How to make a cyclone filter with your own hands. Cyclone vacuum cleaner for the workshop: photos, videos, drawings. Cyclone with figured insert

Today we will tell you about a cyclone filter for a vacuum cleaner in the workshop, because one of the problems that we have to deal with when working with wood is dust removal. Industrial equipment It’s quite expensive, so we’ll make a cyclone with our own hands - it’s not difficult at all.

What is a cyclone and why is it needed?

In a workshop there is almost always a need to remove fairly large debris. Sawdust, small trimmings, metal shavings - all this, in principle, can be caught by a regular vacuum cleaner filter, but it is highly likely to quickly become unusable. In addition, it will not be superfluous to be able to remove liquid waste.

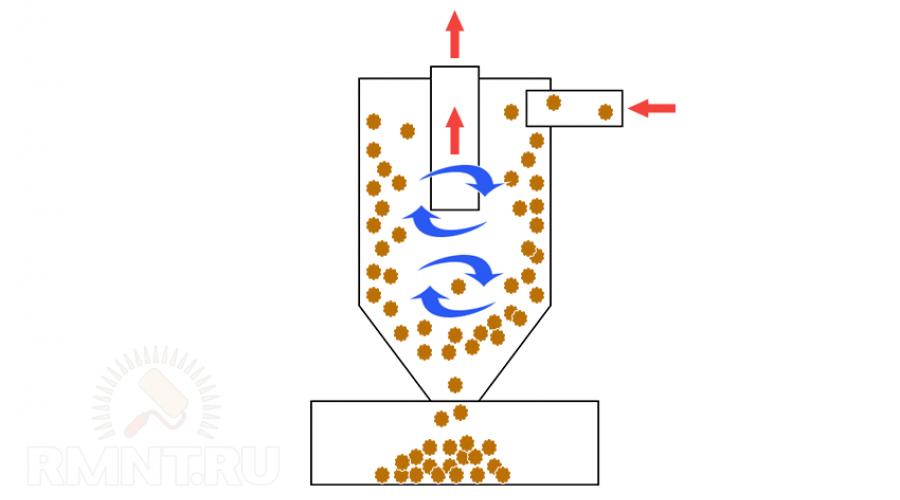

The cyclone filter uses aerodynamic vortex to bind debris different sizes. Spinning in a circle, the debris manages to stick together to such a consistency that it can no longer be carried away by the air flow and settles at the bottom. This effect almost always occurs if air flow passes through a cylindrical container with sufficient speed.

These types of filters are included in many industrial vacuum cleaners, but their cost is by no means affordable for the average person. At the same time, the range of problems solved using homemade devices, not at all anymore. The homemade cyclone can be used both in conjunction with planes, hammer drills or jigsaws, and for removing sawdust or shavings from various kinds machine tools In the end, even simple cleaning with such a device is much easier, because the bulk of dust and debris settles in a container, from where it can be easily removed.

Difference between wet and dry cyclone

To create a swirling flow, the main requirement is that the air entering the container does not follow the shortest path to exhaust vent. To do this, the inlet pipe must have a special shape and be directed either to the bottom of the container or tangentially to the walls. Exhaust duct Using a similar principle, it is recommended to make it rotary, optimally if it is directed towards the cover of the device. height aerodynamic drag due to pipe bends can be neglected.

As already mentioned, a cyclone filter has the potential to remove liquid waste as well. With liquid, everything is somewhat more complicated: the air in the pipe and cyclone is partially rarefied, which promotes the evaporation of moisture and its breaking into very small droplets. Therefore, the inlet pipe must be located as close as possible to the surface of the water or even lowered under it.

In the majority washing vacuum cleaners Air is supplied to the water through a diffuser, so any moisture contained in it is effectively dissolved. However, for greater versatility with minimum quantity It is not recommended to use such a scheme for alterations.

Made from scrap materials

The simplest and affordable option for the cyclone container there will be a bucket of paint or other building mixtures. The volume should be comparable to the power of the vacuum cleaner used, approximately one liter for every 80-100 W.

