Materials for pool lining. Properties and advantages of ceramic mosaic. Finishing pools with mosaics

When creating a swimming pool, there are many complexities to consider. technical issues: arrangement of the foundation, waterproofing of the bowl, filtration systems, drainage and water supply. But few people pay due attention to cladding. In this article we will talk about what it should be good tiles for a pool, and what you should pay attention to when choosing it.

Quick navigation through the article

Cladding requirements

- Pool tiles should have a low water absorption coefficient. According to European standards UNI EN 99, water absorption should not exceed 6%. This is very important indicator, because over time, tiles soaked in water become brittle.

- Another important requirements for pool tiles – chemical resistance. The cladding must withstand exposure to bleach and detergents.

- The tiles must be impact-resistant, frost-resistant and resistant to sunlight.

According to the EU Directive on building materials 93/68/EWG, manufacturers divide tiles into slip classes. It is usually written on the packaging.

- Class A – suitable only for dry rooms (eg locker rooms).

- Class B - can be used in showers, edges for approaches to the pool and areas around it.

- Class C – has the best anti-slip performance. These tiles are suitable for laying on steps and inclined slopes that go under water.

Ordinary tiles are not designed for constant contact with water. It will quickly collapse, and moisture will first begin to affect the waterproofing, and then reach the foundation. In addition, a plaque of bacteria and microorganisms will accumulate on ordinary tiles, which, no matter how you clean it, will still form a slimy film and mold on the surface.

Material selection

What materials meet the requirements described above?

First of all, it is glass. Covering the pool with glass mosaic is the most popular option, since the water absorption of such material is close to zero.

Glass perfectly withstands temperature changes from -30 to +145 degrees, and can survive up to 100 freeze-thaw cycles, and this is important for outdoor pools.

Glass mosaic successfully withstands contact with most types of acids; over time it will not lose its appearance, the paint will not fade or peel off.

Even if some part gets damaged, it can be easily replaced with a new one, and no one will even notice the patch.

Mosaic for the pool is most often square shape. The smaller its size, the easier it will be to cover irregularities and bends.

To speed up the installation process, manufacturers pre-glue the parts onto a mesh, the size of which is usually 30*30 or 60*60 cm. They are glued with a special tile adhesive, and then a waterproof grout is applied.

There are many mosaic manufacturers now: Italian Trend, Vitrex, Aquileia and Bisazza, Spanish Vidrepur and others. The price range is quite large: from 600 to 35 thousand rubles per square meter, depending on the shape and decorative qualities.

Porcelain tiles

Like porcelain tableware, tiles are made from a mixture of several types of white clay, kaolin, feldspar and quartz. Coloring occurs by adding pigments to the composition, most often metal oxides.

The tile is fired at a temperature of 1200-1300 degrees. The result is a very durable product with a glassy surface that does not require additional glazing.

Clinker tiles

Highly plastic clays with many additives are used to make clinker. The plates are made using extrusion or pressing, and then fired at a temperature of about 1200 degrees. Due to this, water absorption is only 0.5%.

Clinker has high strength, so large format tiles can be used for the pool - 294*294*10 mm. It does not crack from exposure to water and can withstand good mechanical loads. Glazed and unglazed clinker tiles are similar in their characteristics. The main difference is that the glazed surface will be smooth, which is well suited for lining a pool bowl. The floor can also be covered with ordinary clinker without glaze; it is not afraid of water.

Clinker tiles practically do not slip, unlike ordinary tiles or tiles made of natural stone, so you don’t have to worry about safety.

Average price clinker tiles is 900-4000 rubles per square.

To cut clinker you will need electric tile cutter with a diamond blade, even it will be difficult to cut.

