What kind of pipe is used for the needle well. Abyssinian well: features, pros and cons, DIY technology. Abyssinian well construction technologies

The Abyssinian well is called artesian well, consisting of a narrow pipe with a diameter of 25 to 45 mm. The lift is carried out by a pump from the aquifer and in an hour you can get 2 or 3 m 3 of water. This is a great way to organize irrigation in a suburban area that does not have central water supply. If you lack productivity, you can build two sources. While liquid is being collected in the first, the second is being used. Moreover, the wells turn out to be so compact that they can be installed even in outbuildings or basements.

The water in such a well contains practically no bacteria and harmful salts, since it is filtered through soil and sand. If you provide protection from the ingress of dirt from above, and equip the bottom of the pipe with a filter to remove sand grains, then the water, as a rule, corresponds to drinking water and will not require additional cleaning.

Conditions

You can dig a well on light sandy or finely gravelly soils with a depth of water in the ground of at least 20 m. Optimal distance– 5–8 m. This is due to the driving method. On harder or clayey rocks, as well as when aquifers are very deep, it is simply not possible to drive a pipe.

Another problem when constructing a well is the sufficient piezometric water level, that is, the distance from the surface of the earth to the water surface. The diameter of the well pipe is too small to install a submersible pump. Therefore, for lifting it is necessary to use a surface vacuum apparatus. Under normal conditions atmospheric pressure 746 mmHg Art. According to calculations, the height of the water column will be 10.5 m, but in fact it will be about 8 m. If the distance is greater, then no pump will be able to lift it. Even increasing its power will not help.

Plastic reinforced or metal galvanized pipes 1 or 2 m long are well suited for drilling. As they are immersed, they are extended by screwing on new sections. Tightness is very important for the operation of the well, so the connections are sealed with silicone or oil paint. Special couplings are placed on top.

To prevent the end of a narrow pipe from becoming clogged with earth during drilling and from silting when collecting liquid, a special tip or filter needle is put on it. It is better to choose the same material for the tube and tip, this will avoid electrochemical corrosion and extend the service life.

If the filter needle is made from a piece of galvanized steel, then holes about 8 mm in size are drilled in the body evenly in a checkerboard pattern. The end is covered with a soldered mesh made of of stainless steel. She will act as a filter rough cleaning from sand and silt. You also need to install a filter inside fine cleaning. Finally, a pointed tip slightly larger than the cross-section of the pipe is welded. Then the drill will move easily through the soil.

Lead should not be used for solder - it is poisonous and can poison water. Take only pure tin.

Reinforced PVC pipe is also suitable for installation in a well. A filter needle is made from it in the same way:

- the wall is perforated with a hacksaw;

- the filter mesh is inserted inside the housing and fused into it.

Creation technology

Drilling an Abyssinian well has its own distinctive features:

- At the location of the future well, a hole measuring approximately 1 cubic meter is dug.

- The top layer of soil is passed through with a conventional drill to a shallow depth until the soil level, saturated with moisture, is reached - quicksand.

- Then they begin to drive the pipe into the ground. To do this, you need a “hammering woman” - a load weighing at least 30 kg. You can use discs from a barbell. Be careful not to overshoot the aquifer level.

- While working, water is constantly added to the pipe. When it starts to go away sharply, the desired layer has been reached. Then the structure must be deepened another half meter or meter. Make sure that the pile remains vertical at all times.

- As the pipe sinks into the soil, the pipe is extended with nozzles, and earth is poured around it and compacted.

- After drilling is completed, the filter needle is washed under high pressure.

- Mounted Vacuum pump, which works by creating a vacuum, and the cloudy suspension is pumped out until the liquid becomes clear.

- To create an additional filtration circuit, marble chips are poured into the well.

- The area around the source is concreted to prevent contamination from getting inside.

All operations are performed quite simply, in a few hours. The usual service life of an Abyssinian well is from 25 to 30 years. But there are wells that have been operating for over two centuries. The installation does not require maintenance, except for replacing the fine filter every few years.

If the water still runs out, the pipe can be removed, moved and a source made in another area. Such a well will not need a lot of space; 1.5–2 m2 is enough.

