Boilers kv gm 4.65 mounted. Water heating boilers KVGM. The procedure for ordering automation or a full range of works for the technical re-equipment of VKGM boilers

Read also

1.

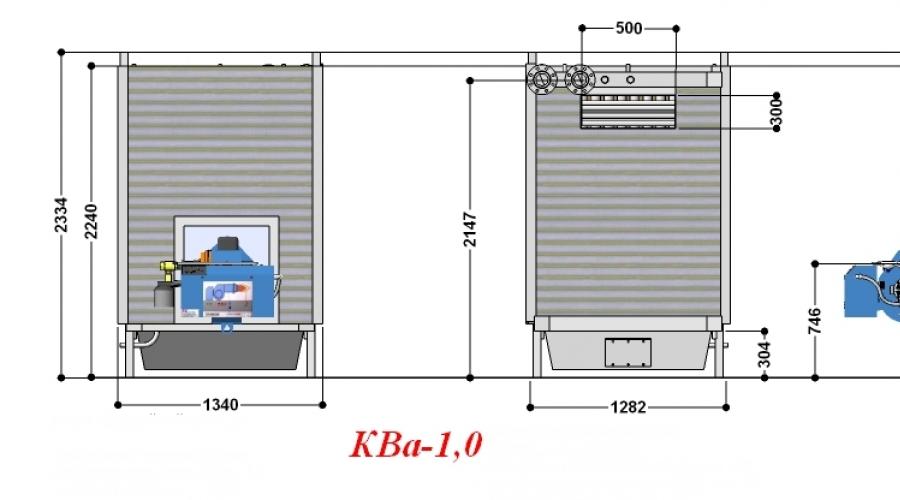

KVA boilers (unsupervised).

2.

KV-GM boilers (power from 4.65 MW).

3.

Boilers KVE, DSEV, DEV-boilers of the E, DSE, DE series manufactured in hot water mode.

Explanation of the designation:

KV - hot water boiler

GM - type of fuel - gas, fuel oil, liquid. fuel.

KVA series boilers - liquid fuel boilers of this series are separated into a separate block due to significant differences in the design of boiler cells, modular boiler systems, and in general the production process of hot water boilers looks different.

Let's start with water-heating water-tube boilers of the collector type; the structure of these boiler units is clearly visible in the drawings indicated above. Everything is as usual: the combustion chamber goes into the convective part, etc. These boilers are interesting because they are not included in the supervised list because pass both pressure (less than 0.6 MPa) and temperature (less than 115 `C), but at the request of the customer they allow you to increase these characteristics.

Boilers of this brand are intended for heating and hot water supply of industrial, public and residential buildings. They operate on gas or liquid (diesel) fuel. Depending on the type of fuel, boilers are equipped with gas, liquid fuel or combined burners.

Water heating boilers of the KVGM series are designed to produce hot water with a pressure of 0.6 (6.0) MPa (kgf/cm2) and a nominal temperature of 95 -115 `C.

Boiler type: water-tube, horizontal with forced circulation.

2. KV-GM boilers.

Boilers of the KV-GM series

- water-heating gas-oil boiler.

Boilers of the KV-GM (KV-GM) series are designed for heating, industrial and technological needs and the production of hot water with a nominal temperature at the boiler outlet of 150°C, used in industrial and domestic facilities. The boilers are designed to operate in a closed heating system with forced water circulation.

Boilers KV-GM-4.65-150 (KV-GM-4-150), KV-GM-7.56-150 (KV-GM-6.5-150)

These are water-tube boilers of a horizontal arrangement of a collector type consisting of a pipe system.

Boilers KV-GM-11.63-150 (KV-GM-10-150); KV-GM-23.26-150 (KV-GM-20-150), KV-GM-35-150

Boilers of this type consist of two blocks, combustion and convection, supplied in bulk or assembled.

Boiler type: water-tube, horizontal with forced circulation.

KV-GM boilers, and indeed KV collector-type boilers in general, are distinguished by the following:

When supplied assembled or in blocks, installation time and cost are reduced, and when supplied in bulk, additional technological openings are not required;

interchangeable components and parts used in this factory series of boilers allow them to be used on similar hot water boilers

boilers are durable, repairable, easy to maintain, have access for inspection, repair and cleaning of pipes

The boiler design is designed to operate in the Far North and areas with seismicity up to 9 points inclusive.

