How to install gabions correctly. DIY gabions. Selection of material for filling gabion structures

Read also

Experts who have been working with gabions for a long time, who have carefully studied their features and properties, note that it is possible to install such structures on our own. Undoubtedly, it is important to take into account the features of the project and its level of complexity. For example, it is difficult to strengthen a huge coastline or create a reliable support using a gabion, so it is better not to take risks. As for fencing, even beginners can do it. In order for you to be able to independently determine whether you should do this, it is better to consider the installation features and the rules for performing this process.

Gabion laying technology

The actual technology for laying gabion structures is quite simple. But in order to achieve the expected result, it is necessary to take into account the manufacturers’ recommendations, read the instructions, and also follow the main steps. Only in this case can you achieve an acceptable result by spending a little time.

Preliminarily carried out preparatory activities. Their essence lies in preparing the surface on which installation will be carried out, as well as assembling gabions.

The surface on which installation will be carried out must be cleared of debris and vegetation. This will allow the mesh and filler to be positioned smoothly. In addition, it is necessary to partially level the terrain if the differences are really large.

Installation of gabions

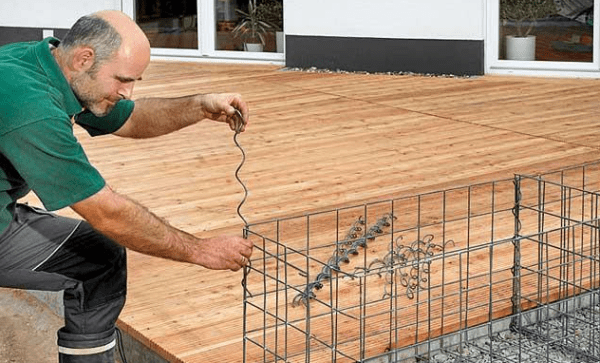

As soon as preparatory process completed, you can proceed to the installation of gabions that have already been designed. Initially, they are placed on a surface without filler, and also leveled in accordance with the current project. Only after this are they partially filled with the appropriate raw materials. Anchors and other elements are installed in the corners, which allows them to be fixed in one position. WITH outside gabions are located wooden frame, with which you can support side panels V vertical position.

Once all the gabions provided for by the project have been installed, you can proceed to filling them. Most often, stone is used for these events. It is important to ensure that the fraction size is 12.5-25 centimeters. More exact dimensions should be determined based on the characteristics of the grid. In some cases it is advisable to use different factions. At the same time, more large stones should be placed near the side panels, and small ones - in the central part of the gabions.

It is not necessary to fill in manually. You can also use special equipment. But, no matter what option is chosen, you need to lay it as tightly as possible. If you plan to further install gabions, then the last structure should remain empty. In this case, you can continue installation, binding and filling without any problems.

Laying gabions

When laying gabions, Special attention care must be taken to place the stone inside the structure. This is due to the fact that it is the correctness of its location that affects such indicators as service life, strength, and reliability.

Gabions should be filled only 30-35 percent in one go. After this, you need to fix the laid stones using special connecting brackets and other fasteners. This principle should be used for the next two layers. If you decide to use Reno mattresses rather than box gabions, then filling can be done in one or two steps. When choosing an acceptable option, you should be guided by the dimensions of this structure.

In order for the shrinkage of the stone, which is located inside the structure, to occur evenly, experts recommend going a little beyond the edges, about 5 centimeters. Over time, everything will level out, nothing will protrude. Once this happens, you can install the cover. It must be placed as close as possible to the edges, and also fixed to the panels using wire and special staples.

It is not difficult to prevent deformation of the lid that can occur during the shrinkage process. To do this, it is worth initially implementing a time reference. After some time, the stone will be evenly distributed around the entire perimeter of the box, after which a more reliable fixation can be made.

Please note that strengthening shorelines with gabions is a complex process. The main problem is that simply installing it is not enough. It is imperative to additionally fix the gabions using anchors and other fasteners. This is due to the fact that gabions are affected by moisture, temperature fluctuations, and wind. If you fix it in a timely manner, you can prevent problems and additional costs.

Gabion assembly

Assembly of gabions is one of the most significant processes. Whether you can carry out the installation normally and strengthen the surface depends on the correct implementation of this activity.

Since the material is supplied in packaging, it must be carefully removed before assembly. The removed gabion should be placed on a flat and stable surface. All edges of the material must be straightened. Be sure to make sure there are no bent, uneven, or wrapped parts.

