DIY staircase to the second floor: photos and drawings with dimensions. How to make a staircase to the second floor with your own hands Where to install a staircase to the second floor

The interfloor staircase is an important part of a private house. It should be comfortable for adults and children. In addition, it is necessary to provide for the possibility of lifting large objects along it. The most popular materials for making stairs inside the house are wood and metal. In this article we will look at how to make a staircase to the second floor in a private house with your own hands.

Requirements for interfloor stairs

For comfortable and safe operation of the staircase inside the house, it must meet a number of requirements:

- high-quality lighting of all spans;

- the width of the flight of stairs must be at least 80 cm;

- a staircase with 3 or more steps is equipped with railings, the height of which is at least 90 cm;

- The slope of the stairs is also regulated, the degree of rise is 38-45°. The ascent to the attic or attic can be equipped with a staircase with a degree of inclination of 65-74°;

- for ease of ascent, it is advisable to make the number of steps in a flight an odd number.

Advice: before making a staircase to the second floor in a wooden house, you need to calculate the load-bearing capabilities of the interfloor floors. Most often, lightweight metal or entirely wooden structures are installed.

Wooden staircase. Features of the material

The leader in popularity for the manufacture of interfloor stairs in country houses and multi-level apartments is wood. It has been used for many centuries. But in order for a product made from it to be durable, it is important to observe a number of nuances.

- The wood has a beautiful appearance and does not require expensive finishing. Depending on the type of wood, it has a different pattern and natural shade. All this can be played out and preserved by covering the material with transparent varnish. Thanks to the ability to artistically process wood, real masterpieces are created from it in the form of carved balusters and other decorative elements. In addition, a wooden staircase creates additional coziness in the room and is indispensable for country-style design solutions.

- A wooden interfloor staircase is especially preferable if the floor is made of logs. The low weight of the structure in this case is an important argument. In addition, to install it you will not need any equipment (faucet, automixer). But it is worth taking into account the specific gravity of different types of wood, since an oak structure is almost similar in weight to a metal structure of the same size.

- It can be installed even if the finishing repairs in the staircase are completed. Since there is no dirty work involved, which is inevitable when welding a metal staircase or pouring concrete steps.

- Relatively low price compared to others. Wood is optimal when combining price and quality. The cheapest will be pine, but it can release resin. Of the budget options, it is better to give preference to birch.

Choosing wood for interfloor stairs

- Premium wooden stairs have a higher price. This is a staircase that becomes the central decorative element of the house. For its manufacture, only expensive and especially beautiful wood is used, such as oak, ash or beech. It is made using carved technique, providing the structure with a large number of decorative elements.

- In the ranking of beautiful and durable, beech and oak share first place. But ash surpasses them in the beauty of the design, while not inferior in density.

- In the cheaper price category are larch, birch and pine. They have lower strength characteristics. But the main argument for choosing them is the lower, and as a result, affordable price for most home owners.

- Pine is the softest wood, so it is often used for temporary stairs. But they make beautiful balusters from it that will decorate the structure for many years. But to create the steps and frame, you should choose birch.

DIY wooden staircase to the second floor

Materials and tools for wooden stairs

- It is best to buy ready-made steps, but if this is not possible, then timber with a cross-section of 40 mm is purchased for their manufacture;

- board 40 mm thick in quantity equal to the calculated amount for the project;

- beams 30 mm thick for treads;

- beams 25-30 mm for risers;

- block for strings and stringers 50x250 mm;

- balusters and handrails;

- wood screws;

- jigsaw;

- screwdriver;

- chisel, hammer;

- level, plumb line, square, tape measure, pencil;

- sanding paper, brushes and finishing material.

Calculation of interfloor stairs

- First you need to decide on the angle of inclination. As stated above, the preferred tilt angle is approximately 40°. But most often the calculation has to be made from the existing dimensions allocated for the flight of stairs and ceiling height.

- The minimum width of a flight of stairs is 80 cm, but 125-150 cm is considered comfortable.

- Now there are many online calculators for calculating stairs. There it is enough to fill in the desired ceiling height and the desired height of the steps (15-20 cm). And the program will produce a 3D model with all dimensions.

Wooden staircase design to the second floor photo

How to make a straight staircase to the second floor

Let's look at the example of building a simple straight staircase without winder steps or landings.

- Installation of stringers. Take a beam, measure the total length and cut it off. You also need to immediately cut off the width of the tread (the thickness of the step itself, usually 4 cm). In the general calculation, the width of the steps was not initially taken into account, and if this does not play any role in the future, then for the first step this is an important point.

- Cutting openings for steps in a stringer. This is done using a square. It marks the height of the riser and the width of the step. The marks are transferred to the stringer and cut out with a jigsaw. The cut areas are sanded or milled, rounding the edges. Then the stringers are placed in a permanent place, secured from below to the floor, and from above to the opening in the ceiling using anchors. It would be good if the ladder was attached to the wall along its entire length.