Technical characteristics of boilers of the KV-GM series.

| Boiler type layout number | Power MW (Gcal). | Slave. pressure, MPa (kgf/cm2) | Pace. graph,`S. | Efficiency, % | Fuel consumption gas, m3/h | Dimensions (LxBxH), mm. | Weight, kg |

| KVGM-7.56-150 (KV-GM-6.5-150) 23.8009.086 | 7,56 (6,0). |

1,0-1,35 (10-13,5) |

70-150. | 92 | 800 | 6670x 3267x 3656. |

10240 |

| KVGM-11.63-150 (KV-GM-10-150) 23.8009.074 | 11,63 (10,0). |

1,0-2,25 (10-22,5) |

70-150. | 92 | 1220 | 9370x 5000x 7975. |

19492 |

| KVGM-23.26-150 (KV-GM-20-150) 23.8009.076 | 23,26 (20,0). |

1,0-2,25 (10-22,5) |

70-150. | 92 | 2450 | 12447x 5000x 7975. |

27800 |

| KVGM-35-150 23.8009.078 | 35,0 (30,0). |

1,0-2,25 (10-22,5) |

70-150. | 92 | 3580 | 14640x 5000x 7975. |

34900 |

| KVGM-58.2-150 (PTVM-50) 23.8009.091 | 58,2 (50,0). |

1,0-2,25 (10-22,5) |

70-150. | 92 | 6340 | 9420x 7250x 13646. |

86532 |

Delivery set and recommended configuration of the boiler cell of KV-GM boilers.

| Boiler size | Basic boiler equipment | Cost, production time | |

| KV-GM-7.56-150(KV-GM-6.5-150) | Boiler block, without casing and insulation (or in bulk). | 1. Fan VDN-10-1000 2. Smoke exhauster DN-10-1000 3. Automation kit 5. Burner RGMG-7 |

see price |

| KV-GM-11.63-150(KV-GM-10-150) | 1. Fan VDN-10-1000 2. Smoke exhauster DN-12.5-1000 3. Automation kit 4. Shut-off and safety valves, safety devices 5. Burner GMPV-13 |

see price | |

| KV-GM-23.26-150(KV-GM-20-150) | Boiler block (furnace and convection blocks), without casing and insulation (or in bulk), fan 19TSS-63. | 1. Fan VDN-12.5-1000 2. Smoke exhauster DN-17X-750 3. Automation kit 4. Shut-off and safety valves, safety devices 5. Burner GMPV-25 |

see price |

| KV-GM-35-150 | Boiler block (furnace and convection blocks), without casing and insulation (or in bulk). | 1. Fan VDN-15X-1000 2. Smoke exhauster DN-17X-750 3. Automation kit 4. Shut-off and safety valves, safety devices 5. Burner GMPV-40 |

see price |

It is possible to equip boilers with burners from other manufacturers.

3. Boilers of the KVE, DSEV, DEV series - steam boilers of the E, DSE, DE series manufactured in hot water mode.

It is worth mentioning separately about hot water boilers made from steam boilers of the series - Boilers of the KBE, DSEV, DEV series (liquid fuel).

- (steam boilers switched to hot water mode). Their peculiarity is that they are manufactured using steam technology in compliance with GOST standards for regulated products.

The result: the service life of boilers in this series is many times longer than that of collector-type and fire-tube boilers.

Drawings of steam boilers transferred to hot water mode of the KBE, DEV series.

Technical characteristics of boilers of the KV-GM, DEV, KVE series.

| Boiler type layout number | Power MW (Gcal). | Slave. pressure, MPa (kgf/cm2) | Pace. graph,`S. | Efficiency, % | Fuel consumption gas, m3/h | Dimensions (LxBxH), mm. | Weight, kg |

