Attaching railings to balusters and posts. Methods of attaching balusters to steps and stair railings. Installation on the plane of steps

The staircase located in the room is the main object of attention, defining the interior of the entire room. Do not forget that the staircase is a rather traumatic structure. Both parameters are equally important during its construction. Installing balusters helps solve these problems.

Rules and requirements for installing balusters

Structurally, balusters are an indispensable element of stair railings in the form of a vertical support, the shape of which matches the style of the interior space and transforms a conventional structure into a design element, and often becomes a work of art. For the manufacture of these staircase elements, the following materials and their combinations are used:

- tree;

- natural and artificial stone;

- metal;

- glass;

- concrete, brick.

Structural safety is ensured by reliable fastening of balusters, which, regardless of their shape and material, must comply with the general rules:

The horizontal or vertical arrangement of balusters does not play a big role in ensuring the safety of the structure, since the load-bearing function of these elements is comparable; they are usually chosen depending on the style and design of the staircase and the interior.

The fastening of balusters depends on the material from which they are made.

How to fasten wooden balusters?

There are two options for attaching balusters to a wooden staircase:

- Balusters are attached to the steps. With this fastening, a slight narrowing of the width of the flight of stairs occurs. Depending on the size of the balusters and the width of the steps, 1 or 2 balusters are placed on one tread; the main thing to remember is that the distance between them should not be more than 15 cm. Before attaching the handrails to the balusters, they must be cut at an angle equal to the angle of inclination of the stairs.

- Attaching balusters to the bowstring. If, during the construction of the staircase, a string of sufficient width was used to place a baluster on it, this will avoid narrowing the flight of stairs. With this method of fastening, the balusters will need to be cut at an angle equal to the angle of inclination of the stairs on both sides.

You can install balusters on a wooden staircase with your own hands in one of the following ways:

- fastening with studs;

- fastening using a wooden dowel;

- connection using self-tapping screws.

It is not recommended to fasten with nails. As a result of the constant load aimed at loosening the structure, this will cause the nail to expand the hole into which it is driven and lose its function. Let's consider each of the acceptable methods in more detail.

Using a dowel

Dowels are small sticks with a diameter of 8-12 mm and a length of 100-120 mm. In addition to the dowel, you will need glue. It is allowed to use PVA glue or special wood glue.

Let's consider the option of attaching balusters to steps; the only difference from attaching to a bowstring is that for the bowstring it is necessary to cut the bottom of the baluster at an angle.

- At the bottom of the baluster, mark the center of the base and drill a hole 1-2 mm larger than the diameter of the dowel to a depth equal to half the length of the dowel.

- Fill the resulting hole with glue and install a dowel in it. It is important to make sure that the dowel does not deviate to the side, otherwise it will not be possible to install the baluster evenly. After installing the dowel, all excess glue that was squeezed out after installation should be carefully removed and the remaining glue should be allowed to harden well.

- We mark the installation points of the balusters on the steps and drill similar holes.

- We fill the holes in the steps with glue and install the balusters. It is necessary to fix the balusters until the glue completely hardens (about 2-3 hours).

- Similar steps are performed to attach balusters to the handrail.

Fastening with studs

The length of the pin is desirable to be at least 10 cm, the diameter depending on the type of wood is from 8 to 10 mm, for hardwoods a smaller diameter is possible. Additionally, prepare PVA glue or wood glue.

Fastening balusters to a wooden staircase using a pin is only possible for perpendicularly located elements. This fastening is carried out when the balusters are located on the steps:

- For fastening with studs, it is also necessary to drill holes equal to half the length of the stud, but the diameter of the hole should be 2 mm less than the diameter of the stud.

- Pour glue into the prepared hole in the baluster and use a gas wrench to tighten the pin so that the side with the screw remains outside.

- Add glue to the tread hole and screw the baluster into it.

The drilling depth in hardwood is greater than the screwing depth, otherwise the pin may break.

Fastening with self-tapping screws

This is the simplest mounting option considered. Before fastening it in the balusters, it is necessary to drill holes with a diameter smaller than the screws used. In the upper part, the hole must be widened in order to hide the screw head.

After installing the balusters on the stairs, the drilled holes for the screws must be masked using wood putty.

Balusters are a structure that acts as a stair railing, and their main purpose is to ensure the strength of the structure. This design is designed to protect people from falls, so the correct fastening of the balusters to the steps is considered a very important point.

Material of manufacture

The material for such a design can be:

- Tree;

- Glass;

- Metal;

- Concrete;

- a natural stone;

- plastic.

