What types of electrical wiring are there? Open external and internal electrical wiring External hidden electrical wiring

Open wiring is the easiest way to lay electrical lines. Unlike the hidden one, it is not laid in the thickness building structures, but above their surface. IN modern houses it is used very rarely. At the same time, this method requires much less time and is not associated with such large labor costs as laying a line closed type. There is also no need for gating, due to which the integrity of the ceiling and walls is practically not compromised.

If you do not plan to install retro-style wiring throughout the house, then it is better to use the open method only in certain areas, for example, when you need to slightly expand the line. Otherwise, a large number of wires, which are clearly visible to the naked eye, will spoil the interior.

Installation of exposed electrical wiring requires careful preparation. This installation method is associated with certain rules that require strict adherence.

Open Type Electrical Wiring Installation Requirements

Here are the basic rules that when laying open type electrical wiring in the apartment must be completed.

Neglecting them is a violation of electrical safety standards and can cause a short circuit and line failure. So:

- It is prohibited to lay the line under pipelines on which condensate accumulates.

- There should be no heat emitters near the cables.

- It is not recommended to use a simple pipeline to lay such a line. It is advisable that the cable have additional protection. Depending on the location of the wiring, it can be rigid or flexible, or shielded.

- If the conductor is laid in plumbing niches, then you should not use junction boxes if quick access to the power transmission line is not possible.

- Cable cores can only be connected to each other in special junction boxes.

It is necessary to ensure easy access to the cover of the latter. If the humidity in the room is high enough, gaskets are installed on the covers of the junction boxes to improve the tightness.

- The protective layer of the conductor must remain intact along its entire length, right up to the connection of the conductors to a socket, switch or electrical appliance.

- To fasten the cable, it is recommended to use plastic brackets selected according to the diameter of the conductor. The distance between the clamps should not be too large, otherwise the conductor will sag under its own weight. The staples must be placed on both sides of the wire, and it is also necessary to install clamps near the points of connection to electrical elements. If the cable is laid horizontally, then the staples should be located from one another at a distance of no more than 40 cm when attaching an unarmored conductor and 75 cm for a wire with an armored coating. If exposed electrical wiring is laid vertically, then the maximum interval between clamps should not exceed 1 m.

- When installing conventional conductors with protective coating in the horizontal direction, the interval between the staples should not be more than 25 cm, and in the vertical direction - 40 cm. The distance from the electrical element to the fastener closest to it should not exceed 10 cm.

- If the wire needs to be bent, the minimum bending radius should be 8 cm.

- If the line crosses a non-electrical pipeline, then the minimum interval between them should be 3 cm.

When laying a cable through a wall, it is recommended to use an insulating pipe to protect it along this section.

Features of installing an open type electrical line

The open method of installing electrical wiring is most often used when laying the wire over the baseboard, at the junction of walls with ceiling tiles, as well as in the corners of rooms. The conductor used must be perfectly straight.

If open wiring is laid in an apartment with suspended ceilings, then the cable should be attached to the walls. If there are a large number of wires, it is worth using throughput channels.

Under no circumstances should you simply run an electrical wire through a suspended ceiling. The installation of connection and branch boxes must be done in such a way that access to them is not difficult.

An example of installing a socket with open wiring in the video:

Advantages and disadvantages of external wiring

Like any other method of laying communications, installing open electrical wiring has its pros and cons. Benefits include:

- Easy to install.

- Minimal damage to the integrity of the walls (ceiling).

- No need for additional equipment.

It has open wiring and its disadvantages. They are:

- Unattractive appearance.

- The need for accounting technical standards premises.

- The need for strict compliance with fire and electrical safety standards during installation.

Of course, external wiring in an apartment does not always look unpresentable. For example, a vintage line in retro style can be a great addition to the interior and give the house an old-world charm. But, firstly, the elements for such wiring are expensive, and secondly, it is worth installing it only if the design of the room is in the appropriate style.

An example of finished open electrical wiring laid in cable ducts in the video:

Installation of wiring in rigid pipes

Recently, many people are discovering the installation of external wiring using rigid plastic pipes. In this case, the cables are placed inside the pipelines, which are then fixed to the walls on special supports. To facilitate such installation, a large number of auxiliary devices have been developed (tees, cable sleeves, T-shaped branches).

