Sheathing the foundation with basement siding. How to cover the foundation with basement siding if the walls are already covered with siding? Panel installation algorithm

Read also

Since the base of the foundation is located close to the ground and is part of the foundation of the house, it must be decorated with a material that is durable and resistant to various types of influences. In addition, the aspect of beauty plays an important role here. Basement siding is currently a very popular material for finishing that part of the foundation that is located above the ground. Its popularity is justified by its low cost and excellent quality characteristics.

If you decide that the house will be covered with basement siding yourself, then it is imperative that you familiarize yourself with the technology and all the nuances of carrying out this work. Otherwise, you may end up with a completely unpresentable appearance and poor quality coating. This article will tell you how to attach basement siding and what is important to consider when carrying out the work.

Features of siding installation

In order to sheathe the foundation with high quality, you need to comply with certain requirements and take into account a lot of nuances:

- Siding panels can serve as finishing only for vertical surfaces. If the base of the house is protruding, then its upper plane is formed by ebbs, but not by siding.

- Fastening should always be done starting from the left side and working to the right.

- During installation, it is imperative to take into account changes in the dimensions of the material due to temperature changes and other conditions. Backlashes, expansion joints and gaps are made at the junctions of the panels with each other and with the extensions.

- The panels are mounted on a sheathing or on a surface covered with plywood.

- All fasteners are screwed or driven into the base by at least 1 cm.

- In order to provide insulation, but not create a greenhouse effect, breathable materials, not foil, should be installed under the panels.

- The fastening element is installed in the very center of the hole on the panel and is not hammered in completely, but a small gap of about 1.5 mm is left between the head and the main surface.

Advice! Calculation of basement panels for covering the foundation with basement siding is made by dividing each foundation width by the length of one panel. Afterwards, all the resulting numbers are added up and result in the required number of parts.

Usually one panel is enough in height, but sometimes you have to install 1.5 - 2 times more parts.

Installation of basement siding

Although basement siding is a very easy-to-install material, it is still better to adhere to the work algorithm in order to do everything correctly. We’ll talk about how to attach basement siding and what you need to do this below.

What materials will be needed

Siding is a panel-type material that protects the external surfaces of walls from the adverse effects of the external environment. In order to sheathe the base with high quality, you will need the following set of materials and tools:

Preparatory work with the base

Before attaching the siding, you need to install the sheathing on the base. In rare cases, panels can be fastened directly to the surface of the base without sheathing, but it must be perfectly flat, which is extremely rare.

Important! It is better to make the lathing from a metal profile, as it is more durable than wood.

The height of the sheathing is selected based on the climate conditions in which the work is carried out. If the soil is prone to freezing during the winter, then the sheathing rises 15 cm above the soil level. If there is no freezing, then installation can be carried out without retreating from the ground surface.

The lathing is attached horizontally in three rows at the top, bottom and in the middle. It is clear where to attach the lower and middle ones, and to attach the last guide you will need to determine the place where the upper part of the panel is located and secure the profile in its place. The metal elements are attached to the base using self-tapping screws and dowels. The method of arranging three horizontal profiles is suitable for designing a plinth one panel high.

You can also make a mixed type horizontal-vertical lathing. In this case, the vertical profiles should be located at a distance of no more than 90 cm from each other, and the horizontal ones in increments of 45 cm.

If the house has a pile foundation, then it is necessary to install an overhanging sheathing along the bottom, which will subsequently be sheathed.

Panel installation algorithm

Typically, sheathing with siding panels occurs with the preliminary installation of additional parts. This is done in the following order:

Installation nuances

Each detail of a house's siding must be secured with a minimum of 5 fasteners.

The fastener must be screwed in at an angle of 90 degrees to the main surface.

There should be no tension between the panels; they should have small gaps between each other in case of size changes.

If the house is located in the northern region or on soil with close groundwater, then before installing the siding on the base, you need to lay layers of heat and waterproofing.

Important! For waterproofing, a specially designed polyethylene film is used.

Also, to install a waterproofing layer, a special mastic can be used, which is made using natural and artificial resins. Insulation can be done using polystyrene foam or mineral wool, which is popular when working with the foundation. At the moment, the construction market offers a huge number of different insulating materials, from which you can choose the right one.

At the time of installation of the base panels, care must be taken to create ventilation for the space that has formed between the wall and the panels. To do this, round holes are cut out in some places on the panels, which are covered with metal mesh after the cladding is completed, to prevent solid contaminants and small animals from getting inside.

Conclusion

Siding for finishing the plinth is a very convenient material for installation and relatively inexpensive compared to other materials. You can install siding on the foundation yourself, but you must adhere to the work algorithm and check each step.