For residential buildings, wooden or metal balusters are best suited.

Tree

Such fences are considered universal in their way, since they are suitable not only for wooden stairs, but also for stairs with treads made of metal, laminate or plastic, as seen in the photo. In this case, installing the posts is not difficult and will not require a very large amount of time.

Installation process

- First you need to determine how often they will be installed. They can be attached through one or two steps. For residential buildings, it is best to fasten the balusters in such a way that the distance between them is as small as possible, as shown in the video;

- At the beginning of the stairs and at the end, in order for the fence to be more durable, the supports must be of large cross-section;

- In order to be able to attach posts to the steps, special-purpose studs will be needed, their lower area will be screwed into the tread, and the baluster itself must be screwed onto the upper part;

- To avoid cracking of the wood, it is necessary to make a hole in it that will correspond to half the size of the length of the pin that needs to be screwed;

- The stud is secured using one of two methods: you can use a special wrench for this purpose, or you can clamp the stud into the screwdriver chuck and screw it in;

- It is necessary to stretch a rope between the end partitions in order to mark the place where the cut will take place;

- Next, you need to remove the wooden partition and saw off the unnecessary part;

- Next, the support is placed back;

- We attach the supports to the top of the balusters;

- The railings must be attached or glued to the railings. An alternative would be to attach the railings directly to the balusters, but in this case they will need to be connected with screws, as shown in the photo.

- All wood elements must be coated with two or three layers of varnish.

Metal

As a rule, fastening of forged metal posts occurs according to the following method:

- The first step will be to determine the partition pitch;

- Next, you need to attach the lower part to the wooden step using bolts or self-tapping screws;

- Attach supports to the upper area of the balusters;

- To them, in turn, it is necessary to glue wooden railings, which were previously varnished.

Metal posts made in high-tech style are popular among owners of private houses. These types of railings are best suited for outdoor types of stairs or for offices. They are covered with a special protective layer, which will protect them from rust and allow them to maintain their original appearance for a long period. It will also protect from sunlight and protect against deformation during operation.

Stairs consist of many parts and necessary elements that make the overall structure safe, reliable and convenient. Despite the apparent complexity, such objects can be made with your own hands. The installation of each part must be approached with all responsibility so that the result does not cause disappointment. Today we will talk about how to properly attach stair balusters.

What it is?

Before you take a closer look at the methods for installing stair balusters, you need to understand what they are.

Balusters are very important components of stairs, which are installed along their entire perimeter between the base and the railings. The main task of these parts is to prevent a person from falling.

Fencing

Most often, stairs are installed in private houses. These structures not only allow residents to move freely to the upper/lower floors of the building, but also decorate the environment as a whole.

Such structures consist of several important elements, without which it may be unsafe to use them. So, stair railings are necessary. These details make the designs more convenient to use.

The main functions of stair railings are:

- Safety. This parameter should be put in first place, since fences make it possible to safely move along the staircase structure. Safety is especially important if we are talking about an intricate spiral or very steep staircase.

- Support. Thanks to the railings, going down and up the stairs is much easier - balance is maintained and the load is distributed correctly.

- Decor. These details give the staircase a more organic and complete look. In some designs, fences are accent details and attract the main attention.

According to the installation method, the following types of stair railings are distinguished:

- Handrails. These elements are installed on the wall like a straight pipe or profile using reliable fasteners.

- Railings consisting of balusters and posts. These types of fencing are classic. They consist of vertical slats, horizontal framing and the railings themselves.

Requirements

Stair railings must meet a number of specific requirements. First of all, any structures that rise above 60 cm must be fenced. This applies to terraces, balconies, galleries, and external stairs with steps and ramps. In addition, fences should complement the boundaries of the internal staircase opening.

Structures that rise to a level of more than 1.8 m must be fenced with railings from 1.07 m.

If the width of the stairs is less than 110 cm, then the railings can only be installed on one side. If this indicator is higher, then the railings must be installed on both sides.

The height of the railings of internal stairs must be at least 90 cm. Spiral and curved stairs must also be equipped with railings on both sides. Handrails are not installed on internal structures that have only two steps, or on external staircases with three steps. One of the stair handrails must be continuous.

The handrail should not protrude beyond the fence by more than 30 cm. It must be attached so that it is at a distance of 4 cm (minimum) from the wall. There should be no sharp corners or protrusions on stair railings.

