How to properly install wall-mounted gas boilers. Do-it-yourself gas boiler installation. Rules for installing gas heating boilers

Gas still remains the cheapest type of fuel. Accordingly, the cheapest heating is obtained using natural gas. True, installing a gas boiler is associated with certain difficulties - the premises must comply with fire safety standards.

To install powerful gas boilers, a separate room is required

Gas boiler installation standards

To avoid any troubles when putting the gas boiler into operation, it is necessary to select the installation location in accordance with current standards. The installation of a gas boiler in a private house (single-apartment or semi-detached) is regulated by SNiP 02/31/2001, and the installation rules in apartment buildings are prescribed in SNiP 2.08.01.

For private houses

According to the standards, a gas boiler can be installed in a ventilated room, which is located:

- on the first floor of the house;

- in the basement or basement;

- in the attic:

- gas boilers with a power of up to 35 kW (according to MDS 41.2-2000 up to 60 kW) can be installed in the kitchen.

There are currently two standards in force regarding the installation of boilers in the kitchen. According to one document, heating devices with a power of no more than 35 kW can be placed, according to another - no more than 60 kW. And we are talking only about heating devices. Gas stoves or other appliances using gas are not taken into account.

What to do? You need to find out what standards your GorGaz adheres to. After all, it is their representatives who will accept the equipment into operation. Actually, the designer should tell you all the details, but it is also advisable to know this - you will need to prepare the room for installation.

Where to put

Now let’s talk about where and how gas equipment of different capacities can be located. We will talk about gas boilers and their power is summed up:

- with a power of up to 150 kW inclusive - in a separate room on any floor, including the basement and basement;

- from 151 kW to 350 kW inclusive - in a separate room on the first, basement or ground floor, as well as in a separate attached room.

More powerful installations are not used in private homes.

Requirements for kitchens in which a gas boiler is installed

When placing a flow-through gas water heater or a gas heating boiler with a power of up to 60 kW in the kitchen, the room must meet the following standards:

There is one more thing that is not specified in the standards, but which exists: installing a gas boiler is allowed only in a room with doors. In light of the latest trends - removing partitions and making doors instead - this can be a problem. Without a door, the permit will not be signed. The solution is to put or . Another option is glass doors. They do not “load” the interior, but they are perceived exactly as doors.

All these requirements must be met. If there are violations, they simply won’t sign the acceptance certificate for you.

Requirements for individual premises

They are similar, but there are some differences:

- Ceiling height - at least 2.5 m;

- The volume and area of the room are determined by ease of maintenance, but should not be less than 15 m3.

- Walls leading to adjacent rooms must have a fire resistance limit of 0.75 hours and zero limit for the spread of fire through the structure (brick, concrete, building blocks).

- An exhaust hood with the same requirements: for outflow - three times exchange, for inflow in the same volume, plus air for combustion.

- The room must have a window. The glass area is at least 0.03 m2 per cubic meter of volume.

If equipment is installed with a power of 150 kW or more, one of the prerequisites is the presence of access to the street. A second exit can be equipped - to a utility room (not residential). This could be a pantry or a hallway. Doors must be fireproof.

Please note that when calculating windows, the glass area is considered, not the size of the window opening. Moreover, in some cases they require at least one glass with an area of at least 0.8 square meters. If enlarging the windows is problematic, you can make a similar window in the door (the regulations do not say that it must be in the wall).

