Submersible pump type ETsV 10 120 60. Warranty periods and service life

Read also

Submersible well pump ECV 10-120-60

Our company provides comprehensive supplies of pumps from stock and to order at dealer prices. Delivery to any location transport company, at the request of the customer.

Table 1

Pump Specifications ETsV 10-120-60

Unit brand

Q, m cubic/hour

H,m

I,A

N,kW

D,mm

L,mm

D sk,mm

M, kg

ETsV 10-120-60

120

60

60

32

235

1615

250

223

Where,

Q – productivity;

N – pressure;

N – engine power, kW

I – current, A

L – pump length, mm

D – pump diameter, mm

Dsk - well diameter, mm

M – pump weight, kg

Fig 1 Dimensions and connecting dimensions electric pumps ETsV 10-120-60

* Guarantee sealing

** Conservation filling

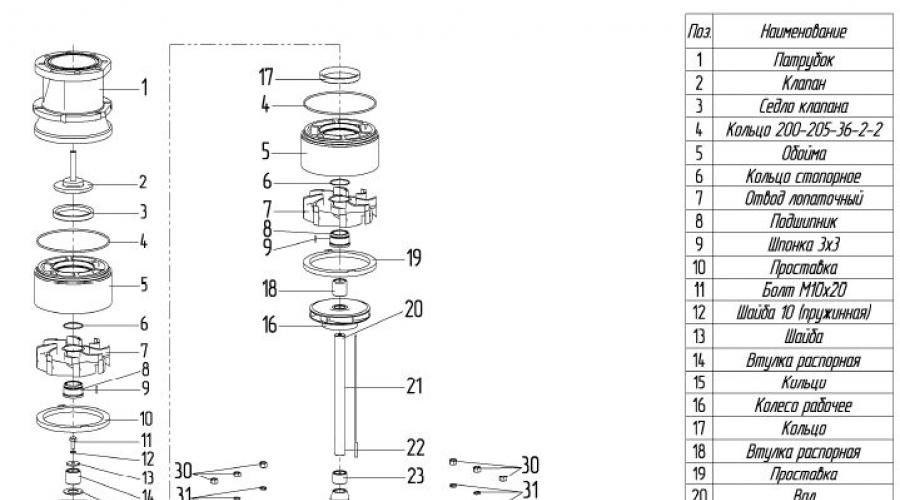

Fig. 2 Design of the ECV 10-120-60 pump

*Equipped with electric motor PEDV

PURPOSE AND APPLICATION

PumpETsV 10-120-60centrifugal downhole submersible

electric pump unitETsV 10-120-60, designed for lifting

from water wells with total mineralization (dry residue) no more than 1500 mg/l with

hydrogen index (pH) 6.5...9.5, with temperatures up to 298 K (25 °C), mass fraction

solid mechanical impurities - no more than 0.01%, with chloride content -

no more than 350 mg/l, sulfates - no more than 500 mg/l, hydrogen sulfide - no more than 1.5 mg/l.

Pumps for clean, artesian water

ETsV 10-120-60can be used for industrial and agricultural

water supply, for water management, housing and communal services, for heat power engineering, as well as for irrigation

and lowering the level groundwater. And for emergency pumping of water and similar

water based on the viscosity of liquids from flooded mines.

ETsV 10-120-60applies to products general purpose type I, recoverable

according to GOST 27.003.

View climatic version U *GOST 15150. The unit is not intended for use

in explosion and fire hazardous industries.

ETsV 10-120-60can be equipped with electric motors DAP or PEDV.

When equipped with a PEDV electric motor, the unit has the symbol ECV.

When equipped with a DAP electric motor, the unit has the symbol 2ETsV.

Design

ETsV 10-120-60consists of a centrifugal pump and an electric motor.

The pump is multistage. The steps are connected to each other by ties made of

steel tape or studs. The shaft with impellers and bushings forms a rotor

pump that rotates in rubber-metal bearings.

Electric motor - three-phase asynchronous with squirrel-cage rotor, submersible,

with a synchronous speed of 50 s-1 (3000 rpm). The electric motor is cooled by washing with pumped water. Rotor rotation direction is right

(clockwise) when viewed from the pump side.

The operating position of the unit is vertical or horizontal (as agreed with the manufacturer). At vertical installation unit load from

There are no pipelines to the pressure pipe.

When installing horizontally, install the unit on special supports and take into account

minimum water level (min 0.5 m). Recommended additionally for the unit

install the cooling jacket. Loads from the pipeline on the pressure pipe

exclude

(e.g. secure the pipeline to appropriate supports next to the unit).

The failure criteria for units are:

Reduction in pressure by more than 15% or reduction in flow by more than 25%

from the value recorded at the beginning of operation;

Stopping the water supply when there is power supply at the output ends

electric motor;

If the current-carrying wire is in good working order, the insulation resistance of the system “current-carrying wire-motor stator housing” decreases below 1 MOhm

when cold and 0.5 MOhm at operating temperature;

Increase in current consumption by more than 25% of the value,

recorded at the beginning of the operation of the unit.