The structure must be treated with a fire-resistant agent. If small children live at home, the stairs are supplemented with a second handrail. This element is installed much lower. A balustrade should be installed along the entire staircase.

The railings should not have crossbars for the safety of children. Also, to ensure children's safety, it is necessary to install vertical fences to a height of up to 1.2 m. If people with mental disabilities live in the house, then this parameter should be increased to 1.8 m.

Railings should not restrict the free space on the stairs. The largest value by which the width of the structure can be reduced is 10 cm. The fastening points of the handrails should not be at a distance of more than 1.2 m. The fasteners of the railings should go 3 cm deep into the stairs. Glass should not be used to fill the stair railings.

Types

Staircase designs are different. It is their structure that directly determines which type of fences are installed.

Let's look at them in more detail:

- For spine stairs. Such fencing is distinguished by its original shape. In such details, as a rule, there are a large number of exquisite curves. In the case of metal structures, additional decorative elements are often installed on the fences using welding.

- For marching stairs. Such designs are distinguished by their discreet appearance - they have straight and long flights. Fences can be installed both on the steps of such stairs and on nearby walls. The main advantage of such designs is that they can be given any look, turning to any stylistic direction.

- For spiral staircases. Such staircases are rightfully recognized as the most spectacular and rich. In these designs, the railing should be a continuous spiral. It is quite difficult to manufacture such parts - for this you need not only to have the appropriate knowledge, but also special tools.

Device

Stair railings consist of the following components:

- balusters and supports;

- handrails;

- filling.

Balusters are racks in a vertical position, which are attached at the bottom to the steps, bowstring or stringer. The upper edge of these parts acts as the basis for the subsequent installation of the railings themselves. The strength, durability and reliability of the staircase directly depend on the quality characteristics of the balusters, so their selection and installation must be approached thoroughly.

The shape and size of handrails are developed taking into account their main functions. A person most often comes into contact with these elements while moving up the stairs. For this reason, handrails must have a perfectly smooth and pleasant-to-touch surface without any kind of sharp points.

The role of filling the railings is usually played by solid or lattice-type elements. They are fixed between the balusters to make the fences safer. In addition, the filling often serves as a decorative addition to the structure.

Varieties

Stair balusters are made from different materials. The performance characteristics of these parts depend on this parameter. Let's take a closer look at what types of balusters exist and what features they have.

Wooden

Wooden balusters are very common. They can be made from different types of wood. Such details look especially interesting and harmonious if complemented with carved ornaments - with such decorations, classic interiors look even more presentable and more expensive. The most common wood species used in the production of balusters are beech, birch, oak, pine and many others.

The most affordable ones are pine and birch elements. Despite their low cost, they look attractive and do not betray their cheapness in any way. However, pine itself does not like dampness and moisture, so it can only be installed in dry rooms.

Balusters made of oak or beech are much more expensive. These elements look expensive and aristocratic. Despite their apparent insignificance, oak or beech balusters can decorate the environment, adding a luxurious touch to it.

Wooden balusters have the following disadvantages:

- options made from soft wood are susceptible to damage;

- such parts must be treated with special protective compounds so that they last as long as possible and do not lose their original attractiveness;

- wooden balusters do not tolerate temperature changes and high air humidity;

- These elements do not look organic in all combinations (for example, they will not look good with metal steps).

Such elements can take the following forms:

- Cylindrical. These are simple wooden pillars. They can be supplemented with carvings. The diameter of the cylindrical elements may vary.

- Flat. Flat stair balusters have a discreet appearance. In cross-section, such elements have the shape of a narrow rectangle or ellipse.

- Sculpturally carved. These types of balusters can easily be called the most attractive and original. They are usually made by hand from expensive wood species, so they themselves are quite expensive.

Stone

Stone balusters look good and expensive. Marble is most often used in the manufacture of these parts. It boasts excellent strength characteristics, long service life, solid appearance and massiveness. Stone structures are more wear-resistant than wooden ones, since they are not afraid of temperature changes, high humidity, or mechanical damage.

However, stone balusters are not chosen so often because they are expensive. In addition, some users find this material too cumbersome.

Stone balusters are not suitable for all interior styles, so their selection should be approached very carefully.

Glass

Glass balusters are cast, so you will not see seams on them. Beautiful crystal glass models can decorate not only the staircase itself, but the entire interior as a whole. Often such details are complemented with lighting - the result is fabulous designs that attract admiring glances.

Of course, according to safety regulations, it is better not to handle such elements if there are small children living in the house. Even the most durable tempered glass can be accidentally damaged/broken and injured by the fragments.

