Wiring diagram for 2 heating boilers. Heating boiler piping. Typical connection errors

Who among us does not dream of a comfortable microclimate in the house? Probably everyone. This can only be achieved with proper setup. heating system, Where main role The cauldron is playing. And in order for such expensive equipment long years uninterruptedly generated heat, did not overheat and did not fail, and the boiler needed piping.

What is heating system piping

Piping is a set of equipment and pipes that provides radiators with a thermal carrier.

The piping includes everything that is located between the boiler and radiators

Simply put, the piping is needed in order to connect the boiler with heating devices(radiators) or with a boiler.

Many people, out of ignorance, do not attach importance to this part of the heating system and completely in vain. Correctly made harness:

In other words, the piping ensures reliability, safety and high performance of the entire heating system, creating coziness and comfort in the house.

Piping diagrams for gas boilers: connecting a thermostat, shut-off valves and hydraulic elements

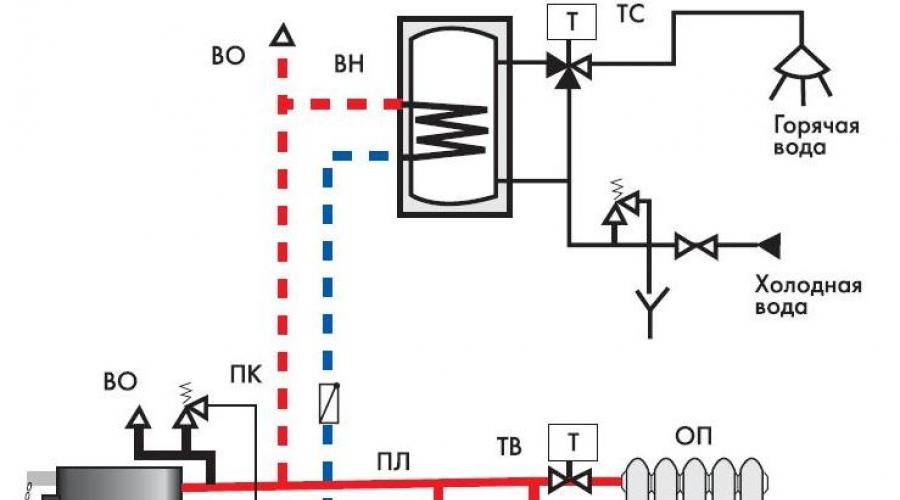

The general strapping scheme is quite simple. It does not depend on the type of fuel and is suitable for any type of boilers, including condensing and solid fuel. Includes the following components:

The choice of strapping method depends on:

The most popular is the piping of boiler equipment with forced circulation, because it is the most practical and convenient.

The most popular is the piping of boiler equipment with forced circulation, because it is the most practical and convenient

Responsible for the movement of the coolant in this circuit is electric pump, thanks to which hot water circulates in the system.

However, such a scheme has its drawbacks - the presence of a large number of pipes, shut-off and control valves and its considerable price, the need for balancing between all links, and dependence on energy sources. This complicates the design and makes installation of the heating system more expensive.

Installation double-circuit boiler requires just such a strapping scheme.

Piping a boiler with natural circulation is much simpler than a classic one; if necessary, you can install it yourself.

Piping a boiler with natural circulation is much simpler than the classic one; if necessary, you can install it yourself

In this scheme there is no pump, and the heat carrier spreads according to the laws of physics - cold water, being more dense, pushes out hot water with lower density.

This scheme (also called gravity) has a number of advantages - affordable cost of equipment, setup and maintenance, the ability to install and quickly repair it yourself. In addition, it does not require connection to electrical network, therefore, allows you to save on a backup power generator.

But, despite this, the gravity circuit has a serious drawback - it is suitable for piping only single-circuit boilers, applicable in a small house or country house, and pipes laid near the floor or ceiling spoil the interior.

