How to make your own grill from a gas cylinder. Barbecue from a gas cylinder. Photo gallery: unusual options for homemade barbecues

With the onset of warmer weather, the thought comes to us more and more often: shouldn’t we go to the dacha to fry some meat in the wild? It’s good if you already have a stationary kebab maker or you are able to purchase a portable version. But what about those who don’t have this opportunity? Make a barbecue with your own hands from a gas cylinder according to our instructions.

Types of barbecues

Braziers, depending on their size, are divided into 2 types:

- portable - compact structures that can be easily disassembled, folded and transported. To reduce their weight, such kebabs are made of thin metal. This is their advantage, since they are mobile, but there is also a disadvantage here - thin metal quickly burns out;

- stationary - solid structures that are impossible or difficult to transport. They are made of stone, brick, thick metal and other heat-resistant materials.

We will tell you how to make a stationary DIY barbecue from a gas cylinder. With proper skill, you will only need a few hours.

Instructions for making a barbecue from a gas cylinder

To make a barbecue with your own hands, you will need:

- empty gas cylinder (you don’t have yours - buy it online);

- Bulgarian;

- welding machine;

- 4 hinges (we suggest using window hinges);

- metal handle (suitable for an old iron or a saucepan);

- metal sheet 1 mm thick;

- 2 corners 40 mm;

- fittings or corner from which we will make legs (7 m);

- hose and water;

- chalk (apply markings).

1. Prepare the cylinder for cutting. Open the tap slightly and release any remaining gas. To avoid poisoning, do this outdoors, away from fire, and try to stay away yourself. Pour water into the container through a hose - it will squeeze out the remaining gas from inside, which can explode from a spark when cutting metal.

2. Apply markings. We take the connecting weld as the center (reference point). The balloon itself reaches 96 cm in circumference. We divide it into 4 equal parts, each 24 cm.

Measuring 24 cm to the right from the seam, draw a longitudinal straight line with chalk - this is the future boundary of the cut.

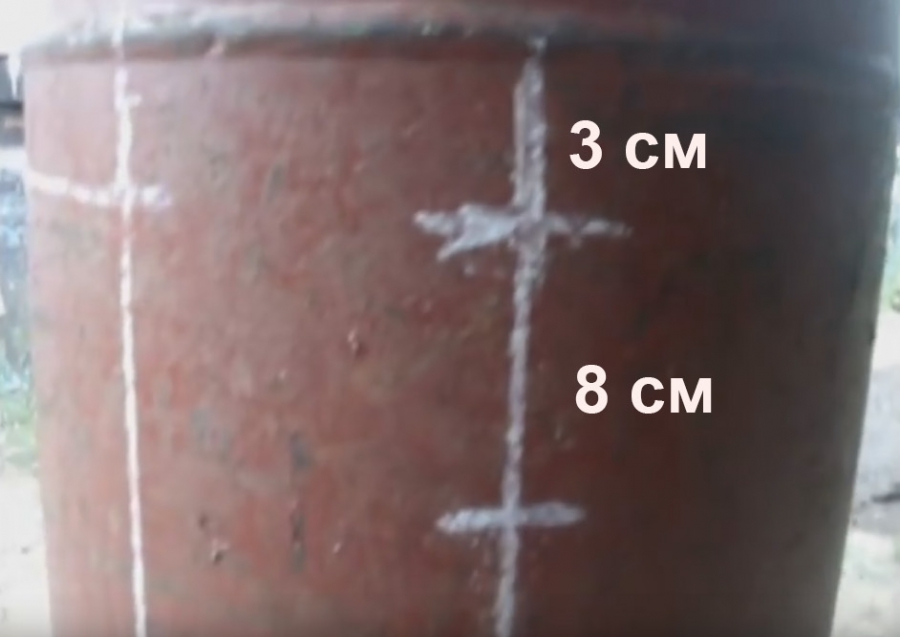

We also measure 24 cm from the connecting seam to the left and draw a parallel longitudinal segment. Having counted 3 cm from the upper and lower circular welding seams, we make notches with chalk. Measuring 8 cm from the top notch, we mark with chalk the locations of the holes for the skewers. If you did everything correctly, there should be 6 of them.