The main advantage of this installation is high degree protection electrical conductors from exposure to water, as well as from mechanical damage.

In this regard, this installation method is most often used in cellars, garages and basements. But this does not mean that external electrical wiring cannot be laid in this way on summer cottage, in a city apartment or country house, since externally the insulating pipes look quite attractive.

Features of installing open electrical wiring in IRL pipes

When laying electric line V insulating pipes There are some important points to remember:

- Pipelines must be attached to the walls so that the distance between them is at least 80 cm, while electrical appliance or element to the nearest latch must be at least 10 cm.

- Cables can only be connected to each other at the terminals of electrical components or inside special junction boxes.

Connecting conductors in pipes is unacceptable.

- The bending radius of pipelines must be at least 6 times greater than their diameter.

For this type of installation, special fixing devices are provided. A list of them can be found both on the Internet and in specialized literature.

If for some reason you cannot buy special fasteners, you can use regular construction paper tape to install insulating pipes. To do this, you need to cut a piece of the required length from the skein and secure it to the surface. The end fastenings should be made at an angle and slightly away from you so that the tape does not sag. The pipe is then secured with ties along its entire length. Sometimes, if it is impossible to get special fasteners, fastening with punched paper tape can be a completely successful solution.

An example of installing a pipeline for electrical wiring in the video:

Necessary tools for installing wiring in pipes

This installation method does not require large quantity tools. To work you will need:

- Marking cord.

- Hammer (for working with concrete walls). This device will also require a drill of the required diameter.

- Plumb.

- Roulette.

- Hammer.

- Building level.

- Hacksaw for metal.

To connect to difficult areas You will need two couplings, as well as a corrugation. The pipelines are installed in such a way that moisture does not accumulate inside them. Therefore you need to pay Special attention for quality rubber seal, which is installed at the junction of the pipe and the electrical element.

It is advisable to use reinforced seals that match the diameter of the insulating pipe. When installing, the cuff should penetrate a small part of the electrical installation product.

If there is no sealing collar, it is recommended to insert the wire from below.

Advantages and disadvantages of the method

The advantages of installing electrical wiring in insulating pipes include:

- Easy to install.

- Additional protection of conductors from mechanical damage and exposure to moisture.

- Attractive appearance.

The disadvantages of this method are the following:

- It is necessary to accurately select the pipe size.

- Quite a lot of additional accessories are required.

In general, installing open wiring in pipes is a completely working method, which allows you to reliably protect cables from damage and give the line elegance.

Conclusion

In this material we talked about what open wiring is, what its features are and how it is installed in various ways. This information will help you decide on the type of wiring and, if necessary, install the power line yourself.

Ecology of consumption. Estate: How to choose The right way laying electrical wiring in the room, taking into account the features of building structures.

Features of electrical wiring installation directly depend on the characteristics building materials, from which the building is constructed. And this is due to the fact that any building material has its own degree of fire hazard. In this article we will consider this dependence, based on current rules electrical installation devices (7th edition of PUE, updated 02/12/2016) and on practical experience users of our portal.

Rules for the location of cable routes

Location cable lines indoors is subject to certain rules:

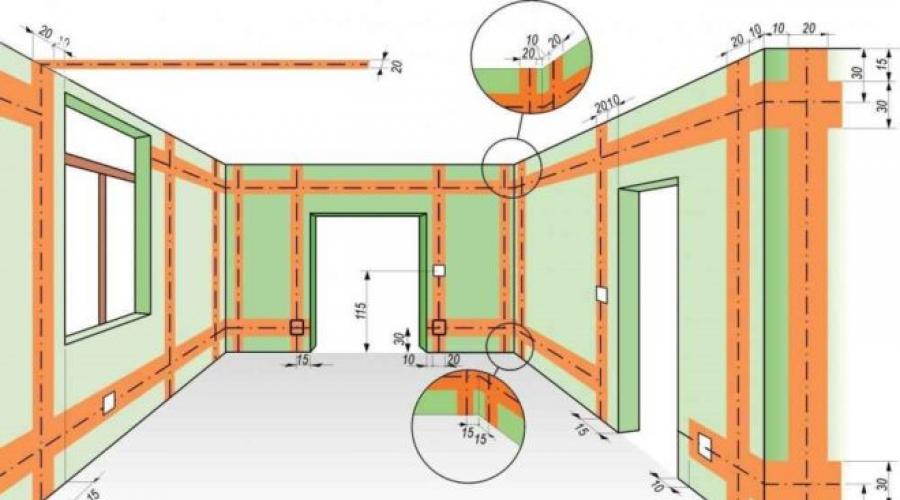

- wiring in the room must be laid in accordance with strictly horizontal or strictly vertical lines, while turning cable route possible only at 90° (creating all kinds of diagonals related to saving conductors is unacceptable);