Specifics of installation of piping for certain types of boilers

It all depends on the model and power of the boiler. When assembling, you should strictly follow the instructions and remember some rules:

Place filters correctly so that all dirt collects at the bottom and not in the pipe. Do not forget about the direction of coolant flow - always in the arrow

American is an analogue of the previously popular squeezing. Using this device, pipes and radiators are connected

You cannot use collective (shared) ventilation shafts for removing combustion products (this applies to apartment buildings). You can't adjust the traction in them. If there is excessive draft, acid dew settles on the walls of the pipes, which can sooner or later destroy the gas outlet, therefore, when installing it, it is recommended to use pipes made of roofing sheet. And if there is a lack of draft, combustion products can fill the room, which is very, very dangerous.

Floor-standing and wall-mounted boilers

These types of boilers differ only in the installation method; there is no fundamental difference in the piping arrangement for them. It is more advisable to install a wall-mounted type for heating a well-insulated room with an area of 80–350 m² connected to the main gas.

It is more advisable to install a wall-mounted type for heating a well-insulated room of a large area

With a smaller heated area, it is more rational to use electric convectors and storage water heaters.

In all other cases, it is better to purchase a floor-standing boiler.

With a smaller heated area, it is more rational to use electric convectors and storage water heaters

Single-circuit boilers

They have one heat exchanger and are intended for heating only. The piping is done using two pipes: for the supply and for the return line. Single-circuit boilers of the latest modifications can work in conjunction with indirect boiler and provide the house with hot water. In this case, the simplest piping is through a three-way valve according to the principle of priority heating of water in the boiler.

This scheme complicates the strapping, but not too much, but its benefits are undoubted.

Single-circuit piping gas boiler with a free-standing boiler is complex, but extremely profitable

Double-circuit boilers

Designed for heating and hot water supply (hot water supply). But, as practice shows, a double-circuit boiler cannot provide a private house sufficient amount of hot water for consumption. Therefore, you have to use it in turn: either in the kitchen or in the bathroom. To increase the volume, an additional boiler can be connected to the system. But the presence of a boiler complicates the piping scheme.

The main distribution function in such a scheme is performed by a three-way valve, as for a single-circuit boiler. But the operating principle here is different: the coolant moves from the main source to the additional one and back. It is this scheme that allows the coolant to gain the most high temperature(in the return line it can reach 80 °C).

Multi-circuit heating systems are equipped with hydraulic distributors

Multi-circuit heating systems are equipped with hydraulic distributors that compensate for pressure differences in the radiators and boiler and balance the coolant flows. In some cases, it is possible to install a system without hydraulics, while the pressure is regulated by balancing valves.

Piping a double-circuit boiler is more complicated than a single-circuit boiler and is more expensive, but such a heating system is much more efficient.

Additional energy sources for a private home: generators and uninterruptible power supplies

For any piping option, it is necessary to provide for an emergency heating mode in the event of a power outage. Be sure to connect the boiler, pumps and fans to gasoline generator, which will power the equipment until the electricity turns on. If gas supply interruptions occur in your area, it makes sense to include a parallel electric boiler in the system.

Assembly, installation and connection of gas boilers

Installation of a heating system begins with obtaining permits and approvals. Need to order detailed project arrangement of the boiler room, conclude an agreement for gas supply (if it is a private house). And only after familiarizing yourself with the project, where the parameters are written necessary equipment, you can start purchasing, assembling, installing and connecting to networks.

Is it possible to install a boiler in a house or apartment?

Special requirements are imposed on the room where the mini-boiler room will be located, and it is not recommended to violate them by doing things on your own. This is not only fraught with heavy fines, but also life-threatening, because gas is an explosive substance and extreme care should be taken when handling it.

Video: example of setting up a simple heating system

Main criteria for choosing a room:

Installation of small-power boilers is allowed in any non-residential premises. Many people place them in the kitchen. If there is at least 0.2 m² of space per 1 kW of gas boiler power, then it is quite possible to obtain permission. When the kitchen is combined with the living room, then an indispensable condition is the presence of a gas analyzer for the timely detection of possible gas leaks.

Small single-circuit boilers can be installed in the kitchen. Moreover, they even decorate the interior

Double-circuit boilers are prohibited from being installed in kitchens.

The location of the equipment also depends on the power of the equipment. With a total power of up to 150 kW, it is possible to equip a boiler room on any floor; above that, only on the first or basement floor.