How to attach boiler rooms

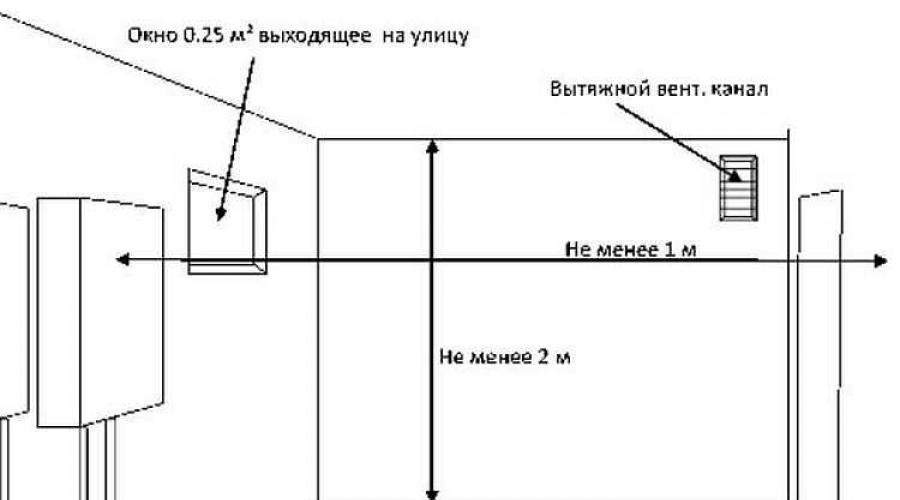

Sometimes it is not possible to allocate a separate room in the house. In this case, the boiler room is added. The standards for ceiling height, volume, glazing and ventilation remain the same as for individual rooms, only specific standards are added:

Please note that the extension must be registered. No one will give you gas without official documents. And one more thing: when designing it, lay down all the standards without deviations, otherwise they won’t accept it. If the installation of a gas boiler is planned in an existing room, they may turn a blind eye to some deviations or offer some compensation (if there is a missing volume or height of the ceilings, they may be asked to increase the glazing area). For newly constructed buildings (and extensions too) there are no such discounts: they must include all standards.

Combined kitchens

Today it has become fashionable to have or. It turns out to be a single large space in which it is easy to implement design ideas. But the gas service regards such premises as residential and prohibits the installation of gas equipment.

It will not be possible to solve the problem with a studio apartment, but with a combined apartment there is a solution. If you are just planning to combine the kitchen and living room, when preparing the documents, call the resulting room kitchen-dining room. This premises is not residential, so there will be no restrictions. If the papers have already been completed, you can try to redo them or go the other way - install a sliding partition. True, in this case, the documents will need to be redone.

Place for installing a gas boiler

If we talk specifically about apartments, then gas boilers are installed in them, mostly in the kitchens. There are all the necessary communications: running water, gas, a window and an exhaust hood. All that remains is to determine a suitable location for the boiler. For this installation, wall-mounted (mounted) boilers are used. They are installed on several hooks fixed to the walls (usually included in the kit).

As for installation in other areas of the apartment or house, as a rule, none of them meet the requirements. For example, in the bathroom there is no window with natural light, the corridor is usually not suitable in size - there is not enough tolerance from the corners or to the opposite wall, there is usually no ventilation at all or it is insufficient. The problem with storage rooms is the same - there is no ventilation and windows, there is not enough volume.

If there is a staircase in the house to the second floor, the owners often want to place the boiler under the stairs or in this room. In terms of volume, it usually passes, but in terms of ventilation it will have to be very powerful - the volume is considered to be at two levels and it is necessary to ensure its threefold exchange. This will require several pipes (three or more) of a very large cross-section (at least 200 mm).

Once you have decided on the location for installing the gas boiler, all that remains is to find a place for it. It is selected based on the type of boiler (wall-mounted or floor-standing) and the manufacturer’s requirements. The technical data sheet usually specifies in detail the distances from the wall on the right/left, the installation height relative to the floor and ceiling, as well as the distance from the front surface to the opposite wall. These may vary from manufacturer to manufacturer, so it is worth reading the manual carefully.

Installation standards according to SNiP

- Gas boilers can be installed on fireproof walls at a distance of at least 2 cm from it.