The bucket lid must be intact and fit tightly onto the body of the future cyclone. It will have to be modified by making a couple of holes. Regardless of the material of the bucket, the easiest way to make holes is required diameter- use a homemade compass. IN wooden slats you need to screw in two self-tapping screws so that their tips are at a distance of 27 mm from each other, no more, no less.

The centers of the holes should be marked 40 mm from the edge of the cover, preferably so that they are as far apart as possible. Both metal and plastic can be scratched perfectly with this homemade instrument, forming smooth edges with virtually no burrs.

The second element of the cyclone will be a set of sewer elbows at 90º and 45º. Let us draw your attention in advance that the position of the corners must correspond to the direction of air flow. Their fastening in the housing cover is carried out according to the following scheme:

- The elbow is inserted all the way into the side of the socket. Silicone sealant is first applied under the side.

- WITH reverse side The rubber sealing ring is pulled tightly onto the socket. To be sure, you can additionally compress it with a screw clamp.

The inlet pipe is located with a narrow rotating part inside the bucket, the bell is located with outside almost flush with the lid. The knee needs to be given another 45º turn and directed obliquely downwards and tangentially to the wall of the bucket. If the cyclone is manufactured with the expectation of wet cleaning, you should increase the outer elbow with a piece of pipe, reducing the distance from the bottom to 10-15 cm.

The exhaust pipe is located in the reverse position and its socket is located under the bucket lid. You also need to insert one elbow into it so that air is taken from the wall or make two turns for suction from under the center of the lid. The latter is preferable. Don't forget about o-rings, for more reliable fixation and to prevent rotation of the knees, they can be wrapped with plumber’s tape.

How to adapt the device for machines and tools

To be able to draw in waste when working manually and stationary tool an adapter system will be required. Typically, a vacuum cleaner hose ends in a curved tube, the diameter of which is comparable to the fittings for dust bags of power tools. As a last resort, you can seal the connection in several layers double sided tape for mirrors, wrapped with vinyl tape to eliminate stickiness.

With stationary equipment everything is more complicated. Dust extraction systems have very different configurations, especially for homemade machines, so we can only give a few useful recommendations:

- If the machine's dust extractor is designed for a 110 mm or larger hose, use plumbing adapters with a 50 mm diameter to connect the corrugated hose of the vacuum cleaner.

- To connect homemade machines to a dust catcher, it is convenient to use press fittings for 50 mm HDPE pipes.

- When designing the dust collector housing and outlet, take advantage of the convection flow created by the tool's moving parts for greater efficiency. For example: a pipe for removing sawdust from circular saw must be directed tangentially to the saw blade.

- Sometimes it is necessary to provide dust extraction from different sides workpiece, for example, for band saw or a router. Use 50mm sewer tees and corrugated hoses for drains.

Which vacuum cleaner and connection system to use

Usually, you don’t choose a vacuum cleaner for a homemade cyclone yourself, but use the one that is available. However, there are a number of limitations beyond the power mentioned above. If you want to continue using the vacuum cleaner for domestic purposes, then at a minimum you will need to find an additional hose.

The beauty of the sewer elbows used in the design is that they ideally match the diameter of the most common hoses. Therefore, the spare hose can be safely cut into 2/3 and 1/3, the shorter section should be connected to the vacuum cleaner. The other, longer piece, as is, is tucked into the socket of the cyclone inlet pipe. The maximum that is required in this place is to seal the connection silicone sealant or plumber's tape, but usually the planting density is quite high. Especially if there is an o-ring.

The video shows another example of making a cyclone for dust removal in a workshop

To pull a short piece of hose onto the exhaust pipe, the outermost part of the corrugated pipe will have to be leveled. Depending on the diameter of the hose, it may be more convenient to tuck it inside. If the straightened edge does not fit slightly onto the pipe, it is recommended to warm it a little with a hairdryer or indirect flame gas burner. The latter is considered excellent option, because this way the connection will be positioned optimally in relation to the direction of the moving flow.