It is recommended to give preference to balusters made of laminated silicate glass (triplex). Such materials are covered with a special film that prevents the glass from crumbling into small fragments.

As for the color scheme, it can be absolutely anything.

Concrete

Similar details in the Stalinist Empire style are made as follows: concrete mixed with gypsum or pure gypsum is added to special molds on a wire frame. It is possible to make a mold for balusters with your own hands using a little ingenuity.

Concrete balusters will not look harmonious in every interior. For example, in houses made in a modern style, such details will not look good. It is better to install them on external structures, gazebos or terraces in suburban/summer areas. However, you need to take into account a significant disadvantage of concrete balusters - they are not durable. Structures made of concrete and gypsum can collapse due to temperature fluctuations, precipitation and external influences.

Metal

Railings for stairs are most often made of metal.

The popularity of such products is due to their positive qualities:

- they are not subject to mechanical damage and deformation;

- have a long service life;

- do not lose their visual appeal for many years;

- can be made in different directions and can be either simple or very effective, decorated with patterned lines and weaves.

Aluminum and stainless steel

These products have a lot in common. This applies not only to their design, but also to their performance characteristics. Aluminum and steel balusters are not subject to corrosion and also have a perfectly smooth texture.

Models made of aluminum and stainless steel can be nickel-plated, chrome-plated or gold-plated. The choice of a suitable product depends only on the preferences of the owners.

Forged

Forged balusters are rightfully recognized as the most beautiful. They have a very original and sophisticated appearance, demonstrating the financial situation of the owners and their excellent taste. To create such elements, a pliable material is used that can be easily processed and molded.

Forged balusters can be made in two ways: cold and hot forging.

Cold forging is made from blanks and is more often used for the manufacture of simple fences. In this way, you can bend metal rods into unusual curls.

Hot forging requires more time and effort - with this method of manufacturing balusters, standard standard solutions are not used, since this is meticulous manual work, which can only be carried out in a special workshop. Thanks to hot forging, truly unique products are obtained in the form of leaves, flowers, curls and other openwork elements.

Forged balusters look good in combination with other materials. For example, this could be wooden railings. In a single tandem, such products look stylish and are suitable for both classical and gothic ensembles.

Polyurethane

Polyurethane balusters are lightweight. Such parts are available in a variety of forms and are quite inexpensive. These types of staircase parts are made from high-density polymers - such materials are not afraid of mechanical damage and heavy loads.

Polyurethane balusters consist of a special shell and a support - a metal rod. It is the last element that gives the entire product weight, making it more reliable and stable.

Many consumers choose these types of balusters because they can imitate almost any natural material.

How to select an element?

The choice of balusters depends on what material is present at the base of the staircase structure itself. Thus, for wooden products it is recommended to purchase balusters from a similar material of the same type. In this case, you need to make sure that their shades match. If you want to build a more original structure, you can create an effective combination with wood of completely different tones.

As for metal balusters, they can be used when decorating a spiral staircase. They will look disharmonious with wooden bases.

Please note that hand-made or forged models can cost a pretty penny, but with their help the staircase will take on a truly expensive and impressive look.

Concrete parts should not be purchased for interiors in more modern or delicate stylistic directions. You should always be careful with such balusters, as they can disrupt the harmony of the environment by breaking out of it. Additionally, concrete options will not last long, especially if they are located outside the home.

Glass structures are considered universal. They are worth choosing if the furnishings in your home are made in a modern and high-tech style. Such items are not always suitable for a gothic, retro or classic ensemble.

Pay attention to the quality of the balusters before purchasing them. There should be no scratches, chips, or sharp edges/particles on such parts. You should refuse to purchase damaged items.

Optimal distance

When installing railing posts, you need to correctly make markings, as well as identify the correct distance between individual elements.

To do this you need to follow these simple rules:

- the step between balusters should not be less than 15 cm;

- if there are children in the home, it is also important to take this into account when fixing the balusters - in this case, it is better to make the space between them even smaller;

- the ideal height of the posts for fixing the railings should be 80-100 cm;

- balusters must be created from the same raw materials, suitable for the material of the stairs;

- The posts need to be fastened at 2 points - at the top and bottom.

The optimal step between supports is 15 cm. If this figure is larger, it may increase the risk of injury. If you cannot comply with this requirement, it is permissible to install 2 racks on one step at once.