| KVE-0.7GM 00.8009.104 | 0,7 (0,6). |

0,6 (6,0) |

70-115. | 86 | 86 | 3180x 1730s 2950. |

3630 |

| KVGM-1.6GM (DEV-1.4-95GM) 00.8009.041 | 1,6 (1,4). |

0,6 (6,0) |

70-95. | 92 | 220 | 3840x 2450x 3270. |

5795 |

| KVGM-2.9-150GM (DEV-4-14GM-O) 00.8022.218 | 2,9 (2,5). |

1,4 (14) |

70-150. | 92 | 272 | 4195x 3980x 5050. |

12886 |

| KVGM-4.6-150GM (DEV-6.5-14GM-O) 00.8022.318 | 4,65 (4,0). |

1,4 (14) |

70-150. | 92 | 441 | 4800x 3980x 5050. |

14120 |

| KVGM-7.56-150GM (DEV-10-14GM-O) 00.8022.430 | 7,56 (6,0). |

1,4 (14) |

70-150. | 92 | 667 | 6530x 3980x 5050. |

17985 |

| KVGM-11.63-150GM (DEV-16-14GM-O) 00.8022.519 | 11,63 (10,0). |

1,4 (14) |

70-150. | 92 | 1088 | 8655x 5210x 6050. |

19835 |

| KVGM-17.4-150GM (DEV-25-14GM-O) 00.8022.625 | 17,4 (15,0). |

1,4 (14) |

70-150. | 92 | 1670 | 10195x 5210x 6095. |

27457 |

| Boiler size | Basic boiler equipment | Recommended boiler cell configuration | Cost, production time |

| KBE-0.7-115GM | 1. Fan VD-2.7-3000 2. Smoke exhauster D-3.5-1500 3. Automation kit 4. Shut-off and safety valves, safety devices 5. Burner GG-1 or RGMG-1 |

see price | |

| DEV-1.4-95-115GM | Boiler block, casing and insulation. | 1. Fan VD-2.8-3000 2. Smoke exhauster DN-6.3-1500 3. Automation kit 4. Shut-off and safety valves, safety devices 5. Burner GG-2 or RGMG-2 |

see price |

| DEV-4-14GM-O | Boiler block, casing and insulation (or in bulk), stairs and platforms, burner GM-2.5. | 1. Steel economizer BVES-I-2 or cast iron economizer EB-2-94I 2. Fan VDN-8-1000 3. Smoke exhauster DN-9-1000 4. Automation kit |

see price |

| DEV-6.5-14GM-O | Boiler block, casing and insulation (or in bulk), stairs and platforms, burner GM-4.5. | 1. Steel economizer BVES-II-2 or cast iron economizer EB-2-142I 2. Fan VDN-9-1000 3. Smoke exhauster DN-11.2-1000 4. Automation kit 5. Shut-off and safety valves, safety devices |

see price |

| DEV-10-14GM-O | Boiler block, casing and insulation (or in bulk), stairs and platforms, GM-7 burner. | 1. Steel economizer BVES-III-2 or cast iron economizer EB-2-236I 2. Fan VDN-10-1000 3. Smoke exhauster DN-11.2-1500 4. Automation kit 5. Shut-off and safety valves, safety devices |

see price |

| DEV-16-14GM-O | Boiler block, casing and insulation (or in bulk), stairs and platforms, burner GM-10. | 1. Steel economizer BVES-IV-1 or cast iron economizer EB-1-330I 2. Fan VDN-9-1500 3. Smoke exhauster DN-11.2-1500 4. Automation kit 5. Shut-off and safety valves, safety devices |

see price |

| DEV-25-14GM-O | Boiler block, casing and insulation (or in bulk), stairs and platforms, burner GMP-16 (or GMR-20). | 1. Steel economizer BVES-V-1 or cast iron EB-1-808I 2. Fan VDN-11.2-1500 3. Smoke exhauster DN-12.5-1500 4. Automation kit 5. Shut-off and safety valves, safety devices |

see price |

Boilers of the KV-GM (KV-GM) series produced by the Biysk Boiler Plant are designed to produce hot water with a nominal temperature at the boiler outlet of 150 ° C, used in a centralized heat supply system for the needs of heating and hot water supply of industrial and domestic facilities, as well as for technological goals of enterprises in various industries.

The boilers are designed to operate in a closed heating system with forced water circulation.

Water-tube boilers, horizontal layout, consisting of: for boilers KV-GM-4.65-150, KV-GM-7.56-150 from a pipe system; for boilers KV-GM-11.63-150; KV-GM-23.26-150, KV-GM-35-150 from two blocks - combustion and convective, supplied in bulk or assembled. Fittings and accessories included in the boiler kit.

- Distinctive features of KV-GM:

- delivery of the boiler in advanced factory readiness ensures the quality of the product and allows reducing the installation time of the boiler;

- when boilers are supplied in bulk, technological openings in the boiler house building for installation of equipment are not required, and the quality of the product as a whole is ensured during installation and is controlled by the customer at the boiler installation site;

- lining of boilers, carried out at the installation site, significantly reduces the weight of the boiler delivery unit and the time required for factory production;

- standardized units and parts used in this factory series of boilers allow them to be used on similar hot water boilers from other manufacturers;

- blocks (with minimal reconstruction) can be used with different burners;

- a device for the return of entrainment and sharp blast in boilers provides more complete fuel burnout, and, consequently, lower fuel consumption and a reduction in CO emissions, not exceeding permissible values;

- boilers are durable, repairable, easy to maintain, have access for inspection, repair and cleaning of pipes;

- boilers with a burner operate in automatic mode, having the ability to adjust parameters and stability of load bearing;

- The boiler design is designed for installation in areas with seismicity of 9 points inclusive.