Two boilers in one system: parallel and series connection

Today, there is increasingly a need to install several heating devices at once in a large country house or cottage. Moreover, these can be different boilers, for example, solid fuel and gas.

Two boilers in one system can be connected according to different schemes:

In a sequential circuit, the coolant heated by the solid fuel (SF) boiler enters the thermal accumulator (TA), and then is supplied to a closed system with a gas boiler

At parallel connection The operation of the solid fuel boiler is controlled by sensors (4). By using three way valve(7) any boiler can be disconnected from the system

Subject to certain conditions (coordination with supervisory authorities and obtaining the necessary permits) it is quite possible to implement one of these systems. At the same time, comfort is achieved (due to a gas boiler) and savings (due to low-cost solid fuel).

As for autonomous heating in apartments of multi-storey buildings, there are no fundamental differences in the installation and connection procedure; there are only a few features related to the choice of equipment:

The gas boiler connection diagram is divided into 6 stages:

For a wall-mounted boiler, you need to mark the wall according to the supplied template and secure the installation bracket using fasteners

The forward and return pipes are connected through American couplings

The boiler is connected via an RCD to protect against electric shock

A gas consumption meter must be installed in front of the boiler.

A thermostat is necessary to maintain the desired temperature in the room.

Where is the best place to install a room thermostat?

A thermostat (sometimes called a programmer) is an automatic room device that regulates the operation of boiler equipment according to specified parameters. It reacts to the air temperature and gives the boiler a command to reduce or increase power. It is recommended to install the thermostat in residential areas away from heat sources, direct sun rays and drafts. It's best to place it in the coldest or most frequently used room in the house.

Features of installing the boiler in unheated rooms or outdoors

In small cottages, it is sometimes advisable to install a gas boiler, for example, in the attic or even outside the house. First of all, this is done to save space in residential premises. But with such arrangement of the heating system, the warranty does not apply to the purchased boiler. Humidity, wind, cold and other factors will negatively affect the operating life of the equipment.

The situation can be corrected by installing a protective cabinet, which must comply with the standards (the distance between the boiler and the cabinet walls is at least 15 cm) and be spacious enough so as not to interfere with the use of the boiler and its maintenance.

Video: how to independently connect a heating system for a cottage

Electrical grounding: two connection options

This is an integral part of the heating system. Without grounding, service departments will not issue permission to put the system into operation.

Grounding is necessary not only to extend the life of gas equipment, but also for the safety of the residents of the house.

Grounding can be done manually in two ways:

The working process:

All grounding electrodes are connected to each other in series using horizontal metal strips

If houses are located close to each other, then linear grounding can be done. The sequence is the same, only the trench should run along the entire perimeter of the house. Grounding conductors are dug in every 2 m.

Grounding conductors are dug in every 2 m

Check is being carried out special tool. At the same time, regulatory authorities pay attention to the soil in which the ground electrodes are located. Therefore, before starting work, it will not be superfluous to find out by what standards the finished structure will be assessed.

Does a gas boiler need a chimney?

A gas boiler definitely needs a chimney. You can build it yourself. Need to choose suitable design, familiarize yourself with the basic requirements and carry out all stages of work strictly according to the instructions.

Special requirements apply to materials. They are regulated in clause 6.2.7 of SNiP - chimney pipes must withstand mechanical loads, temperature fluctuations and not be subject to corrosion. These can be asbestos-cement, ceramic, plastic or metal pipes. The best option- stainless steel pipes as the cheapest and easiest to install.

In addition to pipes for arranging a chimney for a gas boiler, you will need:

Chimneys can be internal or external.