- Installing the bowstring. Bowstrings are measured according to the length of the stringers. Apply to the stringers and mark the places where the steps are attached. Recesses are made in the titative for them.

- Fastening the risers. They are made from a beam of appropriate width. It is sawn into separate elements, sanded and attached with self-tapping screws to the stringer. To prevent the fasteners from being noticeable, you need to tighten them slightly, deepening the caps a little in order to putty them later.

- Installation of steps. Beams or boards are laid on the risers, and after fastening they are sanded. But there is a high risk that the wood will dry out, which will lead to cracks and creaking. Therefore, it is better to buy ready-made steps, made of laminated wood.

- Fastening the railings. Then balusters or other railings are attached to the steps using studs. Handrails are placed and screwed on top.

DIY installation of stairs to the second floor video

Finishing of a wooden staircase

Wood is a complete finishing material. Finishing work often comes down to only emphasizing the design and applying a protective layer.

If the material is damaged, cracked or chipped, they are puttied to match the color of the wood. After coating with tinted varnish or stain, these defects become invisible.

Stages of work

- Upon completion of the staircase assembly, all wooden elements are sanded. Then wipe with a damp cloth to completely remove all dust.

- If there are defects, they are immediately filled with putty and left for a day until the composition has completely hardened.

- Then you can go in two ways: first, tint the stairs with stain, and then apply a protective transparent varnish, or ask the store to tint the varnish. The second option is preferable, since the work will go faster and the color will be the same on all elements.

- The varnish for the treads is chosen to be very wear-resistant - floor or deck. After applying 1 layer and its complete drying, the steps must be sanded with fine sandpaper. Then a second layer of varnish is applied.

Tip: it is quite difficult to apply tinted varnish evenly; even when using a brush with very fine bristles, traces of strokes will be noticeable. It is recommended to use a spray gun.

Metal interfloor staircase

To make a ladder from metal you need to have welding skills. In addition, this design is more complex and expensive to implement. But it has a number of significant advantages over its wooden counterpart:

- high strength and longer service life;

- technical characteristics ensure resistance to heavy loads;

- reliability of connection points;

- the ability to create various designs;

- allows you to extend the installation process. So, during repair work, in order not to pollute the steps, you can only climb along the frame. And after finishing, install the steps;

- the metal frame of the staircase will guarantee that creaking will not appear over time.

Types of metal interfloor stairs

The appearance of the staircase depends only on the imagination and interior design into which it should fit harmoniously. But its design depends on the location.

- Installation location. Inside the house, the staircase is convenient to use all year round and it becomes a decorative element. The outdoor location allows you to save living space; they are often placed to be lifted from the balcony to the attic floor.

- Manufacturing methods. Most often, welded stairs are made. The easiest way is to make them yourself right on the spot. Forged structures are more elegant, but are made in workshops in advance.

- Finishing. In staircases without finishing, it is stipulated that the frame will be visible, which means it must be made of very high quality from an aesthetic point of view. With finishing, the flights of stairs are completely closed on all sides; it is not uncommon to set up a room underneath with a door for storing things or food.

- By build type. One-piece, they are sold in ready-made sections and assembled on site. In this case, its exact dimensions must be known at the stage of designing the house. Prefabricated ones consist of a large number of parts and connecting elements, which allows you to create a structure of the desired height.

- Difference in design. Marching ones are either a staircase with a turning platform or with winder steps. Spiral staircases are the most compact, since the flight is located around one central support pillar.

DIY metal interfloor staircase

Before assembling the stairs to the second floor, you need to prepare all the necessary tools and materials:

- welding machine;

- grinder, drill;

- square, level;

- electrodes, metal screws, cutting and cleaning discs for grinders;

- channel, metal pipe;

- metal corner;

- sheet metal.

Tip: the quantity and characteristics of the material depend on the type of staircase structure, the number of steps and finishing. Thus, stone is much heavier than wood, and when finishing it, the staircase frame must be stronger than when facing it with wood.

Theoretically, the staircase can be made in two ways: welded in advance and installed ready-made on site, or manufactured in stages directly in the installation area. The second option is preferable, as it allows, if necessary, to make adjustments.

Stages of work

- First, the type of frame is determined. If there are winder steps, what will their location be (rotate by 90° or turn by 180°).

- Using the program and known dimensions, a sketch is created. It is recommended to entrust this stage to a professional designer.

- In accordance with the project, the required amount of metal is purchased, and if necessary, it is immediately cleaned from scale and rust with a grinder. Drawings of the elements are transferred to it and sawed. At this stage it is important to mark all parts of the structure.

- If there is a platform, then first its frame is made and installed in the flight of stairs. Next, beams are mounted from the floor to it, acting as stringers.