Video

Hello, dear readers. Let's start the story about organizing water supply suburban area using a needle well or an Abyssinian well. Wells of this kind are usually made by hand, since special equipment for constructing a well is not required.

This article is the quintessence personal experience author and hundreds of studied pages on specialized forums and is not theoretical material, but practical guide. As they say, clever man able to learn from other people's mistakes.

What you need to build an Abyssinian well

So, let's begin. We will talk about the classic scheme for installing a needle well: driving it into the ground.

To plug an Abyssinian well we will definitely need:

- needle filter

- threaded pipe kit

- pipe couplings

- sanitary flax and paste for use in threaded connections

- two pipe wrenches

- well pump

- the tool that will be used to hammer in (we will discuss the options below)

Additional equipment that may be needed:

- Pipe clamp or die for cutting threads (if the thread gets damaged when driving)

- Two hydraulic jacks, if you need to lift the well pipe string

Before we begin to present our personal experience, let us recall the basic principles of the Abyssinian well.

The diameter of the well is small - usually from one to two inches. This diameter does not allow the pump to be lowered inside the well, and water is pumped out using surface pumps - first when pumping with a manual column, then, after pumping the well, you can switch to electric pump, necessarily self-priming.

It is possible to raise water from an Abyssinian well only if the water surface is no deeper than 9 meters. If dynamic level well will be below eight to nine meters from the pump level, it will be possible to raise such water only by placing the pump in a caisson (pit), thus reducing the suction depth to the required value. It should be taken into account that the passport 9 meters of suction can only be shown by the highest quality self-priming pump.

It is important to ensure complete tightness of the line from the water-suction filter to the pump - if a fistula forms in at least one coupling when clogged, water will not be sucked in from the depths.

A needle well is a small diameter pipe, typically 1 inch outer diameter. construction markets and metal warehouses is marked as 25 pipe - by internal diameter) and 1? inches. The fact is that the column-well will be driven into the ground without any drilling, and driving a larger diameter pipe can be extremely difficult.

How does a well-needle filter work?

The very first and important element needle wells - filter. It is made as follows: a 1.2-2 meter section of pancake pipe is taken and a meter section is marked for the future filter. On this section, holes with a diameter of about 8-10 mm are drilled in a checkerboard pattern so as not to weaken the pipe. A steel cone is welded at the end of the pipe near the filter, which will facilitate the passage of the pipe in the ground according to the principle of a spear.

The next step is to wind under the filter. The purpose of the winding is to create a gap between the pipe and the filter mesh, which is mounted on top of the winding. Without winding, water would be sucked into each hole of the filter pipe only through the section of the mesh directly above the hole. With winding, water will be sucked from a much larger surface of the mesh into the created gap, and then into the holes on the pipe. Thus, by performing reeling, we significantly increase the well's flow rate. Winding is usually done from wire of the same material as the filter mesh - for example, stainless steel to stainless steel, to avoid the formation of a galvanic couple. To help you when choosing, here is a metal compatibility table:

When assembling the filter, pay attention Special attention on the compatibility of metals: some of them create a galvanic couple, and upon contact as a result chemical reaction are quickly destroyed. For example, if you wind a pipe with aluminum wire and fasten a brass mesh on top, after a few months you will get holes where these incompatible metals touch. Therefore, in most cases, wire and mesh are taken from stainless steel, because... these materials are easy to obtain.

How to choose a mesh for an Abyssinian well filter

The mesh for the needle hole needs a special one - galloon weaving. This mesh looks like metal fabric. Galoon weaving implies diamond-shaped cells - they are not clogged with grains of sand, which are basically cube-shaped. Exist different kinds filter meshes, with different sizes cells - for different sands. Ideally, the mesh should be selected based on the sand fraction in the aquifer. The filter should pass about 30-40% of sand. Then, when pumping the well, small sand fractions will come out with water, while larger ones will form a natural filter around our needle.

Filtration meshes are metal and synthetic. The finest grains metal mesh They are marked P60 and are designed for dusty sand. Synthetic meshes come in even finer weaving - up to P200. At the same time, take the most fine mesh“with a margin” is not recommended - the finer the grid, the worse the well’s flow rate will be. The finest sand under the pressure of water is compressed around the needle filter, preventing the movement of water.