Next, you need to design a rectangular box. To do this, the side parts must be placed in a vertical position. Please note that the side panels must be at the same level. Only after this can you proceed to fixing the sides. As a rule, wire is used as fastening material. Fastening should be done every 10-12 centimeters. The turns must be both double and single.

You may be interested in these products

Gabions installation

The technology for installing gabions, which is described above, can be modified. But changes must be made based on what kind of project is being implemented. For example, if you plan to carry out partial installation, then in this case the gabions located at the edge should not be filled. As a result, you will be able to move the grids around without any hindrance.

When filling gabions, it is important to ensure that they do not turn into a monolith. In the future, all voids will be filled with soil and particles. But at the same time it is necessary to have a little more than is provided. Such actions will minimize the negative impact of shrinkage, which cannot be prevented.

Those who assume that the process of installing gabions is simple are somewhat right. But only if a fairly simple project is being implemented. If we're talking about about complex, large-scale objects, without special equipment, as well as the help of masters, is indispensable. They are aware of all the features and can quickly navigate, which will reduce costs and achieve positive results faster.

Thus, in order to reap all the benefits of gabions, you should pay special attention not only to the choice suitable model, but also the installation process.

A gabion is a large metal cage made from twisted wire. This design is very easy to manufacture and place on your site. This design is not expensive, and at the same time reliable in use. There is no need to take extra care of it.

Advantages of gabions

If we compare gabions with other similar structures, it becomes clear that gabions have great advantages. Their advantages include:

- high strength, as it can withstand heavy loads;

- each mesh structure can be attached to another, for this you only need galvanized wire, as a result you can get a monolithic structure;

- they go well with the rest of the landscape, so over time the effectiveness of such a structure will only increase;

- low usage and installation costs;

- ease of installation due to light weight products.

Gabions have many advantages, thanks to which they are widely used in various fields and regions.

Types of gabions

Depending on the type, the following gabions are distinguished:

- box-shaped;

- cylindrical;

- flat.

It follows that frame form will look like a cylinder, a flat figure or a box shape, it must be made from a mesh or from a welded structure.

In a welded structure, the rods, which are laid perpendicular to each other, are welded at the intersection points. Welded boxes have a rectangular shape; in order to connect the walls, a wire spiral is made.

The mesh structure is created by attaching a steel mesh to a rigid frame. Each cell of such a grid is hexagonal in shape.

How to make gabions with your own hands

Before you start making gabions, you should ensure that you have next material which you will definitely need:

- metal mesh, the thickness of which should be from 0.2 to 0.8 cm, depending on the parameters of the product. In this case, it is worth taking into account the operating features;

- fittings With its help, the frame is strengthened and given rigidity;

- wire staples and metal spirals. These materials are used to hold structural parts together;

- geotextile. This material is required to provide backfiltration and to reduce the consumption of sand or other fill material during installation work.

Be sure to stock up on stones. If appearance is the main thing for you, then choose a material of different colors or unusual shapes. To do this, you must give free rein to your imagination.

To carry out work on the manufacture and installation of gabions, you need simple tools, many of which you probably already have: pliers or pliers, a stapler for installation, a pry bar, a shovel and anchors.

Attention ! If reinforcing bars are used in the manufacturing process, then it is necessary to use welding, since connecting parts with wire is a rather difficult process, which, moreover, cannot guarantee the required rigidity of the frame.

We make a frame

Since the weight of even a small structure will be significant, the manufacture and assembly of the gabion frame must be carried out at the site of its installation.

The gabion manufacturing process takes place in several stages. First, let's prepare the base; if possible, it is better to strengthen it, for example, compact the soil or remove the top layer of soil. Use sand to make a pillow, the thickness of which will be from ten to twenty centimeters. Everything will depend on the weight and parameters of the gabion.

Attention ! If a fence is being built from gabions, then at a shallow depth it is necessary to equip strip foundation. This is especially necessary in cases where gabions are combined with sections made of traditional materials.

To prevent grass and other weeds from growing on the gabion mesh, it is necessary to make a shallow ditch around the entire structure. After which the ditch should be covered with geotextile fabric or ordinary black film, secured by bending one edge under the future structure.

Then you need to cut the mesh in accordance with the pre-calculated dimensions and begin connecting it.

First of all, it is necessary to install the bottom of the structure, and lay the sides to it and secure them together with metal wire. The remaining wire must be tightly twisted and secured using pliers.

If your gabion needs to be quite large or with one of its sides disproportionately long, you should consider stiffening diaphragms. One of the sides should be open so that the structure can be filled with stones.