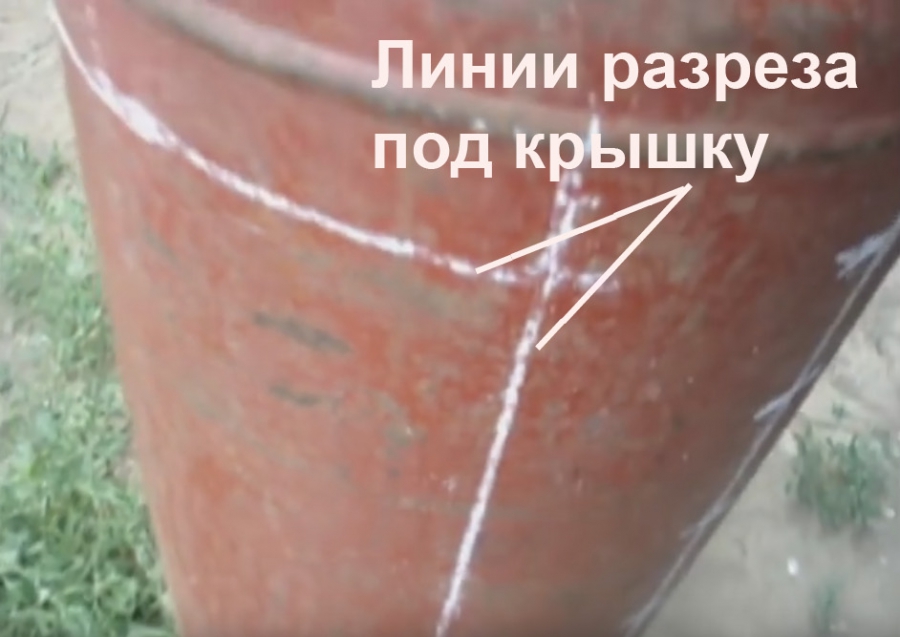

From the line with notches to the left, measure 10 cm and draw a parallel line - this will be the lid.

3. Cut out the cover. Using a grinder, we cut a balloon filled with water. First, we make a cut along a line located 10 cm from the notched segment. Having completed this operation, we weld the hinges, as shown in the photo.

Only after this do we complete cutting out the cover around the perimeter.

We open it and drain the water, the barbecue with your own hands from a gas cylinder is half ready.

4. We make limiters for the lid. We take two 40-mm corners and cut out holders 3 cm wide. We apply it to the grill body (see photo) and weld it.

Now, when the lid opens, it will not fall back and overwhelm the structure. You can increase the size of the angle of the limiters, then the lid will not tilt back much, and you will not have to reach far for it.

5. We weld the handle. You can choose a lid for its location, but then try to choose a handle with heat-insulating material, otherwise it will heat up when preparing barbecue and you may get burned.

The second version of the handle will avoid accidental burns. It is enough to weld a metal rod 10 mm thick to the side of the lid.

6. Cut off the rim of the cylinder. To make it easier, you can make a cross-section.

7. We process the edges of the opening so that the lid does not fall inside. From a sheet of metal 1 mm thick, cut out long strips (3 cm wide), the length of which should correspond to the size of the sides of the rectangular hole for the cover,

and weld them around the perimeter.

It should look like this:

You can stop for a few minutes and watch this video on how to make a portable homemade barbecue using a beer can and four screws:

8. Since we have barbecue grill, make holes into which the skewers will be inserted. Using the marks made earlier (notches placed at an 8-centimeter distance), we drill holes.

Having marked the plate located on the opposite side of the holes in exactly the same way, we make slits in it where the skewers will be inserted.

9. Cut off and weld the top hole where the faucet stood.

10. We make slits to provide oxygen access. We turn the cylinder over with the weld seam facing up, step back 10 cm from the seam towards the round holes for the skewers and draw a longitudinal line.

We measure another 10 cm from it and draw a second one. We connect the resulting two lines with segments, placing them at a distance of 5 cm from each other. These will be the slits.

We apply the same pattern on the other side, there will also be slots there.

We cut the slots.

11. Having finished making the grill with your own hands, we weld its legs. They can be made from a corner

or fittings.