- horizontal sections of wiring should lie at a distance of 10...15 cm from the ceiling;

- vertical sections of wiring should be spaced from door and window openings at a distance of at least 10 cm.

Wiring types

IN modern buildings It is customary to install two types of wiring: hidden and open. Hidden wiring is laid in the voids of building structures or inside walls (in channels made by gating, drilling, etc.).

Open type wiring is laid directly on the surface of the walls. The wires are either attached to special insulators or laid in standard cable channels.

When choosing the type of wiring when building a house, you should not be guided by your own preferences, because only SNiPs, GOSTs and PUE should be taken as the basis.

“Self-taught builders” have the least questions if the electrical wiring is installed on walls made of non-combustible building materials. First, let's talk about such cases.

Installation of wiring on building structures made of non-combustible materials

Modern PUE rules allow the use of wires and cables exclusively with copper conductors indoors (clause 7.1.34.).

If the room has walls and ceilings made of non-combustible materials(concrete, brick, aerated concrete blocks, ceramic blocks, gypsum boards GGP, etc.), then it is advisable to install hidden wiring in it. Firstly, it is aesthetically pleasing, secondly, it is safe in terms of accidental mechanical damage and, thirdly, the PUE rules (clause 7.1.37) completely allow for the installation of hidden wiring in walls made of non-combustible materials.

IN in this case we're talking about about residential premises. In attics, basements (especially unheated ones) and in technical premises, it is recommended to do open wiring.

The PUE rules state: if a building structure consists of non-combustible materials, then it is allowed to lay embedded permanent wiring along it, using technological channels, grooves and voids for this. In this case, it is sufficient to use insulated cables or wires in a protective sheath (for example, VVG cables) as conductors. In this case, wiring is installed without the use of metal pipes, protective corrugations and other additional elements.

If rough wall subsequently it is planned to plaster, then, as a rule, there is no need to resort to chiselling the walls for wiring.

Of course, niches for sockets and switches will still have to be created in the wall itself. But dust, and physical work in this case it will be much less than with widespread wall gating.

As for the power supply diagram: any self-respecting owner should have it. After all, it will certainly be needed in the future. The diagram is needed at least so that during the renovation of the room you do not get a drill into a wire connected to electricity.

If you are laying wiring along walls that are not planned to be plastered in the future, then gating in this case cannot be avoided. You will also have to dabble the walls if in the process overhaul the old wiring is being replaced, and the layer is being removed old plaster not necessary.

Is it worth or not to create horizontal grooves? Is it possible to ditch load-bearing walls And concrete floors? Unambiguous answers to these questions in the environment professional builders does not exist. Of course, from the point of view of the theory of strength of materials, man-made grooves can significantly weaken the strength of building structures (similar to how a thin cut from a glass cutter weakens strong glass). However, the rules of the PUE (clause 7.1.37) allow the laying of electrical networks in grooves (in grooves) of walls, partitions and ceilings. The main thing is not to overdo it with the depth of the groove and its width.

In this case, existing technological voids (for example, in floor slabs) should be used to the maximum.

In grooves, in steel sleeves, in special trays and technological channels allowed joint laying wires and cables belonging to different lines (with the exception of mutually redundant conductors).

Installation of wiring on building structures made of flammable materials

A lot of questions regarding the rules for installing electrical wiring arise from people who begin to independently electrify premises made of flammable building materials. We are talking mainly about frame and wooden houses. Answers to most questions can be found in the same PUE rules.

The design of houses made of combustible building materials allows for the installation of both types of wiring (hidden and open). Which one to use depends on the homeowner's preference. Concerning protective elements, protecting wiring from damage and the building from fire as a result of a short circuit, then their choice depends on the type of cable route.

