Organizational and production structure of nuclear power plants. Types of thermal power plants. What is the secret of thermal power plants

Thermal power plant is a power plant that generates electrical energy as a result of the conversion of thermal energy released during the combustion of organic fuel (Fig. E.1).

There are thermal steam turbine power plants (TPES), gas turbine power plants (GTPP) and combined cycle power plants (CGPP). Let's take a closer look at TPES.

Fig.D.1 TPP diagram

At TPES, thermal energy is used in a steam generator to produce water vapor high pressure, driving the rotor of a steam turbine connected to the rotor of an electric generator. The fuel used at such thermal power plants is coal, fuel oil, natural gas, lignite (brown coal), peat, and shale. Their efficiency reaches 40%, power – 3 GW. TPES that have condensing turbines as a drive for electric generators and do not use the heat of exhaust steam to supply thermal energy to external consumers are called condensing power plants (the official name in the Russian Federation is the State District Electric Station, or GRES). GRES produces about 2/3 of the electricity produced at thermal power plants.

TPES equipped heating turbines and releasing the heat of exhaust steam to industrial or municipal consumers are called combined heat and power plants (CHP); they generate about 1/3 of the electricity produced at thermal power plants.

There are four known types of coal. In order of increasing carbon content, and thereby calorific value these types are arranged as follows: peat, lignite, bituminous (fat) coal or hard coal and anthracite. In the operation of thermal power plants, mainly the first two types are used.

Coal is not chemically pure carbon; it also contains inorganic material (brown coal contains up to 40% carbon), which remains after the combustion of coal in the form of ash. Coal may contain sulfur, sometimes as iron sulfide and sometimes as part of the organic components of coal. Coal usually contains arsenic, selenium, and radioactive elements. In fact, coal turns out to be the dirtiest of all fossil fuels.

When coal is burned, carbon dioxide, carbon monoxide, and large quantities sulfur oxides, suspended particles and nitrogen oxides. Sulfur oxides damage trees, various materials and have a harmful effect on people.

The particles released into the atmosphere when coal is burned in power plants are called "fly ash." Ash emissions are strictly controlled. About 10% of suspended particles actually enter the atmosphere.

A 1000 MW coal-fired power plant burns 4-5 million tons of coal per year.

Since there is no coal mining in the Altai Territory, we will assume that it is brought from other regions, and roads are built for this purpose, thereby changing the natural landscape.

APPENDIX E

An electrical power plant is a power plant that converts natural energy into electrical energy. The most common thermal power plants (TPPs) using thermal energy emitted during the combustion of organic fuel (solid, liquid and gaseous).

Thermal power plants generate about 76% of the electricity produced on our planet. This is due to the presence of fossil fuels in almost all areas of our planet; the possibility of transporting organic fuel from the extraction site to a power plant located near energy consumers; technical progress at thermal power plants, ensuring the construction of thermal power plants with high power; the possibility of using waste heat from the working fluid and supplying consumers, in addition to electrical energy, also thermal energy (with steam or hot water) and so on.

A high technical level of energy can only be ensured with a harmonious structure of generating capacities: the energy system must include nuclear power plants that generate cheap electricity, but have serious restrictions on the range and rate of load change, and thermal power plants that supply heat and electricity, the amount of which depends on the needs of heat, and powerful steam turbine power units operating on heavy fuels, and mobile autonomous gas turbine units that cover short-term load peaks.