Choose the height according to your height. The barbecue with your own hands from a gas cylinder is ready. All that remains is to paint it, giving it a final presentation and providing protection against corrosion.

How to paint a homemade grill?

The barbecue grill can be covered with:

- heat-resistant silicone enamel, which can withstand temperatures up to 600 ° C;

- thermal powder paint. True, this method of corrosion protection is not applicable at home, since it requires firing in a high-temperature oven.

Another method of anti-corrosion treatment of barbecues is oxidation. It is also not easy to implement, but it is quite feasible.

First, you need to treat the body of the grill with 5% sulfuric acid, then boil it in a highly concentrated solution of laundry soap, and then boil for one and a half hours in a solution of sodium hydroxide. Such homemade grill will not rust for a long time.

No matter how high-quality the anti-corrosion coating is, we do not recommend testing its reliability by leaving the grill in the snow and rain. The best place to install it is a canopy. With the onset of cold weather, it is better to move the structure to some room, for example, a garage or barn.

And in conclusion, some tips for proper grilling:

- When lighting a fire in it, conditionally divide the inside of the grill into two zones. In one, where there is more heat, cook meat, in the second, where the temperature is lower, cook vegetables and fish;

- Don't turn the skewers frequently. Normal cooking can be achieved by turning the meat only 2-3 times. The coals should be red with a gray coating of ash;

- do not let the meat become charred: black coating is a direct path to cancer. The other extreme - weak roasting - poses a risk of helminth infection;

- add flavor to your food by throwing a few branches of fruit trees onto the coals;

- When preparing barbecue in rainy weather, don’t even think about moving your homemade grill indoors. Poor draft will lead to increased concentrations of carbon monoxide.

To avoid fire, place the barbecue grill away from flammable objects. There should be no grass, branches or boards near the legs. Do not rush to throw away the ash: it can smolder within a day, which means it can cause a fire.

If you prefer traditional rectangular barbecues, you can watch a video tutorial on how to make them:

Take it for yourself and tell your friends!

Read also on our website.

Everyone needs a barbecue. Some people organize monthly picnics, others cook aromatic meat on their property. Such a vacation is always pleasant and useful, because beautiful landscapes and clean air give a boost of energy and have a relaxing effect. But you don’t always have the funds to purchase a barbecue, because this design cannot be called cheap. But if you have free time, then an old gas cylinder can turn into a good-quality barbecue. This material contains drawings, a diagram, video materials and step-by-step instructions for making a barbecue from a gas cylinder - all this will help you understand the simple work.

We will study three types of barbecue based on a gas cylinder:

- standard grill;

- barbecue steam locomotive;

- grill-smokehouse.

Preparation of tools and materials

In order for the work to go quickly, you need to ensure that you have the necessary tools and materials. To make a barbecue we will need:

- Welding machine.

- Bulgarian.

- Several clamps.

- Metal pipe.

- Electric drill.

- Dense metal sheets to add structural strength.

- Aluminum rivets.

- Hinges for the lid.

- The basis of the barbecue is a cylinder with a volume of at least 50 liters (if the cylinder is smaller, it will be inconvenient to turn over the coals).

The photo shows the main units for making a barbecue.

IMPORTANT! Safety must come first, so sawing the cylinder can only take place when all the gas has left it.

Removing gas is simple: turn the cylinder upside down and twist the valve. Gas is heavier than air, so in this position it will come out intensively. To see whether the process is going on or not, you need to lather the valve hole. If bubbles appear, it means the gas is escaping - wait for completion. To be sure at the end, the cylinder can be completely filled with water so that it washes away the last remaining gas.

Manufacturing process: instructions

When the cylinder is empty and all the necessary tools are at hand, you can get to work:

After drilling the holes, the manufacture of the barbecue can be considered complete. Clean it thoroughly and heat it several times until the smell of gas disappears completely. As for paint, this is an optional step. Some owners paint with a heat-resistant coating, others skip this step. All the same, after a few dinners with good barbecue, the grill will become smoky and black. To increase draft, it is recommended to install a chimney: a round hole is cut out at the end of the barbecue structure, into which a regular drain pipe of a suitable diameter can be welded.