Fastening methods

It is permissible to place supports at the edges of steps or on a string. So, if the width of the steps allows, it is permissible to install two elements on them at once. The quality of the structure as a whole will depend on how securely and firmly the balusters are installed. Today there are several main ways to secure these parts. Let's get to know them.

Hairpins

Installation of posts using a threaded rod on a bowstring is used in situations where the parts are located clearly perpendicular. These components are not used to attach balusters to the handrail.

To make a threaded rod, you will need screws with a head with six edges (such parts are called “wood grouse”). These fasteners are fixed in pre-drilled holes at the bottom of the posts. The pin and hole must be secured with glue. These types of fasteners are well suited for fixing wooden balusters.

Self-tapping screws

Using self-tapping screws and self-tapping screws, it is possible to attach balusters to the floor. These fasteners can be used to install both wood and iron objects.

The most popular approaches are:

- baluster;

- use of a support plate;

- use of direct fixation.

These methods have a lot in common. A stronger connection to the steps can be achieved using plates that are attached with 4 screws. It is also possible to attach balusters to the side railings using self-tapping screws.

If the step is equipped with a riser, then it is convenient to bring the fasteners to the lower part. If the risers are removable, then the areas with joints will need to be properly hidden.

Dowels

Dowels and rods are mainly used in the construction of wood bases. It is important to remember that their diameter should not be more than ¼ of the diameter of the rack, and their length should not be 2 diameters of the baluster itself. In this case, markings should be applied to each element - railings, steps, and pillars. The depth of the hole should be half the diameter of the dowel. When installing fasteners coated with glue, you must start with the steps and then move on to the railings.

Such fasteners can be used when installing balusters on the plane on which the laminate lies.

Installation features

In order to properly fasten balusters with your own hands, it is important to take into account some features of such work.

Let's look at how to properly fix wooden balusters using dowel fastenings as an example:

- First, make markings on the base and make holes that are half the depth of the dowel.

- Coat the fastening areas with glue.

- Install wood dowels into the hole. Next you need to put balusters on them.

If you decide to use a pin for fastening, then the work plan will be different:

- The steel pin must first be sharpened on the side of the cut half at an angle to make it easier to insert into the hole.

- You need to make a hole in the step with a diameter 2 mm smaller than the stud itself. Then you need to carefully screw it all the way, using a gas wrench.

- Next, the post is drilled in the center of the section and screwed onto the protruding part of the thread of the stud.

- If the upper oblique cut of the pillar does not coincide with the specified one, then it is further tightened using a gas wrench.

To strengthen the balusters on the base with screws, they mainly use fasteners with a diameter of 0.5 cm and a length of 4.5.7 cm. Plastic dowels are used under the head of the “capercaillies” and self-tapping screws.

So, a self-tapping screw is screwed into the step located below (through and through). The support post is screwed onto the prominent thread in the center of the end, turning by hand until it stops.

At the same time, take into account some nuances:

- Maintain the optimal spacing between balusters (15 cm). It is important to comply with this requirement if there are small children in the home.

- Maintain a suitable support height - 80-100 cm.

- Attach each support at a couple of points - at the top and bottom.

- The thickness and cross-sectional area of the baluster do not affect the safety and strength of the construction, since these components are not load-bearing.

Decorative plugs

Places where screwed fasteners are visible have a negative impact on the aesthetics of the balusters. To solve this problem, you can use special decorative plugs. Wooden plugs are expensive, so it is better to turn to inexpensive plastic options if the structure and design of the staircase allows it.

Since plastic is not painted, owners may be faced with the problem of choosing the appropriate shade of plugs from the presented palette.

To ensure safe movement, it is necessary to ensure reliable fastening of the balusters to the elements of wooden stairs to form a protective fence. Let's look at what type of structure to choose and how to install it.

Design features and types

First, it’s worth understanding what this element of the staircase structure is. A baluster is an intermediate barrier post on which railings are installed.

Wooden balusters are undoubtedly very impressive and fit perfectly into any interior.

For wooden stairs, it is best to use balusters made of the same material. In this case, the type of wood may differ from the one from which the structure itself is made.

Balusters can vary in shape and design. The simplest are straight products, round or square in cross-section. For more refined and complex designs, shaped milled columns are made. When determining the optimal type of products, it is worth considering that figured balusters should form a beautiful pattern in the gaps after they are installed on the stairs.

Balusters must perform the following functions:

- Ensuring safety and ease of movement on stairs.

- Fencing the structure and giving it a complete, holistic look.

- Decorative - creates a special appearance and determines the style of the staircase.