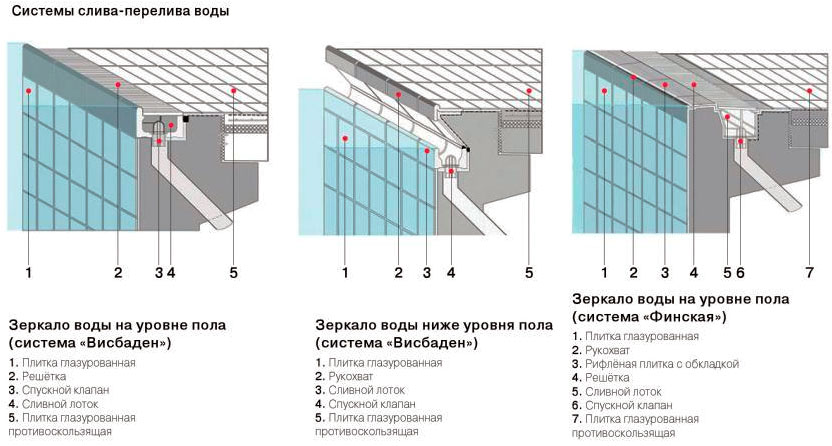

Water overflow systems

In order not to once again subject the lining around the pool to a “strength test”, you need to protect it from water overflows. Of course, the easiest way is to lower the water level in the pool, but imagine how difficult it will be to get out of it. To save high level water, but to solve problems with overflow, you need to install edge elements for the sides and overflow gutters around the perimeter of the pool, which will be covered with a grill.

Size and shape

To prevent the tiles at the bottom of the pool from cracking, they should not be too large. It is not recommended to use tiles larger than 125*250 or 150*150 mm, and for bowls complex shape– maximum 100*100 mm.

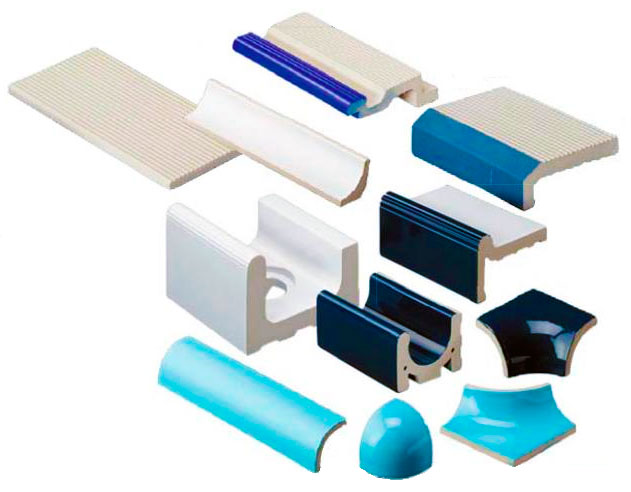

To facilitate cladding, there are special shaped products for finishing sides, steps, creating gutters. Corners covered with such products will collect less dirt.

Tile adhesive and grout

At facing works use special tile adhesive for swimming pools (for example, UNIS Pool, IVSIL AQUA, Pobedit Pool). Average consumption dry mixture is 1.4-1.5 kg per square meter with a layer thickness of 1 mm. In practice, the consumption will greatly depend on the evenness of the base, the size of the teeth on the spatula and its angle of inclination - from 2.3 kg to 7 kg of mixture.

For the pool, a two-component one is used.

Conclusion

Compared with budget option PVC tiles and mosaics for the pool have a large number of advantages: beautiful view, resistance to damage, durability, not afraid of frost and repairable. This the best option, if you are going to make a pool for yourself and for a long time.

comments powered by HyperCommentsSimilar posts not found.

The cladding (finishing) of a concrete pool serves two purposes: aesthetic and waterproofing. Indeed, a pool lined with porcelain tiles or glass mosaics has a beautiful appearance and, at the same time, reliably holds water while following the technology.

Finishing pools with tiles (porcelain tiles for cladding)

Pool tiles intended for lining the bowl must have increased strength and a water absorption coefficient of no more than 0.14%. For its production it is used special materials, burned at high temperature. Such tiles have practically zero water absorption, can withstand multi-ton water pressure and large temperature changes, and are highly resistant to abrasion and influence. ultraviolet rays, chlorine and other aggressive influences that water may have.