- Next, the required number of identical fillies are produced at once - these are triangular elements that will serve as a support for future steps. They are welded along the entire length of the stringer. It is very important to position them correctly, so first you just need to grab them pointwise in a couple of places, check the evenness with a square, and only then make a high-quality seam. They can also be welded to the frame or secured with bolts. The work is carried out from the bottom up, installing the lower fillies, placing a board on them and standing on it, and so gradually moving up to the top.

- If it is necessary to achieve greater rigidity of the steps, then a steel corner is welded between the fillies, which also acts as a support for the step.

- Then comes metal processing. All seams are cleaned, then treated with acetone, an anti-rust agent and primed. After that it is painted.

- Attach the steps to the bolts from below. Then the railings and decorative elements are installed.

Layout of the staircase to the second floor in a private

Finishing of a metal staircase

Tiling a metal staircase:

- Laying the tiles begins from the bottom up. First, it is attached to the riser between the floor and the first tread. Then the tiles are laid along the width of the entire first step and only then the next tread is attached. This method allows for the most efficient application of glue and the absence of sawed edges of the tiles;

- since a metal staircase will vibrate when walking on it, the tile adhesive must be special and of high strength;

- It will not be possible to complete all the cladding in one stage. Since you will have to leave room for walking on the edge until the tile adhesive has completely set in other areas.

Cladding a metal staircase with wood:

- Attaching a wooden tread to a metal step from below would be the best option, since the fixation point will be invisible. To do this, the metal step is pre-drilled in 8 places (4 on each side of the center, at a distance of 25 cm from each other). A wooden step is placed on top and attached to the bottom through the holes with self-tapping screws;

- If fastening from below is not possible, you will have to drill through the wooden step from above along with the metal. To do this, it should be firmly fixed to a metal platform. To hide the heads of the self-tapping screws, drill a 5 mm recess from above with a drill of a larger diameter. The tread is fastened with metal screws, and the head is puttied. Or use special wooden overlays.

Interfloor concrete staircase

- Concrete stairs are very heavy and can only be erected in houses with reinforced concrete floors.

- They are built immediately after the frame of the house with the roof is ready.

- Once the solution has set, it can be used.

- Over time, concrete stairs will not begin to creak like wooden ones, and when stepped on, vibrations will not form like iron ones.

- Due to their solidity, such stairs are considered safer, and if the cladding is damaged, it can be easily repaired.

- But it will not be possible to make a staircase from concrete in a small opening.

Step-by-step instructions on how to make an interfloor concrete staircase

- When all the calculations have been made, according to the project, the formwork of the entire flight of stairs is done. It is made from boards 20-30 mm thick.

- Reinforcement is laid inside the future steps. It can be knitted from a metal or fiberglass rod.

- The lower stage is poured first. While the solution is soft, it is pierced with a metal trowel to remove air bubbles and compact it as much as possible.

- After this, the poured step is covered with film and a board longer than the steps is placed on top so that it rests on the formwork and can be stepped on to fill the next step. The entire staircase is built in this way.

Finishing of concrete stairs

- After dismantling the formwork, the staircase has a massive and unrefined appearance. Careful finishing will be required not only of all elements (steps, risers), but also of all places adjacent to the walls.

- The choice of material depends on the configuration of the staircase. If it is straight, then there will be no problems, but if there are winder and rotary steps, the facing material should be easy to cut.

- Also, the coating of the treads themselves must be non-slip and resistant to mechanical stress.

- Recently, it has become popular to finish stairwells with the same material that was used on the floors of both floors.

- The degree of noise is also important. If wooden steps or those covered with carpet almost completely absorb the noise of footsteps, then stone or finished tiles, on the contrary, can enhance it.

When using rolled material, you should glue it very carefully. If even a small fragment comes off, it can cause a fall. Most often, this is carpet with a high degree of abrasion resistance (wool carpets are not suitable for stairs). It is allowed to cover the steps with cork, but not in rolls, but with a greater thickness in mats.

Modern trends towards rational use of territory, more than ever, encourage building houses not “width”, but “height”. This applies to private buildings, but even apartment residents are trying to organize a multi-level layout, thereby expanding the usable area. To combine the upper and lower spaces, it becomes necessary to build a staircase to the second floor, the features of which we will dwell on in more detail.

Types of stairs by design

When designing a staircase, first of all you will have to focus not on the design, but on the area of the room in order to select the ideal product in terms of design and size. There are two main types:

Marching stairs

A common version of stairs, designed taking into account the biomechanics of movements and providing comfortable, safe movement. They consist of marches ranging from 3 to 15 steps. If the maximum number is not enough, the height is divided into two openings, between which a small platform or winder steps are installed. Such structures are already called two-flight.

