Do-it-yourself mechanical clamps. A DIY clamp makes the craftsman’s work easier and saves him money. Clamp assembled from wood and steel

Read also

Every craftsman who makes products and parts made of metal or wood cannot do without homemade clamps. Previously, such a tool was produced in various modifications, from specialized to universal. The main task is to fix the workpiece for processing and joining operations. Let's look at how to make a quick-release clamp with your own hands in various variations.

Angle clamp

This type of do-it-yourself metal clamp is designed to fix two objects at right angles and connect them together using any methods, however, the main purpose is as a jig for welding metal parts at the angle required for work. To make it properly , you will need the following components:

Corners should be welded at 90 degrees to metal or steel plates. We attach the worm-type structure by welding, and screw a pin-driver into the working nut in order to assemble a stop at the end. The stop must turn freely. Then with reverse side it is necessary to drill a hole where we insert a metal rod as a lever. Incredible simple design and practicality of use have become the key to the popularity of such a clamp among everyone who works with metal and products made from it.

Carpenter's clamp

Such designs used in carpentry are of the following types:

- Standard clamp, which is the most popular or simple;

- In the form of a caliper for small parts and quick fixation;

- Self-clamping clamp for milling processes and working with workpieces of various heights.

The first type is made from two pine blocks, a locking nut, rods, threaded wing nuts and thrust washers. The manufacturing process is very simple:

- We cut out the working pliers from the bars, drill holes for the studs, taking into account a small backlash;

- We screw in the studs and lock them using appropriate methods;

- We ensure alignment with nuts, made either in the form of wings or standard nuts for improved tension.

The second option is used when prompt fixation of small parts is necessary. Production is carried out from small bars and thin-sheet plywood. Furniture nuts and collar pins act as a worm system. One stop is stationary; we attach it to the end of the guide rail, in which we cut out recesses to fix the moving mechanism.

The second option is used when prompt fixation of small parts is necessary. Production is carried out from small bars and thin-sheet plywood. Furniture nuts and collar pins act as a worm system. One stop is stationary; we attach it to the end of the guide rail, in which we cut out recesses to fix the moving mechanism.

There are both portable and stationary option such a design where grooves are cut for movement with fastening fixed stops. The clamp is a furniture nut, a hairpin and a knob. Due to this, you can work with workpieces of any size.

The self-clamping design has a lever with an eccentric at the rotating end. We rotate it at a certain angle, it automatically turns out quick clamp. The height is adjusted with a pin on the workbench. It is made individually for each matrix, depending on its purpose and the purpose of the work being carried out.

Pipe clamp

Welding metal pipes end to end is a complex operation. It is considered simpler to weld the pipe to ready-made system. The design for such cases is made of metal corner and steel plates. The halves of such a device should be fixed traditional method, namely threaded studs. As a result, you can get a fairly simple and efficient design, which will greatly facilitate the work when welding pipes with various designs.

Welding metal pipes end to end is a complex operation. It is considered simpler to weld the pipe to ready-made system. The design for such cases is made of metal corner and steel plates. The halves of such a device should be fixed traditional method, namely threaded studs. As a result, you can get a fairly simple and efficient design, which will greatly facilitate the work when welding pipes with various designs.

There are other types of structures, including cam mechanisms, tape and wire clamps, which can be useful for working with specific structures, including particularly fragile and thin ones. However, their production is the subject of separate master classes and articles on specialized resources.

Homemade clamps are indispensable assistants for any craftsman working with metal and wooden parts and products. Making them is quite simple and very exciting. Here it is important to follow the manufacturing technology, find optimal instructions and videos. You can buy clamps, but they may ultimately not be suitable due to the specificity of the workpiece or work. This is why you should make your own clamps. Good luck working with various workpieces and making homemade quick-release clamps!

Reading time ≈ 5 minutes

A clamp is a tool that resembles a hand vice, which is used to securely fix or glue two elements together. For example, in carpentry it is used to connect two planes while drying. adhesive solution. However, this tool is not always at hand, so you can resort to making a quick-release design yourself. To properly make a metal clamp with your own hands, you need to follow step-by-step instructions with photos and video master classes.