When settling in internal chimney a conical tip is required to protect against precipitation

For their production they are used different materials, but the following requirements remain unchanged:

The chimney in the room must be insulated. At the place of passage interfloor ceilings a special passage block is inserted

Step-by-step diagram of connecting the boiler to the chimney

The fundamental difference between internal and external chimneys No. In any case, the connection begins with connecting the adapter to the branch pipe (sometimes immediately the outlet pipe). Then:

The connection begins by connecting the adapter to the branch pipe (sometimes immediately the outlet pipe)

An external (wall) chimney is safer and easier to assemble and install. For its arrangement, sandwich pipes are used. They are assembled on the ground and then secured to the building with clamps, brackets and braces (to provide greater stability). The height is calculated according to the standards, taking into account the distance from the roof ridge.

external (wall) chimney is safer and easier to assemble and install

Detailed consideration of the main aspects of installation gas heating shows that it is possible to make such a system with my own hands is quite real. We hope that the information presented will help you choose the right equipment, as well as install and launch it in accordance with the requirements of inspection organizations.

What is this - heating boiler piping? Simply put, this is all the equipment that is needed to provide normal operation heating unit and transporting heated coolant from the heat exchanger to the radiators. Moreover, the strapping scheme may vary depending on the type heating boiler, its location, as well as the presence additional equipment.

It should be remembered that ready-made solutions, optimally meeting the requirements of each room or building does not exist.

Which pipes are best for piping a boiler room?

Each material has its own characteristics that affect its performance characteristics. When choosing pipes for piping a boiler room, you need to pay attention to thermal insulation properties, difficulties associated with installation, as well as cost. The most popular solutions are:Boiler piping with polypropylene

Polypropylene pipes are an almost ideal material for piping, but not without their drawbacks. The advantages include:

- Easy installation, assembly of polypropylene strapping is carried out using a special soldering iron. As a result, all work on wiring the heating system of the house and installing additional equipment is carried out within a period of one day to a week.

- Resistance to heat - polypropylene pipes for installation of heating piping are reinforced with fiberglass reinforcement. The fiberglass in PPT creates a frame that protects against expansion when heated. The thermal conductivity of polypropylene is quite low, so heat loss along the boiler-radiator route is almost minimal.

- Coolant circulation rate - piping the boiler room with polypropylene has another advantage. The pipeline core is resistant to the formation of salt deposits. The coolant speed remains the same throughout the life of the product. The declared service life is 20 years depending on the manufacturer.

Piping the boiler with copper pipes

Installation of harness copper pipes requires a certain professionalism from the master, and significant material costs from the customer. The use of copper pipes also has its advantages:

- Good heat transfer from copper - the room is heated not only with the help of the radiators themselves, but also as the coolant moves. Copper heats up well and does not require a large amount of thermal energy.

- Copper is not subject to corrosion. Over time, copper pipes may become coated. thin layer oxide. But this does not affect performance.

- Copper piping is not afraid of freezing. Piping the boiler room with copper pipes eliminates the difficulties associated with freezing of the coolant. In this case, steel and propylene pipes simply burst. Copper is more ductile, so it can withstand freezing loads without losing integrity.

How to properly piping a solid fuel boiler

The design of TT equipment and the principle of its operation significantly influences the differences in connecting it to the heating system. It is worth considering that the simultaneous connection of electrical and solid fuel boiler also has its own nuances that can affect their performance and operation. What needs to be taken into account in this case?

The design of TT equipment and the principle of its operation significantly influences the differences in connecting it to the heating system. It is worth considering that the simultaneous connection of electrical and solid fuel boiler also has its own nuances that can affect their performance and operation. What needs to be taken into account in this case? - Return temperature - this coefficient cannot be lower than 55 degrees or the so-called “dew point”. In this case, a large amount of condensation occurs. It is for this reason that correct piping of a floor-mounted double-circuit wood-burning TT boiler with copper is better than using polypropylene pipes. Copper, which has better thermal conductivity, reduces the amount of condensation.

- If necessary, several boilers can be connected into one network. This will require the use of additional equipment. If you are installing and piping the heating of two solid fuel wood boilers, a heat accumulator is required. This scheme has been used in the West for a long time. Its essence is that all excess heat is accumulated in a special tank, whose device resembles a thermos. If the heating temperature of the coolant is insufficient, thermal energy gets from the reservoir. All excess thermal energy goes to the heat accumulator. Connecting a boiler with a buffer tank (heat accumulator) involves the use of a thermomixer, as well as blast valve. Thermal mixing unit prevents overheating of the coolant.

