How to properly install door frames. MDF door frame: light, beautiful, technologically advanced. Complete set and standard sizes

Read also

Key issue in progress self-arrangement doorway - how to install door frame with your own hands. With proper skill, this work is done quite quickly. If you are doing this for the first time, first you need to become more familiar with the device of this design and its main types.

For self-assembly door frame you need to know all the nuances of this process

Types of boxes

What is a door frame and why is it so important to properly install it in the opening? The door frame is load-bearing element door structure, which holds the leaf and consists of two vertical and one horizontal strip with ledges. It is fixed directly in the opening itself, adjacent to the wall. Such a structure forms a smooth portal and ensures the reliability of fastening the door. Hinges are cut into one part of the frame, on which the canvas is hung. On the opposite side, a hole is drilled for the lock and the counter plate is fixed.

Since the position of the leaf depends on this element, correctly placing the door with the frame is a priority during installation. If there is the slightest distortion, the parts will be overwritten and prevent the door from moving freely. If you do not calculate the weight of the web in relation to the strength of the box, more serious problems may arise.

What are the types of door frames? A classification can be made according to several criteria. For example, assembly may be the determining factor. In this case, the most popular boxes are:

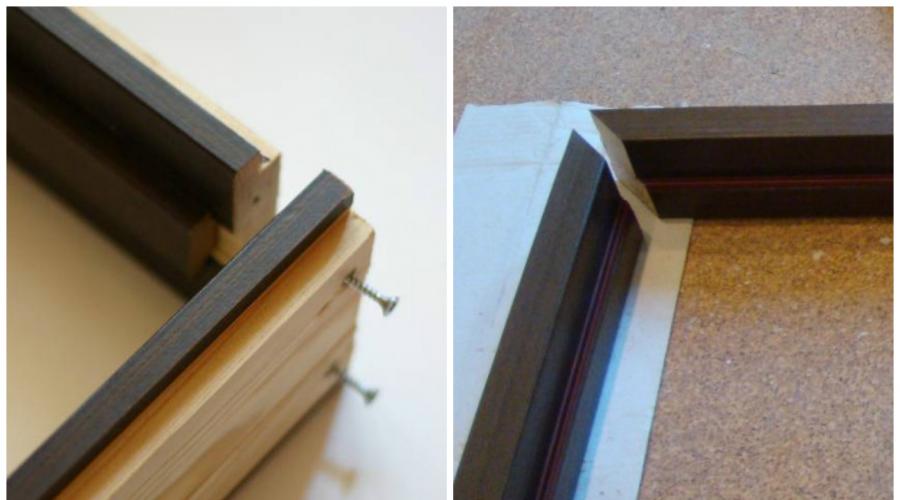

- Straight- elements are connected perpendicularly. Most reliable way- "thorn-groove".

- Diagonal- The edges of the planks are cut at an angle of 45 degrees.

Two types of connection of door frame parts

Also, types of door frames are distinguished by the material of manufacture:

- tree,

- plastic,

- metal.

in apartments for entrance doors mainly use metal constructions, and for balcony systems- metal-plastic boxes.

Preparatory work

Before installing a new door frame, it is necessary to check the presence of all necessary tools and auxiliary materials. Depending on the material of the product, their list may vary. In most cases, do-it-yourself door frame installation is done using the following tools:

- roulette,

- corner,

- pencil,

- level and plumb

- wooden wedges,

- auxiliary bars,

- spacers,

- nails, screws and screws,

- screwdriver,

- jigsaw, hacksaw or file,

- assembly foam,

- chisel,

- miter box.

Necessary set of tools for installing the door frame

Do-it-yourself installation of a new door frame begins with surface preparation. First you need to free the opening from old door and frames. With significant irregularities or deviations from the size of the new box, you need to adjust the walls. For this, plaster is used, and the protrusions are cut off with a grinder.

In order to properly install a new box, it is recommended to make it for the specific dimensions of a pre-prepared opening.

Before you start assembling the door with the frame, clear the floor surface, as pre-assembly must be done in a horizontal plane. Installation takes place in several stages. Let's consider each step in order.

Assembly

At the second stage, you need to correctly adjust the dimensions of the parts. To do this, measure the height of each side and the width of the opening. For a visual assessment of the situation, you can put the planks against the wall and mark the places where you need to shorten them.