- If the wall is fire-resistant or combustible (wooden, frame, etc.), it must be protected with fireproof material. This can be a three-millimeter sheet of asbestos, on top of which a sheet of metal is fixed. Plastering with a layer of at least 3 cm is also considered as protection. In this case, the boiler must be hung at a distance of 3 cm. The dimensions of the fireproof material must exceed the dimensions of the boiler by 10 cm from the sides and bottom, and from the top must be 70 cm larger.

Questions may arise regarding asbestos sheet: today it is recognized as a material hazardous to health. It can be replaced with a layer of mineral wool cardboard. And also keep in mind that ceramic tiles are also considered a fireproof base, even if they are laid on wooden walls: a layer of glue and ceramics provide the required fire resistance.

The installation of a gas boiler relative to the side walls is also regulated. If the wall is non-flammable, the distance cannot be less than 10 cm. For flammable and non-combustible walls, this distance is 25 cm (without additional protection).

If a floor-standing gas boiler is installed, the base must be non-flammable. A non-flammable stand is made on the wooden floor. It must provide a fire resistance rating of 0.75 hours (45 minutes). These are either bricks laid on spoons (1/4 brick size) or thick ceramic floor tiles laid on top of an asbestos sheet fixed to a metal sheet. The dimensions of the non-combustible base are 10 cm larger than the dimensions of the installed boiler.

Most modern private houses have gas boilers. This device can be called affordable, safe and economical, but it belongs to the group of expensive and difficult to install products.

Gas boilers are divided into two groups: single-circuit and double-circuit. The first type is used to heat the room, the second type can simultaneously heat the room and heat water. Therefore, it is important to know the rule of how to install a double-circuit gas boiler in a house. The equipment also differs in power and type of installation.

How to choose a boiler

An important rule for installing a gas boiler in a private home is determining the required power. Low productivity does not allow obtaining the required effect. Too much power is not economically beneficial and is dangerous, since acidic condensate formed as a result of constant temperature changes negatively affects some parts of the device.

To determine the boiler power, it is necessary to divide the area of the house by 10 and multiply by the appropriate coefficient, the value of which depends on the region of residence. For example, for central regions a value of 1.2-1.5 is used, for southern regions - from 0.7 to 0.9, in regions with a predominance of cold - 1.5-2. From this we can conclude that for a house of 120 m2, located in the south of the country, it is enough to purchase an apparatus with a capacity of 8-10 kW.

Using special devices you can change the boiler power value. At the same time, low-capacity devices have a single-stage regulator, middle-class heating appliances are characterized by two-stage regulation, and high-capacity boilers have a modulated regulator.

Gas boilers can be wall-mounted or floor-mounted. Depending on this, the installation of the device has its own subtleties. In addition, the direct installation of gas equipment in a private home requires mandatory compliance with certain rules in accordance with Sanitary Standards and Rules.

In particular we are talking about the following:

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”.

- SNiP 31-01 from 2003 “Residential and multi-apartment buildings”.

- SNiP 42-01-2002 “Gas distribution systems”.

Rules for installing gas appliances

The following rules for installing a gas boiler are presented for the premises:

- To install the boiler, a separate room is required, which can be located on one of the floors of the house, in the basement or attic. Installation of equipment in residential premises and bathrooms is not allowed.

- The boiler room in which the gas boiler will be installed must have certain dimensions. For example, for boilers with a power of less than 30 kW, which are able to cover all the heating needs of a private house, a room with an area of more than 4 m2 is required. Boilers with a power of over 30 kW, but not more than 60 kW, can be installed in a room with an area of 13.5 m2. Equipment with a power exceeding 60 kW requires an area of up to 15 m2. Boilers with a closed combustion chamber can be installed in rooms of any size, starting from the established minimum value.

- The ceilings in the boiler room must be high enough, at least 2.5 meters.

- In a room with gas equipment, a mandatory condition is the presence of a window, 30 cm of which is for every 10 m2.

- The door to the boiler room must have a width of more than 0.8 meters (read also: “Installation of a gas boiler room in a private house - requirements, standards”).

- A gap of 2.5 cm should be provided between the top level of the door and the main opening.