- Serve as support for railings and handrails.

Fastening balusters on a wooden staircase can be done in various ways, the following methods are mainly used:

- to stringers or bowstring;

- to the steps;

- to the floor with or without a support board.

Installation of balusters to the floor

The simplest way is, perhaps, to install balusters on the landing of wooden stairs, that is, to the floor. In this case, an additional bar, the so-called baluster, is preferably used.

Installation of balusters to a special strip

This board allows you to fix all the elements in their proper places and at the same time hide the attachment points.

You can do without a board, but in this case you need to disguise the joints using decorative attachments.

To install balusters to the floor, you first need to determine the location of the fence and screw the baluster. Then mark the attachment points for the balusters themselves and drill holes. Do the same with the columns themselves. Using a pin, place them on the mounting location and screw onto the thread. The finished fence should not wobble or rotate in place. That is why it is recommended to additionally use pins and glue the fastening points, since if you simply insert the posts into the recesses, they can be easily knocked out.

Installation of balusters to steps

Another important point is the method of attaching wooden balusters to the steps on the stairs. In order to complete this task you will need to carry out a number of manipulations:

- Measure the angle of the stairs. This is necessary in order to place the posts under the railings.

- Considering the previous point, determine the required height of each element. This is especially important if two balusters are installed on one step of stairs.

- Drill a blind hole and insert a threaded pin into it.

- Place the balusters, level them and secure them.

If you use dowels instead of pins, be sure to glue the joints.

The simplest and most common way to install balusters on steps

Installation of balusters to stringers

Another installation variation is attaching to the stringers of stairs. There is more than one option for designing a fence.

How to install balusters on stringers of wooden stairs:

- Determine the fixation points and drill holes in the steps so that the drill fits into the stringers.

- Tighten the pin. It should fit into the sidewalls in such a way as not to disrupt the integrity of the element, that is, far enough from the edge.

- Drill the balusters so that when installed they do not extend beyond the boundaries of the stairs.

- Install the posts. If decorative overlays are used, you need to put them on first.

If the installation is carried out on a bowstring, then the balusters need to be cut so that the angle coincides with the slope of the stairs. For fixation, pins on hinges, so-called screw-in hinges, are used.

Option for attaching balusters to a bowstring

The fence attached to the side of the stringers looks very original. In this case, you can fix them with nuts on the reverse side, which will then be hidden by the riser.

Installation of railings

In most cases, the railings are installed after the balusters on the stairs have been installed. In order to determine the most suitable mounting method, you must first pay attention to the type of fence. We are talking about a direct barrier and handrails on the rise.

In the case when you need to install railings on a flat section of the span, for example, on a platform, there is no need to take special measurements. First of all, check whether the length of all balusters is the same; if there are discrepancies, they need to be eliminated. This can be done in two ways: sawing the posts to the desired height or planting them deeper on the base, but this is only possible with minor differences.

After this, measure the distance between the elements and mark their center point on the railing block. Drill blind holes at this location. Insert pins into the balusters and place the railings on them.

Installation of railings is carried out after installation of balusters

For sloping areas, you must first attach a railing bar to level the balusters. After this, clean the surface and drill holes in the center of the elements and at the marked coincidence points on the railing. Installation is carried out using screw-in hinges. To do this, place the halves of the fastening on the intended places, and then connect them.

Screw-in hinges allow you to set the optimal angle of inclination of the upper element of the barrier on the stairs.

To join the staircase elements at the corners, you need to cut down the railing strips at the required degree and drill holes in them in the center. Insert a screw-in loop into one part, and then slide the second one onto it. Insert a special nut into a pre-made hole of a larger diameter at the bottom of the railing and tighten the hinge axis using a hexagon.

If everything is done correctly, your staircase will look perfect, and the level of safety will comply with the rules and regulations.

Balusters are vertical supports for handrails and railings, attached to the bottom of the steps or to the side of the staircase frame. They are designed to create safe stair railings and provide the necessary rigidity for the railings attached to them. An additional, but no less important function is to decorate and create a certain style for the entire staircase structure.

Proper fastening of balusters and staircase posts ensures the safety of people when moving. The railings must be strong and stable. Therefore, the issue of choosing a technology for fastening support elements is very important when constructing stairs.

Types of balusters

Support posts for installing railings are made of wood, metal, natural and artificial stone, gypsum and concrete mixtures, plastic and even glass. They are selected depending on the design and materials of the flight of stairs itself.