Finishing the base with siding is considered one of the most affordable and easiest to implement methods. This type of design allows you to simultaneously perform a decorative and protective function. The technology for carrying out the work does not require rare skills; it is enough to follow all the subtleties and sequence of stages. This approach will ensure the preservation of the decent appearance of the building for a long time and protect the base material from destruction.

Choosing this method of decorating the lower part of the building has a number of advantages.

- The service life of the material is more than 50 years, during which time its color and shape remain unchanged provided that it is properly installed and maintained.

- The lined surface is not afraid of attacks from small rodents and insects.

- Low weight does not lead to increased additional load on the foundation.

- Temperature range (from – 50 to +50°C) allows the material to be used in almost all climatic zones.

- The presence of internal space promotes good air exchange and prevents the accumulation of moisture and the development of mold and mildew. The gap can also serve as a place to place a layer of insulation.

- Installation work does not take much time. This is due to the presence of special devices (locks and latches).

- Simple care of the lined surface allows you to effortlessly maintain it in perfect shape.

- Wide selection of colors and textures. Modern panels imitate various natural materials.

- It is possible to finish the plinth with complex geometry with siding.

- Affordable cost of material.

- Environmental Safety.

- Siding is used to design different surfaces and types of foundation.

Criteria for choosing siding for finishing

There are two options that are used when selecting panels.

The first criterion concerns the material of execution. For production most often used:

- polyvinyl chloride;

- polypropylene with acrylic coating.

Metal siding is less common. This is explained by the need to treat the panels with anti-corrosion agents, as well as the need for careful maintenance.

The method of laying the elements is the second criterion. Finishing the base of a house with siding can be done horizontally, vertically, or include both options at the same time. The horizontal arrangement of panels is more often used. This is explained by the fact that the work is being carried out in a small area, with almost no openings.

Overview of siding materials

Different types of materials are used in the production of panels. Their characteristics have their pros and cons.

Vinyl siding for the exterior of the basement is suitable for the exterior design of the house. It is made from polyvinyl chloride. It is able to imitate different textures and pleases with a wide color palette. Such panels can be used from – 50 to +50°C, subject to the introduction of special additives responsible for plasticity. Otherwise, at temperatures below – At 10°C the material cracks. Affordable price and light weight make the use of vinyl siding attractive. However, a combination of high humidity and sudden changes in temperature can cause unwanted deformation of the plates. This species also does not tolerate mechanical stress well.

The polypropylene analogue has almost the same advantages. In addition, it does not crack upon impact of low force, is inert to the action of microorganisms, and the surface layer of acrylic holds firmly and reliably protects from ultraviolet radiation. This design allows you to maintain the brightness of the color for a long time, and also withstand heating up to 85°C. Significant strength properties, immunity to chemicals and lack of flammability are the main advantages of the material. The disadvantages include higher cost.

Metal siding is the most resistant to various types of impact, so finishing the base with metal siding has a number of advantages. Unpleasant features are low sound insulation, increased noise levels, and the possibility of peeling off the protective coating at the cut site. Aluminum plates are not resistant to mechanical factors, and if their integrity is damaged, they require replacement.

There are different types of panels that are a worthy imitation of natural material.

- The option of finishing the base with stone siding is popular. It has a rough surface that gives the full impression of a stone wall.

- The material in the form of brickwork was obtained from a cast of the original, therefore it accurately repeats all its nuances.

- Rubble stone panels consist of elements of different sizes, arranged in random order. This option for finishing the base with siding in an individual private house looks original and beautiful.

- The “Alpine Granite” variety is made from polypropylene. The service life without loss of appearance reaches more than 30 years.

- Covering the base with “Rocky Stone” siding allows you to obtain a relief finish, with a bright, pronounced texture, in different colors.

Finishing the base with siding yourself

The work is carried out in several stages, but first you should stock up on everything you need. In this case, the process of finishing the base with siding will not cause any particular difficulties or delays.

Tools

The set of installation accessories must include:

- hammer with rubber striker;

- screwdriver or electric screwdriver;

- perforator;

- building level;

- special scissors for cutting metal;

- hacksaw, jigsaw or grinder;

- tape measure, marker;

- fishing line or wire;

- hook for dismantling.

Calculation of the amount of finishing materials

To avoid unnecessary waste of time, money, and nerves, it is advisable to carefully calculate the required number of panels. To do this, measurements are taken of all areas of the base. Calculate its total area. 10-15% is added to the resulting figure as a reserve for possible waste and trimmings.

In addition to the panels, the number of additional elements is immediately determined. These include: starting and finishing strips, internal and external corners, grilles covering ventilation holes, parts for designing a protrusion, etc.