Design Features

A clamp can quickly fail, which is why it is so important to know how to make homemade instrument. The components of this metal structure are a lever part, a frame, clamp lips and a moving part.

What are the advantages of clamping tools:

The clamp can also be made from wood, however metal structure more practical and reliable. Its production does not require special knowledge and skills; you only need the use of welding equipment, a hacksaw and a torch. The whole process with step by step instructions shown in the video.

Models of clamping tools are divided into the following classes based on the operation of mechanisms and structural features:

Manufacturing technology

A do-it-yourself metal clamp is much more reliable and practical than a wooden structure. For the manufacture of homemade units Welding equipment and metalworking units will be required.

Tools for making any type of clamp

1 option

Following the instructions, you can make a homemade clamp from metal reinforcement.

Option 2

To make an angle clamp tool with your own hands, we will need following materials: steel scraps from corners 40*40, 50*50 and 30*50, 200 mm each, 2 F-shaped clamps and a strip 10*50 up to 250 mm long.

Let's get started:

Buy clamps from construction stores quite expensive. Everyone wants to rid themselves of extra costs, if there alternative options. You may need several such tools at once, this is especially true when assembling, manufacturing or repairing pieces of furniture. Homemade clamps will replace your hand vice, as you can choose the model, type and size of the tool. By following the instructions in the photo and video, you can quickly understand the manufacturing mechanism and quickly make a manual clamp from scrap materials.

It will not hurt a novice craftsman to know that in the first stages it is unlikely that he will be able to get by with just a hammer or saw. Subsequently, you will have to resort to using a vice or quick-release clamp to fix the workpiece or glue individual fragments. Making it yourself is quite simple. There is no single clamp that is sufficiently universal to satisfy all needs when performing various types work.

Use of wooden clamps

They are various styles, models and sizes. So you can stock up various models, which will always come in handy. A master can purchase several models of Assistent clamps, and besides, they are not that expensive. If a person does not want to pay for such a purchase, he can make a wooden or pipe clamp with his own hands. Wood models are very popular, you can make them yourself. This model is easy to use and easy to adjust.

Model F is a wooden clamp that has been slightly improved. It uses a maple plank with a width of 5 cm and a thickness of 0.6 cm. The design also contains a metal rod on which a thread is applied. To make a pen, you need to take wooden blank. Suitable for this hardwood without defects.

The moving parts must be well dried in order to slide smoothly on the bar. There should be two nuts on the rod. They are located at the end and then tighten against each other. Thanks to this, they do not separate during use. You can use a separate lock nut or simple model with permanent lock. And two more nuts are needed to secure the clamping pads along with the washer from the outside.

It is permissible to use a locknut and other fastening methods. Double products jam each other. This is the most reliable and easiest way. It's also the cheapest. It is important to leave some space for the screw so it can rotate freely.

Made of wood and steel

Using a hacksaw, cut the threaded rod to 30 cm. First, you need to make an additional cut into a block measuring 9 by 7 cm, if we are talking about unfixed ends. Once all the corners are cut, you need to drill a hole and insert the tightening bolts.

You need to make sure the holes are large enough to fit the bolt head. The threaded rod is fixed in the upper area of the fixed end. The hole needs to be large enough to fit the nut into the rod. Install the fixed end when intending to drill holes. When assembling, you need to make sure that the ends are secured at right angles. Thanks to this, the threaded rod will become parallel to the rod.

Before assembly, it is necessary to make a hole where the nut and threaded rod pass through. Do this in the same block position as for the fixed end. You need to make sure the hole is wide and deep enough to accommodate the nuts. The lower area is small, and therefore it is difficult to insert a sufficient number of screws here. This is necessary to prevent curling.

Shelf dimensions are determined according to the desired length and available equipment. After this, the system components are sawed until required size, cut out the pads for the sponge and drill required holes, pens are glued with a five-minute epoxy resin. When the screw shaft is jagged by a file or sandpaper, fix the handles with epoxy glue.

Easy homemade options

A lightweight, homemade clamp is made on the basis of a metal rod. These clamps, although not as powerful as steel clamps, still provide the ability to create strong clamping pressure for any adhesive. Accordingly, their service life is quite impressive. The rod can be made to any length. The only thing you need to remember is that there should not be a threaded rod running along the entire length of the main rod. The clamp head does not need it at this end, making assembly much easier. Clamping jaws are made of plywood.