If the box is mounted using a diagonal connection, you need to cut the edges of the slats. Since it is rather difficult to correctly determine the degree and cut down the door frame, be sure to use a miter box, then assembly will not be difficult.

Before placing the door frame in the opening, it is necessary to check its dimensions with the dimensions of the leaf. To do this, you need to fix all the details on the floor.

Since it is possible to assemble the box for the door as correctly as possible only in a horizontal position, lay the planks and the canvas on the floor. The assembly begins with an assessment of the size match. To do this, lay out the details around the perimeter of the door. If everything converges, you can begin to fasten the elements.

Assembling the door frame requires precision and accuracy

How to assemble the door frame depends on the type of connection. If a straight line is used, the protrusions must be joined to the grooves. With a simple diagonal, the planks are connected with nails. If you know how to correctly and quickly assemble the door frame with your own hands, there should be no problems with the rest of the work. Check the conformity of the dimensions and the presence of a small gap for the free movement of the blade. Only then can the installation of the box itself be carried out directly.

Installation

After preliminary control, you can put the box in place. Installation is carried out with bolts and foam.

Wedges are used to adjust the door frame in height.

How to install a new door frame with your own hands:

- In order to be able to quickly in the future, it is recommended to pre-embed the hinges into the frame.

- Then you need to carefully place the U-shaped structure in the opening.

- Use bolts and wooden blocks to secure it in place.

- Insert the pegs into the gap between the wall and the frame and adjust the level.

- After the position has been fixed, you can foam the gaps between the wall and the planks. In this case, it is necessary to fix the structure with the help of spacers, since the elements may be displaced. Simply foaming the door frame is not allowed by technology.

- After drying, remove the spacers.

The main stages of mounting the door frame

Final finishing

This does not end the assembly of the door frame. If you do everything with your own hands, you need to bring the matter to the end. This involves the removal of excess fixing materials and decoration opening. First you need to cut off the protruding pieces of mounting foam and wooden pegs.

Please note: if the box does not cover the entire thickness of the wall, additional extensions must be installed.

Opening without box

Not in every case installation of a box is necessary. For example, you can do without it if you put sliding system or an accordion door. But how to put a door without a frame? All parts are attached directly to the wall in the opening or above it, depending on the mechanism used.

When installing the door frame, special mounting spacers are used

To make the passage look neat, it is necessary to level its surface in advance. Usually plaster is used for this or combined with drywall sheets. Instead of a box, you can install decorative panels. They look almost the same, and the installation method is practically no different. Another option is to mount the lamellas on a rack frame.

What kind of finish to choose - you decide. If you decide to follow the traditional approach and install a swing door with a frame, follow the technology carefully to avoid significant flaws.

A properly installed door frame provides 90% success in the whole business.

Before you put the door frame, you need to carefully study the basics of this delicate work.

Tools and materials

Tools necessary for work: tape measure, pencil, hammer, square, construction knife, perforator, drill, screwdriver.

Depending on its design, you can use the following tools and materials:

- wood saw;

- a hacksaw with a small tooth;

- miter box;

- chisel;

- screwdriver;

- perforator;

- drill;

- drill;

- construction knife;

- roulette;

- square;

- bubble level;

- pencil;

- a hammer;

- nail puller;

- direct suspensions;

- self-tapping screws;

- dowels;

- anchors;

- nails;

- mounting foam;

- glue for MDF;

- wedges;

- wooden bars;

- door frame;

- wood putty;

- additional elements;

- ruberoid;

- building mix.

Preparatory work

If the door frame is installed in place of the old one, the latter must first be dismantled. The easiest way to do this is to simply cut the side and top planks in half and pull out the resulting pieces with a nail puller. Sometimes it is necessary to cut the fixing nails and anchors around the perimeter. If there are embedded parts in the opening, it is better to leave them. Subsequently, it will be easier to install a new box on mortgages.

In most cases, an interior door frame can be purchased in the form universal kit. Collect and customize it right size account for on its own. The box set necessarily includes side and top strips, a threshold or bottom strip for interior doors - a rarity, but may be present. The vestibule can be integral with the slats or be laid on. The box itself is either wooden or MDF. The strips included in the kit are designed for use as part of a block with a door leaf 2 m high and 60-90 cm wide.

You can accurately mark the planks before cutting as follows. The detachable porch is installed in side planks, which are laid out with the front surface up approximately along the width of the opening. The canvas is placed on the porches between the slats. The top bar is put in place. With a solid porch, it can be applied with the upper side to the canvas, this will not affect the measurements. A uniform gap of 2-3 mm is set along the perimeter of the canvas, for this you can use cardboard scraps, tile corners, or just by eye. We note the location of the canopies on the side bar and canvas.