The frame is made of a metal profile, which is attached to the base using dowels or brackets. Its quantity is calculated based on the total length and multiplied by 3.

Fastening elements: screws, nails, thermal washers, staples are purchased in some excess. Small parts often tend to get lost, and this measure will eliminate the need for a second trip to the construction supermarket.

Surface preparation

The determining requirement when finishing the base with siding with your own hands is to level the surface in accordance with the building level. Otherwise, installation will be very difficult.

They begin by clearing the base of dirt and dust and removing protruding areas. They repair cracks, potholes and other defects. If the base is problematic, it is reasonable to carry out plastering. Damaged elements are removed and new ones are installed in their place, and a metal mesh is attached to the surface. Apply a layer of plaster, smooth it and leave it for several days until it hardens completely.

Creating a wireframe

It is mounted starting from the starting rail, which must be set strictly according to the level. The profile is secured using dowels and screws 10 cm long. The planks are placed at the top, bottom and middle. The distance from the ground to the lower profile is 3-5 cm, the second element is fixed at the very top of the base, and the third is laid strictly in the middle. All parts of the frame must be located parallel to each other. Fastening is carried out every 30 cm.

If necessary, place a layer of insulation in the gaps and attach it to the base. When using mineral wool, a windproof covering will be required.

Fastening sheets

The process is essentially reminiscent of assembling a construction kit. Follow all the steps consistently and a high-quality result will be achieved.

The cladding of the base begins with the installation of a starting strip along the entire perimeter of the house. The correctness of its position is checked according to the readings of the building level. Fastening is carried out using dowels and self-tapping screws strictly in the middle of the mounting hole. The fasteners are not screwed in completely, leaving a gap of approximately 1 mm. This will avoid distortion during thermal expansion of the material.

Often the bottom line of the plinth has different heights. In this case, a camouflage profile is used instead of the starting strip, and the panels require adjustment in length.

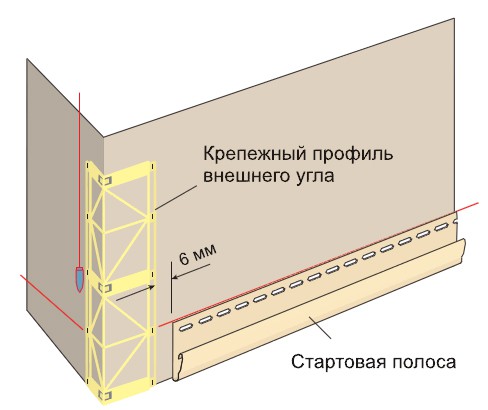

The next step involves installing corner elements.

Work usually starts from the left corner of the building, laying siding from bottom to top.

The first panel is inserted into the starting rail and moved to the left to fit into the groove of the corner part. They check for horizontal compliance and then fix it on the sheathing. Each panel is attached at least 5 points. Attention should be paid to obtaining a uniform gap of 2-3 mm between the sheets.

Further finishing of the basement with basement siding is carried out in a similar way. The last part in the row is adjusted to size, taking into account the required gap.

The next row is mounted in a checkerboard pattern to avoid the joints matching the height of the base.

The top edge is covered with a finishing strip or cornice.

Holes are cut where pipes, electrical wiring and other communication lines exit. It is recommended to calculate their location in such a way as to get to the junction between the panels. The resulting cracks must be filled with waterproof sealant.

The lined base is covered with galvanized steel, the color is selected in accordance with the color of the panels. At the corners, the ebbs are trimmed and overlapped. The joints are treated with silicone sealant. The parts are connected to each other with metal screws.

Frame structures must contain holes for ventilation, covered with decorative grilles or fine metal mesh. It is recommended to make one hole every 3-4 m.

If you carry out the work on your own, it would be useful to learn the secrets of specialists.

- It is better to choose auxiliary elements and fasteners from the same manufacturer as the panels.

- The siding is adjusted using a grinder, metal scissors or a hacksaw. To avoid damage to the material, you should first practice on scraps.

- Self-tapping screws and nails should fall into the center of the hole and enter the sheathing at an angle of 90°. Begin to fix the panel in the installation location from the center to the edges.

- Before starting finishing, it is necessary to keep the panels and other elements outdoors for 3 hours.

- It is important that the joints between the panels are made without gaps.

- When choosing a material, you should pay attention to the uniformity and intensity of color, both on the outside and on the inside. The absence of stains and bright color are a sign of high quality.

- The thickness of the panel must be maintained over the entire plane. Compactions, curvature, swelling, and delamination are not allowed.

- The dimensions of high-quality siding completely coincide with the stated information on the packaging.