The lock nut is an element that secures the clamping jaw to the rod. However, it should not be under pressure. The nut can be cut with a regular hacksaw. It is fixed to the heel with epoxy resin. The recess should be quite wide and suitable for the washer and deep so that the nut and washer can turn without problems.

Here you need to use a 35 mm nut, since you need to drill a hole 38 mm in diameter with a bottom and 15 mm in depth. After drilling the recess, a through hole is made. This is required for the clamping screw. Fix the movable head in a fixed position and mark the places where the hole should be located.

Handle, screw and main assembly

Square blanks of 25 mm are made and 100 mm are cut for each handle. Mark the central part and drill out a fragment of 10.5 mm 60 mm using a drill. As an analogue, you can drill a fairly wide hole and then cover it with epoxy resin. But this method is considered not reliable enough.

The workpiece is sanded to make a more comfortable handle and glued to this clamping screw. Proceed to the main assembly. This is a simple task to apply the film to the stationary head. The lock nut is strengthened and end caps are made. They should prevent the head from slipping off the rod. Therefore, it is advisable to screw a small plate onto the heel. Thereby the nut will not slip out of place. This acts like a hook.

Cam clamp

This device is not only useful, but also extremely simple. It must be remembered that cam clamps are fast-acting, but cannot guarantee great strength clamping parts. That's why they are used when relatively little cutting force is required. They are not suitable for working under high pressure, as is possible with a large clamp. But at the same time they are extremely easy to use.

This device is not only useful, but also extremely simple. It must be remembered that cam clamps are fast-acting, but cannot guarantee great strength clamping parts. That's why they are used when relatively little cutting force is required. They are not suitable for working under high pressure, as is possible with a large clamp. But at the same time they are extremely easy to use.

A special template is used for preparation. It is needed to create curves. The template is made of metal, plastic or wood. It is used to tighten smooth curves. However, the cam mechanisms do not directly follow the French curve. The correct cam must have a profile, increasing the distance between the axis of rotation and constant speed. In this way it resembles a spiral drawn with a pencil.

Experienced furniture makers, carpenters, metalworkers rightly believe that a clamp is no less important tool, how convenient workbench, a well-balanced plane or a set of razor-sharp Swedish steel chisels. The device can be bought or rented, but it is best to make a clamp yourself. In this case, there will be confidence that a simple device will not fail at the most crucial moment.

The essence of the clamp device

Structurally, a clamp is the simplest device that allows you to press a part, a workpiece, several components in one piece for installing fasteners - self-tapping screws, bolts with nuts, rivets, or while the glue dries.

There are two main requirements for the design of a clamp, regardless of the design, material and size of the device:

- The clamp frame should not deform under load; the rigidity of the fixture frame should be sufficient to maintain parallel to the plane pressing jaws;

- The design of the clamping screw must provide adjustable and smooth pressing of the movable support of the clamp on the fixed surface.

There is enough a large number of all kinds of clamp schemes, and although the design of any clamp is primitive in essence, no one is trying to make universal design, which could be used in any situation. The device turns out to be very heavy, inconvenient and difficult to operate.

Therefore, the dimensions and design of the device are selected based on the dimensions of the parts to be connected and the required pressing force. Conventionally, clamps are divided into three large groups:

- Carpentry and furniture ruler clamps, they try to make them from hard wood and metal;

- High rigidity mounting clamps;

- Mechanic's persistent clamps.

In addition to classic ruler clamps, custom-made clamps of non-standard designs are widely used; most of them are manufactured to perform one or two operations of increased complexity.

For example, drilling into an array of several boards to a great depth, cutting or gluing timber in a shaped way under straight or non-standard angle, welding of parts of complex configuration. There are more than enough options The best way ensure the most high quality connections - this is still to make a clamp the right size and shapes.

DIY wooden universal clamp

The easiest way to make a clamp is from wooden plank and timber. Wood is a fairly affordable material, so if you mark the parts correctly and use the proper tools, you can make a clamp of any level of complexity without much effort.