- Combustible finishing materials must not be used in the boiler room.

- It is prohibited to install a false floor or false ceiling in a room with gas equipment.

- There must be a hole for natural air flow. Moreover, for one unit of boiler power, at least 8 cm 2 holes are required.

- It is necessary to supply water to the boiler room to install a double-circuit gas boiler.

- Maintaining an optimal humidity value, since if there is excess moisture in the boiler room, the escape of gas vapor is difficult.

- Installation of ventilation in the upper part of the boiler room. Read also: "".

Parts and pieces of equipment must also comply with the standards for installing a gas boiler in a private house:

- Free access to the device from any side.

- Use only metal gas pipes.

- A gas meter is required.

- Electric boilers require mandatory grounding.

- Parallel installation of a gas analyzer and an automatic valve. The first device will give a warning about a possible gas leak, the second will stop the gas supply if a leak is detected.

Chimney requirements

Installation of chimneys or gas outlets must be carried out in compliance with the installation parameters of a gas boiler in a private house:

- Gas combustion products must be discharged through a separate channel.

- The horizontal section of the chimney should be no more than 3 meters.

- The chimney structure cannot have more than 3 elbows.

- For a certain boiler power, a corresponding gas outlet diameter is required.

- The cross-section of the chimney must correspond to the diameter of the hole to which the flue is connected.

- The top point of the chimney should be located 0.5 meters above the level of the ridge.

Most modern boilers with a closed combustion chamber are sold complete with a coaxial chimney. Such devices can be installed in a room of any size, since combustion air is taken from the street.

The listed requirements for the installation of gas equipment, including the installation of a double-circuit boiler in a private house, may have additions and clarifications in accordance with the region of use. In addition, the gas supply may not be central, but bottled. Also, the rules may be adjusted depending on the material used to build the house and floors.

Design

All this leads to the fact that before installing a gas boiler, it is better to consult with a specialist who will inspect the structure and identify relevant shortcomings.

To obtain permission to install a gas boiler, you must do the following:

- Write an application in the appropriate form to the organization that supplies gas. This document becomes a kind of permission to carry out preparatory construction work. In most cases, permission is issued no later than two weeks from the date of registration of the application.

- After this, it is necessary to make a project; licensed specialists are engaged in its production.

- The finished project is subject to mandatory approval from the gas supply organization. The full package includes an application, design documentation and documents for gas equipment. Approval may take up to 3 months.

Installation in a private house

Installation of floor and wall equipment is carried out according to different schemes.

The technology for installing a floor-standing boiler includes the following steps:

- Preparing a solid foundation that can withstand the weight of the boiler. You can pour a concrete screed or lay a sheet of galvanized iron.

- Checking the level of installed equipment. The boiler must be positioned strictly parallel to the floor level.

- Connecting to the gas outlet and checking the draft.

- Connecting heating system pipes with the obligatory installation of a hard water filter. In addition, the installation of ball valves on all pipes and shut-off equipment on both sides of the filter is required.

- When installing a double-circuit boiler in a private house, a connection is made to the water supply system. In this case, the supply pipe should be located at the top, the return pipe at the bottom.

- Connection to the gas pipeline. This item can only be carried out by a gas technician; independent work of this kind is strictly prohibited.

- Connection to the power supply network.

There are certain rules for installing a wall-mounted gas boiler:

- Choose the strongest wall or partition and protect it with fireproof material.

- Fix the boiler, maintaining a distance from the wall plane of about 5 cm. You should also retreat from other walls and the ceiling by 50 cm, from the floor by 80 cm. The boiler should be located parallel to the floor level.

- Before installation, the walls of the inlet pipes should be cleared of debris by supplying water under pressure.

- Install the filter on the water supply pipe. Install locking mechanisms on both sides of the filter.

- Install a chimney, if provided for by the project, and check the draft.

- Connect the device to the gas pipeline, inviting a gas service technician for this purpose.