A set of porcelain tiles may include: additional elements, used for finishing corners, edges and sides of pools, overflow gutters, bowl elements, etc. Tiles for finishing a pool can be wall tiles with a smooth glazed surface and floor tiles with an anti-slip surface. The back side usually has longitudinal grooves that serve for more deep penetration glue deep into the tile, which contributes to its strong adhesion to the concrete base.

Requirements for tiling a pool bowl

When facing (finishing) a pool bowl with porcelain tiles, several requirements must be met.

The first is to impeccably maintain the geometric dimensions of the bowl during concreting and plastering. After all, the finishing makes even the slightest deviations in geometric dimensions noticeable.

Second - use only high quality materials. It must be remembered that the pool is like engineering system constantly experiences enormous stress. The weight of water primarily affects the facing layer, especially when filling and draining water. In addition, chemically disinfected water itself is an aggressive environment for facing materials, glue and grout.

Third - calibration finishing materials. It is clear even to a non-specialist that if all elements of the pool finishing do not have exactly the same geometric dimensions, high quality impossible.

Fourth - the high professionalism of the performers, from preparatory work to commissioning work.

The selection of the color palette of the tiles depends on the chosen design of the pool bowl, but for interior decoration(cladding) it is better to take tiles of dark tones, since dark color absorbs solar radiation well, and the water will warm up better.

Choosing tiles for finishing bowl surfaces

The sizes of tiles intended for lining swimming pools can vary within very wide limits. Swimming pools rectangular shape can be tiled big size, and for configuration, during registration decorative panels and mosaics use smaller ones ceramic products. Wide color palette modern facing tiles allows you to fulfill any design ideas from a single-color surface to complex ones mosaic panels with various subjects.

Special attention should be paid to the tiles intended for the floor of the room in which the pool is built. The fact is that water can accumulate on the floors of such rooms, so there is a risk of slipping. Anti-slip tiles can be glazed or unglazed and have a structured, embossed or profiled surface. A special classification has been developed to characterize it. According to the classification, anti-slip tiles are divided into three categories:

Category “A” corresponds to tiles whose surface resists slipping at tilt angles of no more than 12 degrees. These are fairly dry areas, which include locker rooms and other utility rooms near the pool;

Category “B” includes tiles whose surface resists sliding up to an inclination angle of 18 degrees. Such premises are showers, bypass paths of pools, inclined sides and approaches to them;

From the above data it is clear: selecting porcelain tiles for finishing a swimming pool is not as simple a task as it might seem at first glance. Tiles with a profiled surface are of particular interest for places where water can accumulate. The upper surface of such tiles always remains dry thanks to protruding profiles that ensure water drainage.

Cladding the pool bowl with mosaics (glass mosaic for finishing)

Finishing swimming pools with mosaics is very popular widespread. This type of cladding should in no way be identified with ceramic mosaics, which are often used for decoration in bathrooms, kitchens and toilets. Facade ceramics, either domestic or foreign, are not suitable for finishing a swimming pool. Outwardly, they are very similar to each other and it is easy for a non-specialist to be misled, since ceramic is no different from glass mosaic for swimming pools.

Glass mosaic tiles are produced specifically for bathtubs, since everything must be a pool tile; all attempts to replace it with cheaper options are doomed to failure and invariably lead to rework, which affects the cost of the work.

Advantages of finishing swimming pools with glass mosaics

The main advantage of glass mosaic for a swimming pool is its price, which is lower than the price of its porcelain counterpart. The glass from which the mosaic is cast must have increased hardness, unlike ordinary glass. Special mineral inclusions provide greater glass strength and less fragility upon impact. The shape of the glass mosaic tiles, which is a truncated pyramid, is of interest. Therefore, when correct installation tiles, the adhesive on which they are attached completely fills tile joints and never falls out of them, even with mechanical destruction.

Mosaics in elite pools are laid in the form of artistic panels on the bottom, on internal walls and even on the ceilings of the rooms in which they are built. For artistic typography, mosaics are used special technologies, in which the picture is first drawn by the artist, and only after that computer processing is performed. Each manufacturer has its own set of colors and patterns, so after computer processing the mosaic is typed and glued to a sheet of paper in the form of a panel or its individual elements.