To make a wooden clamp, you will need the following tools and accessories:

- Desktop drilling machine power 400-500 W for drills from 1-15 mm. The vertical stroke of the drill chuck must be at least 120 mm;

- Electric grinding wheel. You can do it yourself; to do this, instead of an abrasive stone, use an electric sharpener to install a circle of plywood, 10 mm thick and 350 mm in diameter, on which sandpaper sheets are glued on both sides;

- Manual Circular Saw on wood with a disc diameter of at least 150 mm. You can use a grinder or a band saw.

All other operations can be done using hand tools. Of course, you can also drill holes and cut grooves using hand drill and a hacksaw, only achieve the required quality and manufacturing accuracy using hand tools It will be very difficult.

Classic F-shaped clamp

The design of the simplest wooden clamp looks like the Latin letter F. The vertical and upper horizontal strips are one whole - a fixed guide connected by a stop of one of the jaws. The central bridge of the letter F is the movable or mating part of the jaws, which is driven by the lead screw. The third part of the clamp with the drive screw is manufactured in a removable version. The clamp can be rearranged along the length of the guide bar; the distance between the jaws can be made smaller or larger, as long as the length of the base rail allows.

The general view of the clamp is shown in the photo.

First you need to make a guide rail. Larch or spruce board is suitable for these purposes. All other parts of the clamp can be made from any wood, except soft varieties - poplar, linden, birch.

Important! For the manufacture of any fixtures and auxiliary equipment, only defect-free wood is used. If there is none, then it is best to make a clamp from ordinary plywood with a thickness of 15-20 mm.

The base strip is cut to the length of the future fixture. Not on the support moving part The clamping jaws account for the lion's share of the load, so it is best to make a guide from the strongest wood or use a little trick.

A semicircular groove is cut out along the side end of the slats, into which a steel rod with a diameter of 8-10 mm is placed. On one side, the end is bent around the end; on the other end, the rod is connected to a fixed jaw with a nut screwed onto a pre-cut thread.

The fixed part of the jaws is glued to the guide bar with wood glue; after the glue has dried, the supporting surface is carefully cut at an angle of 90° to the guide bar. This part can be made glued, or the mounting groove can be cut using a hand-held circular saw.

The mating or movable part of the jaws is cut out together with the support for the screw from one block. Next, you need to make U-shaped cuts in both blanks, allowing you to fit the parts onto the guide bar. After removing the burr, the workpiece is placed in a package in a drilling machine and a hole is drilled for the lead screw.

If you plan to use the clamp quite intensively, then you need to press a brass tube into the hole for the screw and make a sliding bearing. Otherwise, the lead screw will quickly break the hole by 2-5 mm, which will make the tool unsuitable for work.

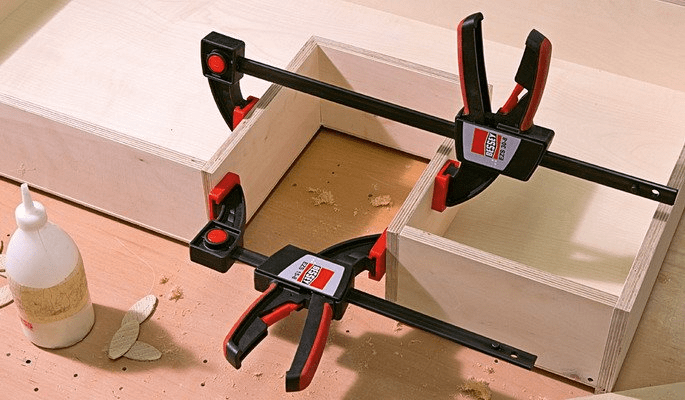

Clamp assembled from wood and steel

A wooden clamp is convenient to use if you need to apply a little pressure to secure a package of several planks or glue two parts. If you plan to process timber or boards with carpentry tools, a plane or a grinder, then it is best to make a clamp for fixing the material with a metal guide.

The process of making a clamp from wood and steel is as follows:

All that remains is to assemble the clamp, the rearranged part is drilled under the fixing bolt, the bolt or pin is installed and tightened with a nut. At the end of the assembly, you need to make two or three idle runs to settle the walls and facilitate the rotation of the screw.