Agree that wooden balusters on a stone staircase look ridiculous, and stone supports with their weight can simply break through the wooden steps. Therefore, in most cases, the material of the pillars matches the surface finish of the steps.

Methods for fixing wooden balusters

Attaching balusters and railings made of wood is carried out in various ways, but the following three are the most widespread:

- metal threaded rods;

- steel screws for wood.

The thread on studs can be the same along the entire length or divided into two parts: on one side it is ordinary metric, and on the other it resembles a long screw of large diameter. With a large length of such products, the thread is cut only to a certain length on each side. The middle remains smooth.

Dowels, or wooden nails, are the oldest and most reliable type of fastener. They are round wooden pins with a length of 50 mm and a diameter of 8-12 mm.

Wood screws used to secure balusters are a special type of screws with a wider thread pitch. The diameter of these hardware products is 5-6 mm with a length of 50-80 mm. Cap for a Phillips bit or socket wrench. The head of the screwed screw is usually covered with a plastic decorative cover.

Securing with threaded rod

Do-it-yourself installation of balusters on a wooden staircase using pins is carried out only if the mounted parts are located at an angle of 90 degrees. In case of fixing the structure on a bowstring, pins are not used. The length of the stud is at least 80 mm. There are 3 ways to secure balusters to metal threaded rods.

In one of the options, a hole is drilled at the end of a wooden post with a depth of 10-15 mm greater than the part of the stud with a metric thread. Its diameter must exactly match the size of the fastener.

A small amount of glue is poured inside the hole. After this, the metric thread of the stud is also lubricated with adhesive, sprinkled with small sawdust and screwed into the baluster. Excess glue that appears is immediately removed.

On the plane of each step, mark the installation location of the mounted column. A hole is drilled through it, the diameter of which is 1.0-1.5 mm smaller than the size of the conical thread of the stud. Lubricate all contact surfaces with glue and install by twisting the baluster with the pin inserted.

Tightening pin.

Tightening pin. In another case, the fastener element is screwed into the end of the post from the side of the conical thread, leaving no metric surface. A corresponding hole is drilled into the steps and one or two metal nuts are glued inside it. After this, the baluster is installed. The main advantage of this method is the ability to disassemble the structure if necessary.

The following method of attaching balusters to a staircase with your own hands can be used when the steps are thin and there is possible access from below to their reverse side. In this case, the pin is fixed in the baluster in the same way as the previous option, but a through hole is drilled in the step. The elements are tightened by installing a washer and screwing the nut on the bottom side of the step.

Installation on wooden dowels

The technology for installing balusters on dowels is fundamentally very similar to using metal pins. A hole with a diameter 0.5 mm smaller than the size of the connecting part is drilled at the end of each column. A small amount of glue is poured into it and a dowel of the required length, lubricated with adhesive, is driven in.

A hole is prepared in the surface of the step. The end of the baluster and the protruding part of the dowel are lubricated with glue. After this, the column is set in place under light blows of a rubber hammer or mallet.

The length of the dowel, which ensures a reliable connection, is 100-120 mm. The diameter of the connecting part is 8-12 mm. Moreover, the softer the wood of the baluster and dowel, the larger the diameter used. Ideally, the wood of the connecting stud should be the same density or species as the post being installed.

Drilling the end hole must be done in 2 stages. First, a drill with a diameter of 5 mm is used, and then drilled to the required size. This method will ensure good accuracy and prevent possible cracking of the products.

Using screws or self-tapping screws

Using wide-pitch tapered screws is the easiest way to install balusters on steps or angled strings. The disadvantage of this technology is the need to install decorative plugs in order to hide the caps of hardware elements visible on the surface. However, if the thickness of the step is small, it can be drilled through, and the self-tapping screw can be screwed in from the bottom invisible side.

Another option involves the upper inclined screwing of self-tapping hardware through the body of the baluster into a step, string or sub-baluster. Tightening is done using an electric screwdriver until the head is slightly recessed into the wood.

The screw head will still be visible, so decorative plugs are inserted or glued to hide it.

The length of the fastening elements is 50-70 mm with a diameter of 5-6 mm. To enhance the strength of the connections, you can place a round steel washer under the screw head.

Features of fastening wooden balusters to surfaces

The fastening of stair railings must be reliable and as strong as possible. The safety of people who will use the stairs depends on this. At the bottom, balusters can be attached to the floor, steps or string.