You can place a couple of cast iron grates at the bottom of the grill. They are used in potbelly stoves and various boilers. By installing these elements, there will be additional ventilation inside the barbecue. Hot grates help save coal, since they also participate in the process of cooking meat. You can place the grill in a brick gazebo or in an open place.

For convenience, the internal barbecue area is divided into two sectors. In one, protrusions are made for the grates, and in the second, slots are cut for skewers.

As tests show, the thickness of the car cylinder is quite enough for normal functioning - the shape of the barbecue is maintained under the influence of high temperatures.

Features of barbecue legs

Legs are the basis of a homemade barbecue. Before you make them, think about whether you will take the grill with you or whether it is created only for use on the site. If you plan to go on a picnic, then you should take care of folding legs. First, you can weld four short bases, which can later be placed on a higher structure.

The legs are usually made from durable pipe. You can secure it either by welding or using bolts: we drill holes and place the bolts there. After installing the legs, the bolts can be tightened with nuts or welding can be used.

Barbecue smokehouse

Using the instructions for creating a regular barbecue from a gas cylinder with your own hands, you can also make a smokehouse. The main difference in the design is the presence of a firebox. Also, the smokehouse must be airtight. A strip is cut off at the bottom of the cylinder, then it is necessary to cut off half of the bottom of the cylinder. As a result, we will have space for the firebox. It is made from dense iron sheets - 2-3 millimeters.

The element is welded to the bottom, after which we get a solid structure. Also, a barbecue smokehouse requires a pipe through which the smoke will escape. This part can be purchased on the construction market or made from a cylinder with a smaller diameter. Some craftsmen even install a motor, whose task is to rotate the spit with meat.

The structure must be coated with safe, but heat-resistant paint. You can start cooking after calcination. Sometimes it’s not possible to get rid of the smell of gasoline the first time.

Brazier steam locomotive

If making an ordinary barbecue with your own hands takes several hours of work, then creating a barbecue-steam locomotive can take more than one week. This is a decorative product that includes a grill, barbecue, grill and even a smokehouse. The brazier was called a steam locomotive because in appearance it really looks like one, especially if the design uses pipes of different diameters. Masters make real masterpieces using several cylinders.

If you can take a standard gas cylinder for the base, then barrels and main pipes are suitable for the remaining elements. The wheels can be made from cut cylinders, but to add originality, you can use forged elements. The barbecue locomotive must be completely covered with heat-resistant paint. For these purposes, take a coating with a temperature limit of 700C°. The paint needs to be renewed, the intervals depend on the frequency of use of the grill.

Forged parts allow you to breathe life into a design made from cylinders. Craftsmen install retractable grilles, comfortable tables, functional and decorative elements to them.

A steam locomotive is not only a curiosity that attracts attention to your site, but also an excellent design that allows you to set the table in the shortest possible time.

If you decide to start making a barbecue from a gas cylinder, then you should think about whether you are good at welding and a grinder. This is a rather complex process, so if you handle the tool ineptly, the result can only be disappointing.

The homemade design has several features. Please take note of these before starting work:

- if you do not apply a heat-resistant coating, you can get seriously burned on such a grill;

- after several “sessions” with kebabs, the cylinder will become smoked, so for transportation you need to take reliable bags or plastic film;

- the structure must be stable, but not heavy, so you need to calculate in advance what supports to make for the barbecue;

- Only coal can be used as a raw material, since there is too little space for firewood.

Drawings and videos

The drawing shows a barbecue firebox made from a gas cylinder:

This drawing diagram should help you understand what a gas cylinder grill is:

Scheme of operation of the grill-steam locomotive:

This video explains in simple language how to build a barbecue from a gas cylinder with your own hands at home:

The video instructions below will help you make a barbecue smokehouse:

In this article I will talk about the most useful homemade product of the summer season, without which almost no event can be done. We will talk about making a homemade barbecue from a gas cylinder. The costs for this assembly will be minimal, and many people probably have an unnecessary gas cylinder.