Wooden clamp for fixing and tightening sets

In 40% of cases, work in a carpentry or furniture workshop requires the use of long clamps to tighten entire sets or packages of planks, form furniture panels, table tops and door leaves. The process of making clamps for screeding needs is practically no different from a conventional wooden F-shaped device.

Unlike other device designs, the clamp for the screed is made of solid timber, with a cross-section of 50x50 mm and a length of at least 100 cm. A series of holes are drilled in the guide bar from the timber on a machine to rearrange the mating part of the jaws.

In addition, you will need three blocks of oak or beech in order to make fixed support with a lead screw and two parts of the jaws - adjustable and movable.

An installation groove is cut on the reciprocal adjustable support and a hole is drilled into which a nut is pressed under the mounting bolt. The distance between the supports can be made larger or smaller if the sponge is moved to the next hole and secured with a bolt.

Wooden clip from hanger parts

A small device, very reminiscent of a tightening type of clamp, can easily be made from ordinary suit hangers. Wooden base hangers are made from two identical halves of a trapezoidal shape.

The first step to making a clip from a hanger is to fold the two halves of the hanger into one bag and clamp it in the vise of a drilling machine.

Without opening the machine vice, you will need to make four holes with a diameter of 8 mm. You get two blanks, each of which has a pair of through holes. All that remains is to make a clamp; to do this, you need to cut off two studs with M8 threads, each 25 cm long. The studs can be glued into one of the halves or a symmetrical version can be made, as in the photo.

The clamp can be used to make a fixing device for gluing boards, holding pipes, or tightening a package of several planks.

Quick C clamp for wood

Except classic options carpentry clamps and clamps; when working with furniture and wood materials, it is necessary to use small-sized clamps. One of these devices is WITH- shaped clamp, made of wood, photo.

Before making a clamp, you need to find a suitable piece of wood. C-shaped clamps require very strong wood, so acacia, elm or steppe oak are used for their manufacture. The U-shaped body is cut out with a grinder. At total size housing 100x100 mm, the width of the sidewalls must be at least 2.5 cm.

In one of the sidewalls you need to make a through hole with a diameter of 12 mm, into which two steel nuts, M8 or M6, are pressed. The easiest way is to screw the nuts onto the threaded rod, coat them with glue and insert them into the hole. You need to make a few gentle blows with a mallet so that the nuts fit into the through hole with a slight tension. All that remains is to make the handle, and the C-shaped clamp is ready.

DIY metal clamp

Most metalwork and carpentry clamps are made of metal, most often steel or aluminum alloys; there are only two reasons for such selectivity:

- High strength of metal parts;

- Long service life even under heavy load.

To make metal clamps, you will need welding equipment, a grinder and a regular electric drill and jigsaw.

Long tension clamp

The most logical thing would be to make a clamp in which the guide beam or wooden strip is replaced with a square profile pipe. A meter clamp can be made from a 20x20 mm square, for a two-meter clamp you will need a 30x30 mm profile. The use of a tubular square profile makes it possible to make the structure very rigid without “stretch” and shrinkage, as is the case with lumber.

The easiest way is to make a long clamp according to the classic design. Stationary, movable and adjustable parts are made of thick plywood.

Each part consists of two halves, which are cut out with a jigsaw and bolted together on a long square pipe. The lead screw can be made from two parts of a threaded rod and a regular piece of reinforcement.

Homemade welded clamp from rebar

Instead of wood, you can use a regular reinforcing bar with a cross-section of 8-10 mm. To make a clamp body from reinforcement, you will need to cut two blanks 65 and 55 cm long. The rods are heated at blowtorch and bent on a steel mandrel at a right angle according to the drawing.

The bent workpieces are welded into one L-shaped structure; the nose and linear sections fittings.

The next step is to make a stand for the lead screw from a 20 cm piece, to which a nut is welded. If the clamping force on the clamp is more than 50 kg, then the stand can be made bent or reinforced with an additional strut.

Homemade G-clamp

The G-body design is also called a screw press due to the enormous force that can be achieved using a lead screw. Making a G-clamp is quite simple. To do this, you need to cut body blanks from thick metal with a grinder, at least 7-8 mm thick.