The hinges are cut before the box is installed in the opening, or better before it is assembled. This makes work more convenient. The bar is laid out on a horizontal surface, the contour of the loop is outlined, excess material is removed with the help of a chisel. It is generally accepted that the canopies are located at a distance of 20 cm from the upper and lower surfaces of the door leaf. For lightweight canvases, amplifiers are made in these places.

The places for cutting the planks are carefully marked with a pencil. For a door with a threshold, the gap to it from the bottom of the leaf is assumed to be 2.5 mm. For a door without a threshold, the clearance under the door is from 1 to 1.5 cm. On the upper and lower strips with a solid rebate, marks are made opposite the edges of the rebate on the side strips. This will allow you to cut off the extra protruding ledge at the top and bottom to match the corners of the box.

We cut all the strips to the desired size with a hacksaw. A miter box will help cut the elements evenly. On the upper and lower slats, using a hacksaw and a chisel, we remove the extra porch along the serifs. Again we lay out the box on the floor and put the canvas into it with the installation of the necessary gaps. We fix all corners with two self-tapping wood screws 75 mm long with a countersunk head. For self-tapping screws, pre-drill holes of a suitable diameter. If you screw in the screws without drilling, you can split the ends of the slats.

When the width of the opening allows, a box of MDF is better reinforce on the sides with additional bars. So the structure will become more rigid. Before trying to insert the door frame into the opening, we fasten 3 straight hangers along its outer side surfaces: 2 at the edges and 1 in the middle. A strip of roofing material is nailed to the lower end of the structure with a threshold.

Door frame installation

We install the box in the opening. It should enter freely and not rest anywhere. Everything that interferes must be knocked down. For the option with a threshold, a strobe in the floor may be required. During installation, it is filled with a mortar or a polymer building mixture.

To begin with, the side of the box, on which there will be sheds, is set according to the level in 2 planes and in alignment with the wall. This side can immediately be fixed to the opening with direct suspensions. Approximately the upper bar is set to the horizon. It is checked that it does not touch anything, it is even better to have a small gap for subsequent adjustment.

It is quite difficult to accurately set the top bar and the reciprocal side rack in terms of level.

Fine adjustment is carried out with the curtain hung. Otherwise, there is a high probability that the door will not evenly approach the porch over the entire plane.

The canvas is placed on the canopies, the upper and side counterparts are exposed with required clearance along the perimeter and along the porch. This is done with wedges. 3 reciprocal direct suspensions are screwed.

For MDF models with a removable porch, the box is rigidly fixed to the opening with anchors or long self-tapping screws through the groove for the porch. AT wooden planks you can hide the location of the fasteners with the help of wood putty that matches the color. MDF versions with a solid rebate can be fixed through the box only in 3 places: under the canopies and the striker of the lock latch. But such fasteners are too close to the edge of the wall and can lead to chips. Therefore, it is better to limit yourself to mounting on direct suspensions and mounting foam.

Before filling the gap with foam, the ends of the opening should be slightly moistened with water. It is desirable to fill in such a way that the foam does not crawl out of the plane of the wall. Cutting it leaves the pores open and reduces the strength and durability of the filling.

So that the foam does not squeeze the opening, it must be wedged. You can simply leave the canvas in the opening, and put cardboard scraps in the gaps. If the door opens into the room, this will not work. You will have to use scraps of wooden bars and wedged them in the opening.

After a day, the foam will harden. The removable porch is fixed with glue. For reliability, you can add small carnations with bitten off hats. It remains to draw an opening and embed fittings. When you want to have a platband on both sides of the opening, and the width of the box is less than the thickness of the wall, additional trims are used.

Having bought a door frame in a store, you should not immediately despair at the sight of a large number of prefabricated elements. To assemble such a design, it is not necessary to be a specialist with higher education. To assemble the door frame with our own hands, we will consider the entire installation process in detail.

Usually, interior doors are sold disassembled, and at first glance, an incomprehensible and chaotic set of elements opens up to our eyes, which includes a profile wooden beam, in the worst case, from MDF, locks and awnings, as well as canvas. All this is vaguely reminiscent of the children's designer from the do-it-yourself series, and most people, seeing all this, panic and begin to look for an experienced specialist in this field, whose services are very expensive. Other enthusiasts are still trying to solve this puzzle, but their efforts run into big sign question, without detailed instructions very difficult to understand the assembly process. In this article, we will try to help you figure out how to outside help assemble the door frame.