In order to make a barbecue from a gas cylinder with your own hands, you will need:

* Gas cylinder

* Angle grinder

* Cutting disc for angle grinder

* Safety glasses, gloves

* Welding machine, electrodes

* Welding mask, gaiter

* Electric drill, metal drills with a diameter of 6 and 12 mm

* Pipe bender

* Tape measure, pencil

* Metal corner with shelf width 40 mm

* Metal rod with a diameter of 14 mm

* Profile pipe dimensions 20*20 mm

* Thick wall pipe with outer diameter 22 mm

* Hand vice

* A couple of cans of black thermal paint

* Semi-automatic core

* Metal tire

* Bed from an old sewing machine

* A piece of reinforcement with a diameter of 10 mm

* Shovel handle

* Metal grinding wheel for angle grinders

* Metal lathe

Step one.

The first step is to start with a gas cylinder. In this case, the gas cylinder is taken from a car and does not have a lower skirt and valve, unlike a stationary one, and due to the fairly wide filler neck, it is safer to disassemble it.

To prevent the cylinder from rolling on the floor during operation, we install car rolls under it.

Then, using a string, we measure the circumference of the cylinder, applying it to a tape measure, after which we divide the resulting figure by two and subtract about 50 mm, the resulting value will be the size of our door.

Next, using masking tape, we paste the balloon along the contour and get such markings that are visible in any lighting.

We take an angle grinder with a cutting disc in our hands and make cuts according to the markings, we don’t cut out the door completely, we leave just a couple of millimeters in the corners to make it easier to weld the hinges. When working with an angle grinder, be careful and wear personal protective equipment such as gloves and safety glasses.

Step two.

Now let's make the hinges that will hold the door on. If you don’t have a metal lathe, you can simply buy hinges at a hardware store; they are inexpensive. In this case, we have a lathe, so we’ll make the hinges ourselves. First, we grind the outer diameter of a thick-walled pipe, initially its diameter is 22 mm, then we fit a rod with a diameter of 14 mm under the hole in the pipe.

The pipe should rotate on the rod without jamming, but without large backlashes. So, from two pieces of pipe and a rod, one powerful hinge is obtained; a pair of these is needed for the door, so we make the second one in the same way.

Using a metal grinding wheel and an angle grinder, we clean the places where the hinges will be attached. After this, we place two thin plates under the hinge to ensure the required gap and begin to weld the hinges to the door and cylinder using a welding machine. First we make tacks, and then, making sure that the loops are located coaxially, we finally weld them. When working with a welding machine, follow safety precautions, use gloves and a welding mask.

We remove the slag from the weld using a hammer and clean it with a wire brush.

After the hinges are welded, cut off the 2 mm left earlier and the door is ready.

The door opens well, there are no distortions or jams.

Step three.

To install the skewer in the grill, you need to make special holes and cuts. With the door open, we apply markings to the cylinder, the distance between each slot is 70 mm, we make them using an angle grinder. We try to make the width of the slots the same, about 4 mm.

In the process of making the slots, their depth was increased by another 5 mm, since there will be an overlap of a metal bus that overlaps part of the slot.

On the back side of the cylinder we make markings for installing the ends of the skewer, the distance between them is also 70 mm, while the distance from the edge should be 25 mm.

Next, using a semi-automatic core, we make indentations according to the marks and drill holes with an electric drill with a metal drill installed at 6 mm, and then at 12 mm. During the drilling process, we add technical oil to the cutting edge, so the cutting tool will last longer and will not jam. When working with an electric drill, be careful and wear safety glasses and gloves.

Step four.

From the bottom of the cylinder we measure 100 mm upward and make markings for the blowing holes.

Next, we also make cores and drill holes with a diameter of 12 mm. As a result, we get 17 holes on each side, the height between the rows is 50 mm, and the distance between the holes of one row is 65 mm.

Since the grill will sometimes be used as a barbecue, it is necessary to make supports for the grid. We take a metal profile pipe measuring 20*20 mm and press it against the wall of the barbecue with a hand vice at the place where the slots end.

Next, we weld the pipe with a welding machine, and then similarly weld the second one on the other side.

The grill is almost ready, all that remains is to make a shredder and a handle, but first we install the cylinder on the base.

Step five.

The base for the barbecue will be the bed from an old sewing machine, which I think many people have.

From a metal corner with a shelf width of 40 mm, we saw off four 40 mm sections using an angle grinder with a cutting disc. These corners will be used to attach the cylinder to the base.