Repair and construction work is not only difficult, but also leaves a lot of dust and debris, which is often too lazy to clean up, and ordinary home vacuum cleaners are simply not able to cope with the task. A cyclone for a vacuum cleaner will help, capable of sifting out shavings, sawdust and other debris without clogging the dust collector itself.

Operating principle

Many people know what construction debris is and how difficult it is to remove it, especially on an industrial scale. There are special construction vacuum cleaners on the market that have high power, in comparison with household ones, but at the same time they have large dimensions and a considerable price. Therefore, masters of their craft create cyclone-type chip extractors with their own hands, thereby improving their household vacuum cleaners and making their work easier.

Many people know what construction debris is and how difficult it is to remove it, especially on an industrial scale. There are special construction vacuum cleaners on the market that have high power, in comparison with household ones, but at the same time they have large dimensions and a considerable price. Therefore, masters of their craft create cyclone-type chip extractors with their own hands, thereby improving their household vacuum cleaners and making their work easier.

The filter is a structure of two compartments: external and internal. Under the influence of centrifugal force, all rubbish entering the dust collector, based on the cyclone principle, sorts into large and small particles.

Large ones settle in external camera, and small ones - in the inner one. It is because of this principle of operation of the filter that it was called cyclone.

DIY making

Before starting work, you need to remember that building such a simple device will not be difficult, so after mastering the principles, you can immediately make your own masterful modifications to the mechanism.

When making a cyclone with your own hands from scrap materials, you need:

To make a vacuum cleaner with your own hands, you need:

- In the lid of the container it is necessary to make a hole for the polypropylene elbow at 90 degrees and in the side of the container itself the same hole for the elbow at 30 degrees.

- A filter is placed inside the container, already connected to a polypropylene elbow.

- All holes should be sealed tightly with sealant.

The hose is tightly fixed with a polypropylene elbow and is directed clearly downwards, thereby setting a stable trajectory. Testing is carried out on hard litter.

Aquafilter from improvised means

If you have problems finding a store-bought aquafilter, you can easily make a cyclone filter for a vacuum cleaner with your own hands. For this you just need plastic pipe, the dimensions of which are determined based on the size of the container (a sewer pipe of small diameter is suitable).

If you have problems finding a store-bought aquafilter, you can easily make a cyclone filter for a vacuum cleaner with your own hands. For this you just need plastic pipe, the dimensions of which are determined based on the size of the container (a sewer pipe of small diameter is suitable).

To make a filter yourself, you need to cut the pipe into pieces and tightly connect it into a T-shape so that air can easily pass between the chambers, and the side branches need to be plugged with breathable fabric material.

From below, at the base of the wide part, it is necessary to drill holes in a checkerboard pattern (for water intake). Next, you need to connect the cyclone filter to the water filter using a polypropylene elbow so that the water filter, while inside the container, lightly touches the water.

Water is added immediately before using the vacuum cleaner.

Dust bag

When making a vacuum cleaner bag with your own hands, any material is suitable, but it is important that it be dense. In order to make such a bag, you will need only three materials:

- Textolite (the size is selected individually for each vacuum cleaner).

- Any textile dense bag (many people use shoe bags).

- Clamp for debris dump part.

A hole is made in the PCB with a diameter the size of the dust collection valve outlet; the sizes are different for everyone, depending on the model of the vacuum cleaner. Next, the same hole is made in the bag and secured between the PCB and the bag.

A hole is made in the PCB with a diameter the size of the dust collection valve outlet; the sizes are different for everyone, depending on the model of the vacuum cleaner. Next, the same hole is made in the bag and secured between the PCB and the bag.

A hole is made in the opposite part of the bag to discharge dust and debris, after which the bag is secured with a clamp.

Cyclone was created in 1986 Jameson Dyson and since then has gained its authority in the sales market and maintains its position to this day.

Not a single industrial sector can do without this invention, which has such qualities as speed and reliability.

When carrying out repairs and construction work a lot of garbage appears. Sawdust, shavings, scraps of materials mixed with dust must be removed regularly. Regular sweeping with a mop is excluded due to the specifics of the work, if dust and small particles can stick to the surface, for example, after priming or painting.