Historical reference

The Biysk Boiler Plant has mastered the production of boilers of the KV-GM series with a capacity of 4.0; 7.56; 11.63; 23.26 and 35 MW and pressure 1.0; 1.35 and 2.25 MPa since 1959.

In the late 60s and early 70s of the 20th century, a sharp industrial rise and rapid development of housing construction began in the country. There was a growing need to quickly increase thermal capacity, both at existing thermal power plants and at the construction of new heating plants.

The optimal solution to this problem was the installation of relatively inexpensive peak water heating boilers, included in the heating network and designed to cover short-term peaks in heating load, as well as as the main source of heat supply throughout the heating season and to cover the need for summer hot water supply.

To achieve this task, a standard size range of a series of peak heating hot water boilers with a heating capacity of 30, 50, 100 and 180 Gcal/h for burning gas and fuel oil was selected.

Technical and working designs were developed by VTI, the Moscow branch of the Orgenergostroy Institute and BiKZ. Since 1959, the Biysk Boiler Plant began producing boilers with a capacity of 100 and 180 Gcal/h. Subsequently, the production of this series of boilers was transferred to other boiler plants of the USSR, as well as to Czechoslovakia and Romania.

Simultaneously with high-power boilers, according to the patent of BiKZ, TsKTI and DKZ, a series of water heating boilers of the KV-GM type with a heating capacity of 10.0 was developed; 20.0; 30.0; 50.0 Gcal/h. The boilers were mass-produced and produced in large quantities.

Currently, the Biysk Boiler Plant produces boilers of the KV-TS, KV-GM and PTVM series, as well as boiler and auxiliary equipment for them: fans, smoke exhausters, economizers, water treatment equipment.

Water-heating water-tube boilers of the KV-GM series are designed for heating and hot water supply of housing, communal and industrial facilities. A boiler is a heating unit that heats water from heating networks directly or through heat exchangers. The boiler is designed to heat water with temperature curves of 95\70,115\70,150\70 with a constant flow of water through the boiler within the load control range. The load control range is 30–100%. Boilers operate on natural gas, diesel fuel, fuel oil, and solid fuel.

Design

The KV-GM boiler is a water-heating water-tube gas-tight boiler, with a horizontal or vertical arrangement of heating surfaces. According to the movement of flue gases, boilers are single-pass (span), two-pass, three-pass. The boiler design includes a combustion chamber and a convective heating surface located behind the combustion chamber. The combustion chamber of the boiler and the convective part are shielded by membrane panels assembled from pipes with a diameter of 51x4.0 mm, with welded spacers that ensure gas tightness of the boiler for operation under pressurization. The convective heating surface consists of a certain number of packets. Each package is assembled from horizontally or vertically located screens made of U-shaped pipes with a diameter of 28x3 mm. Drains and air vents are made of pipes with a diameter of 28x3 mm. The boiler design provides the necessary hatches and peepholes for operating the boiler. The gas-tight design of the boiler allows the use of lightweight thermal insulation 50 mm thick with decorative cladding. It is also possible to use boilers for working with vacuum.

Burner devices

KV-GM boilers are used with modern automated burner devices from leading European and Russian manufacturers, approved for use by the boiler manufacturer.

Advantages

- High efficiency– is ensured by the design of the boilers and is characterized by a consistently high value at different loads.

- The boilers are gas-tight– these are stable characteristics of the boiler during long-term operation.

- Low NOx emissions– are guaranteed by the design of the combustion chamber and efficient combustion of fuel on modern automated burner devices.

- Quick boiler output to the specified mode– ensured by a small volume of water in the boiler and high speeds of water movement in the pipes.

- Reliable and simple boiler design, long service life– the requirements and operating experience of Russian heating networks are taken into account; the standard service life of boilers is 20 years.

- Possibility of using boilers in open heat supply circuits– is an important advantage of water tube boilers, in contrast to fire tube boilers.

- High maintainability– this is accessibility to any boiler unit, which allows you to quickly and cost-effectively carry out the necessary repairs.