We screw the corners to the bed of the sewing machine, having previously drilled holes the size of the bolt and rounded the edges of the corners so as not to accidentally get hurt. The distance between the corners was 220 mm.

Next, we install the cylinder on the corners and make several tacks with a welding machine, after which we put on the grill and finally scald the fasteners. Use a hammer to remove the slag formed during the welding process.

Since the temperature in the barbecue is quite high, it was decided to strengthen the door by welding two fittings with a diameter of 10 mm at the edges.

We bend the metal bar using a homemade pipe bender from a vice.

After that, we press it to the barbecue door with a hand vice and weld it with spots on the inside so that everything looks beautiful from the outside.

Finally, spring has come into its own, and it’s time for barbecue. But to cook juicy and tasty meat, you need a grill. You can buy it at a specialty store, but why waste money? After all, the device can be made with your own hands. To do this, we will need some tools, and we will prepare an old gas cylinder from the materials.

A homemade design for the dacha can be made without much effort if you have a little skill in working with tools. The brazier we make will be mobile, so it can be installed anywhere without any problems.

Before carrying out work, it is necessary to completely release all the gas from the cylinder to avoid unpleasant consequences.

If you take a creative approach to making a structure for preparing barbecue, you can create an original design. As a result, you will get not only a functional device, but also a decorative element for your personal plot.

The article will give all the necessary dimensions to complete the work. Therefore, follow the step-by-step instructions and you will succeed.

Preparing a gas cylinder for a barbecue

For safety reasons, first you need to get rid of the remaining gas in the container. To do this, we unscrew the valve and leave it for a couple of hours.

To completely get rid of liquefied gas and condensate, we need to remove the valve. It will not be possible to unscrew it immediately; to do this, we need to make a cut near the pin using a hacksaw for metal, and remove it using pliers.

Now all we have to do is unscrew the top part of the tap, it is shown in the photo below.

We turn the cylinder over and leave it for a while and wait for the remaining gas to come out; for this you can use soapy water to control the process. Then we completely fill the balloon with water and leave it for a couple of days. It is recommended to drain the liquid away from residential premises to protect others.

This moment is very important. To better understand how to remove gas completely, watch the video below:

Drawings and manufacturing diagrams

As a guide for drawing dimensions, we will use the weld of the container, which will act as the zero point.

The diameter of the container is 96 cm, and to determine the middle of the container, we measure 24 cm from the seam in each direction, as shown in the drawing below.

In order for air to flow into the grill, we need to make cuts 10 cm long. To do this, from the zero point, mark 10 cm in each direction. For the cut you will need a 2-2.5 mm disc.

We retreat 6 cm from the transverse seam from the edge, and mark the places for the holes in increments of 8 cm. From the back of the future barbecue, we mark 10 cm from the line and mark the places for the loops.

On the front side of the structure, from the transverse seam, we also mark 6 cm, and mark the cut marks for kebabs in increments of 8 cm.

In the area of the seam on the cylinder there is a double backing, which will be difficult to saw with a grinder, so we retreat 1.5 cm from the bottom and top seams, this is enough. Now we need to cut out the structure in accordance with the markings.

Cutting the balloon to size

In accordance with our marks, we cut off part of the cylinder.

In the places where the holes are marked, we drill them, also make cuts using a grinder and cut off the upper part of the container with the valve.

Now we have a hole in place of the tap. It can be used for extraction. To do this, weld an L-shaped pipe.

We weld the hinges to the base of the grill in the marked area and attach the cut out part that will act as a lid.

As legs, you can use ordinary profile pipes or the frame of some old structure.

On the front side of the grill we attach the corners for the handle. You can secure the lid with a chain.

For such a barbecue, skewers with a length of 30 cm are suitable.

The barbecue structure is ready, you can decorate it as you wish.

Making a barbecue with your own hands in the shape of a pig

If you have experience in welding, you can decorate your device in an original way in the shape of a pig. See how you can implement this option in the video below:

You will also need to paint the grill, wait until it dries, and use it for its intended purpose. As you can see, making such a design is not at all difficult if you have the necessary tools.