The last stitching should be done after all installation work is completed and the entire volume is completely filled.

After completing all work on the manufacture of the structure frame, it must be finally installed and fixed. To ensure the strength and reliability of the structure not only due to its own weight, the structure should be secured using anchors or homemade stakes. You can also use fittings, the diameter of which should not exceed 1 cm.

When manufacturing a structure consisting of more than one tier, it is possible to allow for the possibility of saving material, for example, when constructing fences. IN in this case the gabion mesh of the lower tier can become the bottom for the upper one.

Filling the gabion with stones

After ready-made designs installed and firmly fixed to each other, you can proceed to the next stage - laying the stones. This is not a difficult stage, but it requires compliance with certain rules:

- you need to start filling when the gabion is in its place;

- if for internal filling stones selected various sizes, then large ones should be laid along the edges, and the center should be filled with smaller stones;

- if you use small stones that have the same size and shape, then you need to lay them in bulk, in several steps, compacting all parts;

- with a gabion height of more than 1.5 meters, stones should be laid in several layers, the thickness of each of them should be from 15 to 25 cm. In addition, after the structure is 1/3 filled, it will be necessary to make stretchers, which will opposite sides are fastened to prevent deformation;

Advice ! If the structure has a height of more than a meter, then this procedure should be done again after a certain period, for example, after filling two-thirds and three-quarters of the volume

- if the gabion consists of many levels, then the bottom row should be filled with stones, taking into account their shrinkage under the influence of their own weight, as well as under the influence of external load, so they need to be filled on average 5-7 centimeters above the upper edge of the structure;

- sometimes it is possible to use stones that have a smaller fraction than the parameters of the cell, but then they must be laid in the middle of the structure or at the bottom of the structure; they must first be wrapped in geofabric, which will not create an obstacle to water, seeping through the gabion, but will not allow it to wash the filler from the gabion;

- after completing the installation and filling of the gabion, you need to perform the last step - cover the installed structure with a lid and secure it with a metal spiral made of wire.

Advice ! To ensure that the stones do not move and the image does not lose its appearance, perform the steps in several stages. Lay out the stones by hand, making sure to compact each layer in the gabion.

Conclusion

Gabions are a good tool for cheaply and cheerfully creating decoration in your backyard or garden. This type of landscape design is flexible and mobile. And this gives free rein to your imagination.

Your masterpieces will look respectable and beautiful. And the main thing is to make a gabion with your own hands and with minimal costs. Show a little imagination and imagination, be a designer, create and give joy to your loved ones and those around you. After all, when your eyes are pleased with such beautiful elements of landscape design as gabions, your mood will improve and your soul will be at ease.

What is a gabion? landscape design? Manufacturing Designer Lessons

Decorate your site in an original way or make reliable fence, support for the building can be made using stones that are filled into metal mesh. Such structures are called gabions; the simplicity of the technology allows you to make them yourself - you will find the corresponding step-by-step instructions in this article.

What is a gabion and what is it for?

The word "gabion" French origin and literally translates as “big cell.” This is the name given to metal mesh, which is made from twisted wire. Typically, the shape of a gabion really resembles a cage, although you can make more shaped options that can be used to decorate the design of your site in an original way. Various stones are poured into the nets, which create an attractive, neat appearance for the fence.

In domestic terminology, in accordance with GOST R 51285-99, gabions are also called gabion mesh products (GSI). Requirements regulatory documents involve the use of metal cells that are a regular hexagon. However, in landscape design you can use absolutely different variants, since GOST contains instructions for the use of products in the economic sphere.

Gabions are used in various fields:

Thus, if initially gabions were used for purely practical, protective purposes, now they are becoming one of modern means design.

What advantages do gabions provide?

The reason for the popularity of gabions lies in the advantages that they provide in comparison with other stone products:

- Gabions are much cheaper than monolithic stone slabs and can be delivered to the right place much simpler.

- Gabions are easier to work with than slabs.

- Gabions allow you to show much more creative imagination, since the stone slab has a pre-prepared shape, and the mesh can be built of any size and type, adapted specifically to your site.

- Due to the fact that metal mesh bends very well, the gabion will naturally take the shape of the surface on which it is placed. As a result, even during the flood and rainy season, the structure will stand quite steadily without additional supports.

- The gabion itself is very durable: stones and metal practically do not deteriorate from moisture and temperature changes. In addition, special drainage system there is no need to do anything to drain water - as a result, time and money are saved during installation.