There are two ways to install open wiring indoors:

- Installation of retro wiring.

- Laying wires in cable channels.

Installation of retro wiring

The extent to which the design of retro wiring complies with the rules of the PUE is a controversial issue. In this regulation, the creation of wiring of this type is not even considered. Nevertheless, let's try to understand this issue.

In the case of retro wiring, a special twisted cable (“retro”) is mounted directly on the wall, to which it is attached using small insulators. Considering that such a conductor is coated with artificial silk impregnated with a non-flammable composition, it can easily be classified as a fire-retardant wire. Consequently, installation of retro wiring on walls made of combustible materials does not violate the rules of the Electrical Installation Regulations.

In accordance with the rules of the PUE, the distance from the conductor to the surface of a combustible material must be at least 10 mm, which is fully ensured by the design of insulators for retro wiring.

If the wire sags a lot, the distance between the insulators can be reduced to 50 cm.

When installing retro wiring, one important nuance should be taken into account: most modern electrical appliances must be connected to the grounding circuit. For this reason, a three-core cable should be used as part of the wiring (if it is not commercially available, then it is advisable to weave it yourself).

Where wiring passes through a wall or ceiling made of flammable materials (for example, wood), the cable (wire) must be laid in a metal pipe that has localization capabilities. The ends of the pipe should be sealed with a non-flammable compound (for example, fire-resistant foam).

The localization ability of a pipe is a quality that allows it to withstand short circuits in electrical wiring without burning out the walls of the pipe itself. In order for a pipe to have this ability, its walls must be of a certain thickness:

- for copper conductors with a cross section of up to 2.5 mm², the wall thickness is not standardized;

- for copper conductors with a cross section of 4 mm², the pipe must have a wall thickness of at least 2.8 mm;

- for copper conductors with a cross section of 6–10 mm², the pipe must have a wall thickness of at least 3.2 mm.

Open wiring in cable channels

If open-type wiring is laid in cable ducts and electrical baseboards, then cables (wires) with high fire resistance (VVGng or NYM) should be used as conductors. At the same time, the material of the cable channels should also prevent the spread of fire.

When installed on walls made of flammable materials, socket boxes must have fireproof linings (for example, made of asbestos cement or gypsum mortar) 10 mm thick. Where wiring passes through combustible structures, metal sleeves with localization capability must be installed.

Hidden wiring in walls made of flammable materials

The peculiarities of laying hidden wiring in walls made of flammable materials (for example, wood) boil down to the fact that wiring in the voids of such walls and partitions must run inside metal pipes that have localization capabilities (PUE rules 7.1.38.).

There is only one rule, and there can be no relaxation in relation to its implementation. All other options (the use of plastic corrugation, metal hoses and other protective elements) should obviously be excluded, because from the point of view fire safety they are unacceptable.

When laying wires and cables along combustible structures (or inside them), in all cases the possibility of replacing conductors must be ensured.

By the way, electrical wiring spread over the floors is the most in a convenient way arrangement of hidden wiring in rooms made of combustible materials. In this case, the grooves to sockets and switches will simply go down from the main highways.

When laying pipes and ducts for electrical wiring in technological voids of combustible structures, the ends of the pipes and ducts should be covered with quickly removable non-combustible material (for example, polyurethane foam).

In order to ensure that when installing replaceable wiring in metal pipes it was possible to create a sufficient number of turns; in the corners of the electrical route it was necessary to use junction boxes. Access to these elements must always remain open.

The internal diameter of the pipe should be selected in such a way that the cable laid inside it occupies no more than 40% of the total free space. This rule applies to all protective elements (cable ducts, corrugations, trays, etc.).

It should immediately be noted that the creation of hidden wiring in rooms with wooden walls- the process is labor-intensive. After all, channels for wiring will have to be arranged on our own. Space for pipes must be cleared by drilling, making grooves and creating recesses.

Vertical channels in the walls should be drilled during the laying of the log house. In this case, horizontal holes are made after the walls are ready. To make it more convenient to pull the cable through the pipes, an auxiliary cable for pulling (conductor) should be placed in advance into their internal clearance.