1.1 Types of electrical power plants and their features.

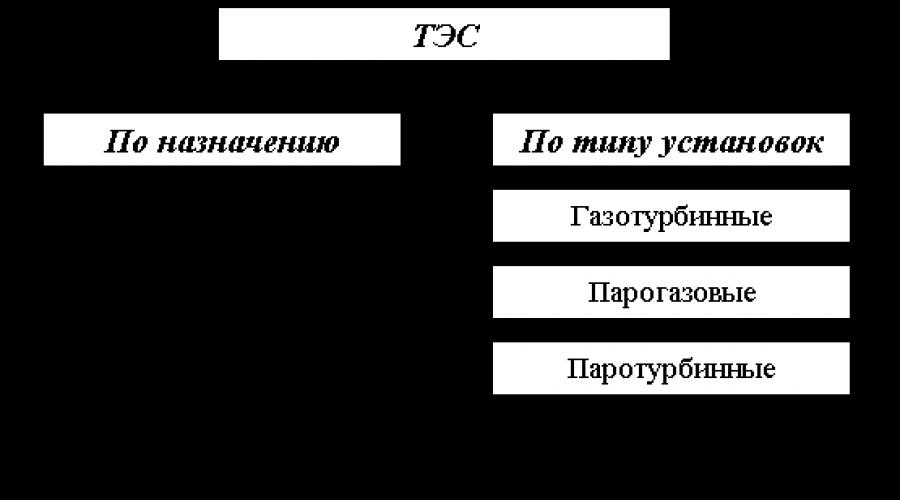

In Fig. 1 presents the classification of thermal power plants using fossil fuels.

Fig.1. Types of thermal power plants using fossil fuels.

Fig.2 Fundamental thermal diagram TPP

1 – steam boiler; 2 – turbine; 3 – electric generator; 4 – capacitor; 5 – condensate pump; 6 – low pressure heaters; 7 – deaerator; 8 – feed pump; 9 – high pressure heaters; 10 – drainage pump.

A thermal power plant is a complex of equipment and devices that convert fuel energy into electrical and (in general) thermal energy.

Thermal power plants are characterized by great diversity and can be classified according to various criteria.

Based on their purpose and type of energy supplied, power plants are divided into regional and industrial.

District power plants are independent public power plants that serve all types of consumers in the region (industrial enterprises, transport, population, etc.). District condensing power plants, which generate mainly electricity, often retain their historical name - GRES (state district power plants). District power plants that produce electrical and thermal energy (in the form of steam or hot water), are called combined heat and power plants (CHP). As a rule, state district power plants and district thermal power plants have a capacity of more than 1 million kW.

Industrial power plants are power plants that supply thermal and electrical energy to specific production enterprises or their complex, for example a chemical production plant. Industrial power plants are part of the industrial enterprises they serve. Their power is determined by the needs of industrial enterprises for heat and electrical energy and, as a rule, it is significantly less than regional thermal power plants. Often industrial power plants operate on the general electrical network, but are not subordinate to the power system dispatcher.

Based on the type of fuel used, thermal power plants are divided into power plants operating on fossil fuels and nuclear fuel.

Condensing power plants operating on fossil fuels, at a time when there were no nuclear power plants (NPPs), were historically called thermal power plants (TES - thermal power plant). It is in this sense that this term will be used below, although thermal power plants, nuclear power plants, gas turbine power plants (GTPP), and combined cycle power plants (CGPP) are also thermal power plants operating on the principle of converting thermal energy into electrical energy.

Gaseous, liquid and solid fuel. Most thermal power plants in Russia, especially in the European part, consume natural gas as the main fuel, and fuel oil as a backup fuel, using the latter due to its high cost only in extreme cases; Such thermal power plants are called gas-oil power plants. In many regions, mainly in the Asian part of Russia, the main fuel is thermal coal - low-calorie coal or waste from the extraction of high-calorie coal (anthracite coal - ASh). Since before combustion such coals are ground in special mills to a dusty state, such thermal power plants are called pulverized coal.

By type of thermal power plants used at thermal power plants to convert thermal energy into mechanical energy rotation of the rotors of turbine units, there are steam turbine, gas turbine and combined cycle power plants.

The basis of steam turbine power plants are steam turbine units (STU), which use the most complex, most powerful and extremely advanced energy machine - a steam turbine - to convert thermal energy into mechanical energy. PTU is the main element of thermal power plants, combined heat and power plants and nuclear power plants.

STPs that have condensing turbines as a drive for electric generators and do not use the heat of exhaust steam to supply thermal energy to external consumers are called condensing power plants. STUs equipped with heating turbines and releasing the heat of exhaust steam to industrial or municipal consumers are called combined heat and power plants (CHP).

Gas turbine thermal power plants (GTPPs) are equipped with gas turbine units (GTUs) running on gaseous or, in extreme cases, liquid (diesel) fuel. Since the temperature of the gases behind the gas turbine plant is quite high, they can be used to supply thermal energy to external consumers. Such power plants are called GTU-CHP. Currently, in Russia there is one gas turbine power plant (GRES-3 named after Klasson, Elektrogorsk, Moscow region) with a capacity of 600 MW and one gas turbine cogeneration plant (in the city of Elektrostal, Moscow region).