The pipe is cut into pieces of 1-1.5 meters, external threads are cut at the ends. The pipes will be connected using couplings of the appropriate diameter. Short pieces of pipe are needed to make it easier to drive it into the ground.

What tool is used to drive the Abyssinian well needle?

Sledgehammer

The simplest and most barbaric way to hammer a needle is with a sledgehammer. If you have experience in carefully handling this powerful tool, perhaps everything will end well and no threaded connection in your underground will crack. The advantages of this method are that the sledgehammer is easy to find, you don’t need to bother with special equipment for scoring. Disadvantages - when striking with a sledgehammer, it is impossible to direct all the impact energy downward, strictly along the axis of the borehole needle. This means that the pipe will bend to one side and flatten. The load on the threaded connections increases. If you decide to hammer the needle with a sledgehammer, do not hit the piece of pipe that you are planting in the ground. Screw a steel coupling onto the pipe and use a piece of threaded pipe to screw it into the coupling. These pipe ends are sold in construction stores under the name “thread” and cost pennies. They flattened one, replaced it and continued to score further.

Grandma and the womanizer

Hammering with a headstock is the preferred method. The design of the headstock can be different. Most often this thick wall pipe, one of the ends of which is welded. Handles are welded to the side; any iron can be welded to make it heavier. The weight of the headstock is usually 20-50 kg. At the upper end of the pipe to be driven in, a “grandfather” is also attached through a coupling - a piece of pipe with a thread, which will receive the blow. The headstock in this design is put on the pipe being driven, and then rises 40-60 cm and is thrown down. Since the headstock is fully dressed on the pipe being hammered, it moves almost perfectly up and down, and all the energy of the impact propels the needle towards the target.

There is another option for the headstock design. This is a heavy cylinder with a hole not much larger than the diameter of the needle being driven. A coupling is screwed onto the pipe being driven in, and the next similar pipe is screwed into it. When hammered, this pipe will serve as a guide for the headstock to move up and down. And it will hit the cradle - a steel cylinder, tightly fitted onto the needle tube, and resting against the coupling, which has a diameter several mm larger than the needle. The grandmother gets up and throws herself down onto the support. This, in turn, pushes the pipe string down.

We note very important fact– in order not to damage the threads on pipes and couplings, you need to select the length of the thread on the pipes in such a way that the pipes, screwed into the coupling, are joined inside it. Thus, the load from blows from the headstock will be placed not on the threads, but on the ends of the pipes.

Rod

Clogging a needle with a rod is also very common. The rod needs to be of such thickness that it fits freely inside the pipe of the Abyssinian well. We will hit the bottom of the lowered pipe column with a rod - into the opposite part of the cone that crowns the filter. The cone must be firmly welded to the filter pipe. Gradually, as the column is lowered, you can lengthen the rod (by welding, or by pre-arranging the threaded connection of the rods). If the mass of the rod is sufficient for impact, and its length is already shorter than the column being lowered, you can tie a steel cable to it and drive the needle by lifting the rod inside the pipe column by this cable and throwing it from a height. Hammering with a rod is considered more preferable from the point of view of safety threaded connections pipes

Hammering a needle hole with a hammer drill or jackhammer

Unfortunately, you cannot simplify your task by using a power tool. The reason for this is the large mass of the lowered pipe column. The hammer drill and the bumper will simply bounce off the structure that has a larger mass. This fact has been verified more than once, so don’t waste time.

To what level should the needle be hammered?

The needle is driven deep until the filter is in the aquifer. Ideally this is coarse sand or pebbles, but usually the aquifer is fine sand. As we mentioned earlier, water from a well can only be raised from a depth of 8-9 meters. Does this mean that it is pointless to drill a well deeper than 9 meters? Of course not. It is not the depth of the well that is important, but the water level in it. Experienced drillers know that the water of the second aquifer often rises to the groundwater level (level groundwater). It even happens that from a well depth of 15-30 meters the water is flowing self-outpouring.

The second question when driving a needle is how not to miss the aquifer? There is an easy way. Every half a meter, when driving needles into the pipe, add water. If the filter is located in an aquifer, the water will quickly flow into the pipe. The main thing here is that when passing through a layer of clay, the mesh does not become clogged with it. Otherwise, you simply will not understand that you have entered an aquifer. Water will not escape through a mesh clogged with clay in any case.