Cable laying under plasterboard, behind suspended and suspended ceilings

Laying hidden wiring inside frame partitions, under plasterboard or plastic sheathing, as well as behind various types of ceilings, is regulated by a vault building regulations SP 31-110-2003 (clause 14.15) and the rules of the PUE (clause 7.1.38.). In accordance with these regulations, hidden wiring can be mounted in two ways:

- If partitions, wall bases or their cladding are made of flammable materials, then conductors (for example, marked VVG) should be placed in metal pipes with localization ability, or in closed boxes.

- If building structures are made of non-flammable materials, then the wiring should consist of flame retardant wires (cables) (for example, VVGng), and it should be mechanically protected with non-flammable non-metallic boxes or pipes (for example, a corrugated self-extinguishing pipe).

In both cases, the wiring must be replaceable.

If the wiring is mounted under plasterboard sheathing, and the supporting profile is almost flush against the wall, then it is advisable to lay the wires in grooves made in the wall or plaster.

When laying conductors under ceilings, under plasterboard or plastic surfaces, as well as inside frame partitions, you should be guided by the general rules for installing electrical wiring on combustible or fireproof building structures (presented in the previous sections of the article).

Wiring under the floor

Installation of electrical wiring under the floor – perfect way create hidden cabling without resorting to horizontal gating walls In this case, the cable (main wire) is supplied directly to the locations of sockets, switches and distribution boxes.

The method of creating floor wiring directly depends on what material the floors are planned to be made from. In general, it is necessary to focus on the rules of the PUE that are already known to us.

If the wiring is installed in the lower layers of a cement floor, then a simple protective corrugation is sufficient for its installation. Of course, you can lay a cable inside the screed without any corrugation, but replace the wiring without resorting to destruction flooring, in this case it will not work. By the way, the difficulty of repairing and replacing cables (wires) is the only significant drawback floor wiring, and it should definitely be taken into account when deciding on the type electrical wiring. published

Modern life cannot be imagined without electricity. To provide comfortable conditions life and work, houses and cottages, offices and apartments are supplied with electricity necessary for the operation of household appliances.

Electrical wiring is a complex consisting of cables or wires, various fasteners and other elements (clamps, terminals), protecting and supporting structures and parts.

Electrical wiring is considered one of the most important parts utility networks, based on the purpose of the building used different kinds electrical wiring, used various ways gaskets

Classification of electrical wiring

According to placement, wiring is divided into types:

- internal.

External wiring is arranged according to external walls houses, on supports or under canopies. The internal one is mounted from inside the building.

There are also types of electrical wiring that differ in installation methods:

- hidden;

Open electrical wiring is laid along the ceiling, walls and other building structures. There are several ways to lay wires:

- along the walls;

- in tubes, sleeves, boxes;

- hanging, etc.

Concealed electrical wiring is laid inside the building structures - floor, walls, in the cavities of the foundation and ceilings.

There are many ways to lay wires when installing hidden electrical wiring:

- in flexible sleeves;

- in tubes;

- in special channels and cavities of panels;

- in wall grooves.

The installation of open external electrical wiring is carried out according to air lines, consisting of individual supports and the wire (cable) itself.

The design of such wiring must be carried out in compliance with the following basic requirements:

- uninsulated wires should be located at a distance of at least 2.75 m from the nearest horizontal surface (for example, the roof of a house);

- when laying over a road, the distance from its surface to the wire should be more than 6 m;

- the overhead line is not allowed to be laid on the roofs of buildings, except for the area necessary for introducing power into the building;

- for lines with rated voltage 220V the gap between adjacent uninsulated wires is taken to be more than 0.15 m;

- distance from wires to windows and balconies residential buildings must be more than 1.5 m.

Connecting buildings to power lines is usually done using bare aluminum wires, but recently insulated aluminum SIP wire, also known as “tornado”, has become more popular.

The service life of aluminum wire is more than 45 years. It has proven itself during operation in various climatic regions.

The cross-section of the wires must be selected based on the need to provide power to all consumers, taking into account possible voltage drops, connections and branching of wires through terminals.

Wiring into the building should be carried out using an insulated cable or SIP wire; the wires are connected using clamps. If possible, it is recommended to prefer copper wire to aluminum wire when inserting, because its electrical conductivity is one third higher, and overheating does not occur as often.

