher indicator efficiency; the gas sucked in by the compressor does not come into contact with the hot walls of the compressor parts;

6. The processes of suction, compression and discharge are “stretched” along the angle of rotation of the shaft and therefore, even at a high frequency of the shaft, the gas velocities are low.

7. Lack of valves on the suction, and often on the discharge;

8. A scroll compressor, like a screw compressor, can operate in a cycle with “recharging”;

9. The scroll compressor, like all compressors of the positive displacement principle, can operate on any refrigerant, on any gas, and even with droplet liquid injection.

Compared to piston compressors of the same power, a scroll compressor has the following advantages:

The disadvantages of scroll compressors include the following:

1. Spiral machines require new spiral parts for mechanical engineering, for the manufacture of which milling machines with CNC.

2. A complex system of forces acts on the moving spiral: axial, centrifugal, tangential, requiring competent calculation and balancing, and, consequently, balancing of the rotor.

3. If there is no discharge valve, then the theoretical indicator diagram of a scroll compressor will be the same in appearance as that of a screw compressor, with possible undercompression and overcompression of the gas, i.e. with additional losses.

Scroll compressors began to be installed in residential air conditioning equipment from the late 1980s. In commercial air conditioning systems, scroll compressors have been widely used since the late 1990s. Now they have found application in refrigeration units, heat pumps, and transport. Scroll compressors They are installed not only in air conditioning systems, but also in central refrigeration units for supermarkets, telecommunications technology, industrial refrigeration systems, process equipment, dehumidifiers and air conditioners for subway cars. And customers continue to find new applications for the equipment.

| |

|

| |

A scroll compressor consists of two steel scrolls. They are inserted into one another and expand from the center to the edge of the compressor cylinder. The inner spiral is fixedly fixed, and the outer one rotates around it. The spirals have a special profile (involute), which allows them to roll without slipping. The movable compressor scroll is mounted on an eccentric and rolls along inner surface another spiral. In this case, the point of contact of the spirals gradually moves from the edge to the center. The refrigerant vapor located in front of the contact line is compressed and pushed into the central hole in the compressor cover. Touch points are located on each turn of the internal spiral, so vapors are compressed more smoothly, in smaller portions, than in other types of compressors.

As a result, the load on the compressor motor is reduced, especially when the compressor starts. Refrigerant vapor enters through an inlet in the cylindrical part of the housing, cools the engine, is then compressed between the spirals and exits through an outlet at the top of the compressor housing.

Now in various systems cooling, millions of Copeland compressors operate around the world, differing high quality and advanced design. Every year, up to 4 million scroll compressors are produced at nine enterprises located on 3 continents. Copeland Engineering Support Centers are located in Europe, Asia and the USA.

1  |

2  |

3  |

4

|

5  |

6

|

7  |

8  |

9  |

10  |

11  |

12  |

13  |

14  |

15  |

16  |

17  |

18  |

19  |

1. Dimensional drawing scroll compressor Copeland ZR22K3...ZR40K3

2. Dimensional drawing of the Copeland ZR47...48KC compressor

4. Dimensional drawing of the Copeland compressor ZPD61...ZRD83

5. General dimensional drawing of the Copeland compressor

7. Marking of Copeland scroll compressors

9. Sectional view of a Sanyo scroll compressor

10. Photos of compressors Sanyo C-SB, C-SC, C-SB Low temp, C-SC Low temp, C-SB Inverter, DC Inverter Horizontal, C-SB Tandem, C-SC Tandem

11. Sanyo range of scroll compressors

12. Sanyo C-SB series scroll compressor

13. Sanyo C-SD series scroll compressor

14. Sanyo C-SC series scroll compressor

15. Dimensional drawing of Sanyo C-SBN373H8D compressor

16. Dimensional drawing of the Sanyo C-SB 2.6-4.5 KW compressor

17. Dimensional drawing of the Sanyo C-SC 6.0-7.5 KW compressor

18, 19 Photo of compressor SANYO C-SBN303H8D

Scroll compressor - history

The idea of a spiral has been known to mankind for more than 3 thousand years. Spirals (from the Greek speira - turn) are curves that twist around a point on a plane (flat spirals), for example, an Archimedean spiral, a hyperbolic spiral, a logarithmic spiral, or around an axis (spatial spiral), for example, a helix. But technically, humanity was able to bring the idea to life only towards the end of the 20th century.

It all started in 1905, when the French engineer Leon Croix developed the design of a scroll compressor and received a patent for it. However, at that time this technology could not be implemented, because there was no necessary production base. Therefore, the design of a working prototype had to wait until the second half of the twentieth century, because For efficient operation, a scroll compressor must have a small design gap in the mating parts (spirals). Such precision was only possible with precision machining developed during the second half of the twentieth century, which explains the relatively recent introduction of the scroll compressor to the high-tech market.

The concept of scroll compressors was revived by physicist Nils Young in 1972. Young gave the idea to employees of the Arthur D. Little company (USA). The management of "Arthur D. Little" saw high potential this concept and began development of a possible model in January 1973. Large manufacturers of refrigeration and petrochemical equipment were very interested in developing a fundamentally new compressor design that would achieve significant efficiency. Already during testing of the prototype scroll compressor, it was revealed that it has the ability to create a high compression ratio and the highest efficiency that existed in the early 70s. refrigeration compressors, and also has high performance characteristics (reliability, low noise level, etc.).