There is another way to determine which layer the needle filter is in. When you hammer in the needle, the upper tube must be constantly, every 10-20 strokes, tightened clockwise with a pipe wrench. This way we compensate for the self-unscrewing of the threaded connections of the column. If you can rotate the column completely so that the filter moves in the ground, it is easy to hear the friction of the soil against the filter cone.

Thus, clay makes almost no sound when turning the filter, coarse sand clearly creaks, and pebbles grind.

What to do if the filter mesh is clogged with clay or the pipe becomes clogged with sand when clogged

If the filter mesh of an Abyssinian well is clogged with clay, you can clean the filter mesh by pumping water under pressure into the pipe. It will wash away the clay. If flushing does not help, you will have to remove the entire column and clean it. Then a clean needle can be lowered into the finished hole without the risk of contaminating the filter.

It also often happens that if the filter mesh is chosen too large, or the pipe is used without a filter at all (some soils allow the use of Abyssinian without a filter mesh, if the aquifer is pebbles or very coarse sand). If the inside of the pipe is clogged with sand, it should be washed by lowering a narrow hose into the pipe, feeding water into it from outside the well and moving it so as to lift the turbidity from the sand in the pipe. This turbidity will come out of the pipe around the hose to the outside, washing away the sand.

How to prevent pipe clogging with sand and clay when plugging an Abyssinian well

There are a couple of ways to avoid filling the needle with sand and clay. The needle can be filled with salt or tightly stuffed with rope while hammering. The end of the rope must be constantly passed through all the pipes, so that after driving to the desired depth it is easy to get it out. Naturally, these two methods are only suitable if there are several Abyssinian wells nearby and the depth to which the needle needs to be driven is known in advance.

How to pump a well with a needle?

For pumping, a manual pump-column is best suited. Such pumps are not afraid of sand in the water, and at first there will be a lot of sand inclusions in the water. Depending on how well the mesh used matches the sand fraction in the aquifer, the well build-up time can range from half an hour to several months. At the same time, we repeat once again, a mesh that is too fine will clog faster and reduce the flow rate.

In principle, when using a sufficiently fine mesh of galloon (twill) weaving, it is quite possible to use a self-priming pump for pumping surface pump. It is desirable that the impeller be metal, because... The plastic one will quickly wear off with sand.

The hand pump is also good because it can easily cope with the initial low flow rate of the well. An electric pump cannot work if the water supply is poor; the water column in the Abyssinian well breaks and the pump stops working. The situation can be partially corrected by placing a tap at the outlet of the pump and choking the water outlet.

For easy start of the pump, install in front of it check valve. Under no circumstances should you place a check valve at the bottom of the column; it will quickly become clogged, and it will be impossible to replace it without raising the well column. In this case, the “extra” check valve will create additional resistance to the movement of liquid and “conceal” the meter of the potential suction height of the pump.

What to do if the connections poison the air, i.e. there is no tightness of the column?

It is not so rare that after a column is clogged, it turns out that water is not pumped out, despite the fact that the water surface is not far away. If a working self-priming pump is used, this means that there is air leakage in the line, which does not allow creating a vacuum inside the pipe and raising water. In this case, it is recommended to raise the pipe string (the method is described below) and seal the connections. If this is not possible, you can use the “imperfect well” design. A pipe of smaller diameter is lowered inside the Abyssinian well and water is sucked out through it. The problem is that since no vacuum is created in the pipe when water is pumped out, the water flows into the filter by gravity rather than being sucked in. Because of this, the well's production rate drops sharply.

How to raise the pipes of an Abyssinian well from the ground

It happens that you need to lift a pipe column if you have penetrated an aquifer, or you need to completely remove the well. This can be difficult to do, because... the soil tightly grips the pipes. To fix the pipe, you can use a specially made vice, which consists of two strong steel plates, tightened with bolts. You can simply put a cradle or a suitable washer on the pipe sticking out of the ground, fix its upward movement with a coupling screwed onto the thread, and pull it evenly upward with two jacks installed on both sides of the well. IN clay soils You can use the following technique: strongly strain a column of pipes upward, even if it does not move, and leave it like that overnight: under tension, the clay gradually opens up and releases the pipes.