An ordinary vacuum cleaner will not cope with such debris or will quickly break down. Household electrical devices designed for medium short-term load.

For such cases, specialized equipment is produced. A construction vacuum cleaner can work for quite a long time without stopping, has significant power, and uses completely different filter systems than household vacuum cleaners.

When should you use a construction vacuum cleaner?

Those who are constantly faced with construction, repair and carpentry work know about the need for timely cleaning of the workplace at the end of the stage. Cleaning can be done multiple times in one day, so it’s reasonable to want to make the process easier for yourself.

Those who are constantly faced with construction, repair and carpentry work know about the need for timely cleaning of the workplace at the end of the stage. Cleaning can be done multiple times in one day, so it’s reasonable to want to make the process easier for yourself.

Pieces of foam and polyethylene film , scraps of gypsum board, chipped plaster, dust from cutting aerated concrete - all this debris settles not only on horizontal surfaces, but is also electrified and attached to vertical walls.

Cleaning with a mop and dustpan is not always appropriate due to large areas, and washing will only turn dry dirt into wet slurry, especially in unfinished rooms.

Ordinary household appliance Due to the small size of the dust container, it will quickly become clogged and will have to be continuously cleaned. If large particles get in, there is a high risk of breaking the equipment.

It is in such conditions the best solution will use a construction vacuum cleaner.

Pros and cons of a construction vacuum cleaner

Greater power allows professional equipment work without interruption for a long time, and the long hose provides access to remote areas without the need to carry the vacuum cleaner or interrupt work.

But it also has disadvantages:

- High price. If periodic or one-time work is necessary, purchase a new one expensive instrument inappropriate.

- Large size and weight.

Some craftsmen have come up with a way out in the form of additional option to existing technology. At fairly low costs, you can assemble a cyclone filter for a vacuum cleaner with your own hands. This design will increase the capabilities of an existing conventional household vacuum cleaner.

Making a cyclone with your own hands

There is a huge selection of instructions on the Internet. self-production cyclone filter, including attached drawings and photographs. But they are united standard set components.

So, what do we need:

Assembly instructions.

The main indicator that a cyclone for a vacuum cleaner is assembled correctly with your own hands will be debris collecting at the bottom or settling on the walls of the container, while the suction will be fast and high-quality. Do not forget to check the tightness of the structure.

The history of the cyclone filter

The creator of cyclone filter technology is James Dyson. It was he who first made a filter with operation based on the action of centrifugal force. Why did this device become so popular and in demand that the inventor filed a patent for it?

The creator of cyclone filter technology is James Dyson. It was he who first made a filter with operation based on the action of centrifugal force. Why did this device become so popular and in demand that the inventor filed a patent for it?

The filter consists of two chambers. Under the influence of centrifugal force inside the unit, the debris begins to swirl into the funnel. Large trash at the same time, it settles in the first chamber, the outer one, and dust and light debris collects on inside. This way, clean air comes out through the top hole.

The main advantages of the cyclone filter:

- no need for dust collection bags and their constant replacement;

- compact filter sizes;

- quiet operation;

- An easy-to-remove lid allows you to regularly check the level of contamination and promptly dispose of garbage;

- speed and efficiency of work.

A vacuum cleaner with a cyclone filter can be used both at home and for professional purposes.

Recently I became interested in working with wood and the issue of removing shavings and sawdust arose very urgently. So far, the issue of cleaning the workplace has been solved with a home vacuum cleaner, but it quickly becomes clogged and stops suction. You have to shake out the bag often. In search of a solution to the problem, I looked through many pages on the Internet and found something. As it turns out, it is possible to make fully functional dust collectors from scrap materials.

Mini vacuum cleaner made from a plastic bottle

Here is another idea for a mini vacuum cleaner based on the Venturi effect

This vacuum cleaner operates using forced air.

Venturi effect

The Venturi effect is a pressure drop when a liquid or gas flows through a constricted portion of a pipe. This effect is named after the Italian physicist Giovanni Venturi (1746–1822).