Then "Arthur D. Little" made significant efforts at the end of 1973 to develop a working model of a refrigeration scroll compressor for the American corporation "Thane". A little later, many large companies, for example, "Copeland" (USA), "Hitachi" (Japan), "Volkswagen1" (Germany), begin intensive research and improvement of the design of the refrigeration scroll compressor, mastering the technology of manufacturing parts and the scroll compressor as a whole. Development of the air scroll compressor prototype was slower. At the end of the 80s. Hitachi and Mitsui Seiki (Japan) presented an oil-lubricated air compressor. However, these compressors were simply modifications of refrigeration scroll compressors. Iwata Compressor (Japan) entered into a license agreement with Arthur D. Little for the development of an air scroll compressor in 1987. As a result, Iwata Compressor was the first in the world to introduce a “dry” (oil-free) scroll compressor in January 1992 compressor. Initial power air compressors was 2.2 and 3.7 kW. The main advantages of "dry" scroll compressors "Iwata Compressor" compared to piston "dry" compressors are: durability, reliability, low noise and vibration.

Currently, all manufacturers of compressors for the refrigeration industry are conducting large-scale research in the field of scroll compressors. Refrigeration scroll compressors have successfully stood the test of time and have actively begun to displace other types of compressors (especially piston ones) from the market refrigeration equipment, having achieved a dominant position in the air conditioning and heat pump market in just a few years. Every year, scroll compressors are increasingly used in refrigeration and air conditioning systems. This is due to the fact that they are more reliable in operation, contain 40% fewer parts than piston ones, produce less noise and have a longer service life.

Scroll compressor production has increased rapidly over the past few years, with over 20 million compressors produced by January 2000.

Scroll compressors are used in all major air conditioning systems, including split and multi-split models, floor-standing versions and in chillers, roof tops (rooftop air conditioners) and heat pumps. Typical applications are air conditioning in apartments, ships, factories and large buildings, also in automatic telephone exchanges, in refrigeration processes and in transport. Refrigeration scroll compressors are widely used in condensing units, supermarket "refrigeration" systems, industrial refrigeration and transport applications, including containers. The refrigeration capacity limits for scroll compressors are constantly increasing and are currently approaching 200 kW when using a multi-compressor station.

The popularity of scroll compressors is very high due to their wide range of applications, which is explained by their reliability and versatility.

Household air conditioning

Scroll compressors meet the requirements of this air conditioning sector with low noise levels, compact dimensions, and reduced weight compared to piston compressors.

Their characteristics, being more constant, better meet the requirements of comfort air conditioning.

Single-phase motors (used for room air conditioning) do not require start relays or capacitors. They are preferred due to their minimal impact on other circuit elements.

Commercial air conditioning

Their cooling capacity is more than sufficient to meet commercial air conditioning requirements.

Scroll compressors are also used for air conditioning in shops, travel agencies, offices, banks, restaurants, fast food eateries, bars and many other facilities. Air conditioners with scroll compressors - successful technical solution, especially for units operating in summer and year-round, as well as in heat pump mode.

Heat pumps

In heat pumps, scroll compressors have the advantage of increased reliability over other types of compressors used in heat pumps due to the ability to control the liquid refrigerant entering the emergency situations into the compressor (without destroying its components).

Refrigeration units for computer centers and automatic telephone exchanges

These areas require virtually continuous work refrigeration units, often over 8000 h/year. It is especially important to ensure continuous operation under these conditions through ongoing service. Under these conditions, scroll compressors can be effective in reducing energy consumption due to high efficiency.

Low level The noise level of scroll compressors is another factor that allows them to be used in air conditioning systems, often installed in the air-conditioned rooms themselves.

Autonomous roof-top units

Their most typical applications are factories and grocery supermarkets, where the high performance benefits of scroll compressors are particularly needed because these are sectors typically characterized by high energy consumption of air conditioning systems and refrigeration units.

Reliability is another important contribution that scroll compressors make to overall cost savings in supermarket operations where uptime is a critical factor.

Other Applications

The versatility of scroll compressors expands their applications in technological processes, for example, in autoclaves for wine purification, cooling systems for molding machines in the chemical industry, refrigeration systems, testing chambers, refrigerated canning of raw materials of biological origin (meat products, fruits and vegetables, etc.), cooling of water-free cleaning equipment (solvent condensation), food processing raw materials, etc.

Scroll compressors have proven themselves to be reliable, energy-efficient and easy-to-use units for producing compressed air. In such compressors, air is compressed by two spirals - one of them is stationary, and the second rotates at high speeds and moves at the same time. The movement of the movable spiral reduces the volume of the chamber containing air - and due to this, the density of the gas increases.

Application

Spiral installations allow you to obtain an output stream of the highest degree cleaning: during the compression process, the air does not come into contact with oil or other lubricants and, accordingly, does not mix with it. Therefore, scroll compressors are used in those industries where particularly stringent requirements are imposed on air quality (medical and dental clinics, food and pharmaceutical production, manufacturing of high-precision electronics, etc.). And the use of such equipment together with dehumidifiers and additional filtering devices ultimately allows you to obtain the best air flow in terms of quality.