A traditional modern gas turbine unit (GTU) is a combination of an air compressor, a combustion chamber and a gas turbine, as well as auxiliary systems that ensure its operation. The combination of a gas turbine unit and an electric generator is called a gas turbine unit.

Combined-cycle thermal power plants are equipped with combined cycle gas turbine units (CCGTs), which are a combination of gas turbine units and steam turbine units, which ensures high efficiency. CCGT-CHP can be designed as condensing (CCP-KES) and with thermal energy supply (CCP-CHP). Currently, there are four new CCGT-CHP plants in Russia (North-West CHPP of St. Petersburg, Kaliningradskaya, CHPP-27 of Mosenergo OJSC and Sochinskaya), and a cogeneration CCGT plant has also been built at the Tyumen CHPP. In 2007, the Ivanovo CCGT-KES was put into operation.

Modular thermal power plants consist of separate, usually of the same type, power plants - power units. In a power unit, each boiler supplies steam only to its own turbine, from which it returns after condensation only to its own boiler. All powerful state district power plants and thermal power plants, which have the so-called intermediate superheating of steam, are built according to the block scheme. The operation of boilers and turbines at thermal power plants with cross connections is ensured differently: all boilers of the thermal power plant supply steam to one common steam line (collector) and all steam turbines of the thermal power plant are powered from it. According to this scheme, CESs without intermediate overheating and almost all CHP plants with subcritical initial steam parameters are built.

Based on the level of initial pressure, thermal power plants of subcritical pressure, supercritical pressure (SCP) and supersupercritical parameters (SSCP) are distinguished.

The critical pressure is 22.1 MPa (225.6 at). In the Russian heat and power industry, the initial parameters are standardized: thermal power plants and combined heat and power plants are built for subcritical pressure of 8.8 and 12.8 MPa (90 and 130 atm), and for SKD - 23.5 MPa (240 atm). For technical reasons, thermal power plants with supercritical parameters are replenished with intermediate overheating and according to a block diagram. Supersupercritical parameters conventionally include pressure more than 24 MPa (up to 35 MPa) and temperature more than 5600C (up to 6200C), the use of which requires new materials and new equipment designs. Often thermal power plants or combined heat and power plants for different levels of parameters are built in several stages - in queues, the parameters of which increase with the introduction of each new queue.

The energy hidden in fossil fuels - coal, oil or natural gas, cannot be immediately obtained in the form of electricity. The fuel is first burned. The released heat heats the water and turns it into steam. The steam rotates the turbine, and the turbine rotates the generator rotor, which generates, i.e. produces, electric current.

Scheme of operation of a condensing power plant.

Slavyanskaya TPP. Ukraine, Donetsk region.

This entire complex, multi-stage process can be observed at a thermal power plant (TPP), equipped with energy machines that convert the energy hidden in organic fuel (oil shale, coal, oil and its derivatives, natural gas) into electrical energy. The main parts of the thermal power plant are the boiler plant, steam turbine and an electric generator.

Boiler plant- a set of devices for producing water vapor under pressure. It consists of a firebox in which organic fuel is burned, a combustion space through which combustion products pass into chimney, And steam boiler, in which water boils. The part of the boiler that comes into contact with the flame during heating is called the heating surface.

There are 3 types of boilers: smoke-fired, water-tube and once-through. Inside combustion boilers there is a series of tubes through which combustion products pass into the chimney. Numerous smoke tubes have a huge heating surface, as a result of which they make good use of fuel energy. The water in these boilers is between the smoke tubes.

IN water tube boilers- it’s the other way around: water is released through the tubes, and hot gases are passed between the tubes. The main parts of the boiler are the firebox, boiling tubes, steam boiler and superheater. The steam formation process takes place in the boiling tubes. The steam generated in them enters the steam boiler, where it is collected in its upper part, above boiling water. From the steam boiler, steam passes into the superheater and is further heated there. Fuel is poured into this boiler through the door, and the air necessary for combustion of the fuel is supplied through another door into the ash pit. Hot gases rise upward and, bending around the partitions, travel the path indicated in the diagram (see figure).