- Connect to the power supply.

Both options provide for filling the system with water before starting and first turning off the device. To avoid the formation of air bubbles, water must be introduced into the system very slowly.

In addition, the procedure for installing a gas boiler in a private house provides for temperature restrictions. Installation of a gas stake can be carried out at temperatures from +5 to +35 degrees.

Maintenance of gas boilers during operation

Gas equipment must be checked at least twice a year. Moreover, one of them falls on the period before the heating season. Gas service specialists check the tightness of the chimney and its operability, the condition of the ventilation system, and carry out maintenance and repair work.

Using a gas floor-standing boiler to heat a house or apartment is considered the cheapest and highest quality option. At the moment, this issue is quite relevant, so there is a wide selection of modifications on the markets from both domestic and foreign manufacturers, differing not only in price, but also in the presence of various functions and additional options.

In order to independently understand the offers and choose a good, economical floor-standing gas boiler, you need to analyze a lot of information that will help you choose the best option.

Principle of operation

Gas heating device

Almost all floor-standing gas boilers operate identically. To operate them, natural or liquefied gas is used as an energy source, which, when burned, heats the heat exchanger located inside it.

The latter contains water, which is heated and circulated through the system. In this case, for high-quality heating of the room, you need to choose a device with a high-quality heat exchanger.

Conventionally, they can be divided into several categories, differing in the material from which it is made:

- Cast iron. It is recognized as the most durable, as it is not subject to corrosion and has high resistance to burnout. There are many cases where such an element has worked for 50 years. Among the disadvantages is that cast iron is considered a brittle material. A sudden change in the temperature of the liquid inside it or mechanical impact can lead to damage to the housing.

- Steel. Floor-standing boilers with a steel heat exchanger are significantly lighter and more resistant to possible impacts. But a significant drawback reduces their positive characteristics. This is primarily due to the fact that metal will burn out much faster than cast iron, and it is also susceptible to corrosion. Therefore, the average service life of such devices is significantly lower and is only 10 years.

To compare the efficiency of gas floor-standing boilers, a table is provided that analyzes the use of heating devices operating on different types of fuel.

The information is presented using the example of heating for a private house with an area of 350 m2. The data are given in average values based on 6 months of the heating season.

| Fuel type | Average calorific value | Average cost as of 2019 | Annual fuel consumption with a consumption of 120 gJ and a heated space volume of 370 M3 | Average efficiency and type of boiler used | Total costs for the heating season, rub |

|---|---|---|---|---|---|

| Chopped firewood | 14.7 mJ/kg, 2450 kcal/kg | 1300 rub/m3 | 9.5 t | Classic boiler, efficiency 66% |

11400 |

| Peat briquettes | 24 mJ/kg, 4750 kcal/kg | 7000 rub/t | 5.80 t | Pyrolysis boiler, efficiency 86% Classic boiler, efficiency 66% |

40250 |

| Brown coal | 19 mJ/kg, 4000 kcal/kg | 900 rub/t | 7.8 t | Pyrolysis boiler, efficiency 86% Classic boiler, efficiency 66% |

7110 |

| Wood pellets | 19 mJ/kg, 4300 kcal/kg | 3500 rub/t | 7.5 t | Special automatic, efficiency up to 94% | 25900 |

| Wood briquettes | 19 mJ/kg, 4300 kcal/kg | 3900 rub/t | 7.8 t | Pyrolysis boiler, efficiency 84% Classic boiler, efficiency 64% |

30810 |

| Natural gas | 33.8 mJ/kg, 8000 kcal/kg | 2.93 RUR/m3 | 3380 m3 | Condensing, efficiency 103% Classic, efficiency 91% |