- Block supply of boilers– high-quality production of boilers in the factory, significantly reduces costs and time for installation work and transportation to the construction site.

- Wide standard range of KV-GM boilers– allows you to correctly select capacities and competently carry out projects for quarterly and district boiler houses, as well as reconstruct existing boiler houses with the replacement of boilers from other manufacturers.

- Optimal price/quality ratio of boilers– allows you to significantly reduce and optimize capital costs for the construction of district heating sources.

- Use of boilers with burners from leading European and Russian manufacturers.

The boilers have a modern and reliable design, are mass-produced by the manufacturer and supplied to customers as:

- Single-pass (span) for flue gases

- 13 standard sizes / 22 modifications

- Temperature charts 95\70 °С, 115\70 °С, 150\70 °С

- All boilers are certified according to the GOST R system and have permission for use by Rostechnadzor of the Russian Federation

- The standard service life is at least 20 years

Boilers of the KVGM (KV-GM) series.

- water-heating gas-oil boiler.

Boilers of this brand are intended for heating and hot water supply of industrial, public and residential buildings. They operate on gas or liquid (diesel) fuel. Depending on the type of fuel, boilers are equipped with gas, liquid fuel or combined burners.

Water heating boilers of the “KVGM” series are designed to produce hot water with a pressure of 0.6 (6.0) MPa (kgf/cm2) and a nominal temperature of 95 -115 °C.

Boiler type: water-tube, horizontal with forced circulation.

Boilers of the KVGM (KV-GM) series have, in particular, the following modifications: KVGM-10, KVGM-20, KVGM-30, KVGM-50, KVGM-100, KVGM-180. As you can see, these modifications repeat the PTVM series.

In the fuel and energy complex of Moscow, boilers of the KVGM-10, 20 series are installed at KTS, KVGM-100 - at RTS and KVGM-180 at thermal power plants.

KVGM-10 installed on KTS-54 and KTS Nekrasovka,

- heat load (Gcal/hour) - 7.65 (KTS Nekrasovka).

- year of installation from 1973 (KTS-54) to 1996 (KTS-54)

- total number of boilers - 8

KVGM-20- 7 boilers installed on KTS-11, KTS-18, KTS-54,

- heat load (Gcal/hour) from 14.4 (KTS-24) to 8.3 (KTS-20)

- year of installation from 1972 (KTS-24) to 1989 (KTS-18)

KVGM-100 installed on RTS

- heat load (Gcal/hour) varies from 83.1 to 12.6 (RTS Mitino)

- year of installation from 1991 (RTS Mitino) to 1997 (RTS-Zhulebino)

- total number of boilers - 24

KVGM-180(180-150) installed at the thermal power plant

- heat load (Gcal/hour) from 137 (CHP-26) to 77.7 (CHP-11)

- year of installation from 1983 (CHP-26) to 1997 (CHP-25)

- total number of boilers - 18

Technical characteristics of water-heating gas-oil boilers KVGM

| Boiler brand | KV-GM 1.25-115 | KV-GM 2.5-115 | KV-GM 3.5-115 | KV-GM 4.4-115 |

|---|---|---|---|---|

| Nominal heating capacity, MW (Gcal/hour) | 1,25(1,07) | 2,5(2,15) | 3,5(3,0) | 4,4(3,79) |

| Heated area, m2 | 10800 | 21500 | 30000 | 37900 |

| Type of fuel | Natural gas GOST 5542-87 Emergency fuel oil M100 GOST 10585-75 |