- All holes have the same shape, smooth edges.

And lastly: you should not change the siding finishing technology at will. Such amateur activity increases the risk of deformation and destruction of panels at the fastening points.

At first, it is enough to wash away dust and small dirt with water from a hose, avoiding high pressure.

Treating the surface with a soft brush helps a lot. Hard bristles and abrasive products can scratch the coating.

In case of mold growth, oxygen bleach will save the situation. Products containing chlorine are not used for these purposes. There is also a taboo on all organic solvents. To achieve cleanliness, professionals suggest treating the surface with one of the following compounds.

- A solution of 700 ml water and 300 ml table vinegar.

- A mixture of 4 liters of water, a third of a glass of washing powder and half a glass of oxygen bleach.

After applying the mixture, leave it to act for no more than 10 minutes, rinse with clean water until the residue is completely removed.

Good results are obtained by using regular dishwashing detergent diluted with water.

Protect the surface for a long time in autumn – In winter, special wax-based mixtures will help. After treatment, the panels become water-repellent.

If these methods fail to prevent the appearance of mold, then a solution of copper sulfate in a concentration of 100 g per 10 liters of water can be applied to the base.

More and more often we see houses on the streets whose basement is covered with siding. It is in favor of this material that many people make a choice and refuse to use traditional brick.

This trend can be fully explained, because siding for cladding the basement of a house has its advantages and disadvantages. Let's talk about this in more detail. In addition, we will consider the process itself - how exactly the house is finished with basement siding. This is really interesting, because there are a lot of nuances in such work that it is better to know before starting repairs.

Pros and cons of siding for finishing the basement

So, suppose you are seriously thinking about using siding to cover the basement of a cottage or an ordinary private house. It's time to talk about why this material is so attractive, whether it is worth using it in finishing work at all, or is it easier to choose some other time-tested solution.

Details:

- Facing with basement siding is good in the sense that this material perfectly tolerates temperature fluctuations, as well as various external influences. As experiments have shown, siding does not lose its properties when the temperature is in the range from minus fifty to plus thirty degrees;

- The material is perfect for finishing various external surfaces, and the type of structure can be any - this does not play a special role;

- The front part is finished with materials of special resistance - due to this, the entire structure benefits in durability - this cannot be denied;

- You can always use additional insulation - thanks to this you will benefit from reducing heating costs;

- If you decide that finishing your house with basement siding is exactly what you need, there is no need to doubt it. The material has an aesthetic appearance, and you can easily choose for yourself exactly the texture, exactly the color that you require. Not every material allows you to do this;

- The finishing material weighs very little (compared to stone), so there is no need to strengthen the foundation - this is also good, because such a procedure is not easy to perform and is expensive;

- Installation of siding on a plinth is carried out quickly, the work is not complicated - many consumers are captivated by this very moment. Strictly speaking, every person is capable of producing such finishing if he has the desire - he doesn’t even need assistants;

- The cost of the material is more than suitable; due to this, almost any family can afford basement siding.

Before you go to the store and purchase this siding, also find out what disadvantages are typical for this material. But they exist – and now we’ll talk about it.

Flaws:

- Cladding with this siding will seriously increase the dimensions of your basement section. The material is attached to the frame, which is why the area increases;

- If we consider the minimum installation distance, it is only 100 mm. In general, a lot depends on how flat the base plane is.

Before purchasing, please note that basement siding from different manufacturers can vary significantly in quality. If you don’t want to take risks, make a choice only in favor of the famous ones.

It is better not to purchase such material from Chinese little-known manufacturers. Remember that products may not only be of poor quality, but even harmful to your health and the environment!

In addition, a disadvantage of siding is that if the fastening is done incorrectly, condensation may appear. It is very harmful to the main wall; it also causes fungus to appear, which will not have the best effect on the original condition of your base. Watch the video on how to properly install siding on a plinth - this will help you avoid common beginner mistakes.

Installation of basement siding

If you have decided for yourself that this particular finishing option will be the most optimal, it’s time to talk about how the installation is carried out. The fact is that the work should be carried out in accordance with certain fastening rules - they cannot be ignored. Otherwise, you can’t count on the cladding to last for a long time.

Preparing the surface

We can say that finishing begins precisely from this point. If you prepare the surface incorrectly, then there is a high probability that very soon everything will have to be redone. Roughly speaking, starting from scratch, and no one wants that. If the preparation is done correctly, you will not be afraid of many troubles, and the service life of the entire structure will be very long.