Rationale

The Venturi effect is a consequence of Bernoulli's law, which corresponds to the Bernoulli equation, which determines the relationship between speed v liquid, pressure p in it and height h, on which the fluid element in question is located, above the reference level:

where is the density of the liquid, and is the acceleration of gravity.

If the Bernoulli equation is written for two sections of the flow, then we will have:

For a horizontal flow, the average terms on the left and right sides of the equation are equal to each other, and therefore cancel, and the equality takes the form:

that is, with a steady horizontal flow of an ideal incompressible fluid in each of its sections, the sum of the piezometric and dynamic pressures will be constant. To fulfill this condition in those places of the flow where average speed fluid is higher (that is, in narrow sections), its dynamic head increases, and the hydrostatic head decreases (and therefore the pressure decreases).

ApplicationThe Venturi effect is observed or used in the following objects:

- in hydraulic jet pumps, in particular in tankers for oil and chemical products;

- in burners that mix air and combustible gases in the grill, gas stove, Bunsen burner and airbrushes;

- in Venturi tubes - constricting elements of Venturi flow meters;

- in Venturi flow meters;

- in ejector-type water aspirators, which create small vacuums using kinetic energy tap water;

- sprayers (sprayers) for spraying paint, water or aromatizing the air.

- carburetors, where the Venturi effect is used to draw gasoline into the inlet air stream of an internal combustion engine;

- in automated swimming pool cleaners, which use water pressure to collect sediment and debris;

- in oxygen masks for oxygen therapy, etc.

Now let's look at the samples that can take their rightful place in the workshop.

Ideally, I would like to get something similar to a cyclone filter, but from scrap materials:

Homemade chip separator.

The principle is the same, but made much simpler:

But I liked this option the most, since it is a smaller analogue of an industrial cyclone:

ch1

Since I don’t have a traffic cone, I decided to settle on this design, assembled from plastic pipes for sewerage. An undoubted advantage is the availability and low cost of material for assembling the structure:

Homemade cyclone from plastic sewer pipes

Please pay attention to the mistake that the master made. The garbage collection pipe should be located like this:

In this case, the desired vortex will be created.

On next video shown similar design at work:

And finally, a slightly modified version:

Quite often after various types work remains a large number of fine dust and debris that can only be removed with good vacuum cleaner . Simple home apparatus not suited for this. An industrial vacuum cleaner must be used high power. You can make a filter for it yourself.

People who constantly work in the construction industry need to clean up a large amount of various small debris and dust. It could be old plaster, remains of foam plastic, drywall or wood dust. Such debris can settle in a thick layer throughout the room. It is very difficult to sweep this dust with a broom or wipe it with a rag, because due to large sizes Such cleaning of the premises will take a long time.

Using a vacuum cleaner in this case is optimal. A regular product used at home is not suitable for these purposes. The ingress of wood chips or sawdust will clog the vacuum cleaner or completely disable it. Also, a large amount of fine dust will quickly clog the dust collector, which will need to be cleaned every 20 minutes.

Using a vacuum cleaner in this case is optimal. A regular product used at home is not suitable for these purposes. The ingress of wood chips or sawdust will clog the vacuum cleaner or completely disable it. Also, a large amount of fine dust will quickly clog the dust collector, which will need to be cleaned every 20 minutes.

But construction vacuum cleaners are large, inconvenient to use and maintain, and have very high cost. For this reason, some home craftsmen have learned to increase the capabilities of their household product by equipping it with specialized cyclone filter. Such dust collectors can be purchased at hardware store or make it at home with your own hands. On the Internet you can find many drawings of dust collectors for woodworking workshops.

Experts highlight the following advantages of cyclone filters:

- no need to constantly buy disposable bags and containers for collecting fine dust;

- small sizes;

- quiet operation of the device;

- when the filter housing is made of transparent plastic, it is possible to monitor its contamination;

- high efficiency.

Operating principle of a cyclone filter

The cyclone consists of several parts:

- pipe branch;

- frame;

- dust collector;

- chamber with membrane filter;

- intake fan.