|||

| Dimensions of the boiler assembly, mm | ||||

| - length | 3978 | 4550 | 5510 | 5370 |

| - width | 2230 | 2610 | 2625 | 2911 |

| - height | 1872 | 1818 | 2470 | 2350 |

| Boiler weight, kg | 3300 | 6200 | 6500 | 7500 |

| Burner type, quantity | RGMG1 | GM-2.51 | GM-4.51 | GM-4.51 |

| Smoke exhauster brand, quantity | D-3.5M1 | D-5Zh1 | D-5Zh1 | D-6.31 |

| Fan brand | VTs-14-46-2.51 | VTs-14-46-2.51 | VTs-14-46-41 | VTs-14-46-41 |

| Automation type | AVK-01 BUK-MP-011 | |||

| Electric single-turn mechanism | MEO3 | |||

| Valve block (kit) | S3N-4-30 (flange with filter) | |||

| Boiler brand | KV-GM-4.65-150 | KV-GM-4.65-115 | KV-GM-7.56-150 |

|---|---|---|---|

| Nominal heating capacity, MW | 4,65 | 4,65 | 7,56 |

| Type of fuel: | gas GOST 5542-87/fuel oil | gas | gas GOST 5542-87/fuel oil |

| Working water pressure, MPa | 1-1,56 | 1-1,56 | 1-1,56 |

| Inlet water temperature, °C | 70 | 70 | 70 |

| Outlet water temperature, °C | 150 | 115 | 150 |

| Hydraulic resistance, MPa | 0,12 | ||

| Heat output control range in relation to nominal, % | 20-100 | ||

| Boiler weight without burner, kg | 25000 | 25000 | 26260 |

| Dimensions: | |||

| - length, mm | 5200 | 5200 | 6500 |

| - width, mm | 3000 | 3000 | 3000 |

| - height, mm | 3900 | 3900 | 5000 |

| Water consumption, t/h | 49,5 | 88,7 | 80 |

| Fuel consumption, m3/h, gas/fuel oil | 530/500 | 530 | 850/800 |

| Mean time between failures, hour, not less | 5000 | ||

| Average service life before write-off, years, not less | 20 | ||

| Boiler efficiency, % not less than, gas/fuel oil | 90,5/86,3 | 90,67 | 88,3/87,0 |

| Specific emission of nitrogen oxides, mg/m3, no more, gas/fuel oil | 230/340 | n.d. | |

| Specific emission of carbon monoxide, mg/m3, no more, gas/fuel oil | 15/20 | n.d. | |

| Equivalent noise level in the service area, dBa, no more | 80 | ||

| Outdoor temperature (isolated) boiler heating surface, °C | 45 | ||

| Temperature of flue gases, °C, no more than, gas/fuel oil | 150/245 | 154,4 | 153/245 |

| Total aerodynamic drag, kg/m2, gas/fuel oil | 22,1/25,8 | 14,9 | 22,9/31,4 |

| Boiler brand | KV-GM-10-150 | KV-GM-20-150 | KV-GM-30-150 | KV-GM-50-150 | KV-GM-100-150 | |

|---|---|---|---|---|---|---|

| Heating capacity, Gcal/h / (MW) | 10 / (11,63) | 20 / (23,26) | 30 / (35) | 50 / (58) | 100 / (116) | |

| Design pressure, kgf/cm2 g. | 25 | 25 | 25 | - | - | |

| Working pressure, kgf/cm2, not less | 10,3 | 10,3 | 10,3 | - | - | |

| Water temperature, °C | ||||||

| - at the entrance, no less | 70 | 70 | 70 | 70 | 70 | |

| - at the output, no less | 150 | 150 | 150 | 150 | 150 | |

| Water consumption through the boiler, t/h / peak | 123,5 | 247 | 370 | 618 / 1230 | 1235 / 2460 | |

| Hydraulic resistance of the boiler, kgf/cm2, no more | 2,5 | 2,5 | 2,5 | |||

| Overall dimensions, mm | ||||||

| - highest mark | 7300 | 7300 | 7300 | 13400 | 13400 | |

| - width | 3200 | 3200 | 3200 | 5700 | 5700 | |

| - depth | 6500 | 9700 | 11 800 | 5900 | 9558 | |

| Weight of boiler metal, t | 18,4 | 26,2 | 32,4 - 35 | 82 | 142,4 | |

| Burner - brand, quantity | RGMG-10 1 piece | RGMG-20 1 piece | RGMG-30 1 piece | RGMG-20 2pcs | RGMG-30 3pcs | |

| Source - Installation company Teploenergostroy. | ||||||

Apparently the KVGM boiler is a further development of the boiler PTVM. At least it is newer, since in Moscow the PTVM has been installed since 1958, and the KVGM since 1972.

It would be interesting to watch the discussion among specialists on the comparative characteristics of the PTVM and KVGM boilers.

Boilers of the KVGM type were once produced in the Soviet Union by the Dorogobuzh Boiler Plant in large series. These boilers are still produced today by several enterprises.

This design has proven its right to life both from a technical point of view and from the point of view of the possibility of its implementation in the heat and energy market.

However, boilers operating for a long time are exposed to corrosion and erosion, resulting in the need to replace individual elements. In some cases, modernization and reconstruction of boilers of this type makes it possible to extend their service life for an indefinitely long time.

On the page Repair and modernization of PTVM and KVGM boilers a list of organizations performing similar work is presented.

An even more advanced series of boilers of this type are boilers of the brand