9932 |

| Electricity, heaters | 3.7 mJ/kWh | 3.80 RUR/kWh | 34020 kWh | 97% | 129238 |

| Electricity, water heating radiators | 3.7 mJ/kWh | 3.80 RUR/kWh | 33680 kWh | 98% | 127946 |

| Diesel fuel, 1 l/0.78 kg | 41 mJ/kg, 11000 kcal/kg | 23.50 RUR/l/ 30.12 RUR/kg | 31190 | 91% | 95781 |

| Propane gas - butane, 1 l/0.60 kg | 47 mJ/kg | 16.90 RUR/l/ 28.26 RUR/kg | 32800 | 92% | 81664 |

Single-circuit

A single-circuit floor-standing boiler is considered the most common. The advantage of using it is the following characteristics:

- efficiency. The cost of such domestically produced boilers varies around 20,000 - 30,000 rubles. In addition, long-term operation is confirmed by reviews;

- maintainability. While for some types of imported devices it can be difficult to find the part you are interested in, parts for a Russian heating boiler can be found in every city. And you can make small repairs yourself;

- lack of complex electronics. This makes it easy to maintain and use without training;

- low gas consumption.

Gas boilers for heating a private home come with an open or closed combustion chamber. The difference is that the former use fresh room air to function, and carbon monoxide is removed through the chimney.

The second - with the help of fans they take air from the street and similarly remove the exhaust gas outside. An open boiler operates on the principle of a gas burner: they heat up and heat the air around them. From this we can say that their efficiency is significantly lower than that of a closed one, from which all the heat goes into the heat exchanger.

Dual-circuit

The cost of such a device will differ from single-circuit ones by 20 - 30% upward. But this is explained by a number of reasons that characterize it on the positive side:

- high heat transfer;

- performing double functions: heating and providing hot water;

- a wide range of options equipped with electronics, which allows us to talk about reliability and self-stop when a malfunction is detected.

Installing a floor-standing double-circuit gas boiler with your own hands is not particularly difficult. To do this, you need to connect it to the heating pipeline and connect it to the water mixer. After this, contact a specialized workshop to call a technician who will connect the boiler to the gas pipeline and carry out the first start-up of the device.

Considering the principle of operation, we can distinguish 2 main actions:

- when the hot tap is opened, the gas supply to the heat exchanger is turned off;

- in this case, the burner operation switches to heating the circuit associated with heating the water supply. In this case, the heating procedure itself is carried out in flow mode without the use of storage tanks.

Separately, it should be noted that automatic shutdown, based on electronics, will only work if there is a power supply. If the power is turned off, the functionality of such equipment will drop sharply.

Special requirements

Modern gas floor-standing boilers meet all safety requirements and comply with regulations. In some cases, it is practiced to use combined devices in which, when the gas supply is turned off, the system automatically closes the valve and starts it from the electrical network. See all the pros and cons of installing a double-circuit boiler in this video:

The simplest models are not equipped with automation, so you need to switch them yourself. Therefore, it is recommended to periodically check its performance in case of possible outages.

Entrust boiler installation to specialists

Gas is considered a source of increased danger, therefore, to connect a gas boiler in a private house, it is necessary to invite a specialist licensed to carry out this activity.

When building a private house, the issue of planning should be taken very seriously. The fact is that the installation of a gas floor-standing boiler is allowed only if all conditions are met. They are regulated by the requirements specified in SNiP and fire safety regulations. Any non-compliance or deviation from them will lead to the fact that in the best case, during periodic inspection, the owner will receive an administrative fine, and in the worst case, it will end in an explosion or fire.

These requirements do not apply to electric boilers; they can be installed anywhere. But to achieve a violation of the aesthetics of the room, it is recommended to use a special room for these purposes.

Advantages and disadvantages of AOGV

AOGV is optimal in terms of fuel consumption and heat transfer

A floor-standing gas boiler for heating a private home is considered the most popular for newly built or renovated buildings.

When you contact a specialized organization with a question about what equipment to install to heat your home, most likely you will receive the answer that it is a floor-standing AOGV. This is primarily due to the fact that in terms of material consumption and heat transfer, gas is the leader in this rating.