What do we have to do:

- Finishing with basement siding begins with careful preparation of the main surface. First, you must remove all the coverings that were previously there (if any). Usually a metal brush is ideal for removing all this. If the old coating doesn’t hold up well at all, you can simply knock it off with a chisel and hammer;

- When the previous step is completed, you need to apply an antiseptic to the surface - you can easily find it in any hardware store. An antiseptic must be applied, there is no way without it;

- Next, a layer of primer is applied to the surface.

Installing basement siding

Covering the base with siding is usually done on the sheathing - it is on it that the weight of the entire structure will be supported. In addition, the sheathing is responsible for ensuring that the correct geometric shape is formed. That is, we are talking about very responsible work, and it is too early to relax at this stage.

How exactly is the sheathing installed in order to finish the base with siding? If winters in your region are not very cold, installation can be done directly at ground level. And if everything is different, it is lowered below the ground by 100-150 mm.

When marking to install the cladding, keep one important detail in mind. It is important that the floor line is covered with insulation. This is done taking into account the dew point. In other words, you cannot forget about physical laws - otherwise you will only get the opposite effect.

- The most crucial moment is the installation of the very first panel. It should be fixed as evenly as possible, and the first siding panel should be positioned strictly parallel to the ground. To do this, proceed as follows: make a mark on the wall. After this, it will need to be correctly transferred to other planes. If you make an uneven line, then in the future the entire structure will have an irregular geometric shape. To avoid mistakes and not take risks, a construction level is used in the work - you can easily buy it today. So, we move the mark;

- Next, the lines need to be connected - specifically so that the mounting outline is indicated. To do this, you can use a nylon thread or simply fill the required installation level;

- The starting rail is attached in accordance with the line that we made. When its installation is completed, the internal and external corners are fixed at the corners of the room;

- The panels themselves are mounted using steel nails, the length of which is no more than 4 cm, and such nails have a wide head. To make the fastening more reliable, it is better to use self-tapping screws - but they are used only in combination with a press washer. This connection will be truly reliable.

Please note that when connections are made, they should not be made too rigid. A gap must be maintained - but not more than 1 mm. Connections are made only through special holes that are available on the panels. This is necessary specifically to avoid damage due to thermal expansion.

In addition, thermal clearances should be made at the corners of your structure. In the future, they will simply be hidden by special decorative overlays, so that the overall aesthetics of the finish will not be affected.

Finishing the fastening of the panels:

- When the sheathing is installed, the insulation is attached. During this process, it is important to remember that the waterproofing is installed first, and only after that the panels with insulation are installed;

- It is recommended to start installation from the left side. What is also interesting is that if your task is to create an imitation of brickwork, you should trim the panel along the left edge so that the edge comes out even;

- The panel is then installed in the very first one (starting panel), as well as the platband, which looks like a corner. Next, they attach it to the rail;

- All subsequent panels are attached in exactly the same way;

- The last panel usually does not go in completely, so it is first applied and marked. Next, they are cut to the required size, inserted into the corner, and carefully secured;

- When the cladding is completed, the finishing strip is attached.

That's all - the basement of the house has been covered with siding. Now it's down to the little things - you can apply a protective coating to your finish if you wish. Products that contain wax are best suited for this. This is good in the sense that water will be repelled - the coating will always be under reliable protection.

It is better to apply such products before the onset of winter - due to this, the entire resulting structure will remain in its original form for much longer.

The construction of any buildings is a step-by-step process that must be completed to the end. At the final stage, it is necessary to cladding the building, which will ensure its durability and attractive appearance. Now one of the popular types of facing material is basement siding.

First, a few words about what accounts for this popularity:

- Low

- A simple technology for installing siding on a plinth. Even a non-professional can work with siding

- The shortest terms for facing work. You can cover your house with siding in a couple of days.

- Stylish appearance, large selection of textures and colors

- It is these indicators that made basement siding so attractive to home owners

Description of material

Modern basement siding is a material made in the form of panels. The panels are made of vinyl, and this is what ensures its durability; vinyl does not deteriorate for fifty years. The material is not afraid of various atmospheric conditions, ultraviolet rays and frost. Plinth panels are not exposed to temperature changes ranging from + 50 to - 50.

Modern basement siding is a material made in the form of panels. The panels are made of vinyl, and this is what ensures its durability; vinyl does not deteriorate for fifty years. The material is not afraid of various atmospheric conditions, ultraviolet rays and frost. Plinth panels are not exposed to temperature changes ranging from + 50 to - 50.

The physical characteristics of the material include its lightness; the material does not create a load on the lined wall. The material does not require additional investments, does not require painting or coating with any substances. These indicators indicate that the siding is installed once and does not require any maintenance during further operation.