Those who often grill shish kebab and barbecue in the country know how unreliable and fragile store-bought grills can be. The heat is low, the structure bends and creaks, the dimensions are somehow non-standard, and contrary to the assurances of the sellers, the structure quickly rusts. Maybe stop wasting money on unnecessary things? If you have an old gas cylinder at your dacha, it is quite possible to use it to make not only a barbecue, but also a luxurious smokehouse. How to make a barbecue from a cylinder correctly? Our article is just about this.

Preparing tools

To build a gas barbecue with your own hands, you will need a cylinder with a capacity of 50 liters and a height of 120 centimeters. In our opinion, these are the best sizes, allowing you to cook a sufficient amount of food at one time.

Having taken out the old cylinder from the barn, carefully inspect it. The product is considered suitable if it is free of corrosion. Otherwise, the rusty places will burn out, and instead of a high-quality barbecue from a gas cylinder, you will get an obscene sieve.

Naturally, in addition to the barbecue, you will need a certain set of tools. Now we will list it: a drill and an angle grinder, a chisel, a hammer, a screwdriver and an adjustable wrench, two hinges, a metal pipe, a corner. Since the main range of work will involve cutting metal, the grinder will be your main tool in the manufacture of structures from cylinders.

You can’t do without an angle grinder

You can’t do without an angle grinder What will we make from the balloon?

Before we get started, let’s take a closer look at exactly what types of barbecues can actually be built from a metal gas cylinder.

There are four main varieties:

- a classic barbecue made from a gas cylinder with your own hands without a lid;

- smokehouse;

- smoker;

- barbecue maker

With the first classic type, everything is clear, and it does not need unnecessary advertising. Now let’s look at how exactly the other three types differ from each other.

B-B-Q It is a fairly simple design not only externally, but also internally. In short, you cut off part of the side, attach it to hinges, and use it instead of a door. A mesh is placed inside. This is where you will fry mushrooms and meat.

B-B-Q

B-B-Q The good thing about a DIY gas cylinder barbecue grill is that you can fry almost anything on it. Cooking will be quick and simple.

What's special smokehouses? It turns out that it has its own firebox, and the structure itself is surprisingly airtight. To make a smokehouse, as in the photo, a strip of metal is cut out at the bottom, and part of the bottom is also sawed off. The firebox, which is made of strong iron or a second cylinder, is welded. For unhindered smoke removal, a pipe is welded. As soon as the smokehouse is ready, it is thoroughly calcined with wood 2-3 times.

Smokehouse

Smokehouse What kind of locomotive is this? Don't be surprised, but smoker This is what people actually call it. Assembly is more complicated, but the design is many times more functional. It combines absolutely everything: grill, smokehouse, barbecue from gas cylinders. To build a super unit, you will definitely need 2-3 balloon pipes. Each will have its own option.

All in one - smoker

All in one - smoker Opening the container correctly

You don’t need to be a great physicist to understand that when working with equipment that is somehow associated with gas under pressure, safety should always come first. So it’s definitely not worth throwing yourself at a cylinder with an angle grinder. There are likely propane residues left inside, and any spark can lead to unpleasant consequences.

Armed with a wrench, carefully unscrew the valve and wait until the gas has completely evaporated. Then turn the structure over with the valve down and drain all condensate that has formed. By the way, it’s easy to monitor the propane output. To do this, apply a little soap suds to the valve. Once it stops bubbling, work continues.

The structure is laid on its side and the valve is sawed off. The cutting area is constantly watered with water. The last step is to attach a hose to the cut and fill the container with water to the very top. From time to time the cylinder is shaken so that the inner surface can be washed from gas residues.

From cutting to installing legs

Many users are interested in what video instructions and drawings should be used when planning to make a barbecue from a gas cylinder without outside help. Let us explain - the process itself is so simple and understandable that you can easily do without a drawing. The final result and procedure entirely depends on your personal preferences.

And here is a clear example. The owner of the house wants to make a barbecue, but plans to use only a grate and ready-made coals. In this case, the distance between them should be kept small. Our advice is to cut the balloon exactly in the middle. If you plan to burn real wood every time and use skewers from time to time, the lid is made smaller than the base.

When the metal container is completely washed and well dried, all you have to do is cut it lengthwise. The result is two open classic barbecues. One will be the basis for coals, the second can be scrapped, used to create a lid, or given to a neighbor - also for making a barbecue.