Advantages

The main inspection of the installed gas boiler will take place in winter

The wide popularity of gas floor-standing boilers for heating residential and non-residential premises is explained by the fact that such equipment has a number of advantages that distinguish it from its main competitors.

First of all, this is a significant savings, the ability to perform partial installation yourself, ease of further maintenance and ease of operation. In addition, we can highlight a number of other advantages of such equipment:

Flaws

If you are afraid of fire, do not choose devices with an open burner

Despite the fact that a floor-standing gas boiler has such significant advantages, before giving it preference, you should familiarize yourself with the special conditions of its design and operation, which can be presented as disadvantages of such equipment.

For some they may seem insignificant, but for others, on the contrary, they may seem significant. Here are the main ones:

- Before installing floor-standing gas heating boilers, you need to collect a lot of permitting documentation. For example, approval from the State Technical Supervision Service, providing a project for the upcoming installation, a chimney inspection report, a floor plan in which a specific place is allocated for its installation.

- Low pressure in the gas pipeline can lead to the fact that they begin to smoke, as a result of which the chimney becomes clogged and the efficiency of the equipment decreases.

- Choosing devices with an atmospheric burner is not advisable for people who are afraid of open fire. This is due to the fact that in such boilers the flame is in plain sight.

When faced with the question of how to choose the best option for your home, you should give preference to boilers equipped for operation in Russia.

This is due to the fact that the pressure in the system can change significantly, therefore, having dropped to a minimum level, the imported burner can begin to burn itself, which will lead to failure of the entire boiler.

Boiler selection

Which is the best floor-standing gas boiler to buy for your home? This question is asked by almost everyone who is faced with its acquisition. In this case, you will have to face the following questions:

- single-circuit or double-circuit;

- imported or domestic;

- with open burner or closed.

Having resolved all these issues, the problem of determining the power of the device will arise. It should be noted that this value directly depends on the area of your house, the presence of warm pilaf in it, which is used to heat some rooms, the number of residents and a number of other reasons. For more information about choosing a device for a country house, watch this video:

For an approximate overview of the calculation methodology, you can use the table below.

| House area, m2 | Heating, kW | Number of devices | Number of persons | Standard range of boilers, kW NS/A/ND (explained below) |

|---|---|---|---|---|

| 100 | 19 | 10 | 4 | 26/25/26 |

| 150 | 20 | 11 | 4 | 26/25/26 |

| 200 | 26,5 | 17 | 4 | 31/34/35 |

| 250 | 27 | 20 | 6 | -/37/38 |

| 300 | 31 | 26 | 6 | -/45/45 |

| 350 | 34 | 30 | 6 | -/45/45 |

Abbreviated terms in the last column, designated *: NS – wall-mounted boiler, A – floor-standing boiler with an atmospheric heater, ND – floor-standing boiler with a fan burner.

Observe safety precautions when working with gas equipment

Having decided to install such equipment yourself, in order for it to provide high-quality and economical heating of the room, you should take into account that natural gas is an explosive and flammable substance.

Therefore, even if you know how to install floor-standing gas boilers for heating, you cannot do it yourself. As mentioned earlier, for this purpose there are specially trained licensed specialists who will perform this work correctly, and most importantly, in compliance with safety regulations.

Recently, boilers that run on natural gas are increasingly being used to heat country houses. The principle of their operation is to heat the coolant. Gas boilers have a number of advantages: environmental friendliness, compactness, noiselessness, ease of operation, and the possibility of installation in a private home.

The degree of heating of the entire house depends on the performance of the boiler. But at the same time, the gas that is used as a coolant is a very explosive substance, so the choice of this equipment must be taken seriously, and the existing rules must be followed when installing a gas boiler.

Installing gas boilers with your own hands is quite a complex, labor-intensive and responsible task. Employees of gas supply organizations receive the necessary certificates, the presence of which, however, only authorizes access directly to the gas pipeline.