If it is possible to supply good water pressure into the well, this can also help, to the point that the water will erode the soil around the well pipe and flow to the surface outside the pipe.

This article will be developed and supplemented. Please write your ideas and suggestions in the comments.

An Abyssinian well (“needle”) means a water intake with a diameter of 2.5-5 cm to the first aquifer and a depth of up to 10 m. It is inexpensive standalone source water, the productivity of which can reach 3-5 cubic meters. meters per hour.

How does an Abyssinian well work?

- metal tip (point) made of hardened steel;

- main pipe for pumping water;

- filter;

- couplings;

- foot valve;

- concrete rings;

- piston hand pump;

- rubber rings.

Initially, such wells were arranged like this: they took a section water pipe with a diameter of 2.5-3 cm and made a sharp tip, above it a perforation was created (small holes were drilled in the pipe). The resulting structure was driven into the ground up to the first aquifer. Water was pumped out from the source using hand pumps. In such structures, the water pipe simultaneously played the role of operational and casing. They were popular back in the 19th century during the war with Abyssinia, which is where they got their name.

The undeniable advantages of water intake:

- simplicity and high speed source devices. Having the necessary set of tools at hand, you can drill an Abyssinian well in just a few hours without involving complex equipment.

- possibility of device on small areas and even indoors. Due to their compact size, needle wells can be located in basements, garages and bathhouses.

- quite high productivity (can reach 50 l/min).

- high quality water. Despite the fact that the Abyssinian well, the so-called “needle”, has a small depth, the quality of the resulting water is quite high (it contains no soluble compounds heavy metals, other harmful impurities).

- significant service life - up to 50 years.

The source is cleaned quickly and at no extra cost.

Most economical option of all possible ways creating a water intake.

The Abyssinian also has disadvantages, and the main one may be poor filtration of the aquifer, which entails a high content of impurities in the extracted water. Insufficient filtration leads to rapid siltation of the source, which reduces water quality. Decide this problem succeeded using perforated well pipes wrapped in fine mesh or wire. Modern design The water intake is a pipe, in the lower part of which there is a filter with a tip (“needle”), and at the top there is a manual or electric pump. As a rule, the length of the pipeline does not exceed 10 meters; rarely the source can reach 30 m.

The limitation for creating such a water intake is the depth of the piezometric water level. The water surface should be no deeper than 8 meters, although the well itself can be located lower. If the distance to the mirror is 10-11 meters, it is necessary to further deepen the pump.

Abyssinian well as a source of water supply at home

The answer depends on individual conditions area where the water intake is planned to be located. The following factors should be analyzed:

- burial depth groundwater . The well is designed to lift water from the first aquifer on which wells are installed. In order to understand whether the “needle” can meet the water needs of the house, you should take a rope up to 15 m long and tie a weight at the end, go around 5-6 neighboring houses, measure the depth of the well and also the distance to the water surface. If the depth of the sources does not exceed 12 m, and the mirror is located no deeper than 7 meters, you can start drilling Abyssinian well with your own hands.

- water quality and quantity. The first aquifer is the most vulnerable to bacterial technogenic and chemical pollution. Therefore, it is necessary to analyze at what distance from the planned location of the water intake there are neighboring septic tanks, sewage pits, fields treated with pesticides, and other pollutants. You can also try testing your neighbor's well water. A separate issue is the well flow rate. It largely depends on the saturation of the aquifer.

- water intake location. The best option will be placing a "needle" on local area, although it is also possible to install a well in the basement or garage. By arranging a separate pit and placing a pumping station there, you will protect the source and equipment from rain and Wastewater, and yourself - from unnecessary noise.

Drilling an Abyssinian water well

- hammering with a barbell. A rod is understood as a metal rod with a diameter of 6-22 m, which can be extended as it goes deeper. Using a rod, blows are applied to the tip of the filter, as a result of which the dense soil at the end of the tip moves apart;

- hammering with grandma. Grandma represents special device, which is a load with a hole located inside, which acts on the wellbore. To do this, screw a special attachment onto the head. The result is the advancement of the tip deeper into the rock. At this method When drilling, special attention should be paid to the quality of the threads used, since they bear the main load.