For protection and control, the pumps are equipped with

which protects it from overload and protects the pump from overcurrent, and,

as a result, from breakdown.

The unit must be connected to the electrical network:

Through the control and protection station in accordance with the accompanying documentation

on her;

Or through a circuit breaker, magnetic starter, thermal relay.

The circuit breaker (with characteristic D) is designed to protect

electric motor against overcurrent.

A magnetic starter is designed to start and stop an electric motor.

The thermal relay is designed to protect the electric motor from overload and loss

phases.

The circuit breaker, magnetic starter and thermal relay must be selected based on the power of the electric motor. Connect according to

with accompanying documentation for circuit breaker, magnetic

starter and thermal relay.

Features/Benefits

For ECV:

Consist of asynchronous electric motor PEDV series with improved cooling

and a multi-section centrifugal pump part, interconnected by a rigid

coupling.

The pump rotor and the electric motor rotor rotate in rubber-metal bearings, which allow pumping water with a small content of mechanical impurities

(up to 0.01% by weight).

For 2ECV:

They are a unit consisting of a sealed electric motor DAP and multi-section centrifugal pump part.

The internal cavity of the electric motor is isolated from the pumped water, thereby eliminating the possibility of sand getting into the electric motor bearings and causing the electric pump to fail for this reason.

Corrosion of stator and rotor plates is excluded, which allows significantly

increase the service life of the electric motor and ensure high efficiency throughout the entire service life of the electric pump.

Reliability indicators:

Average product life up to overhaul 16000 hours or service life

5 years, including

Shelf life: 2 years when preserved

Average time to failure is 6000 hours.

The average time to recovery is 8 hours.

The package includes:

Unit - 1 piece;

Instruction manual - 1 pc.

Safety justification (at customer's request) - 1 pc.

Set of mounting parts: -adapter flange (for a fee) - 1 pc.

At the customer's request, we can supply adapter sleeves from threads from G2 1/2-B to G2-B and from G3-B to G2 1/2-B, as well as adapters from thread SP-114-D GOST633-80 to flange.

Rice. 3 Installation diagram ETsV 10-120-60

L1 - Backwater, at least 1 m;

L2 - Dynamic water level, m;

L3 - Static water level, m;

L4 - Lowering the water level. The difference between dynamic and static levels water, m;

L5 - Immersion depth, m.

Rice. 4 Hydraulic characteristics of the pump ETsV 10-120-60

Legend:

Pump ETsV 10-120-60 TU 26-06-1659-92,

Where:

Electric pump, centrifugal, vertical - ECV

ETsV - unit equipped with a PEDV electric motor, 2ETsV - unit equipped with a DAP electric motor

10 - internal diameter casing pipe wells, mm, reduced by 25 times;

120 – nominal flow, m3/h;

60 – nominal pressure, m.

TU 26-06-1659-92,- technical specifications pump manufacturing;

Interchangeability:

Well pumps Grundfos SQ

Downhole submersible pumps Belamos TF, TM, etc.

Request price and commercial offer

Technical characteristics of the pump ECV 10-120-60:

VIM INDUSTRY company offers to purchase Submersible borehole pump ETsV 10-120-60 trademark"Green Submersible pump» produced by the PKP ZPN plant.

The ECV 10-120-60 pump is a centrifugal, multi-stage, downhole submersible unit used in various industrial enterprises, in the housing and communal services sector, as well as agricultural needs. Used for water supply, lifting and pumping water from artesian wells.

Pump operation ECV 10-120-60 occurs in water wells with the following restrictions:

- water temperature up to 25C,

- total mineralization no more than 1500 mg/l and

- pH value = 6.5 – 9.5.

- the pumped water must not contain impurities and various inclusions(mass fraction of solid mechanical impurities no more than 0.01%)

- the content of chlorides is no more than 350 mg/l, sulfates – no more than 500 mg/l and hydrogen sulfide – no more than 1.5 mg/l.

Please note that the pumps ETsV 10-120-60 from ZPN meet all the requirements of hygienic standards and will not provide any negative impact on the pumped water.

On pumps ETsV 10-120-60 uses electric motors of the PEDV brand, manufactured with a lower thrust bearing made of graphite fluoroplastic KV.

Borehole ECV 10-120-60 pumps have a number of advantages:

- Simple and reliable design;

- High quality units;

- High pressure characteristics: powerful and constant water pressure (in any operating mode of the pump);

- Power reserve up to 15% in hydraulic and electrical parameters;

- Elimination of the possibility of clogging the working parts of the pump with sand and silt (due to the design features of the impeller)*;

- There is no negative impact on the pumped water;

- Durability and maintainability of parts;

- Reliable thrust bearing PEDV: its wear resistance and impact resistance are ensured by the use of graphite fluoroplastic grade KV - the latest anti-friction material;

- PEDV resistance to voltage surges in the power grid (which is most important for rural areas);

- Low power loss and heating level of the PEDV during operation.