But a competent and hardworking person can do anything! Moreover, almost any man can handle installing the boiler, supplying water and connecting electricity.

In addition, self-installation of heating devices allows you to significantly save money.

Introductory video guide

Main types

Gas boilers are classified according to various criteria: purpose, power produced, type of draft and installation method. Single-circuit boilers are installed exclusively for heating the house, while double-circuit boilers allow not only to warm up the premises, but also to provide the house with water with the possibility of heating it.

Low-power boilers are regulated according to a single-stage principle, medium-capacity units are regulated according to a two-stage principle. High-performance boilers usually provide modulated power control.

Closed-type boilers operate on ventilation draft. There are also gas boilers with natural draft - open type, or atmospheric.

The simplest boiler, the so-called “water heater,” consists of a gas burner and a heat exchanger. Water and gas are connected to it, and the exhaust is discharged into the chimney. But even the installation of such a simple system requires obtaining appropriate permission! Let us consider in detail the process of installing a wall-mounted and floor-mounted gas boiler of a more complex design.

Installation of a wall-mounted boiler

- We protect the section of the wall where the boiler will be located with a layer of fireproof material, leaving a gap of 4.5 cm between it and the wall.

- We prepare the boiler for installation. Under high pressure of water, we clean the walls of the inlet tubes from small debris remaining after assembly.

- We install a filter and shut-off valves on the water supply pipe - before and after the filter.

- We install the chimney. This device also has certain requirements: the diameter is not less than that specified in the manual for the gas boiler; the cross-section is similar to the chimney opening of the boiler; an elevation above the roof ridge of at least 0.5 m (section 6 of SNiP 41-01-2003, section 4 and Appendix 6 of MDS 40-2.2000). It is best to use a steel cylindrical chimney with a cleaning hole.

- Checking the traction. If it deteriorates, the automation that modern boilers are equipped with must stop the gas supply.

- Using a steel pipe and a special pipe for its installation, we insert the boiler into the gas pipeline. To carry out this work, it is necessary to invite gas service specialists.

- We connect the gas boiler to the power supply and connect an automatic device for overload protection.

You may also be interested in the article on heating

Installation of a floor-standing boiler

- We build a strong pedestal that can withstand the weight of a cast iron boiler. In the extension, for this purpose, we pour a concrete screed; in other rooms, we place a piece of galvanized sheet iron on the wooden floor.

- We install the gas boiler with our own hands, controlling its position using a level.

- We connect the boiler to the chimney and, if it is not equipped with forced draft, check the draft.

- We connect the boiler to the in-house heating system. At the same time, to protect the unit from blockages, we install a coarse filter, placing it after the outlet line that fills the system with water, before entering the return line boiler.

- We connect the double-circuit boiler to the water supply system, making the connection closer to the house, before the branching begins.

- Using a steel pipe, we insert the boiler into the gas main, as in the previous case, with the participation of specialists.

Video guide

Operating rules

In private houses, however, as in any other facilities, gas boilers are allowed to be installed and operated only in dry rooms. High humidity prevents the dispersion of foreign substances in the air, including gas vapors. That is why the requirements for furnaces and the rules for installing gas boilers are so strict (see above).

To increase the performance of the heat exchanger, it is necessary to protect it from dirt and dust using a coarse filter. To improve the quality of water you also need to use filters.

Before the start or end of the heating season, it is recommended to perform maintenance on gas equipment. And, in order to avoid dangerous situations, this must be done regularly!

Maintenance

During the maintenance process, the condition of the chimney and the proper functioning of the ventilation are checked, the filters are cleaned and washed, as well as the entire system. To do this, you can use detergents that effectively remove various deposits.

Don't forget about cleaning the burner. Worn parts must be replaced without fail! Before starting the system, you must carefully check the tightness of all connections.

Compliance with established standards, proper connection of the gas boiler, operation in accordance with the rules and timely maintenance will increase the service life of the entire system, while reducing the amount of fuel consumed.