Marching stairs vary in shape and can be straight, rotary (L-shaped or U-shaped) or curved. When determining this parameter, it is necessary to rely on the area of the room, the height of the ceilings, and the location of the second floor.

Based on the type of supporting structure, there are two types of marching products: on stringers and bowstrings. In the first case, the steps are laid on top of the beam, and in the second, special grooves are made on the inside of the supporting element.

You will also have to choose the type of steps. Parts with risers look more massive and will fit perfectly into a classic interior, while those without them are suitable for a modern home due to their lightweight design.

In general, staircases are presented in a wide range, and even for small ones you can choose a suitable example or combine it with other items.

Spiral staircases

The principle of such structures is very simple: steps are attached to an installed rod, which rise upward in a spiral. They do not take up extra space and are quite compact.

The main reason why spiral staircases are inferior to marching ones is the difficulty of moving due to the lack of solid support. It is not recommended to install such an instance in a house where children or elderly people live. The following parameters are considered optimal: the central width of the steps should be at least 20 cm, and the widest part should be no more than 40 cm.

In other cases, spiral staircases can be considered an excellent option for both modern and classic styles. Thanks to their spiral shape, they become a key element of the interior, and products of different shapes - from square to octagonal - will help diversify the design.

Stairs on rails

It is not possible to install this type of staircase in the center of the room - it is supported by a load-bearing wall, to which the steps are attached using bolts. Collected into one system, they form a single load-bearing element, giving the structure a light, almost weightless appearance, thanks to which it is often used in modern interiors.

Despite the visual fragility, the products can withstand from 500 to 1100 kg, depending on the material and manufacturer. In addition, the bolts allow you to adjust the height of the steps after installation.

Staircases on rails with railings, which take part of the load upon themselves, are popular. You can experiment with the base, shape and lighting to create a unique look for your home.

Choosing material for the stairs

Stairs are made from different materials, which give them certain aesthetic and practical properties.

Wooden stairs

When imagining a staircase in a house, an image of a solid wooden structure with curly railings and a beautiful deep texture immediately appears. It can be luxurious wenge, oak or minimalist wood of simple species. Ash, walnut, and beech are considered the best options, but pine is not strong enough to withstand the required load. The varnish coating will protect against the negative effects of the environment, but it will have to be updated regularly.

This material is suitable for any designs, but looks most organically as marching products. For country or American style, such a solution is indispensable.

Metal stairs

Metal structures will serve you for half a century, maintaining their original, neat appearance. To do this, choose items made of stainless steel, which does not corrode, since chrome-plated or painted options have a limited service life - no more than 6-7 years.

The plasticity of the base allows you to give the staircase and its parts any shape. Metal is often combined with other materials, such as wood, glass, concrete. It makes elegant wrought iron handrails.

Concrete stairs

Unlike more natural materials, concrete does not have lightness or sophistication; in its pure form it is unlikely to fit into a classic interior, but instead will give a feeling of solidity and integrity.

Such structures are quite reliable, can withstand high loads and do not deteriorate over time. Unfortunately, they are difficult to install yourself, but the low cost of raw materials makes up for this drawback.

An important advantage of concrete stairs is the possibility of decorating them: with stone, wood or even tiles. The unique rough texture will not be noticeable, but you will get an aesthetic design at an affordable cost.

Stone stairs

Marble has a stunning deep texture, but as a stair covering it wears out quickly, within just a few years. Granite or quartzite have the opposite properties. Much cheaper artificial analogues also cope well with their role.

Stone stairs are often combined with metal handrails, and by adjusting the decor you can fit them into many styles.

Glass stairs

If design, which does not require ten years of service, comes first, glass structures have no competitors. Steps are made from this material, which are attached to bolts or used on spiral staircases. It acts harmoniously in tandem with metal, enhancing the gloss effect and adding reliability to such a fragile product.

Indeed, glass stairs can be damaged by a strong impact, but even without it, noticeable scratches appear on the surface over time. For greater strength, it is better to take hardened or laminated varieties. Acrylic glass is considered the most reliable, but tends to darken over time.

Styles and design

Because of their shape, stairs often stand out among the interior ensemble, while remaining an organic part of it. To do this, when developing a design, you need to focus on the basic style of the premises.

Staircases in a modern style

Modern aesthetics loves laconicism and restraint, the use of practical materials, and their combination to create a more complex look. Preference is given to pure geometric shapes, lines, and smooth surfaces.

The style works with the characteristics of the space, so the type of staircase design can be any, the main thing is that it looks good in the interior.

Classic style stairs

As mentioned above, classics are characterized by the use of three materials: wood, metal and decorative stone, among which the first is clearly the leader. Initially, you need to choose rooms with a large area, since even the staircase here has a massive appearance.

Often these are marching products on stringers or bowstrings with closed risers, divided into several spans and fenced with strong railings, often with characteristic carvings.