The body is welded using the letter P. On the top shelf you need to make a hole for the nut, then screw it onto the lead screw and install it at the welding site. A small piece of metal is placed on the bottom shelf - a table, which is pressed with an unscrewed screw. You just need to make a few welding points or seams to weld the table and nut, and the clamp is ready.

Wooden spacer to support a metal clamp

An important part of any clamp is the lining installed under the supporting surfaces of the clamp. This is done to achieve two goals:

- Avoid damaging the part being clamped with a clamp, since in metal devices the clamping pressure can easily reach several hundred kilograms;

- Evenly transmit and distribute the force from the lead screw to the surface furniture board or fixed part.

It is best to make the gasket from ordinary birch plywood or soft wood with an unsanded surface.

Clamp for wrapping wire onto a mandrel

Reliably fixing a steel wire on a round piece, such as a rubber pipe or the head of a fitting, is considered a very difficult task. Structurally, such a device consists of a double body and a winding pin.

The wire is wrapped around the pipe and hooked onto a pin with a bolt head. In 2-3 turns with the key, the wound one-and-a-half loop is tensioned to the desired state. All that remains is to turn the housing to twist the wire on the hose into several turns and cut off its ends.

DIY corner clamps

The use of specialized clamps remains the only option today possible way assemble any rectangular or square structures made of wood and metal with a perfectly aligned right angle.

For example, a system of ready-made triangles that cover the planes of the joining sides and firmly hold them in in the right position, until the fasteners are installed or welding is completed.

Universal clamp for any angle

A right angle, as a rule, does not pose a particular problem when working with clamps; it is much more difficult to make an angle of any size. To solve such problems, you need to make an adaptation to the clamp, as in the photo.

At the core additional device a regular pine block with a sector cut out in the center is used right angle. The second detail is the usual right triangle, which can be made from spruce or pine slats.

A through hole with a diameter of 5-6 mm is drilled at the top of the sector corner. It is the hole that allows the triangle to swing and change the angle of inclination of the clamp by 3-7 degrees.

Angle steel clamp for assembly

Connecting two parts at right angles is much easier if you secure them in corner clamp. In the simplest case, the device consists of two guides from cut profile pipe or steel angle.

The guides must be set using a square at an angle of 90° and connected with additional sheet metal overlays.

To ensure that the workpieces do not fall out of the device during operation, two G-shaped clamps are additionally installed on each of the guides.

DIY quick-release clamp

Sometimes when working with wood, clamps are required, with which you can fix or hold a part to a work table or place within just a few seconds.

In order to make a quick clamp, you will need wooden boards or plywood 16-18 mm thick. Initially, the tracing paper of the parts is transferred to wood and cut out using a jigsaw. In the driven parts, you will need to make cuts to fit the mating part.

At the marked points of the axes you need to make holes with a diameter of 20 mm.

Hinge axles are cut out of a round blank, ground and pressed into the holes. The result is a clamp design that is somewhat reminiscent of scissors. The drive uses a standard lead screw with a diameter of 6 mm.

Clamp for holding and securing small parts

In a similar way, you can make a clamp for fixing especially small parts. You will first need to mark and cut out two halves of a device similar to tweezers or a medical clamp from OSB or plywood.

The crescent-shaped blanks are connected to each other using a wooden axis, so a hole of the appropriate diameter must be made in each of the parts of the clamp. Ash or spruce can be used for the clamp body; the axis must be made of more hard material- oak or beech.

Clamp made from rebar and wood

Using a reinforcing rod 50-60 cm long and 8 mm in diameter, you can make a very strong and at the same time lightweight frame for universal use.

The design is based on a support wood block from hard wood. Block dimensions 150x50x30mm. Dimensions may vary depending on the thickness and bending radius of the reinforcing bar. A hook made from a piece of reinforcement can be bent with a heavy hammer to steel pipe. The bend must be done so that the bent reinforcement is flat.

Universal tape clamp

One of the most interesting unusual designs of clamps uses a thick belt made of polyester fabric as a strength element. A band clamp is used where it is necessary to tighten several parts evenly.