Size is especially important mosaic tiles when lining conical or spherical surfaces of a pool bowl, where manual laying of each element separately is required. In some cases, the mosaic even has to be trimmed to avoid large and asymmetrical seams. After cutting the mosaic tiles, the edges should be dulled. It is not recommended to use cut tiles to decorate panels on the floor of the pool, as this can lead to cuts on the feet of swimmers.

Finishing a pool with tiles is the most common finishing option. Tiles in in this case called the material that does not absorb moisture. It can be porcelain or glass mosaic any size, granitogress tiles or marble.

In all cases, the same method of lining the pool is used, the main thing being that water absorption facing material was very low, otherwise it will begin to peel off and fall off. Ceramic and clay tiles, which you can purchase at any plumbing store, are definitely not suitable for finishing a pool.

Technology

It should be remembered that tiles are the most upper layer decorative finishing and it doesn't hold water in the pool. And it is held in place by waterproofing. Waterproofing in this case is a special acrylic composition of two components, which is applied to the plastered pool bowl in 2-3 layers. The formed strong “crust” holds water well. By and large, after this event the pool can be used, it just still has an ugly gray appearance.

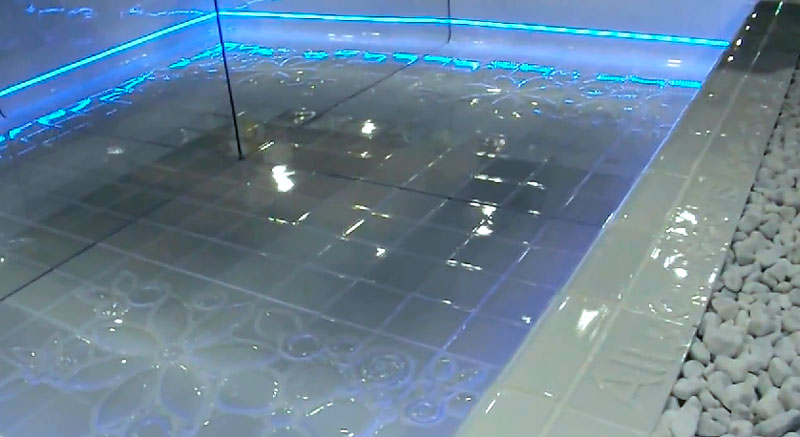

To decorate it, tiles are laid. Often a mosaic mix of blue and white squares is used, but you can always choose something else.

For finishing with tiles, a special white glue is used, which does not absorb water and ensures its reliable retention.

Grouting of joints is usually done with antibacterial white grout, designed specifically for swimming pools.

Remember that when finishing the pool you must use only professional pool construction chemicals, since most products that offer construction stores are not suitable in this case. For example, cement-based waterproofing is suitable for showers, but not suitable for swimming pools.

Most, unfortunately, do not study all aspects of this issue and purchase what is cheaper. As a result, the pool leaks and everything has to be redone.

Advantages and disadvantages

Advantages of tiling:

- Durable quality material;

- Beautiful appearance;

- Large selection of colors;

- The design possibilities are unlimited;

- The ability to create the most complex round bowl;

- Possibility of finishing with mosaic panels.

Flaws:

- More expensive compared to film;

- Long installation time;

- Finishing is carried out only on a monolithic concrete bowl;

- The cold in an outdoor pool is poorly tolerated.

Although tiles have their drawbacks, they are still an ideal material for an indoor pool. With its help you can do unique design your pool.

Additional Information:

- Laying PVC tiles with your own hands is perfect for finishing a kitchen, hallway, bathroom, utility room, while technology and installation...

- Options for laying tiles in the bathroom is the first question that arises for those who want to renovate. After all, you always want...

- Porcelain tiles are the most common material used in kitchens and bathrooms. However, how to choose the right one tiles so that she has...

- Furnace finishing ceramic tiles with your own hands great idea For home handyman However, you need to know how to lay tiles on the stove. Preparation…