- Subject to certain conditions, it is possible to use polypropylene pipes for piping a solid fuel boiler. But if you consider that the coolant in such a system will be constantly heated to temperatures above 60 degrees, it becomes obvious that they must be reinforced and heat-resistant. Pipes with optical fiber reinforced with an aluminum rod are ideal. On the other hand, the piping scheme for a solid fuel heating boiler with polypropylene pipes does not require, as in the case of copper, the mandatory use of grounding and electrical insulation.

Installation of a heat accumulator will require additional expenses, but as a result, investments will be able to pay off in the near future due to savings on excessive fuel consumption and operation heating equipment.

How to properly piping a gas boiler

If we talk about the connection diagram for a gas boiler, it is worth noting that ready-made solutions in this case simply do not exist. The piping scheme for a gas boiler depends on how exactly the water heating equipment will be used and how many separate heating systems will provide heat. The following recommendations should be taken into account:

The piping diagram for a floor-mounted single-circuit gas heating boiler, energy-dependent type, should include mandatory installation bypass. The bypass controls that the coolant circulation does not stop even after a power outage.

Wood-electricity boiler piping

Connecting a heating boiler using solid fuel and electricity can be done in series and parallel ways. The essence of installing two types of heating equipment at once is to ensure continuous heating of the coolant in the system. This is done as follows:

Connecting a heating boiler using solid fuel and electricity can be done in series and parallel ways. The essence of installing two types of heating equipment at once is to ensure continuous heating of the coolant in the system. This is done as follows: - A TT boiler is installed as the main heating source. Throughout the day it provides normal heating of the coolant.

- At night, after the firewood burns out, the electric boiler automatically turns on, which continues to heat the liquid in the system until the main boiler is flooded.

How to properly piping a diesel boiler

Connecting a boiler room with a diesel boiler involves installing additional equipment that ensures stable coolant circulation and operation of the heating system. The use of the following nodes is mandatory:

The fuel tank piping for a diesel boiler must take into account the installation of a fuel supply pump, as well as the storage tank itself.

It is possible to connect a diesel and solid fuel boiler to one network. In this case, a sequential circuit is assembled. The main source of heating is CT equipment. When the coolant heating intensity decreases, the diesel heater turns on. Since the latest model has all necessary automation, during installation correct settings, human intervention in the continuous heating process will be minimal. You will definitely need to calculate the wiring diagram for the TT of the diesel boiler and the heat storage tank.

Equipment for heating boiler piping

The equipment that is used to piping any heating boiler must perform several important functions. Namely:- Ensure normal conditions for the operation of heating equipment.

- Protect from possible emergency situations: overheating of the coolant, water hammer (occur due to the temperature difference in the supply and return).

- Maintaining the required pressure in the system.

- - connecting the boiler with a buffer tank is a mandatory requirement for all TT boilers and desirable for gas equipment. At the same time, economical Europeans install a heat accumulator for another reason of significant benefits. The cost of heating a room using a tank is reduced by approximately 5-10%.

- - at its core, this device is a conventional distribution mechanism. After the heated coolant arrives, it directs it in accordance with the settings, energizing the heating circuits. The same operating principle is used in systems central heating. A distribution frame is provided for each entrance of a multi-storey building.

- - this equipment can be placed in a separate category due to its demand. Regardless of the configuration of the boiler itself, it may be necessary to install a circulation pump when using a hydraulic arrow (you will need one device for each circuit), as well as when heating a large area.

You may also need additional fittings for piping boilers: safety valves, expansion tanks, fuel pumps, pressure sensors, etc.

Components for boiler room piping

In addition to acquisition special equipment, to ensure the operation of the boiler you will need Consumables, with the help of which it will be tied.- Polypropylene pipes for installation of piping. For the work, it will also be necessary to purchase a certain number of angles, coarse filters, taps and other components. A complete calculation of materials for soldering the polypropylene strapping can be carried out by the master who will carry out the installation.

- Insulation - in places where heating pipes pass through load-bearing walls you will need to lay the Merilon. This is a special insulation for pipes, which simultaneously performs the function of preventing unnecessary heat loss and protecting against mechanical stress. Insulation of the piping pipes will also need to be carried out if the expansion tank is placed in an unheated attic room. Copper must be insulated without fail. For her there is special materials, Teploflex, Energoflex.