It should be taken into account that direct connection between aluminum and copper wires using the “twisting” method is impossible due to their oxidation and reduced conductivity.

It is best to use wires made of the same material when twisting. For example, “aluminium-aluminum”. The aluminum-copper connection can only be used using a clamp adapter.

The insulating layer, made of PVC, has a service life of up to 25 years. Cable grades AVVG (aluminum, PVC insulation) and VVG (copper in PVC insulation) may be produced for connection to “air ducts”, but due to the rapid destruction of PVC under the influence of the sun, it is better to use them as input cables into the building.

External hidden electrical wiring

In urban conditions, due to limited space, the laying of open lines is carried out mainly only for the purpose of organizing street lighting, and all other electrical networks are located below ground level. The buildings are connected to each other through distribution substations via cable routes.

Cables are laid in special concrete gutters or metal pipes that reliably protect against moisture getting inside. Cable protection is provided by insulation made of polymer materials or artificial rubber, since with this installation method the main thing is to protect the terminals and cable from moisture, and not from light.

VRG cables are predominantly used ( copper cable power in rubber insulation and PVC sheath) and AVRG (power aluminum cable in rubber insulation and PVC sheath).

Open wiring is convenient primarily in office and rental premises, when each new tenant or owner remodels and moves electrical wiring at your own discretion.

The wire is carried in plastic (PVC) channels, fixed to the walls, and supplied to workplaces and equipment. Terminals are used to branch the wire. PVC is considered not only an excellent insulator, but also a fire-resistant material, which is why box-shaped channels with a tightly closing lid have become widespread.

Installing box-shaped channels on the walls has one significant drawback - it makes all the unevenness and curvature of the walls noticeable.

Open wiring can be arranged both horizontally and vertically. At horizontal way the wires are laid parallel to the floor line at a distance of at least 20 cm from the ceiling; when laying a pair of wires between them, it is necessary to maintain an interval of at least 10 cm. Laying vertical way is carried out strictly at right angles to the plane of the ceiling.

The selection of channel cross-section depends on the diameter and number of wires placed in them, minimum size taking into account possible installation clamps – 10 mm. In addition to the channels themselves, there are various elements and parts with which wiring is carried out:

- boxes;

- external and internal corner connections;

- tees;

- crosses;

- terminals.

Internal wiring, laid in the channels, is carried out using standard wires with PVC insulation, their cross-section is taken from the power of the consumers. Usually for lighting fixtures and sockets, copper wire is used.

An alternative to cable channels can be called hollow baseboards, consisting of two elements - a box mounted on the wall and a decorative, tightly closing lid. These skirting boards carry wires to electrical outlets, and boxes are used to connect to lighting fixtures. The wires are connected using clamps.

It is much less common to find open wiring on staples. These types of electrical wiring, despite being sufficiently reliable, do not differ in aesthetic properties and are more often installed indoors industrial purposes– for organizing lighting of workplaces and power supply of machine equipment.

For this purpose, copper wire with rubber insulation in a combined sheath is mainly used (for example, PRS 4 mm brand NRG).

Open types of electrical wiring, in which the wires are laid in insulators made of glass or ceramic materials are still popular despite their high cost. For styling old wiring A pair of twisted wires is pulled between the insulators at a distance of more than 25 mm from the surface of the ceiling or walls.

Real ceramic and glass insulators are quite difficult to find these days, which makes such wiring expensive.

The advantage of this method is the complete accessibility of each site electrical circuit, starting from the distribution panel, terminals and clips, and ending with a socket or lamp.

The difficulty of implementation lies not so much in the acquisition of insulators, but in the manufacture twisted wires– previously they were made from copper wire with insulation made of cotton or rubber.

Hidden types of electrical wiring are more suitable for individual houses, apartments or production premises. The choice of this type of wiring depends primarily on the materials from which the building is constructed. Hidden wiring is where free access to it is prevented by some barrier. The wire can be hidden not only in the ceiling, walls or floor, but also covered with suspended or frame structures.

For example, when installing suspended ceilings installation of lamps or chandeliers is carried out. These devices require a wire supply, which is placed in corrugated tubes made of non-flammable plastic, attached to the frame. The service life of such “corrugations” is more than 15 years.