Loft style stairs

Concrete stairs to the second floor harmoniously interact with the style of the loft, emphasizing its industrial character. However, other bases would also look appropriate.

The staircase should have an extremely simple design, ensuring comfortable movement. Since the loft interior, according to the rules, is located on large areas, you don’t have to worry about the size of the structure.

Stairs in minimalist style

It is desirable that minimalist staircases attract attention to themselves as little as possible. Ideally, they should fit into the overall volume of the room, forming a single functional whole with it.

Means of expression are kept to a minimum: the texture of the material, smooth lines, natural colors. An excellent solution is steps on rails.

Art Deco staircases

Elegant and multifaceted Art Deco strives to emphasize its “status” in all details - from the base of the stairs to the railings. The latter can repeat complex, intertwining patterns inspired by floral images.

Marching staircases will look monumental and noble; spiral staircases, due to their spiral shape, themselves correspond to the Art Deco style, but bolt-on fastenings will seem too simple.

Where to post: basic rules

Installing stairs to the second floor is a very personal process that depends on the size, layout and height of the ceilings in your space.

The most popular place for a staircase remains the hallway, especially in spacious mansions. Thus, upon entering the house, you immediately have access to all rooms without wandering along the corridors.

The second most popular place to place a lift is the living room. This is convenient for buildings with a medium area, if the second floor leads to a private room, for example, a bedroom. In the hall combined with the kitchen, the stairs can be used for zoning.

To somehow compensate for the impressive size of the staircase, it can be combined with another functional item, using the empty space. This applies to marching structures located next to the wall. The construction of such products is more complex and requires detailed measurements and careful planning, but the final result will allow you to make maximum use of every square meter of the room.

The under-staircase area can serve as a frame for cabinets. The solution is relevant in the hall (storage of clothes and shoes) or living room (for a home library and household items).

The staircase can be organized in the form of a wall in the living room, along the protruding parts of which movement between floors is carried out.

Connoisseurs of quality drinks can arrange a large collection of wines by enclosing it with glass doors and installing lighting.

In the resulting niche you can put a small sofa, create a cozy place for relaxation and privacy, and install shelves on the side walls.

The space under the stairs is suitable for creating a separate room - a storage room, a study or a mini-workshop. Any child will be delighted with such a secluded children's playroom.

Using these ideas will allow you to take a different look at stairs in the house, which will turn from a bulky object into a functional solution.

Design of the staircase to the second floor - photo

It is difficult not to notice the staircase even in the most spacious interior, which is why so much attention is paid to its design. Even more diverse shapes, decor options and layouts are in our photo selection. Enjoy watching!

When building a house with at least 2 floors, you definitely need to think about the stairs in it. And if the house is built with your own hands, it is logical to build the stairs as well.

Various photos of stairs help you make a preliminary choice and clearly understand what type of lift you need. But before you take on the work, carefully calculate the future structure for strength and dimensions, this will save time and money, because incorrect calculations (or lack thereof) will lead to numerous alterations of the original project.

Types of stairs

There are a large number of different options for flights of stairs. They differ in the material of manufacture (wood, concrete or metal), the type of rise (sloping staircase, spiral staircase, with a turn at a certain degree).

The most common is a wooden staircase. Staircases are also often constructed with a 90-degree turn. It is not uncommon for these two types of lifting devices to be combined into one.

In case of limited space, make a spiral staircase from metal. The screw type of lift allows you to save space, and making it from metal increases the strength of the structure. Concrete is used for stairs in massive buildings (for example, mansions).

What to pay attention to

In a low-rise building, without any construction experience, it is better to order a modular staircase, a kind of construction set, where all the parts are cut out and numbered, and all you have to do is assemble them using the instructions. This is how wooden stairs are usually made.

When building a concrete staircase, in addition to pouring the frame, you will need to perform external finishing (with beautiful stone or wood materials). It turns out to be a double waste of time and money. However, for cottages with 3 or more floors, they are mandatory according to fire safety requirements.

When making a staircase for the first time, you don’t need to jump straight into a complex structure. The simpler the model, the more likely it is that you will be able to successfully build this lifting device on the first try.

Pay attention to the angle of inclination of the stairs: if it is more than 45 degrees, the ladder will be considered an extension, and you can only go down it backwards. The optimal elevation angle is considered to be 37 degrees.

Wood is preferable as a material for construction, since, thanks to its properties, it allows you to correct minor construction flaws that arose due to inaccurate calculations and inexperience of the work performer.

Also, after construction, the building may settle due to loose soil, as a result the staircase can become several centimeters higher or lower than the floor, and it is easier to correct this in a wooden structure.

When constructing a lift with a turn towards, the distance between spans must be at least 100 mm.

Construction stages

Answering the question of how to make a staircase to the second floor with your own hands, there are several stages of construction.