- auger drilling. The best option drilling wells, including when you need to create an Abyssinian well with your own hands. It not only allows you to make holes of a larger diameter than the diameter of the pipe with the filter, but also reveals the aquifer as accurately as possible. It is best to choose the dry method (no rinsing). If necessary, the filter zone is sprinkled with fine crushed stone, which will have a positive effect on the quality of water and extend the life of the source.

A hole with a diameter of 50 mm is created to a depth of 8-10 meters. You can use it at work garden auger or a small-sized screw installation.

It is better to choose a self-priming pump for an Abyssinian well (well). It should be connected to a pipe, due to which a vacuum will be created and the water will rise to the surface.

Video - Pumping station for an Abyssinian well

Abyssinian well with connected pumping station 1100 watts Well productivity - 2 m3/hour. Such a well can be made in almost any room. Minimum working space 60*80 cm.

The design of the water intake part should be selected depending on the structure of the aquifer. If it is quicksand, it is better to install a filter on the Abyssinian well on the intake. As a rule, mesh models with a cell size of 0.22-1 square meters are used. mm. On perforated pipe wind the mesh with a gap between the turns of 1.5-2.2 mm. You can improve the quality of the filter by putting a mesh on the wire.

It is best to lift water from the water intake using a submersible vibration pump. If the well has a small diameter, water can be lifted using an air lift.

The easiest way to ensure country cottage area water - make an Abyssinian well with your own hands. Within five to ten hours after the start of work, the owners of the dacha will receive the first liters of their own clean water. The equipment that is used is so compact that it is possible to install an Abyssinian well even in the basement of a residential building or in inspection hole garage.

Principles of creating an Abyssinian well

The idea of the design is very simple and consists in piercing the soil to the depth of the aquifer with a pipe about one inch in diameter. To do this, a thin tip is attached to the end of the pipe, thanks to which a needle hole is created.

This uses pipes with a diameter of only an inch and a half. A self-priming pump is mounted on a recessed pipe, operating on the principle of creating a vacuum. If there is not enough water coming from the finished well, another needle well can be built on the site with your own hands.

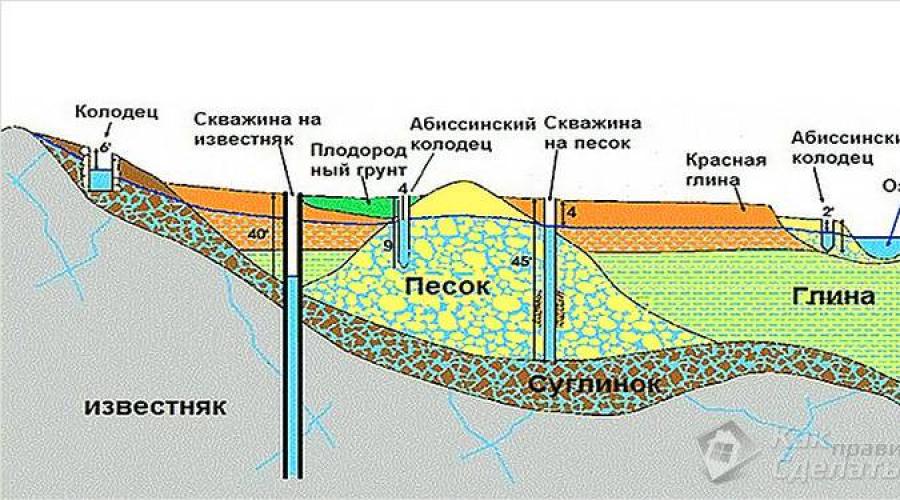

Location of classic water intake workings: as you can see here, an Abyssinian well can be built on light sandy soil

Despite the relatively low costs of labor and materials to create such a well, it is not possible to install it on every site. First of all, you should make sure that the water level that is reached after opening the aquifer is no more than 8 meters (the so-called piezometric level). This does not mean that the depth of drilling a well or passing a needle will necessarily be 8 meters. It can reach 10-15 meters, and in some cases for an Abyssinian well it is necessary to go deeper even 20-30 meters.