Dirty air enters the cylindrical body of the product through the pipe. The pipe is located tangentially to the side walls of the housing, so the air flow near the cylinder walls twists in a spiral. Due to centrifugal force, dirt particles are pressed against the body of the device and then fall into a special dust collector. The remaining air with dust particles enters another chamber, which is equipped with several membrane filters. As a result, all collected dust ends up in the receiving fan.

The membrane compartment is the least contaminated and must be cleaned only after cleaning. The collected dust is simply removed from a special storage device, and the device is again ready to perform its duties.

Vacuum cleaners with a similar principle of operation are much cheaper than water ones, but more expensive than membrane ones. For this reason, home craftsmen assemble the cyclone themselves and then connect it to a household vacuum cleaner.

DIY cyclone from scrap materials

It is quite easy to assemble a cyclone filter for a vacuum cleaner with your own hands. It is often necessary when processing wood. Together with Fraser or electric plane vacuum cleaner membrane type gets clogged very quickly and needs to be cleaned frequently, which greatly distracts from production process. When a craftsman is engaged in carpentry in small room, That small sawdust creates a lot of problems. For this purpose, a cyclone was designed and manufactured from simple parts, which is not inferior to its factory counterparts.

Materials for production

To make a homemade cyclone, you will need the following materials:

Assembling a cyclone for a household vacuum cleaner

On the lid plastic containers a special bracket for a small air filter, which can be made from metal strip or corners. The air filter must fit very tightly to the plastic lid of the container. Otherwise, dusty air will enter the outlet pipe. Next, the outlet pipe must be sealed tightly on top of the lid. Through it, purified air will flow into the household vacuum cleaner. Experts advise leaving membrane filter household product. This will help keep the fan free from dirt and will not weaken the air flow.

Near the air filter it is worth placing a special dust trap, which is assembled from thin metal sheet. This element is capable of repelling small particles of dirt that do not fall under the influence of gravity, which allows you to clean the filter much less frequently. An old woman's stocking can do the same job, protecting the filter pores from large and light particles of dust.

The homemade inlet pipe must be positioned tangentially to the walls of the housing and slightly tilted towards the bottom of the device. Dirty air will be immediately sent in the right direction. To ensure that the walls of the container do not collapse due to the vacuum environment, they must be well reinforced with a strip of metal. Plastic containers are not able to withstand heavy loads because the material is quite thin. Since the device is large in size, it is worth making a plywood frame, which it would not hurt to equip with small swivel wheels.

Next, you need to properly secure the assembled filter and household vacuum cleaner to the frame. The fastening must be ensured quick dismantling to clean the container from collected debris. At the end of the work, you need to test the device. At the bottom plastic container All trash must remain.

How to make an aqua filter for a vacuum cleaner

When a person does not need a professional construction vacuum cleaner, then you can make a water filter for chips in another way. For example, it can be made from an ordinary traffic cone. Any plastic container with thick walls and a well-closing lid will serve as a dust collector. It is worth noting that plastic container plays a role air system , and leakage has a bad effect on the power of the device. It is necessary to cut the support square from the traffic cone. Based on the resulting hole shape, you need to cut out the top cover from plywood.

An outlet pipe is fixed into the top cover using sealant, which should be made from ordinary sewer pipe. This part must be lowered to the middle of the construction cone. When it is raised higher, the dust swirl will be incorrect. If the outlet pipe goes down too low, dirt will be sucked into it.

The narrow part of the traffic cone is also sealed into a circle of plywood, which is attached to the trash compartment. It is worth checking the tightness of all seams and connections several times. An inlet pipe is placed near the upper cut of the cone, into which dirty air will enter.

Next, you need to check that the dust collector is assembled correctly. The outlet pipe must be connected to the inlet of a household vacuum cleaner using a factory hose. Therefore, the nozzle should be selected in accordance with the diameter of the vacuum cleaner hose. The waste collection hose is connected to the inlet pipe of the product. A test run is required. When the device is assembled correctly, all debris will accumulate at the bottom of the plastic container, and the membrane filter of the household vacuum cleaner should remain clean.

You can make the cone shape with your own hands. For example, make it from metal sheet, having previously calculated the layout of the product. An old galvanized metal bucket may also work.