Sizing the box

First and very milestone the entire assembly process is an accurate calculation, to the millimeter, of the length of the loot racks, the threshold (if any) and the upper jumper.

Measurement of racks

The height of the posts must be equal to the height of the door. Usually the standard door size in height is 2000 mm. After making sure of this, we add the width of the gap between the door leaf and the opening to the height of the door leaf by a width of 2-3 mm. In the case of installing doors with a threshold, the width of two gaps of 3 mm in size must be added to the height of the door leaf, a total of 6 mm. In the version without a threshold, we add only one gap of 3 mm in size, and add 1 cm at the bottom so that the canvas does not cling to the floor when opening and closing the doors.

As a result accurate measurements we get the following parameters: for the option with a threshold, the height of the doors and pillars will be 2000 mm + 2 gaps of 3 mm = 2006 mm; with the option without a threshold, the height of the doors and pillars will be 2000 mm + 3 mm + 10 mm gap = 2019 mm.

Threshold and upper jumper measurement

The size of the threshold and the upper lintel of the door frame must be the same. Let's determine their length correctly, which will be equal to the sum of the width of the door leaf, the width of the gaps between the door and the chute, and the thickness of the profile bar from which the chute will be assembled.

In addition, on both sides of the sections of the jumper and the threshold, it is necessary to cut out the landing samples, that is, cut off the protruding parts of the loot, against which the door rests when closing. The cut should be equal to the thickness of the rack at its widest point.

To correctly cut out the samples, we measure the thickness of the rack from the edge of the jumper on both sides and carefully cut it out with a small hacksaw.

After that, you can screw the door frame with a calm heart.

Do-it-yourself door frame assembly

We screw the door frame with self-tapping screws or confirmations for wood with a length of 55 mm or more. In order for the profile bar or MDF to not crack, you must first make holes of a slightly smaller diameter than the screwed self-tapping screw, by about 2-3 mm.

In order for the structure to hold firmly and not fall apart during installation, all joints must be fixed with self-tapping screws at least twice.

Marking and inserting canopies

The final step in the installation of doors is the connection of the leaf with the door frame. With the help of a simple operation, this will not be difficult. Having laid the door frame on the floor, it is necessary to put the door leaf into it with canopies embedded in it.

Place the leaf in the door frame so that the gap is the same on all sides and equals 3 mm. To do this, you can use a school ruler, the thickness of which is just 3 mm.

After the door in the box has been leveled, it is necessary to copy the location of the canopies from the doors to the loot using a marker.

Pull the doors out of the box, put it on its side and use a chisel or router to cut out seats for awnings.

Connect the doors with the frame into a single structure and screw the hinges to the hatch.

The assembly of the door frame is completed. Now the whole structure is ready for installation, and you can say with confidence that you have mastered the puzzle of assembling a door frame with your own hands!

Door frames are sold in construction stores usually already assembled, ready-made, but their individual components (sliced lumber) are also on sale, there is one advantage in acquiring the latter - during assembly, the box can be adjusted to the required dimensions of the doorway. Installing a door frame with your own hands is not an easy task and it is not recommended to take it on without certain knowledge. Therefore, we propose to study the installation technology, as well as assembly schemes.

Instruments

To perform self-assembly of the door frame, you need approximately the following set of tools:

- a set of bars (should be included in the door frame kit);

- level or plumb (to avoid distortions);

- a hammer;

- nails;

- screwdriver or drill with a special nozzle for tightening screws;

- electric milling cutter;

- screws;

- hacksaw;

- slats made of wood;

- a set of chisels;

- cuttings for wedges;

- assembly foam.

Availability of the kit professional tool- this is an expensive pleasure, but it provides a quality result of the work. After all, if you carry out the installation with simple improvised tools, and besides, without the appropriate experience, you may simply not be able to withstand the required accuracy. Therefore, before starting work, contact one of the many companies where you can rent any right tool or a device for a small fee.

Assembly technology

The assembly of the door frame is carried out in several stages.

Stage 1

- Lay the bars of the door structure on the floor.

- Carefully inspect the available material and make sure that the shortest bar of the structure has grooves (their presence is important for the convenient connection of all parts).