You can find out the value of the piezometric water level on the site by interviewing neighbors who already have a well or well. If it turns out that the water is somewhat deeper, a meter or two, it is still possible to make a well of this type, but this will require going deep into the ground a couple of meters.

The condition of the soil should also be correctly assessed. On the lungs sandy soils an Abyssinian well can be made without any problems. But if the soil turns out to be too hard, containing boulders and stones, the project will have to be abandoned.

Pipe, filter needle and other nuances

The functioning of any well, including the Abyssinian well, depends on the quality of the pipe. It is best to use inch or one and a half inch pipes, metal or plastic, which are cut into pieces 1-2 meters long. As the pipes are immersed, they are extended to the required length using threaded connections. They are sealed using plumbing flax, silicone, oil paint and so on.

In addition, special couplings are used. It is very important that the pipe connection is as reliable as possible. Any violation of the tightness will lead to damage to the entire structure.

The diameter of the tip should be slightly larger than the diameter of the pipe to ensure free movement of the structure through the soil.

At the end of the pipe, it is necessary to install a special needle filter, which will facilitate the penetration of the pipe into the ground, protect the Abyssinian well from silting, and also ensure the purity of the incoming water. It is best if the needle is made of the same material as the main pipe. This will prevent possible electrochemical corrosion.

To make a filter needle from a galvanized metal pipe, you need:

- Drill holes with a diameter of 5-8 mm in the pipe, placing them in a checkerboard pattern.

- Solder a stainless steel mesh on top. As an alternative to mesh, you can use wire that is wound around the perforated end of the pipe, leaving a gap between the turns. The wire also needs to be soldered.

- Weld a spear-shaped tip to the end of the pipe. Its diameter should be slightly larger than the dimensions of the pipe so that the structure following the needle moves freely through the soil.

Reinforced is quite suitable for such a well polypropylene pipe. To make a needle filter from PVC pipes follows:

- Insert the filter mesh inside the pipe.

- Secure the mesh using the fusion method.

- Perforate the pipe by making slits on its surface using a hacksaw.

Some experience with PVC pipes is required to perform these operations.

All necessary materials can be purchased separately at hardware stores, however ready set for an Abyssinian well will save time and effort.

What is better - driving or drilling?

To make an Abyssinian well on your own, two methods are used: driving and small-diameter drilling. To drive a structure into the ground, a “driver” is usually used. At the same time, water is constantly added to the pipe. When the water suddenly sinks into the soil, the structure is deepened by about half a meter, after which you can begin installing the pump.

When creating Abyssinian wells, it is easier and more convenient to drill a small diameter well

For self-creation The driving method for the Abyssinian well is excellent, but when using it, a number of dangers must be taken into account. There is a possibility of passing by the aquifer. In addition, if a stone is encountered at great depths, the structure may be completely damaged.

The method of preliminary drilling with a small diameter requires the involvement of a team with special equipment, but it guarantees the presence of water in the well. This method is clearly presented in the video:

Classic order of construction work

The task of driving the pipe into the ground looks quite simple. However, in order for all operations to be successful, a number of nuances should be taken into account. Experienced builders It is recommended to make an Abyssinian well as follows:

- Select and mark a location for the well.

- Dig a hole approximately one cubic meter in volume.

- Pass the upper layer soil with a garden auger to remove some of the soil.

- Start driving the pipe into the soil using a load weighing approximately 30 kg (cast iron, “pancakes” from a rod, etc.) or start drilling.

- The pipe should be in the center of the hole; a certain amount of soil is gradually added to it, which is compacted.

- Screw additional lengths onto the main pipe successively to ensure the required length.

- Once the aquifer is reached, the filter should be washed to remove clay with water supplied under pressure.

- Install a manual piston pump and pump out the cloudy layer of water until the water becomes clear.

- Concrete the area around the well to prevent runoff and contaminants from entering the well.

After installing the well, it is connected to the house water supply system, if necessary.

Abyssinian wells are durable and easy to use, the main thing is a suitable location

The advantage of Abyssinian wells is not only their simplicity of design. They are durable and very easy to use. These are small devices that will not cause any serious damage to the landscape. Wide access roads will not be needed for their construction and operation. Finally, if necessary, you can remove the pipe from the ground and install it in another suitable place. At the same time, the water coming from the Abyssinian well always remains fresh and clean.