IN once-through boilers The water is heated in long coil pipes. Water is supplied to these pipes by a pump. Passing through the coil, it completely evaporates, and the resulting steam is superheated to the required temperature and then exits the coils.

Boiler installations operating with intermediate superheating of steam are integral part installation called power unit"boiler - turbine".

In the future, for example, large thermal power plants with a capacity of up to 6,400 MW will be built to use coal from the Kansk-Achinsk basin. energy blocks 800 MW each, where boiler plants will produce 2650 tons of steam per hour at temperatures up to 565 °C and pressure 25 MPa.

The boiler plant produces high pressure steam, which goes to the steam turbine - main engine thermal power plant. In the turbine, the steam expands, its pressure drops, and the latent energy is converted into mechanical energy. The steam turbine drives the rotor of a generator, which produces electric current.

IN major cities most often built combined heat and power plants(CHP), and in areas with cheap fuel - condensing power plants(IES).

CHP is thermal power plant, generating not only electrical energy, but also heat in the form of hot water and steam. The steam leaving the steam turbine still contains a lot of thermal energy. At a thermal power plant, this heat is used in two ways: either the steam after the turbine is sent to the consumer and does not return back to the station, or it transfers heat in the heat exchanger to water, which is sent to the consumer, and the steam is returned back to the system. Therefore, CHP has a high efficiency, reaching 50–60%.

There are CHP heating and industrial types. Heating CHP plants heat residential and public buildings and supply them with hot water, industrial - supply industrial enterprises with heat. Steam is transmitted from thermal power plants over distances of up to several kilometers, and hot water is transmitted over distances of up to 30 kilometers or more. As a result, thermal power plants are being built near large cities.

A huge amount of thermal energy is directed to district heating or central heating our apartments, schools, institutions. Before October revolution district heating there were no houses. Houses were heated by stoves, which burned a lot of wood and coal. District heating in our country began in the first years of Soviet power, when, according to the GOELRO plan (1920), the construction of large thermal power plants began. The total capacity of thermal power plants in the early 1980s. exceeded 50 million kW.

But the main share of electricity generated by thermal power plants comes from condensing power plants (CPS). In our country they are more often called state district electric power plants (SDPPs). Unlike thermal power plants, where the heat of the steam exhausted in the turbine is used for heating residential and industrial buildings, at IES, steam exhausted in engines (steam engines, turbines) is converted by condensers into water (condensate), which is sent back to boilers for reuse. CPPs are built directly near water supply sources: lakes, rivers, seas. The heat removed from the power plant with cooling water is irretrievably lost. The efficiency of IES does not exceed 35–42%.

Railcars with finely crushed coal are delivered to the high overpass day and night according to a strict schedule. A special unloader tips the wagons and the fuel is poured into the bunker. The mills carefully grind it into fuel powder, and it flies into the furnace of the steam boiler along with the air. The flames tightly cover the bundles of tubes, in which the water boils. Water vapor is formed. Through pipes - steam lines - steam is directed to the turbine and hits the turbine rotor blades through nozzles. Having given energy to the rotor, the exhaust steam goes to the condenser, cools and turns into water. Pumps supply it back to the boiler. And the energy continues its movement from the turbine rotor to the generator rotor. In the generator its final transformation takes place: it becomes electricity. This is where the IES energy chain ends.

Unlike hydroelectric power stations, thermal power plants can be built anywhere, and thereby bring the sources of electricity closer to the consumer and distribute thermal power plants evenly throughout the economic regions of the country. The advantage of thermal power plants is that they operate on almost all types of organic fuel - coal, shale, liquid fuel, natural gas.

The largest condensing thermal power plants in Russia include Reftinskaya ( Sverdlovsk region), Zaporozhye (Ukraine), Kostroma, Uglegorsk (Donetsk region, Ukraine). The power of each of them exceeds 3000 MW.

Our country is a pioneer in the construction of thermal power plants, the energy of which comes from atomic reactor(cm.