- When laying in frame partitions it is necessary to take care of the pipeline insulation. Thermal insulation is especially necessary if copper or metal piping is used. Metal pipes have good thermal conductivity and heat up significantly. For example, copper, when the coolant is heated to 90 degrees, will show approximately the same temperature and heat the wall, which can lead to certain problems.

Seeking help from specialists to compile a competent project documentation including a wiring diagram for heating water heating equipment, will help to significantly increase its service life and heat transfer coefficient.

There are no ready-made boiler piping solutions! The project is drawn up on site, taking into account the characteristics of the heated building and the heating system used.

Almost all piping in this case consists of connecting the supply pipeline and return pipeline to the boiler.

When such piping of a gas heating boiler is implemented, the scheme will be working as soon as you hang the boiler on the wall and connect the heating system pipes to it. Of course, if you have a main gas supply or a gas holder installed.

If you have it installed, then bringing cold water to its second circuit tap water, you will receive hot water for domestic hot water at the outlet.

Piping diagram with a floor-mounted single-circuit gas boiler

What will be the wiring diagram for single-circuit? In fact, it will be identical to the one we discussed above. Only the boiler body will be “gutted” - all components will be outside and stand alone.

It turns out that the floor-standing housing will contain only two components from the list above:

- Gas-burner.

- Heat exchanger.

All other devices will be located in the boiler room itself - this is a safety group, an expansion tank and a circulation pump.

And in the case of domestic hot water production, the role of the “second circuit” will be played by the BKN - indirect heating boiler.

That is, the system has become more “scattered”, but formally retained all the same parts as in the diagram with a double-circuit gas wall-mounted boiler.

All other attributes of heat generating equipment - water mixing system and supply gas pipe with sensors and counters - the same in any scheme. That is, they can, of course, be different and no longer depend on the type of boiler.

More on this topic on our website:

-

Correct, competent, high-quality organization of home heating contributes to uniform heat distribution throughout the living area. Gas piping wall-mounted boiler with two... -

A simple piping of a wall-mounted double-circuit gas boiler, the photo of which you see on this page, can be done by your master, or you can... -

The simplest piping of a double-circuit heating boiler with polypropylene, diagrams, photos and drawings of which are presented on this page, can be done by your own... -

In order not to spend money on a full-fledged chimney, you will need a coaxial pipe for a gas wall-mounted boiler. The installation, the photo of which is published on this...

Autonomous heating allows you not to depend on established consumption standards, the pricing policy of heat suppliers and their mood. This makes it possible to independently control the heating process and maintain the most comfortable temperature in the house, saving resources at the same time.

And if you have installed a heating boiler piping with your own hands, then it will last longer, and financial resources“takes away” less, doesn’t it? But have you never engaged in tying, and the word itself seems incomprehensible to you at first glance?

Don’t be intimidated by the abundance of pipes, devices and technological steps - after reading the article you will be up to the task. Here we consider the wiring diagrams for floor and wall types of heating equipment, select visual photos and recommendations from specialists for performing strapping at home.

A heating boiler piping is a system of pipelines and equipment designed to provide radiators with coolant. Simply put, it's everything except the batteries.

The first step is choosing a heating boiler, the performance of which must be determined in advance.

For calculation required power heating unit is influenced by many factors, these are:

- volume of the building;

- number of windows and total area glazing;

- number and area of doorways;

- thermal conductivity of materials used in the construction of walls;

- degree of insulation of load-bearing structures;

- average annual temperature in the construction region;

- location of the building, i.e. Which side of the world faces the main, traditionally most glazed, façade?

However, there is an average indicator that, without in-depth calculations, allows you to determine the required performance.

For the middle zone, 1 kW per 10 m² of heated area can be taken as a starting point (but not a guide to action!). It is imperative to add a reserve of at least 20% to the design power of the heating boiler.

Heat for heating buildings is obtained by processing fuel in boilers that heat the coolant

Types of heating boilers

Conventionally, heating boilers can be divided into autonomous and manual loading.