- Carefully fit the grooves on the top bar together with the side bars, and then knock all these elements down. In order not to damage the material, use a wooden mallet.

- Fasten the parts together with screws and check the reliability of the resulting structure.

- In the absence of grooves in a short bar, all parts of the structure are fastened with nails or screws.

Stage 2

The next step is to install the door hinges.

Stage 3

- On inside measure 20 cm from the top edge.

- Attach the door hinge and circle its outline with a pencil.

- It is known that the folded hinge leaves a small gap from the door to the frame (0.4 cm). Given the thickness of the hinge, calculate the depth of its installation.

- Using a router, make a platform for attaching the loop. If you didn’t have an electric mill, you can use a set of chisels for this purpose.

- Similarly, make a seat for the bottom door hinge. But keep in mind that the distance from the bottom edge of the structure should be 21 cm (1 cm is allocated to the bottom gap).

- Attach the door frame, with the hinges installed on it, to the door and mark the places on the door where the hinges will be attached. Arrange the slots on the door for the hinges in the same way that you previously made them on the frame.

Stage 4

- Take measurements of the height of the side of the doorway and then transfer the resulting dimensions to the side bars of the door structure.

- Keeping safety in mind, carefully lift the U-shaped box from the floor and proceed directly to its installation in the opening. Using a plumb or level, carefully check the verticality of the box, the perpendicularity of all its constituent elements and the horizontality of the top bar. From the first time, the frame may not “fit” into the opening (even if you have made all the measurements correctly). But that's not a problem. The resulting gaps between the opening and the box can be easily and quickly eliminated using wooden wedges or mounting foam.

- After you install the frame in its place, be sure to secure it. Screw the door frame with dowels to the slopes of the opening.

- Make sure that the door frame you assembled fits securely into the doorway.

- Remove the temporary braces and battens, and don't forget to saw off the protruding parts of the wooden wedges.

Proceed to hanging the door on the hinges and fastening the trim.

Fasten platbands with nails, screws, or glue. After installation, the nail heads are usually overwritten, and if self-tapping screws were used, decorative plastic caps are put on them.

As you can see, the installation of a door frame requires not only knowledge, but also experience. installation work and patience.

Video

The subtleties of installing the door frame:

Schemes

This section will show you how to install the door frame:

A photo

The photo shows how to install the box:

Sooner or later you have to change interior doors. The procedure is not so complicated that it is necessary to hire a specialist. If you have at least some skills in handling a saw, a level and a plumb line, you can tighten a few self-tapping screws - you can handle it yourself. When replacing, before installing interior door, the old one must be dismantled. And here, too, there are features. About all the subtleties - in the photo and video with detailed instructions.

Interior doors are made from different materials. Moreover, the material of both the door leaf and the frame is different. The door leaf is:

- From fiberboard. These are the cheapest doors. Represent wooden frame to which laminated fiberboard is attached. Differ in low sound insulation, are afraid high humidity are easily damaged.

- From MDF. They are much more expensive, but the quality is much higher. They are better in terms of sound insulation, are not afraid of moisture, are stronger and more durable.

- Wood. The most expensive doors Make out different varieties wood - from pine to oak or more exotic species.

Door frames are made from the same materials. The worst choice is fiberboard boxes, they even bend under their own weight, and hanging a door leaf on them is sheer flour. So try to take either MDF or wood. There is another material: laminated wood. The good thing is that you do not need to process and paint, but the service life depends on the quality of the film.

Dimensions and equipment

Interior doors are produced in standard sizes, it is a pity that the standards in different countries are different. For example, in our country swing doors make a width of 600 - 900 mm in increments of 100 mm. In some EU countries, the norms are the same - in Germany, Italy and Spain. In France, others are standard. Here are the most narrow doors 690 mm and further in increments of 100 mm.

Is the difference really that important? If you want to change only the door leaf without a box, then it is important that you have to choose from your segment or completely change it along with the box. There are much more interior doors of such a standard as in our country, as in France - many times less.

How wide doors are needed depends on where you are going to put them. In terms of standards, the following values are recommended:

- in living room width from 60 to 120 cm, height 2 m;

- bathroom - width from 60 cm, height 1.9-2 m;

- to the kitchen, the width of the door leaf is at least 70 cm, the height is 2 m.

If, when replacing a door, it is decided to make the opening larger/smaller, permission is not required for this, but it is necessary to remain within the limits specified for each room.