Material calculation and purchase of additional parts

To start finishing the basement of a house with siding with your own hands and carry it out effectively, you need to carefully consider purchasing the necessary materials and fasteners. you need to start by calculating the area of the wall that will be covered. The area is calculated as follows:

To start finishing the basement of a house with siding with your own hands and carry it out effectively, you need to carefully consider purchasing the necessary materials and fasteners. you need to start by calculating the area of the wall that will be covered. The area is calculated as follows:

The height of the wall must be multiplied by its length.

Thus, it is necessary to measure all the walls and the results obtained. The final calculation figure must be divided by the square footage of the siding, which is indicated on one pack. We get the approximate number of packs of siding that will be needed for cladding. To avoid troubles, panels should always be purchased with some reserve.

What else is needed to cover the base with siding?

- Metal profile for sheathing.(Its calculation is carried out piece by piece, the length of the wall is measured and it is estimated how many profiles are needed to lay them to the top at a distance of 40-50 cm. The height profile is also calculated in the same way.)

- Self-tapping screws. They need to be purchased in sufficient quantities, since they will be needed for both sheathing and siding.

- Additional details.(Angles, modules, sockets, etc.)

- Insulation. (In case you plan to lay it under siding. Calculation of the amount of insulation is also done based on the square footage of the walls.)

- Tools. (Screwdriver, grinder, assembly knives, hammer, scissors, tape measure, level, metal ruler)

It is better to purchase materials immediately so as not to be distracted from work later. It is also better to calculate the costs of these acquisitions in advance, at least approximately. For example, the price of siding for a basement ranges from 400 rubles to 1200 rubles per square meter.

How to prepare a house for siding installation

Another positive characteristic of this material is the fact that no special preparation is required before installing the base with siding. That is why old houses made of adobe or shingles are often covered with siding. Such walls cannot be plastered or mounted with any heavy materials, and siding is an ideal material in this case.

Another positive characteristic of this material is the fact that no special preparation is required before installing the base with siding. That is why old houses made of adobe or shingles are often covered with siding. Such walls cannot be plastered or mounted with any heavy materials, and siding is an ideal material in this case.

The walls that are going to be covered with siding do not need to be peeled, plastered or covered with any material. You just need to check that there are no protrusions or sharp protruding objects on the plane of the wall.

After the wall has been inspected and all bulging areas have been eliminated, the creation of the frame or sheathing begins. In most cases, siding is mounted on a sheathing made of wooden blocks or metal profiles. Sometimes siding is mounted directly on the wall, but this is only possible if the wall surface is perfectly flat and the wall material allows the installation of fasteners.

Important: The lathing must be made of a metal profile, as it is guaranteed to last longer than wooden blocks, even coated with special impregnations.

How lathing is done

You need to start installing the sheathing directly from the ground, or directly from the ground. The first guide profile must be leveled and strengthened at a distance of approximately 5-10 cm from the ground surface. If there is a concrete blind area around the building, then it can be mounted directly from the blind area.

You need to start installing the sheathing directly from the ground, or directly from the ground. The first guide profile must be leveled and strengthened at a distance of approximately 5-10 cm from the ground surface. If there is a concrete blind area around the building, then it can be mounted directly from the blind area.

The distance of the sheathing from the wall will also depend on the purpose of installation. If you intend to lay insulation between the wall and the siding, then you need to retreat as many cm as the thickness of the insulation. But if a simple installation of siding is carried out, then the thickness of the profile will be sufficient. The profile is mounted in the form of a lattice, that is, it is mounted parallel and perpendicular. The result should be squares approximately 50 cm by 50 cm.

Tip: Particular attention should be paid to the corners of the building; if you wish, you can create curly or protruding corners; they are also made from their profiles.

Installation instructions for basement siding

The installation of this material must begin with the installation of the first panel; special attention must be paid to this. The first panel should be aligned very level so that all other panels are also level. To do this, the corners of the sheathing are equipped with starting rails, to which the panels are attached. The starting rail is mounted on the profile using metal screws. After this, a panel is inserted into the starting rail and secured with self-tapping screws.

Tip: The screws should not fit tightly to the panel, that is, they do not need to be scrolled all the way. The screw head should be at a distance of 1 mm from the surface of the panel.