The first stage of any structure, be it a staircase into a house or an interfloor staircase, is the creation of a project. Particular attention should be paid to the safety of the building and its ease of use.

The structure must support the average weight of an ordinary person with a fair margin. Be sure to use railings!

If they are not there, another fence must be designed to ensure the safety of descent and ascent.

Consider creating a wooden staircase with stringers

After you have designed your building, you need to prepare the materials. In our case, choose boards of suitable thickness and length, prepare balusters with railings and prepare stringers. This will be the second stage of construction.

A 4 cm thick pine board is suitable as a material for stringers. On it, mark the steps according to the pattern and cut them out with a jigsaw.

Note!

We use the resulting product as a sample for the second (and if the width of the staircase is more than a meter, then the third) stringer. Let's cut the required number of steps to size.

The third stage will be assembling all the parts together. First of all, the stringers are installed in their permanent locations. Then, using self-tapping screws, the steps are attached to the stringers.

Then, using pins, balusters are placed on the steps, and handrails are attached to them. The staircase is ready!

DIY staircase photo

Note!

The tree is always popular among owners of private houses. This pliable material is suitable for any construction work. The potential of wood is especially revealed when constructing stairs to the second floor. We'll tell you how to competently draw up a project, calculate dimensions and select tools.

There are the following types of interfloor stairs:

Single march.

Single march with a platform.

Double march.

Screw.

Spiral.

Circular.

Combined.

The final choice depends on the dimensions and geometry of the room. Most simple option - one-march, and most difficult- combined.

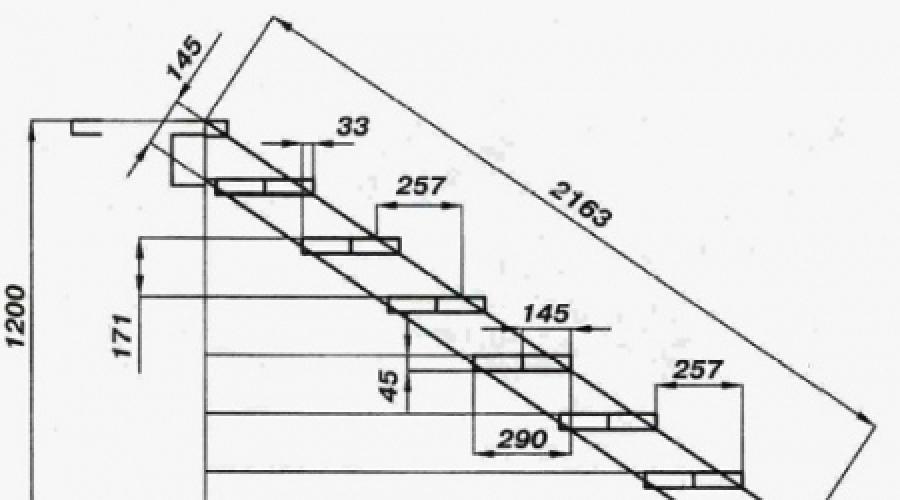

A detailed cross-sectional drawing of the staircase is shown in the picture below. Before manufacturing structural elements, you should determine its dimensions.

Since the staircase to the second floor will be constructed, the height is known in advance - this distance between floors.

Need to measure the distance from ceiling to floor taking into account the thickness of the overlap. In our case it is 2700 mm:

The step has a horizontal plane - tread and vertical (lifting height) - riser. There are stairs with and without risers.

Practice has proven that the optimal step height is calculated based on the indicators 150-200 mm. For example, the size of our staircase steps is 200 mm. Then 2700 mm is divided by 200 mm, and it turns out 13 steps.

IN SNIP precisely defined dimensions:

For residential and public premises: riser height - 148 mm, tread width - 300 mm.

For basements and attics: riser height - 171 mm, tread width - 260 mm.

Often steps rest on the cutouts in the bowstrings, are inserted or crash into into the inner part of their surface.

Further it is necessary project the design stairs to the floor of the room in order to determine how it will be placed in the room. The width of the stair tread is within 250-300 mm. We have it 250 mm, and after multiplying the value by 13 steps, the resulting projection size is equal to 3250 mm.

The last thing to do is calculate length stairs. It is determined according to the Pythagorean theorem. This value corresponds to the square root taken from the sum of the squares of the legs of a right triangle.

In our case, the hypotenuse is equal to 3260 mm. That's what it is required length.

Next stage- production of parts and elements of stairs. It is necessary to take a wooden beam with a section 140×60 mm, from which they will be made stringers.

Kosour- the supporting structure of a flight of stairs, in the form of a beam (bar) with a ridge along the top, on which the steps are installed.

They are needed two pieces, and they are made from boards thick 30-40 mm - 13 steps, and from boards thick 25-30 mm it turns out 13 risers. The length of the step should be chosen based on the size of the room.