How to determine what width to buy doors? Measure the door leaf that is available and you will know what you need. If there are no doors, find the narrowest place in the opening by measuring it, you can find out what width you need door block. This is a door leaf + door frame. So the outer dimensions of the door frame must be less than the measured value. For example, you got 780 mm, look for a block with parameters of 700 mm. Do not insert wider ones into this opening.

The most complete set of interior doors - with a box, extensions and platbands

When choosing a door, pay attention to the package. There are three types of assembly:

- Door leaf. You buy the box separately.

- Doors with a box. Everything is included, but the box is in the form of separate boards. You will have to saw down the corners and connect, hang the loops yourself.

- Door block. These are doors ready for installation - the box is assembled, the hinges are hung. Just cut the sidewalls to the height, set them evenly and fix them.

With the same quality of the door leaf, the prices for these kits differ significantly. But the difference in time that you spend on installation is decent.

Step by step installation of interior doors

In general, there are many subtleties. We will try to describe and illustrate the most common moments in a photo or video material.

Step 1: Assembling the door frame

If you didn't buy a pre-assembled door unit, the first step is to assemble the door frame. It consists of two long racks located on the sides, and one shorter crossbar at the top - lintels.

Connection methods

There are at least two options for how to connect these strips to each other:

Regardless of which way you are going to connect the elements of the door frame, the first thing you do is wash down the racks and lintels on one side. Then they are put into a box on the floor, checking the correct connection. Next, you need to decide on the height of the side parts of the door frame.

We determine the dimensions

In the folded state, the required length is measured along the inside of the rack. Racks are not always made the same: the floor is often uneven and this must be taken into account. To do this, take the level and check how flat the floor is. If it is perfectly level, the racks will be the same. If there is a deviation, it must be taken into account: make one of the racks longer. Usually it is a few millimeters, but even this is enough to warp the door.

When calculating the height, keep in mind that the racks should be 1-2 cm longer than the door leaf (including saw cuts). A gap of 1 cm is made under the door, if they do not intend to put a rug under it. If there is a rug / carpet / carpet, it is better to make it bigger. Don't be afraid to leave gaps. They are required for . Once again, pay attention: the height is measured along the inside of the door frame - from the bottom edge to the cut. Having cut off, try on the racks in the doorway.

Now you need to saw off the lintel along the length and, if necessary, saw it down on the other side (if the joint is at 45 °). The length of the lintel should be such that, when folded, the distance between the uprights is greater than the width of the door leaf. The minimum gap is 7 mm, but more is often done. 7-8 mm are distributed as follows: 2 mm for hinges, and 2.5-3 mm for expansion gaps. Any interior doors - MDF, fiberboard, wood - change their dimensions depending on the humidity. Clearances are required to account for these changes. And 5-6 mm is not always enough, especially during wet rooms. For the bathroom, just leave a little more, otherwise, with high humidity, they can be difficult to open.

So, we decided on the minimum gaps when installing interior doors:

- on loops - 5-6 mm;

- top, bottom and sides - 3 mm;

- below - 1-2 cm.

After cutting off all the pieces and making the cuts, lay the box on the floor. If you notice any shortcomings in the docking - eliminate it with the help of sandpaper fixed on a bar. The more accurate the match, the smaller the gap.

Assembly

Regardless of the material of the box and the connection method, holes are pre-drilled for fasteners so that the material does not tear. The diameter of the drill is 1 mm smaller than the diameter of the self-tapping screw.

The box is folded, angles are set to 90 °. Holding the rack and the lintel in this position, drill holes with a drill. If there is an assistant, he can hold. If you work alone, temporarily fasten the correctly set box with two transverse bars - closer to the top and bottom. This will help not to make mistakes and make the right connection.

If connected at an angle of 45 °, three holes are made on each side. Two on top - stepping back a centimeter from the edge, and one on the side - in the center. A total of three self-tapping screws are required for each connection. The direction of installation of self-tapping screws is perpendicular to the connection line.

If connected at 90 °, everything is easier. Drill two holes from above, pointing the drill straight down.

Step 2: Insert hinges

Most often, 2 hinges are installed on interior doors, but 3 are also possible. They are placed back 200-250 mm from the edge of the door leaf. If the frame and door leaf are made of wood, choose a place where there are no knots. First, attach the hinges to the door leaf. The order of work is this:

- We apply loops to the selected places, outline the contours. The easiest way to do this is with a finely sharpened pencil, but experts advise using a knife blade. So it turns out more accurately and smaller gaps remain.