Thermal power plant

Thermal power plant

(TPP), power plant, in which, as a result of burning organic fuel, thermal energy is obtained, which is then converted into electrical energy. Thermal power plants are the main type of power plants; the share of electricity they generate in industrialized countries is 70–80% (in Russia in 2000 - about 67%). Thermal power at thermal power plants is used to heat water and produce steam (at steam turbine power plants) or to produce hot gases (at gas turbine power plants). To produce heat, organic matter is burned in boiler units of thermal power plants. Coal, natural gas, fuel oil, and combustibles are used as fuel. At thermal steam turbine power plants (TSPP), the steam produced in the steam generator (boiler unit) rotates steam turbine connected to an electric generator. Such power plants generate almost all the electricity produced by thermal power plants (99%); their efficiency approaches 40%, single installed capacity– to 3 MW; the fuel for them is coal, fuel oil, peat, shale, natural gas, etc. Power plants with heating steam turbines, in which the heat of waste steam is recovered and supplied to industrial or municipal consumers are called thermal power plants. They generate approximately 33% of the electricity produced by thermal power plants. In power plants with condensing turbines, all exhaust steam is condensed and returned as a steam-water mixture to the boiler unit for reuse. These condensing power plants (CPS) produce approx. 67% of electricity produced at thermal power plants. The official name of such power plants in Russia is State District Electric Power Station (GRES).

Steam turbines of thermal power plants are usually connected directly to electric generators, without intermediate gears, forming a turbine unit. In addition, as a rule, a turbine unit is combined with a steam generator into a single power unit, from which powerful TPES are then assembled.

In the combustion chambers of gas turbine thermal power plants, gas or liquid fuel. The resulting combustion products are sent to gas turbine, rotating the electric generator. The power of such power plants, as a rule, is several hundred megawatts, the efficiency is 26–28%. Gas turbine power plants usually built in conjunction with a steam turbine power plant to cover peak electrical loads. Conventionally, thermal power plants also include nuclear power plants(NPP), geothermal power plants and power plants with magnetohydrodynamic generators. The first coal-fired thermal power plants appeared in 1882 in New York, and in 1883 in St. Petersburg.

Encyclopedia "Technology". - M.: Rosman. 2006 .

See what a “thermal power plant” is in other dictionaries:

Thermal power plant- (TPP) - an electric power station (a complex of equipment, installations, equipment) that generates electrical energy as a result of the conversion of thermal energy released during the combustion of organic fuel. Currently, among thermal power plants... ... Oil and Gas Microencyclopedia

thermal power plant- Power plant converting chemical energy fuel into electrical energy or electrical energy and heat. [GOST 19431 84] EN thermal power station a power station in which electricity is generated by conversion of thermal energy Note… … Technical Translator's Guide

thermal power plant- A power plant that produces electrical energy as a result of the conversion of thermal energy released during the combustion of fossil fuels... Dictionary of Geography

- (TPP) generates electrical energy as a result of the conversion of thermal energy released during the combustion of organic fuel. The main types of thermal power plants: steam turbine (prevail), gas turbine and diesel. Sometimes thermal power plants are conditionally referred to... ... Big Encyclopedic Dictionary

THERMAL POWER PLANT- (TPP) an enterprise for the production of electrical energy as a result of the conversion of energy released during the combustion of organic fuel. The main parts of the thermal power plant are a boiler installation, a steam turbine and an electric generator that converts mechanical... ... Big Polytechnic Encyclopedia

Thermal power plant- CCGT 16. Thermal power plant According to GOST 19431 84 Source: GOST 26691 85: Thermal power engineering. Terms and definitions original document... Dictionary-reference book of terms of normative and technical documentation

- (TPP), produces electrical energy as a result of the conversion of thermal energy released during the combustion of organic fuel. Thermal power plants operate on solid, liquid, gaseous and mixed fuels (coal, fuel oil, natural gas, less often brown... ... Geographical encyclopedia

- (TPP), generates electrical energy as a result of the conversion of thermal energy released during the combustion of organic fuel. The main types of thermal power plants: steam turbine (prevail), gas turbine and diesel. Sometimes thermal power plants are conditionally referred to... ... encyclopedic Dictionary

thermal power plant- šiluminė elektrinė statusas T sritis automatika atitikmenys: engl. thermal power station; thermal station vok. Wärmekraftwerk, n rus. thermal power plant, f pranc. centrale électrothermique, f; centrale thermoélectrique, f … Automatikos terminų žodynas

thermal power plant- šiluminė elektrinė statusas T sritis fizika atitikmenys: engl. heat power plant; steam power plant vok. Wärmekraftwerk, n rus. thermal power plant, f; thermal power plant, f pranc. centrale électrothermique, f; centrale thermique, f; usine… … Fizikos terminų žodynas