The Abyssinian well is also called a needle well due to its small diameter, 25-40 mm.

Americans began to use this drilling technology at the beginning of the 19th century. But it became known throughout the world in the middle of the last century, when the British carried out military operation in desert Ethiopia. While extracting water, they learned to dig shallow, narrow wells using a Norton drill. Ethiopia was then called Abyssinia, which is why the wells began to be called “Abyssinian”. Let's take a closer look at the advantages of this type of well.

Mini well in a well

And the Bissin well is plugged both on the surface and inside the old well. This is why owners of private houses and summer cottages choose an igloo well:

It is possible to do it yourself. And if you invite craftsmen, it will cost less than digging a new well or deepening it with wells with a casing pipe.

An Abyssinian well, plugged in compliance with all the rules, will provide you clean water. Melt and rain streams will not fall into it (although, of course, a filter is placed inside the well).

The average service life of Abyssinian wells is 30-40 years. By the way, there are still active wells in Ethiopia from the time of the “Abyssinian operation” of the British!

Disadvantages of Abyssinian wells

- It is demanding of the aquifer - the layer of soil that contains water. It makes sense to drill a needle hole only in soil consisting of coarse sand or gravel. It is much more difficult to drill an Abyssinian well if the soil is rocky. In this case, you will need the help of professional drillers and special equipment.

- Limitations on pump selection. Due to the small diameter it will not fit into the Abyssinian well submersible pump. Therefore, surface pumps, manual or electric, are used, but they are less productive.

- The Abyssinian well must be used constantly, otherwise it will silt up. This problem is eliminated by cleaning the well with a bailer.

Install deep and fine water purification filters

Place for drilling a needle well

- The first thing you need to do is find out how deep the aquifers are in your area. “Abyssinian” technology allows you to drill shallow wells, 10-15 meters. Therefore, if the water in your area is lower than 15 meters, choose a different type of well.

- It is possible to learn about the depth of water layers by studying geodetic maps. Communication with neighbors, owners of wells and wells will also help.

- Then evaluate the soil, and depending on its composition, decide whether to make a well yourself or resort to the services of master drillers.

- On hills and slopes (due to risk of landslides)

- Closer than 1 kilometer from cemeteries, cattle burial grounds, etc.

- Closer than 15 meters from a residential building, barn and other buildings (the soil may shrink)

- Closer than 30 meters from the cesspool

- Closer than 3 km from factories, settling tanks and chemical production

If your old well is in a dangerous area, it is better to abandon it and drill for another water source.

Drilling Abyssinian wells in a well

Now let’s take a closer look at the technology of drilling a needle well. IN general outline This is the deepening of a drill string into the ground using the percussion drilling method.

Drilling a well in a well follows the same principle as drilling an “Abyssinian” from the surface. The only difference is that the drill string for driving a well in a well is longer. It is also more convenient to drill wells in a well using a tripod drilling derrick.

Important detail: casing not used when drilling an Abyssinian well.

Needle hole drilling tools

The drilling tool for the Abyssinian well consists of the following parts:

- Norton drill, which is a pipe with a filter and a sharp tip

- Drill string made of pipes

- Bottom clamp

- Cast iron or concrete frame

- Rope

- Upper clamp

The process itself takes place in several stages

INSTALLATION

The Norton drill is installed strictly vertically in the place at the bottom of the well where you decide to make a well. If the well is dry, first dig a small pit.

LET'S SCORE

The rubble is driven into the ground most often with the help of a woman. To do this, the first piece of pipe is inserted into the plugged drill bit. A headstock is put on it, then a woman and a collar. The cable is threaded through the pulleys, with its help the woman is raised and sharply lowered down, gradually deepening the drill string into the ground.

DRILL COLUMN

You gradually build up the drill string with new pipe sections. It is recommended to cut them 1-2 meters long. The headstock, headstock and clamp are moved onto them, continuing to drive. Make sure that the connections between the pipes are tight. Tightness can be achieved using threaded connections with seals or by fastening pipes with couplings.