- If they have it, if not, they take a chisel and choose the material for the thickness of the loop. More sampling is not necessary, only for the thickness of the metal.

- A loop is installed in the prepared recess. Its plane should be on the same level with the surface of the canvas.

- The exposed loop is fixed with self-tapping screws.

Having fixed two hinges, the door leaf is laid in assembled box, set the correct gaps: from the side of the loops - 5-6 mm, 3 mm from the opposite side and from above. Having exposed these gaps, the canvas is fixed with wedges. Expose exactly in horizontal and vertical plane(You can use pads if needed).

After setting, mark the location of the reciprocal parts of the loops. Sometimes it is more convenient to remove the already installed loop, and then install it in place. According to the markup, they also make a recess. Depth - so that the surface of the hinge is flush with the surface of the door frame.

Do-it-yourself door hinge is described in detail in the video.

Step 3: Installing the door frame

The assembled box must be correctly inserted into the opening. This is a very responsible task. Before you install an interior door, knock down everything in the opening that can fall off. If the wall is too loose, the surface is treated with primers deep penetration with astringent effect. If there are too many big holes, they are covered with plaster, very large protrusions are hemmed. It is easier to insert an interior door into the prepared opening. If this is your first time doing this on your own, make your job easier.

The box is exhibited without a door leaf. It is oriented strictly vertically. The verticality is checked not only by the level, but also by the plumb line. The level often gives an error, therefore it is more reliable to check with a plumb line.

To prevent the box from warping during installation, install temporary spacers on the floor, in the corners - slopes, which give a high degree rigidity. In order for the doors to open, they are inserted in the same plane with the wall. Only in this way will it open completely. If the wall is uneven, put the box not on the wall, but vertically. Otherwise, there will be problems with opening or closing the door.

How to insert an interior door with your own hands - in the same plane with the wall

After the position is selected, you can fix it. This is done using mounting wedges - triangular wooden or plastic bars. First, the wedges are placed on both sides of the lintel - crossbars, then above the uprights. Thus, the position of the box relative to the doorway is selected and fixed. Next, the verticality of the racks is checked again. They are checked in two planes - so that they do not turn out to be tilted forward or backward.

Then the wedges are installed at the bottom, then after about 50-60 cm, checking that the racks are exactly level. Wedged additionally and the transverse bar - in the middle. They check whether the elements of the box are bent somewhere, if necessary, correct. You can start fastening.

Step 4: Attaching the frame to the doorway

There are also two ways of fastening: straight through to the wall and mounting plates. If the wall allows and you are not afraid of the fastener caps in the box, you can attach it through and through. It's safe.

To install interior doors, it is quite enough to screw two self-tapping screws into the cutouts for the hinges and, on the other hand, under the plate of the reciprocal part of the lock. Additional holes are drilled in the cut out recesses. They are made so as not to fall into the holes for fastening the hinges or the mate. Make sure that the head of the self-tapping screws is recessed and does not interfere with the installation of the hinges and lining.

Installation of interior doors according to this scheme is shown in the video. There are also several interesting nuances about the door frame.

If such a quantity of fasteners seems unreliable, they drill through and close the holes with decorative washers matched to the tone. Or there is also a special MDF molding with removable slats. The fastener is installed in the prepared groove, and then closed with a bar.

The second method is hidden, the fasteners are not visible. First fasten from the back of the box mounting plates. In principle, it can be used for drywall, but there are also special ones - thicker, although drywall is enough when installing interior doors.

Step 5: Foaming

After all the gaps are set and the wedges are installed, the gaps between the box and the wall are filled mounting foam. For better polymerization, the wall is moistened with water from a spray bottle. After that, the foam is squeezed out, filling no more than 2/3. Too much a large number of foam may cause the box to blow inwards. Therefore, do not overdo it.

To ensure that the foam does not warp the doors, spacers are installed. But if you do not overdo it with foam, nothing should happen.

Spacers for fixing the box - with this installation of the interior door, the box should stand exactly

After the foam polymerizes ( exact time indicated on the cylinder) spacers are removed, hung door leaf and check the operation of the door. Next come Finishing work: and platbands, if necessary - extras.

You know how to install an interior door with your own hands. There is nothing super complicated, but we tried to describe the main nuances. There is a lot of useful information in the video - these are recommendations from practitioners.