Installation instructions for basement siding

Installation instructions for basement siding Installation of siding panels

Siding panels should always be mounted from left to right, the panel should be inserted into the previous one and clearly rest it against the groove on the previous panel. Then the panel must be secured with several screws, and so on. The main thing is to carefully insert the next panels and make sure that there are no gaps at the joints. There are some nuances to this process:

Siding panels should always be mounted from left to right, the panel should be inserted into the previous one and clearly rest it against the groove on the previous panel. Then the panel must be secured with several screws, and so on. The main thing is to carefully insert the next panels and make sure that there are no gaps at the joints. There are some nuances to this process:

- The final row of siding is installed only after installing the final strip

- To avoid swelling and deformation of the siding in the future, it is necessary to avoid strong tension on the panels during installation

- Installation of siding panels must begin from the bottom up

- When installing siding under eaves or window sills, you first need to attach a couple of finishing slats and then just start installation

- If you need to cut holes in the siding panels for gas pipes or heating pipes, then the hole should be approximately 6 mm wider than the diameter of the pipe

By covering an old wooden house with basement siding, you can breathe new life into the appearance of the house. Finishing with this material will give a unique design to the building. Knowing and following all the rules, siding will last for many decades.

By covering an old wooden house with basement siding, you can breathe new life into the appearance of the house. Finishing with this material will give a unique design to the building. Knowing and following all the rules, siding will last for many decades.

Basement siding goes well with other types of siding, for example, metal. Read about installing metal siding yourself. This material is reliable and also resistant to the vagaries of nature.

Final finishing

The final stage of finishing with siding will be to give the entire structure a finished look. To do this, you need to use all kinds of corners, both internal and external, small modules and small parts.

The final stage of finishing with siding will be to give the entire structure a finished look. To do this, you need to use all kinds of corners, both internal and external, small modules and small parts.

Video about installing basement siding

How to cover the base of a house with siding.

Video instructions for installing basement siding. Basic principles of installation.

Basement siding installation technology. How to turn an ordinary country house into a beautiful fortress using basement siding.

Cladding the façade of buildings with tiles, natural stone or wood is now considered an unnecessarily labor-intensive task. Complex structures that have natural roots and reduce the amount of these very natural materials are being replaced by lightweight panels made of plastic, vinyl and metal. Siding is not only an environmentally friendly type of building decoration, but also very economical. And if you don’t want to clad the entire house, but you simply need to create a confident and strong foundation for the house, unpretentious but picturesque basement siding comes to the rescue.

Kinds

The cladding of the basement of a building is divided into types according to two criteria: material and installation method.

The most common materials for siding:

- polyvinyl chloride;

- vinyl;

- polypropylene.

All of them are universal finishes for basement siding because they have excellent resistant properties: to ultraviolet radiation, to moisture, and to temperature changes. They can easily last for many years. Of course, metal siding is also available. But it requires additional treatment of the material itself with anti-corrosion agents and more careful maintenance.

Depending on the installation method, types of basement siding can be horizontal or vertical.

Most often, it is for the lower part of the building that professionals and amateur construction workers use horizontal laying. And in order to provide the base of the house with high-quality cladding as simply, quickly and efficiently as possible, you need to acquire the basic tools and prepare the base of the building for installation.

Preparation and tools

Before proceeding directly with installation, it is necessary to prepare the surface for work.

First of all, attention should be paid to the evenness of the walls. Basement siding will give away any of your skeleton (read: unevenness). And it should also be remembered that when covering the base of a house with synthetic canvases, an excellent environment for the appearance and spread of fungus, mold and other moisture-loving microorganisms can form underneath. Therefore, the walls under the slabs must be treated with an antiseptic or any other impregnation.

A prerequisite before laying the siding slabs is to clean the base from debris, dust, cobwebs, etc., so that the surface is perfectly free of foreign objects.

The next step in preparation will be to decide on the insulation or ventilation of the facade. Since both of these phenomena are very common in today's environment, training should be carried out with these features in mind. With any of these options, it is necessary to make allowances for the purchased materials.

To install basement siding yourself, you will first need the following tools:

- screwdriver - you can use your grandfather’s old screwdriver, but such work will take more time;

- self-tapping screws with a flat head (a lot of screws);

- water or infrared level;

- metal hacksaw or jigsaw.

Of course, each case and each master has its own set of tools. This list is meant to get you started.

As for the components of the siding itself, everything is simple. To install the panels on the plinth, you need: lathing (metal profiles or wooden blocks), starting strip, finishing profile and j-profile. That's it for attaching the panels to the plinth wall. The main parts that make up the siding itself are: sheathing panels with the selected design and corner panels.

But before you buy these components of the future “face” of the foundation of the house, you should make preliminary, as accurate calculations as possible.

Calculation of material quantity

It is not difficult to correctly calculate how much siding is needed to finish the basement. But special care should be taken here. Nobody wants to go to the store in the middle of the installation process and buy more material. Or, conversely, buy a bunch of panels, and then don’t know where to put the rest, and why so much money was spent.

Let's start measuring the base of the façade of the house. Measuring the width and height of one side will give you the surface area to cover. Do the same with the rest of the sides of your country house or country house. Adding all four numbers gives you the total surface area.