You can make two barbecues at once from a cylinder

You can make two barbecues at once from a cylinder But those who make a barbecue from a gas cylinder with their own hands will have to go a different route. You will need a “pattern” of a rectangle that will become the lid. We leave the second part as a basis.

To do this, draw a rectangle from the cut lines on the surface. Make sure that the horizontal lines run strictly in the middle of the cylinder, and the transverse lines 20 centimeters from the edge.

How to cut a barbecue cylinder with a lid

How to cut a barbecue cylinder with a lid How to cut correctly?

Your job is really simple - pick up a grinder and cut the balloon. In order to outline the boundaries of the lid, you will need to step back from the welding seam that connects the bottom and base and mark the cut line.

Even if you follow all the rules, force majeure situations during the cutting process are also possible. When the cylinder has thick enough walls and the work is done intensively, by the end of the cutting the grinder’s disc may simply burn out.

To avoid this, we advise you to either stock up on several discs in reserve, or not cut each cut to the end. Subsequently, you can easily finish the job with a chisel.

Having carefully estimated what size barbecue will be optimal for you, start attaching the legs. For ease of welding the roof, the structure is installed on the ground.

In the photo you can see how to make a barbecue with legs from a sewing machine. If your grandmother didn’t leave you such antiques, it doesn’t matter. It could well be replaced by the underframe of a school desk. The pipes are bolted to the bottom. Just make four holes and then insert the bolts. They are either fixed with nuts or welded - the choice is yours.

In the photo you can see how to make a barbecue with legs from a sewing machine. If your grandmother didn’t leave you such antiques, it doesn’t matter. It could well be replaced by the underframe of a school desk. The pipes are bolted to the bottom. Just make four holes and then insert the bolts. They are either fixed with nuts or welded - the choice is yours. Grill legs from a sewing machine

Subtleties of handle installation

Your lid will be held in place by its hinges. Therefore, it is necessary to ensure that holes are made for them. Each hinge is secured with a rivet and welded securely. You can see what it looks like in reality in the photo.

Your lid will be held in place by its hinges. Therefore, it is necessary to ensure that holes are made for them. Each hinge is secured with a rivet and welded securely. You can see what it looks like in reality in the photo. Welding hinges to the grill lid

Welding is required because the rivets may not withstand constant exposure to high temperatures and can easily fall off. Some craftsmen install a removable version of the lid without hinges. In this case, metal strips are attached to the transverse edges of the structure. This way the lid will never fall inside. The handle for the grill lid is secured using hinges. Drill the holes, fix them, and you can safely open and close the lid. Ask your hardware store if they have handles that won't burn or are heat resistant. Buy these.

The limiter on the lid is made from part of a pipe or angle, the lid itself is fixed with chains.

From assembly to painting, the grill is almost ready!

Why do they make holes in the bottom? It's simple - they simplify the extraction of coals and drainage of rainwater. However, something else is important - 10-15 holes will provide excellent traction from below.

The smoke exhaust pipe is always installed where the valve used to be. By the way, this is a desirable, but not mandatory, measure, and you can completely do without it. This is especially true for situations where you plan to cook food exclusively with the lid open.

The pipe is usually installed in place of the valve

The pipe is usually installed in place of the valve Remember when we wrote about installing a corner for more convenient turning of skewers and protection from deformation? Not everyone attaches such a corner, and here's why. There is a completely working, alternative way - to make slits in the sides to install each skewer.

In principle, the grill is ready - all that remains is to paint it with good paint. First of all, this procedure is important from an aesthetic point of view. It is better to buy heat-resistant paint. It is not afraid of high temperatures and does not decompose, so the food will always smell delicious.

On sale you can find a great variety of paints and varnishes designed to work at temperatures from 600 to 800 degrees. Buy them. First, the grill is opened with a primer, after which environmentally friendly paint is applied.

Painting the barbecue (video)

Conclusion

If you have read the article to the conclusion, congratulations - you are completely ready to create a barbecue or grill from a gas cylinder. Don’t forget to load a decent amount of meat and vegetables into the grill you made yourself, and invite people close to you to visit. Let the gas grill become a symbol of hospitality and a place that will gather family and friends all year round!