Depending on the fuel used, autonomous boilers are:

- liquid fuel.

The order in the list determines the cost of heating depending on the type of fuel: gas boilers will be the cheapest to operate.

Image gallery

Installation of a gas wall-mounted double-circuit boiler is not a final action that fully ensures the operation of the heating system and DHW supply.

Boiler - essential element heating circuit, it provides hot water supply, but it is only a source of thermal energy.

To evenly distribute heating over the entire area of the house, a peripheral part of the system is required, which is installed based on operating conditions, room configuration and other considerations.

Mistakes made during its creation can negate all costs of purchasing a boiler and reduce heating efficiency to a minimum.

Let's take a closer look at this issue.

Boiler piping is a complex of pipelines and external components that is installed on gas boilers and heating appliances. In addition, piping is usually called the process of installing the periphery that forms the external part of the heating circuit.

Since the boiler is a double-circuit boiler, together with the heating it is necessary to assemble the DHW wiring and connect it to the water supply devices. Installation - responsible and important work, requiring the involvement of competent, qualified specialists.

It is also possible to independently strap the system if the user has the skills soldering work on copper or knows how to handle polypropylene pipelines.

In any case, the result depends on the thoroughness and accuracy of the contractor, his level of training in the creation of heating systems.

Advantages and disadvantages

The advantages include:

- It becomes possible to supply thermal energy to the premises through coolant circulation.

- The organization of hot water supply becomes possible.

- Some boiler models do not have built-in circulation pumps. The harness allows you to use external devices, completely solving the problem.

- Increasing the efficiency and economy of the boiler and the entire system as a whole.

- The need for careful design of the heating circuit.

- We have to perform a complex of complex and time-consuming work.

- For tying it is necessary to involve experienced specialists.

Despite the existence of some disadvantages, the operation of the system without strapping is impossible. Therefore, the main task becomes competent design and quality work installers.

NOTE!

All attempts to minimize labor costs or financial expenses V in this case dangerous - they can lead to destruction or unproductive operation of the system.

What elements does the diagram contain?

The wiring diagram is a complex made up of the following elements:

- Circulation pump.

- Valves for various purposes(safety, reverse, distribution, etc.).

- Expansion tank.

- Ball valves - drain, balancing, etc.

- Pressure gauge.

- Filters for purifying liquids from solid particles.

As a rule, most of these components are built into a wall-mounted double-circuit boiler, and there is no need to duplicate them in the external part of the system. Elements such as a circulation pump, expansion tank, all taps and valves are initially present in the boiler design as components.

A modern unit practically does not require the installation of external components, connecting directly to the system. The exception is non-volatile boilers, not equipped circulation pump and other important elements.

An important element of the piping is air removal devices. A circulation pump can perform this function, but the efficiency of the process is low and takes a long time.

It is easier to install Mayevsky taps on radiators and place the supply pipeline in vertical position(on non-volatile systems). In addition, pressure and temperature monitoring devices, which provide information about the operation of the system, are of great importance.

Shut-off valves allow you to regulate or cut off the system lines in case of emergency situations.

What materials are used

Materials for the manufacture of pipelines in heating systems are:

- Steel. In Soviet times steel pipes were practically the only option. They are cheap and can withstand high pressure. The disadvantage is the need for welding and the tendency to corrosion and formation on the internal walls. limescale, capable of completely blocking the pipeline cross-section. Later pipes appeared from of stainless steel, which are not prone to lime deposits and corrosion.

- Copper. The most common material for creating piping for gas boilers. Connected by soldering, withstands high pressure. Not prone to corrosion or deposits on the inner walls of the tubes.

- Metal-plastic. Pipes appeared relatively recently. Their main value lies in the ease of installation - it does not require welding, all connections are made using wrenches. Metal-plastic pipes have plasticity, which in some cases makes it possible to do without fittings.

- Polypropylene. A special soldering iron is used to install it, but it is inexpensive, like the pipelines themselves. Recently, this material has been actively used for assembling systems in private homes, since such pipes do not burst when frozen. The autonomous system assembled from polypropylene pipes will remain intact in the event of an accident, which is highly valued by users. The walls of the pipelines are quite thick, which some people think is a disadvantage.