In hardware stores today you can find a wide variety of wall panels for siding from different companies and manufacturers. So, you can find different sizes, textures, and installation methods. Some manufacturers produce their products already with fastenings specifically for their panels. Moreover, each package indicates the exact total area of the panels and the usable area. Pay attention to the first value and calculate how many packages of this material are needed in your case.

Be sure to add 10-15% to the resulting number of packages. This will help you remain confident that in the event of force majeure you have reserves. At the same time, this is not an exorbitant amount that costs crazy money.

With a complete set of materials, components and tools, you are happy to begin installing basement siding.

Step-by-step instruction

When starting to install basement siding with your own hands, you should start with a supporting base. It is worth noting here that in some cases lathing is not required. When the walls of the house are perfectly smooth (from foam and gas blocks, etc.), sheathing as such may not be needed.

Installation of the sheathing begins with the installation of the planks you have chosen: wooden or metal. The next step is the correct placement of these planks.

There are three types of sheathing installation:

- vertical;

- horizontal:

- combined.

For cladding the plinth, horizontal is best suited, since this is a small area with practically no openings. If you decide to cover the entire house with siding panels at once, then it makes sense to install a common vertical or combined sheathing.

Let's focus on the metal profile. From the outside, the profile strips are attached to the base using dowels and screws (if the wall material is brick or stone). An important point is to leave a gap of one to one and a half centimeters between the head of the screw and the sheet to allow temperature fluctuations to make changes in the shape and volume of all components without compromising the appearance of the siding.

For a timber base, you can use standard self-tapping screws or galvanized nails, also remembering to leave a small distance between the head and the base.

Do not forget, before installing the sheathing on the base, you must complete all steps to insulate or ventilate the facade. After installing the supporting structure, you will no longer have this opportunity.

Once all the work on installing the sheathing is completed, we begin installing the siding panels. The first to be installed is the starting bar, which is a kind of guide indicating the path for further movement of the entire siding structure. Therefore, it is very important to use a building level at this stage. It also happens that the ground around the house is not level enough, in some places it is even very uneven. It is not possible to cut siding panels in such a way that it looks aesthetically pleasing. This is where the J-profile comes to the aid of builders. This is a metal bar with an external j-shaped harpoon hook. The profile is installed as close to the ground as possible, and the starting bar is attached to it without sacrifice or distortion.

To install the panels on the plinth sheathing, you should follow a certain sequence, which will help you quickly and efficiently install all the panels.

The movement of laying elements occurs from left to right and from bottom to top.

- First, the corner siding element is installed.

- The first piece is trimmed vertically along the left edge to completely line up that side. It is put on the starting strip or J-profile and moved as far as possible to the left to fit into the groove of the corner element. Don't forget to leave natural gaps between siding panels.

- The level of this part is carefully measured. When it becomes exactly level, you can fasten it with self-tapping screws to the sheathing.

- Continue installing subsequent elements in the same way. Each subsequent row is laid in a checkerboard pattern so that the joints do not run in a straight line along the entire height of the base.

- Before installing the last row, the finishing strip is attached.

Installing basement siding is not a particularly complicated process, but it requires care and precision, without which it is impossible to achieve a good final result.

I would especially like to focus on covering the pile foundation with polyvinyl chloride panels.

Screw piles are used to base a house in places where it is simply impossible to level the ground surface, and the owners do not want to bother and wait a long time. The main difference between basement siding in such structures is that first of all it is necessary to very carefully treat the piles themselves with a waterproofing agent and carry out all the necessary drainage work. Check for debris, vegetation or wildlife burrows under the house. The rest is all done in the same sequence as with a regular base.

When installing basement siding with your own hands, you can resort to the advice and recommendations of experienced specialists.

- If you want to recreate curly, unusual corner structures, you can also use a metal profile that can take any shape if you make small cuts in the right places.

- The number of decorative siding corners is always equal to the number of rows of plinth cladding panels. Thus, their preliminary quantity can be easily calculated.

- Fixing one corner first, then installing the panels, then covering everything again with a corner is wrong. There is a risk of not calculating and not guessing with the grooves. The installation of all siding elements must be carried out taking into account all the recommendations given in the instructions for it.

- Please note that facing a private house with siding involves the use of a large number of screws or nails. So, one standard panel can take up to five pieces. They must be screwed into special holes. At the same time, so that the load on all panels is distributed evenly, screws or nails should be placed strictly in the center of the holes of the horizontal panels. As for the corners, here a nail or self-tapping screw is inserted into the very first lower hole in its lower part, and then also in the middle.