Fixing to the floor

Floor installation of pillars is provided for the lower and upper support elements, on which the handrail rail subsequently rests. To fix their position, a hole is drilled in the floor and the following can be installed:

- expansion anchors for concrete floors and monoliths with reverse conical thread;

- embedded elements for reinforced concrete monoliths;

- steel studs with a metric thread on one side and a conical thread, like on screws, on the other for wooden floors.

IN first case, before attaching the balusters to the floor, a hole is drilled in the concrete corresponding to the diameter of the anchor. When screwing in the metric thread of the pin, the fastener expands and is firmly fixed. After this, the wooden support post is screwed onto a cone-shaped thread protruding from the floor, pre-lubricated with glue.

In second option a recess of at least 80 mm is knocked out in the concrete monolith and an embedded element with a conical or metric thread in the upper part is installed into it. The embedded part is filled with cement mortar and after it hardens, a baluster is screwed onto a vertical stud.

For wooden floors, you can install a pin in the floorboards and then screw the post or do the opposite. A baluster with a hairpin is screwed into a hole drilled in the floor.

Both options are equally reliable. It is not recommended to use self-tapping screws in this case, since they will not be able to provide a sufficient level of reliability for the outer support pillars.

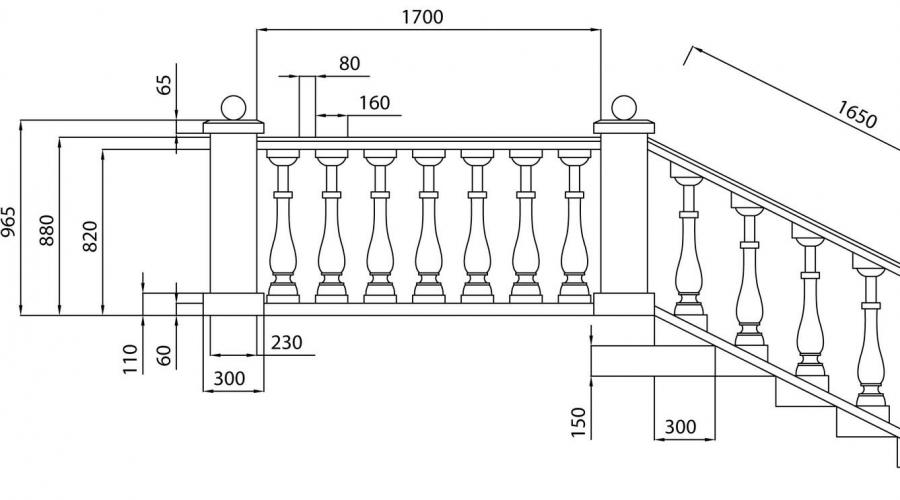

Installation on the plane of steps

Installation on horizontal wooden surfaces can be done using studs, dowels or self-tapping screws. The technology describing how to fasten balusters on a wooden staircase along the steps was discussed in some detail above.

Installation using dowels.

Installation using dowels. Mounting on an inclined string

The presence of an inclined plane does not allow the balusters to rotate during installation. Therefore, wooden dowels or screws are used to fix them. The bottom of the balusters must be cut to match the existing angle of the installation support.

Installation can be significantly simplified if you use a sub-baluster - a longitudinal rail of a certain cross-section. It is temporarily fixed on the surface of the bowstring, marking the installation locations of the elements and removed.

After this, the balusters are screwed in and the already assembled structure is returned to the surface of the string. Next, the sub-baluster itself is fixed with self-tapping screws in the open areas between the posts.

Attaching handrails to balusters

A feature of the installation of railings is the need for an identical bevel at the ends of the balusters, corresponding to the angle of inclination of the stairs. It is best to do it in advance, immediately after installing the flight of stairs.

To do this, take one post, place it on the side of the stairs and draw a line on it parallel to a string or a flat rail placed on the steps. All other columns will be trimmed according to this pattern.

Fastening the railings can be done using:

- wooden dowels;

- self-tapping screws screwed in at an angle;

- flat longitudinal wooden slats.

The length of the screws should be such that after screwing in, the sharp edge of the hardware does not come out onto the surface of the railing. You can install the handrail using a slatt in the same way as using a baluster when installing poles on a bowstring.

Features of fastening metal fencing supports

The design of metal balusters must provide for the presence of fastening units. To install metal parts on wooden stairs with your own hands, side mounting plates with holes are welded at the top and bottom of the pillars and ordinary self-tapping screws are used. Fastening to concrete surfaces is carried out using expansion anchors or dowels.

Video on the topic