- (TPP) A power plant that produces electrical energy as a result of the conversion of thermal energy released during the combustion of fossil fuels. The first thermal power plants appeared at the end of the 19th century. (in 1882 New York, 1883 in St. Petersburg, 1884 in... ... Great Soviet Encyclopedia

ORGANIZATIONAL AND PRODUCTION STRUCTURE OF THERMAL POWER PLANTS (TPP)

Depending on the power of the equipment and circuits technological connections Between the stages of production at modern thermal power plants, a distinction is made between workshop, non-shop and block-shop organizational and production structures.

Shop organizational and production structure provides for division technological equipment and the territory of thermal power plants into separate areas and assigning them to specialized units - workshops, laboratories. In this case the main structural unit is a workshop. Depending on their participation in production, workshops are divided into main and auxiliary. In addition, thermal power plants can also include non-industrial farms (housing and subsidiary farms, kindergartens, holiday homes, sanatoriums, etc.).

Main workshops are directly involved in energy production. These include fuel and transport, boiler, turbine, electrical and chemical shops.

The fuel transport workshop includes railway and fuel supply sections with a fuel warehouse. This workshop is organized at power plants that burn solid fuel or fuel oil when it is delivered by rail.

The boiler shop includes areas for supplying liquid or gaseous fuel, dust preparation, and ash removal.

The turbine shop includes: heating department, central pumping station and water management.

With two workshops production structure, as well as at large thermal power plants, the boiler and turbine shops are combined into a single boiler-turbine shop (BTS).

The electrical workshop is in charge of: all electrical equipment of thermal power plants, an electrical laboratory, an oil production facility, and an electrical repair shop.

The chemical workshop includes a chemical laboratory and chemical water treatment.

Auxiliary workshops serve the main production. These include: a centralized repair shop, a repair and construction shop, a thermal automation and communications shop.

Non-industrial farms are not directly related to energy production and serve the household needs of thermal power plant workers.

Shopless organizational and production structure provides for the specialization of units in the implementation of basic production functions: operation of equipment, its repair service, technological control. This leads to the creation of production services instead of workshops: operation, repairs, control and improvement of equipment. In turn, production services are divided into specialized areas.

Creation block-shop organizational and production structure due to the emergence of complex energy units-blocks. The unit equipment carries out several phases of the energy process - burning fuel in a steam generator, generating electricity in a turbogenerator, and sometimes converting it in a transformer. In contrast to the workshop structure, the main production unit of a power plant in a block-shop structure is the blocks. They are included in the CTC, which are engaged in the centralized operation of the main and auxiliary equipment boiler and turbine units. The block-shop structure provides for the preservation of the main and auxiliary workshops that take place in the workshop structure, for example, the fuel and transport workshop (FTS), chemical, etc.

All types of organizational and production structure provide for production management on the basis of unity of command. At each thermal power plant there is administrative, economic, production and technical and operational dispatch management.

The administrative and economic head of the TPP is the director, the technical manager is Chief Engineer. Operational dispatch control is carried out by the duty engineer of the power plant. In operational terms, he is subordinate to the duty dispatcher of the EPS.

Name and quantity structural divisions, and the need to introduce individual positions is determined depending on the standard number of industrial production personnel of the power plant.

The indicated technological, organizational and economic features of electric power production affect the content and tasks of managing the activities of energy enterprises and associations.

The main requirement for the electric power industry is a reliable and uninterrupted power supply to consumers and coverage of the required load schedule. This requirement is transformed into specific indicators that evaluate the participation of the power plant and network enterprises in the implementation of the production program of energy associations.

The power plant is set to be ready to bear the load, which is set by the dispatch schedule. For network enterprises, a repair schedule for equipment and structures is established. The plan also specifies other technical and economic indicators: unit costs fuel at power plants, reduction of energy losses in networks, financial indicators. However manufacturing program energy enterprises cannot be strictly determined by the volume of production or supply of electrical energy and heat. This is impractical due to the exceptional dynamics of energy consumption and, accordingly, energy production.

However, the volume of energy production is an important calculation indicator that determines the level of many other indicators (for example, cost) and the results of economic activities.