Inside frame walls and ceilings, boxes made of tin or plastic are laid. The design of such boxes does not provide for a lid; its function is performed by covering the frame or by a plastic fastener.

Wiring in concrete or brick walls hiding behind a layer of plaster.

The wires are laid in grooves - cut grooves, connections are made in boxes, and special sockets are cut for them in the wall. This wiring method is considered irreplaceable.

Internal electrical wiring - the totality of all wires and cables with their associated fasteners and parts - is a rather complex thing. Therefore, let's look at it in more detail.

Types of electrical wiring and methods of laying them

First you need to decide on the type of electrical wiring. And it could be:

- open, that is, passing along the surface of walls, ceilings, and other elements of the building. Methods for laying open wiring are incredibly simple: it is either a free suspension on rollers, or placing it in electrical baseboards and trim;

- hidden. IN residential buildings laid inside structural elements building or its decoration. In this case, such laying methods are used as placing wires in the voids of building structures (for example, interfloor ceilings), as well as in the grooves under the plaster;

- external - placed on the outer walls of buildings or between them on supports (for example, from a residential building to a barn, workshop, bathhouse). External wiring itself can be either open or hidden.

Wires and cables

To do right choice, you need, firstly, to know the difference between a wire and a cable; and secondly, be able to decipher the abbreviation of their markings.

So, a wire is one uninsulated or several insulated conductors enclosed in a non-metallic sheath, winding or braiding made of fibrous materials. A cable is one or more insulated conductors enclosed in a metal sheath, on top of which there is a protective cover.

Marking of wires and cables contains information about what material the conductors, insulation and sheath are made of, the nature of the insulation and sheath, the number of cores in the wire and cable and their cross-section; and consists of alphabetic and numeric characters. The meaning of the symbols and their place in the markings is as follows:

- in the first place is the designation of the material of the current-carrying conductors: aluminum - a, copper - the letter is omitted;

- in second place in the marking of wires there can be P - wire or PP - flat wire; in the cable marking, the insulation material is indicated in second place: B - polyvinyl chloride, P - polyethylene, P - rubber, N - neurite;

- in third place in the marking of wires the insulation material is indicated (see above), and for cables - the sheath material (designation alphabetic characters the sheath material corresponds to the designation of the insulation material);

- in fourth place, in both cases they are encrypted additional information: G—flexible, N—non-flammable;

— further, digital symbols indicate the number of cores and their cross-section.

For example, APRN-2.5-1: A - aluminum core, P - wire, P - rubber sheath, N - non-flammable rubber sheath, 2.5 - core cross-section 2.5 mm2, 1 - single-core; or cable APVG-5-3: cable - the word speaks for itself, A - aluminum core, P - polyethylene insulation, B - polyvinyl chloride insulation, G - flexible, 5 - core cross-section 5 mm2, 3 - three-core.

The brands of wires and cables used in one place or another of the internal electrical wiring must be indicated on the electrification diagram of your building, which is part of the overall project.

If you still refuse the services design organizations, then the following information will be useful to you:

— in dry rooms for open electrical wiring, you can use the following brands of wires and cables: APV, APPV, AVVG and AVRG;

- in dry rooms for hidden electrical wiring in plastered grooves - APV and APPV;

- in wet areas(for example, showers and bathrooms) for open electrical wiring - APPV;

- in wet rooms for hidden electrical wiring - APV and APPV;

- in hot rooms (for example, baths and saunas) for open electrical wiring - ANRG, AVVG and AVRG;

- in hot rooms, hidden wiring is installed only in steel pipes, which is unacceptable for living conditions;

— for external open electrical wiring, wires and cables of the AVVG, ANRG and AVRG brands are used;

- for all premises, two-core wires are used with a core cross-section size: copper - at least 2.5 mm2, aluminum - at least 4 mm2.

If you are observant, you will notice that only brands of aluminum wires and cables are indicated. This is due to the fact that wires and cables with aluminum conductors are the cheapest. Copper wires and cables are 2-2.5 times more expensive, but electrical wiring is made of copper wires and cables are much more reliable than their aluminum counterpart; their contact connections stronger, so the wiring does not overheat; copper wires withstand large quantity deformations, which means the wiring is more durable.