- Polyethylene low pressure(PND). These pipes are also not burst by frozen water. However, HDPE pipes are not suitable for heating systems because they have low operating temperature. They can only be used for the external part of underfloor heating systems.

Choice of the most suitable material determined by the capabilities and preferences of the home owner.

Piping diagrams for a double-circuit wall-mounted boiler

There are several strapping schemes used depending on the type and specific features of the system:

- Gravity circuit, which is used in systems with natural coolant circulation. Pipelines and radiators are installed with a slope that ensures that hot layers of liquid move up and cooler layers move down.

- Circuit with a circulation pump. The coolant movement is forced, the operation of the system is more stable and efficient. This option is used most often.

- Collector circuit. It appeared relatively recently; its difference from the generally accepted options is the connection of the boiler to the manifold, from which all lines of the system are powered. Suitable for complex systems, consisting of radiator line and heated floor.

- Emergency scheme. It is designed for use in the event of a sudden power outage. Usually boilers stop working, but if there is an emergency piping circuit, you can use heating for natural circulation coolant.

Both collector and emergency circuit are more expensive and require more labor during assembly. At the same time, they allow you to get more effective work heating and the ability to heat the house during a power outage.

What does the scheme depend on?

The choice of piping scheme depends on the configuration of the heating system, its type and composition.

The main influencing factors are:

- Type of system - open or closed.

- Is there an additional water heater (boiler).

- Are there additional circuits or a heated floor system?

Depending on the combination of certain elements, different connection methods can be used:

- Direct connection. Used on conventional systems that do not have any add-ons.

- With hydraulic separator. This option is necessary when there are several circuits with different temperatures- a heated floor system cannot have a temperature higher than 30°, and the radiator circuit requires a significantly higher temperature.

- With additional heat exchanger. This is a method when the coolant from the boiler circulates in a small circle, and there is another heat exchanger outside, where thermal energy is transferred to another. liquid directly circulating in the system. This option is rare and is used where needed different types coolant (with different freezing temperatures).

Choice the desired option depends on the configuration and composition of the system. Most often, a direct connection is used, which is simple and reliable..

Doesn't depend on what

The piping scheme does not depend on the type of boiler and the type of fuel used. The same piping methods are used for all types and designs of boilers, regardless of the installation method (floor or wall), the type of fuel (gas, pellets, electricity or diesel fuel) and so on.

For complex systems, minor amendments are sometimes made at the design stage, but they do not play a decisive role and do not change the general principle.

The only difference that is possible is the piping for single- and double-circuit boilers, when either there is or is not a hot water supply line.

The most popular scheme

Let's look at the procedure for creating the most popular type of binding - straight. The most common are energy-dependent boilers, so a piping scheme with an existing circulation pump will be described.

Necessary actions:

Installation of all devices

All radiators, washbasins, bathtubs or showers are installed, kitchen sink. It is necessary that by the time the elements of the heating circuit or DHW are connected, all elements are installed and ready for connection.

The readiness of the heating line is especially important, since the hot water supply circuit works for delivery and can be expanded during operation.

Connecting heating system pipelines

All radiators are connected in series with each other by pipelines. One end is connected to the flush line (supply) of the boiler, the other to the return line.

It is important to ensure the tightness and integrity of the system. To avoid errors, you should constantly check the wiring diagram created during the design of the system.

DHW connection

A pipeline is installed, connected to the DHW pipe of the gas boiler. Taps for mixers are connected to the gap through tees. It is recommended that each mixer be equipped with its own ball valves to shut off the water supply when necessary.

The last step will be to connect the boiler to the power line - supply cold water . After this you can make trial run and check the quality of work and integrity of all pipelines.

All detected errors are immediately eliminated, for which the system is stopped, the water is drained and the circuit is readjusted.

Reviews

Let's consider the reviews of the owners autonomous systems heating:

(( reviewsOverall )) / 5 Owner rating (3 votes)

Your opinion

0"> Sort by: Most Recent Highest Score Most Helpful Worst Score

Be the first one to leave a review.