Pumps for wells ECV 10-120-60 are structurally composed of two parts. This is the pumping part itself, which is a multi-section centrifugal pump. And the second part is a submersible electric motor. Both parts are connected through a rigid coupling. In the figure below, you can familiarize yourself with the design of ECV pumps in more detail.

Main characteristics ETsV 10-120-60

Hydraulic characteristic ETsV 10-120-60

Additional characteristic ETsV 10-120-60

Electrical characteristics ETsV 10-120-60

Dimensional characteristics ETsV 10-120-60

Purpose

The electric pump unit ETsV is designed for lifting drinking water from artesian wells for the purpose of urban, industrial and agricultural water supply, irrigation and other similar

Design features

The unit consists of an asynchronous electric motor and a multi-section centrifugal pump part, connected to each other by a rigid coupling. The pump rotor and the electric motor rotor rotate in rubber-metal bearings. At the bottom of the electric motor there is a thrust bearing that absorbs the axial load. A protective mesh filter is installed at the entrance to the pumping part, protecting the pump from the ingress of large mechanical particles. The electric motor is water-filled with a squirrel-cage rotor, with a synchronous rotation speed of 3000 rpm. The “squirrel cage” of the rotor is made of copper. The stator winding is made of waterproof wire. The electric motor is cooled by pumped water. The unit is connected to three-phase network 380V, 50Hz through a control and protection station that protects the electric motor from operating in abnormal conditions. The connection is made with an ERW cable with a cross-section corresponding to the current consumed.

Legend

Symbols of the electric pump unit.

The average service life before decommissioning of the unit is at least 3 years.

- Average time between failures, hours, not less than 10500.

- Average life before the first major overhaul, hours, no less than 14,000.

After these indicators have expired, the units are removed from service and a decision is made to send them for repair or disposal. Criteria limit state are indicated above. It is not allowed to use the units for purposes other than their intended purpose.

The average shelf life in original packaging when stored under conditions 2 according to GOST 15150 is at least 2 years.

The manufacturer guarantees reliable and trouble-free operation of the unit, provided correct installation and servicing it in accordance with the requirements for operation and storage set out in this passport.

The warranty period for the operation of the unit is 24 months from the date of commissioning, but not more than 30 months from the date of shipment from the manufacturer.

The consumer is obliged to keep accurate records of the operating hours and operating conditions of the unit, entering information in the section “Information on the operating conditions of the unit.”

The manufacturer does not accept claims regarding the quality of units without providing information about their operating conditions.

Manufacturer's warranties are terminated in the following cases:

- Disassembly of the unit by the consumer;

- Operation of the unit without a pump valve;

- Getting sand, clay, or solid materials into the unit;

- Turning on a unit that is not filled with water;

- Availability mechanical damage electrical wires and unit housing;

- Operation of the unit without a control and protection station;

- Lack of a passport for the unit;

- Operation of the unit without the lower plug of the electric motor (for PEDV 6 electric motors);

- Absence of a well report during the calendar year of operation of the unit.

- Use for controlling units of frequency converters, without strictly following the recommendations.

Recommendations for the use of frequency converters for well pumps type ECV 10.

When operating ECV type downhole units with frequency converters, the following requirements must be observed:

To ensure sufficient cooling of the electric motor, the pump must operate in the operating range, its flow should not decrease by more than 20% of the nominal (for example, for the ETsV6-10 pump this is 8 cubic meters/h). Typically, the unit is controlled not by flow, but by pressure. In this case, the supply may decrease below the set level. That's why it is necessary to install a fluid flow sensor (relay), which would turn off the electric motor when the supply drops below the operating range or, using a flow meter, set the pressure at which the pump should turn off;

To protect the windings of electric motors from overheating, insulation melting and breakdown, it is recommended to install a temperature sensor that turns off the motor at temperatures above 70°C;

For normal operation radial and thrust bearings, the rotation speed of the electric motor shaft must be not less than 2700 rpm (45 Hz);

To protect the pump motor from high-frequency voltage pulses, which can lead to premature wear and breakdown of winding insulation, when long length connecting cable between the electric motor and the converter, it is necessary install output filters: du/dt filter or sine wave filter. Recommendations for the use of appropriate filters should be obtained from the manufacturers of frequency drives.

Due to the fact that water extraction from the Rozhnovsky tower is very uneven, and to cool the electric motor, the pump flow should not decrease below the set value, it is impossible to use a frequency converter without an intermediate storage tank or a hydraulic accumulator of appropriate capacity, because To do this, it is necessary to organize forced cooling of the electric motor in the well. You can also use a regular container and supply water from it using a type D pump with a frequency converter.