It should also be taken into account that when the width of the flight of stairs is less 1 meters certain inconvenience during the construction and operation of stairs.

When buying wood to build a staircase, pay attention to the quality of the material. It should be uniform in color, without grayish areas, deformations or cracks.

Humidity You won’t be able to determine the wood without special instruments, but too much “water” is felt by weight - such a board will be much heavier than you expected.

Planed wood(and this is exactly the kind of wood you should buy) should be smooth, without roughness, without knots and other defects. Knots on stair stringers should be especially avoided.

On one linear meter of lumber there should not be more than one knot.

If you cannot find boards of the required width, you can make steps from several narrow boards by connecting them furniture dowels on glue:

In order to connect the boards with dowels, side faces recesses equal to half the length of the dowel are drilled, and the wooden nail is driven in with a hammer until it stops. Then its ends are smeared with paint, and the boards are moved towards each other with their side edges.

In those places where a trace of paint remains, holes are drilled a little deeper than protruding dowels.

And the boards and wooden nails in the places where they will be joined, need to be lubricated with glue and assembled. To avoid leaving marks on the surface from hammer blows, you need to lay a wooden strip. Dowels need to be attached every 150-200 mm.

Such a step, assembled from several boards, will completely replace made from a single board. Flaw this stage - miniature gap, because the lumber cannot be aligned absolutely exactly, so the surface will need to be modified with a plane in order to finally level it.

Before assembling the stairs into a single structure, you need try on all the details, and, if necessary, adjust them to size. After this, the elements should be cleaned with sandpaper. Pay special attention to the end surfaces.

Connect all the parts you need stainless screws with preliminary coating of surfaces with glue PVA, wood glue or Bustilate.

Then all the elements of the stairs covered with stain, and after it several layers of transparent waterproof varnish are applied. If there is no stain, then it is allowed to treat wooden surfaces with heated drying oil 2-3 times. It is better to apply the composition before assembly parts so that the screw heads do not get dirty.

To protect places, on which glue will be applied, from varnish and drying oil, their sealed with special masking tape.

If you want your staircase to look sleeker and more elegant, you can use a scheme with mortise steps. The marking of all elements in this case is performed in the same way as before.

To cut grooves in stringers To firmly fix the steps, a chisel is used along with a hacksaw:

It is better to assemble this structure not with screws, and fasten the steps with bolts with a rounded head, which is equipped with a slot for a wide slotted screwdriver.

The connection is made like this:

After selecting the grooves for the steps in the stringer, you need to drill holes diameter 10 mm in the central part of the groove.

Step inserted into the groove, and a mark is made through the drilled hole. Then a hole is drilled at this location so that the threaded insert can be screwed in.

Screwdrivers are best used for threaded bolts M8 length 40-50 mm.

Insertion required screw into the step, which is then inserted into the groove and tightened with a bolt. This installation method will provide excellent reliability and good strength. You can also fasten it with furniture screws.

Screw head needed recess into the drilled chamfer, which will then be closed with a decorative plastic plug.

All fasteners and wood drills buy in construction stores.

It is impossible to build a wooden staircase to the second floor without reliable fixation. But, if the structure is small in size: for a country house in 5-6 steps, then additional fastenings for steps it is not necessary to arrange. A good frame will withstand the load.

Everything is clear with the drawings, design and process of assembling a wooden staircase with your own hands. A tools These are what you will need:

To drill holes, you will need a hand or electric drill, or in extreme cases, a brace.

To cut boards and other wooden parts, a hacksaw is required. For small elements, you can use a hacksaw with large teeth.

For fastening bolts, screws and screws, you will need screwdrivers with an appropriate set of tips or an electric (cordless) screwdriver. You can also use an electric drill, but it is too heavy.

To make grooves, you should stock up on a chisel. A light hammer will also come in handy. Masses in 200-250 grams will be enough.

When grinding and leveling lumber, you can’t do without a plane and sandpaper of all sizes: coarse, medium and fine.

For marking and measuring you need to take with you a tape measure, a bench angle, a simple hard pencil and several rulers long 50-80 cm.

Fine grain paper definitely necessary clean all parts, otherwise, after the varnish dries, the wood fibers will begin to bristle, which will negatively affect the appearance of the entire staircase.

Training video

At the end of the material, we suggest watching a video with the manufacture of a wooden two-flight staircase:

Modern private country houses are growing like mushrooms, or rather like pine trees or even sequoias. Today, it is not uncommon for country houses to have two or even three floors. There are also houses with an attic. Not to mention the two-level apartments. In order to go upstairs you need stairs or an elevator. The latter, of course, is self-indulgence, although it has its place. We’ll talk about how to make a wooden staircase on your own.