To make a tape clamp, you need to make corner elements and a device for tensioning the polyester belt. Three corners are cut out of ordinary pine using printed tracing paper. The fourth element, the tension device, is made of two blocks and a tension screw.

The tape is passed around the block; if you unscrew the screw with a wrench, the distance between the blocks increases, and the belt of the device is tensioned, pressing all four blocks to the part.

Cam quick clamps

Often, a part or workpiece in a clamp needs to be fixed quickly, and the clamp must be made without unnecessary movements. For example, when drying or painting a batch of panels or frames. For these purposes, it is best to make a specialized device with cam clamps, photo.

Difference of this device consists in the fact that instead of a traditional lead screw, plywood eccentrics are installed on the vertical jaws of the clamp.

To do this, you must first make a cut along the thickness of the eccentric on wooden racks.

Telescopic folding clamp

The idea of a telescopic clamp is based on a set of pipes that fit into each other with minimal clearance, like a folding fishing rod, and a set of ring clamps with a screw lock.

A ring is cut from each pipe, to which a metal block with a thread is welded. A wrapped screw or bolt secures the pipe located inside, allowing the entire structure to be clamped into one extended rod.

Universal mounting clamps

In addition to clamps, two-shelf universal clamps are widely used for fixing glued parts of complex configurations, photo.

The idea of a clamp - a clamp - is borrowed from a bookbinding press; the dimensions and number of clamps are selected depending on the size of the part.

4-way poly clamps for wood panels

The lack of reliable fixation remains one of the problems that one has to face when assembling and gluing a shield from several wide and flat strips. It will not be possible to make an assembly even from five or six glued strips and tighten the material with ordinary long clamps; with the slightest increase in force, the shield bends in an arc.

The solution to the problem is a device with four clamps, photo.

The panel is fixed with two pairs of clamps. At the ends of each pair you need to make a cross-shaped clamp from a nut and metal plates. A height-adjustable hinge is installed at the opposite end of the fastening. The lead screw of each clamp rests against a wooden plate. It is enough to make a few turns of the screw so that a pair of bars firmly compresses the parts to be glued.

Clamping box for installation on a workbench

If there is no special mounting cradle, parts of complex configurations are not so easy to attach to a flat workbench surface. In this case, for processing wooden part complex spatial design It is best to make a clamp box.

The design is quite simple to make:

- A box-shaped frame is assembled from plywood;

- Along the long sides of the box, two beams are sewn, best made of pine, with a cross-section of 50x50 mm;

- A series of mounting crossbars are made from the same material.

The box allows you to use clamps to hold any, even the most complex part. If you plan to use powerful power tools to process it, you also need to make a clamp or clamp for the box-shaped base to secure the device to the table.

Homemade coffee table clamp

Serious problem for everyone wooden tables magazine type was and remains low lateral stiffness frames, even without a load, the tabletop often has a small but extremely unpleasant play.

You can fix the problem by installing homemade clamp or garter spring. Two planks or blocks of wood are connected to each other by a long metal bracket.

The device can be made with a screw clamp or self-clamping. In any case, the bars will strengthen and fix the frame with the legs, thereby eliminating the existing play.

Inexpensive simple clamp made from a PVC pipe ring

Sometimes you have to look for improvised means to hold when carrying, but more often when drilling or processing parts and objects round section. The simplest version of the clamp can be made from a ring of PVC pipe.

It is enough to drill two through holes, insert a couple of pieces of reinforcement and cut the wall of the ring in one place. The device is designed for a certain diameter of the part, so you will have to make a whole set of clamps to work.

Racks for a set of clamps

Working tools and clamps should first of all be stored in a specially designated place. Instead of a pile of tools, from which it is difficult to find and select the necessary device, it is best to make several split racks or shelves. In this case, it will take only a couple of minutes, and not half a day, as before, to quickly select several clamps that are most suitable in size and design.

Improvised clamps

Often in carpentry or when assembling wooden structures there is not enough time to make full-fledged clamps and clamps. Then ingenuity and experience come to the rescue.

For example, a round workpiece can be fixed using several rings stuffed onto the frame.

A reinforcing rod or water pipe can be clamped using an improvised clamp made from several bars and tape.

A regular trunk locking cord will help you tighten a set of a dozen wooden slats like a band clamp.