You also need to remember that if there is a large static component in the pressure characteristic of the system, the use of frequency regulation does not increase economic efficiency well pumps, but only allows you to reduce the volumes and, accordingly, dimensions of intermediate tanks, as well as reduce hydraulic shocks in the system.

Artesian pumps ECV used to transport water upward from artesian wells into the system autonomous water supply, watering and for other needs. The working position of the unit is vertical, with a similar shaft placement.

The transported liquid is water, the total mineralization of which (dry residue) does not exceed 1500 mg/l, in terms of pH - from 6.5 to 9.5, temperature - up to 25 ° C, mass fraction of solid insoluble impurities - up to 0.01 %, chloride content - up to 350 mg/l, sulfates - up to 500 mg/l and hydrogen sulfide - up to 1.5 mg/l.

Where is the ECV 10-120-60 chro pump used?

Pump brand ECV 10-120-60 chro. It is used for the same purposes as simply ETsV 10-120-60, in in this case marking chro means - stainless steel body, carbon fiber reinforced stainless steel outlet, Working wheel made of cast iron.

Where is the ECV 10-120-60 nrk pump used?

ETsV 10-120-60 nrk. It is used for the same purposes as simply ETsV 10-120-60. The difference between the ETsV 10-120-60 nrk and the conventional pump ETsV 10-120-60 is in the material used and improved wear. In this case, the marking NRK means - housing and impeller made of stainless steel, outlet made of carbon fiber reinforced stainless steel

Where is the ECV 10-120-60 N pump used?

ETsV 10-120-60 N are used for the same purposes as simply ETsV 10-120-60. The difference between the ETsV 10-120-60 N and the conventional pump ETsV 10-120-60 is in the material used and improved wear. In this case, the marking H indicates the body, outlet and impeller made of stainless steel

Pump designation ECV 10-120-60

- E - electric motor drive

- C - centrifugal

- B - pumped medium (water)

- 10 - casing diameter in inches

- 120 - flow, m 3 / h

- 60 - head, m

Material: - nrk - housing and impeller made of stainless steel, outlet made of carbon fiber reinforced stainless steel;

- chro - stainless steel body, carbon fiber reinforced stainless steel outlet, cast iron impeller;

- H - housing, outlet and impeller made of stainless steel

The pumps are equipped with PEDV type motors

- P - submersible

- ED - electric motor

- B - filled with water

Design of the pump ETsV 10-120-60

The pump for wells ECV 10-120-60 is structurally composed of two parts: a pump and a submersible electric motor filled with water. Both parts are connected through a rigid coupling.

The pump has a multi-stage design. Each stage consists of a blade or bearing outlet and a centrifugal impeller located in a cage. Impellers are made of plastic and reinforced stainless steel. Through the coupling, rotation from the electric motor is transmitted to the pump shaft. A check valve is installed at the top of the pump.

Pump design ETsV 10-120-60

* - Equipped with electric motor PEDV

Water enters through a supply located between the pump and the electric motor and protected from large mechanical particles by a mesh filter.

Installation diagram ETsV 10-120-60

L1 - Backwater, at least 1 m;

L2 - Dynamic water level, m;

L3 - Static water level, m;

L4 - Lowering the water level. Difference between dynamic and static water levels, m;

L5 - Immersion depth, m.

ETsV 10-120-60 is suitable for pipes with an internal diameter of 10 inches. The capacity of the ECV 10-120-60 pump is 120 m 3 /h, the lifting height is 60 meters. Pumps ETsV 10-120-60 are suitable for domestic and industrial water supply. Artesian pumps require a line voltage in the three-phase supply network equal to 380V with a frequency of 50Hz.

Warranty periods and service life

The warranty period is 12 months from the date of sale and 18 months from the date of manufacture.

Average product resource before major overhaul is 16,000 hours or service life 5 years or until completely worn out with specified maintenance and repairs

Average time to failure is 6000 hours.

Average time to recovery - 8 hours

Contents of delivery

The delivery set of the ETsV10-120-60 pump includes:

Pump ETsV10-120-60;

Manual;

Cable for connecting the unit to the electrical network (1 m).

For an additional fee, the delivery additionally includes:

Adapter flange (adapter 020), for connection to the pumping system;

(Required for this pump);

DVNU-sensor of upper and lower levels

Advantages of the ECV 10-120-60 pump

- Easy to install and operate

- The use of an electric motor and pump part of the same diameter for operation without a cooling jacket

- Possibility of disassembling/assembling the pump if necessary without the use of special tools

- Stable operation under unstable power grid parameters

The engine is easy to operate and does not require checking the filling with a special liquid. Filling occurs with water when the pump is installed in the well.