One might assume that this is not so difficult, but in reality such work has its own subtleties and requires knowledge of the matter. After all, you don’t need just any staircase, but a structure that is beautiful, durable and so safe that it can be safely used for a long time.

Stairs for a country house, cottage or cottage are often made of wood. The right choice of durable wood is a guarantee that the staircase will last a long time. At the same time, the environmental component is of no small importance.

Types and types of staircase designs for a private house

The choice of staircase is often limited by the available space for its installation, and of course the budget. But, it is better to be guided by the convenience of location and aesthetic preferences. Among the existing designs of wooden stairs, the most common are marching and spiral.

Spiral staircases

This option is convenient when space is limited. Such a ladder can be placed on a heel of 1.5 meters. True, it can only be used to move one person up or down. It will no longer be possible to lift something large, such as furniture.

This option is convenient when space is limited. Such a ladder can be placed on a heel of 1.5 meters. True, it can only be used to move one person up or down. It will no longer be possible to lift something large, such as furniture.

In addition, it has a complex structure and its construction requires more labor.

At the same time, many nuances have to be taken into account: check the structure for strength, first of all, the supporting racks must be reliable.

The complexity of the design is due to the fact that the main parts have to be calculated taking into account all the design features.

Experienced specialists can handle this type of work better. It is difficult to do it yourself without special skills and tools.

Marching stairs

Wooden staircases for a home can be single-flight, two-flight, three-flight and multi-flight (each of them is used in certain conditions, which depend on the number of floors and area of the building).

Marching stairs are divided into straight and rotary according to their orientation. They can be placed along the wall or as an independent structure in the middle of the room.

It is worth noting that the installation of a straight staircase requires sufficient free space, as it takes up a lot of space. In general, this type of design is much easier to implement independently compared to the screw version.

If the number of steps is more than 10, it is recommended to divide the staircase into two parts, connecting them together with an intermediate platform. If necessary and to save space (this depends on the characteristics of the room), the staircase can go up from the intermediate platform with a turn, the so-called staircase with turning steps (trapezoidal steps, which are also called winder steps).

A staircase with a 90-degree turn is called a quarter-turn staircase. The half-turn staircase has a rotation angle of 180 degrees.

When the turn is 360 degrees, then this is already a variant of a circular or spiral staircase. Although, in principle, this is an ordinary staircase with winder steps and a turn of * degrees.

Combined stairs

Depending on the layout and design of the house, it is possible to install a combined staircase structure, which will consist of two or more types of stairs. For example, a flight of stairs on a certain flight is complemented by a screw element supported on bowstrings or stringers. Of course, such a design is very complex and requires precise calculations.

Before choosing one design or another, you should sensibly assess your capabilities. It is better to have a simpler straight staircase, but reliable and made of high-quality materials, than an intricate spiral or combined one, which may not have enough money or effort to build.

And of course, space is of decisive importance, so that later it does not turn out that the stairs will take up more than half of the house.

Start with measurements and calculations. Draw a drawing or order from specialists. You can even create a 3D model of the future staircase and clearly see the location in your layout.

Interfloor wooden stairs - selection of components and load-bearing elements

It is possible that the staircase you are creating will be your first experience, then a straight staircase will be the best choice. This option is easy to manufacture, its installation and assembly are also not very complicated, and the resulting result will meet all the basic requirements for strength, convenience and durability.

Making a wooden staircase with your own hands is possible if you have the appropriate tools, high-quality lumber and experience.

Material for staircase construction:

- Bars for steps, the thickness of which must be at least 40 mm.

- The boards are approximately the same width and size as specified in the project.

- Beams for tread 30-40 mm.

- Beams for risers no less than 30 mm.

- Beam for stringers or strings 50x250 mm.

- You can make handrails, railings and balusters yourself, but it is better to buy ready-made ones.

- Stainless steel screws are used for fastening.

The pictures show drawings of wooden stairs

Do-it-yourself installation of a wooden staircase:

- As mentioned above, you first need to think through the design, calculate the number of steps and determine the dimensions of the staircase (width, length); you can download a ready-made drawing on the Internet or make a simple diagram yourself.

- A standard march can be built with the steps supported by strings that run from both sides. Another fastening option involves supporting the steps on stringers, which are beams located at the bottom of the steps.

- All steps are first connected to strings, then the structure is strengthened with supporting bars, which are placed under the stairs at an equal distance from each other. With a sufficiently high angle of inclination of the march, there is no need for bars, although it is still advisable to install them to guarantee safety.

- The bottom and top of the bowstring should be attached to the walls, floor or ceiling.

The performance and decorative qualities of a wooden staircase, its ability to withstand humidity and other influences, for example, wood pests, are significantly increased when it is treated with a special varnish or stain. Such a staircase will not lose its original appearance and reliability for a long time.

How to make a wooden staircase with your own hands - video instructions

Photos of wooden stairs for home