- Such structures are also undemanding in terms of maintenance - you just need to keep an eye on external cleanliness.

- Gabions, used as fencing, absorb noise well and retain dust from the road, which settles on the uneven, embossed surface of stones.

- Gabions can well strengthen the soil on a site if structures are laid out along its perimeter - stones are more reliable than textile fiber, sand and other drainage protect against erosion.

- Finally, a fence, support or figure made of gabion is a truly safe product from an environmental point of view: stone and metal do not pose any health hazard and do not pollute the site.

Thus, gabions are metal meshes that are filled with stones (sometimes with other available materials). You can assemble gabions with your own hands - the step-by-step instructions are quite simple.

The only disadvantage of these products is that there are enough of them heavy weight. If small gabions can be removed manually, then for more capital options you need to carefully consider the placement location - moving them without damaging the mesh is almost impossible.

THIS IS INTERESTING Over time, the cells of the gabions will begin to be filled with earth, sand and plant seeds, which will begin to germinate right between the stones. Oddly enough, this gives the structure additional strength due to the fact that the space between the cobblestones is filled, and the entire gabion acquires a monolithic structure.

Gabion device

A typical gabion consists of twisted metal wire filled with stones or (less commonly) other types of improvised materials. There are certain requirements for wire and filler.

Wire for gabions

Double torsion technology is usually used for reinforcement. The requirements for the metal base are obvious in this case:

- strength;

- elasticity;

- corrosion resistance (especially for underwater gabions).

To make a gabion with your own hands according to step-by-step instructions, you should use galvanized steel mesh, since it is most resistant to moisture, precipitation, air humidity and temperature changes.

The following types of wires are used:

- with zinc coating (layer density from 250 g/m2);

- With anti-corrosion coating made of alloy (zinc 90% and aluminum 5%);

- With PVC coated- enough new variety: the coating consists of artificial organic polymers, which, due to chemical inertness, do not interact with moisture, air and other components environment; in addition, polymers are resistant to low, high temperatures and temperature changes.

Along with twisted wire, specially designed for weaving mesh, gabion structures often use knitting wire, which attaches the main wire to the frame. Since in this case the binding wire serves as fastening materials, special requirements are imposed on it:

- Wire breaks are not allowed.

- All ends must be connected by twisting or extending.

- In this case, the twist length should be 2 cm or more.

- The main requirement is to accurately follow the ratio of dimensions (diameter and length) of the wire, edge and bundle of elements. Experienced way a certain relationship between these parameters has been derived - the corresponding data is presented in the table.

Technology for forming a gabion from mesh

Technology for creating a single structure from a sheet metal mesh There are 2 types:

- Frame: gabions are made of mesh with regular cells in the form of regular hexagons. The mesh is fixed to a frame, which is also made of metal.

- Welded: Wire or steel rods are intertwined and welded together into a box or cylinder (depending on the project).

Exactly welded structures have the greatest strength: welding allows you to solder the rods as tightly as possible and keep them in this state, despite the strong tension from protruding stones. Besides welded gabions they look more attractive, and unlike frame ones, they can be wrapped into original figures or flower beds, which is why they are most often used in landscape design.

Stones and other fillers for gabions

You can make a gabion with your own hands - for this you will need simple equipment and available materials (detailed step-by-step instructions are in the corresponding section). In this case, it is important to pay special attention to the filler, because the aesthetic appeal of the structure depends on it.

Usually these are stones, but often waste and used materials are used:

- logs, logs;

- tiles;

- bricks;

- pipe cuttings, etc.

Despite the fact that they are used in literally waste, such products will find their application in landscape design thanks to unusual style and warm orange-brown tones.

Specific technical requirements to the stones are the following:

- heaviness – with a specific gravity of stones from 18 kN/m3;

- mechanical strength from 400;

- water absorption no more than 0.6%

- resistance to low temperatures more than MP350;

- softening coefficient (from water absorption) from 0.9.

Such requirements are largely intended for construction complex structures, designed for heavy loads (bridge supports, foundations, protection of banks from erosion by water, etc.). In everyday life, stones are essentially subject to two basic requirements:

- They must be significantly larger than the cell parameters.

- By color it is better to choose light gray or warm shades, which contrast well against the background of the lawn or soil. However, in every specific case You should focus on your taste and the characteristics of your site.

The relationship between the diameter of the mesh cell and the size of the stones has been experimentally established: the stones should be 1.2-1.5 times larger in diameter compared to the mesh holes. It is this parameter that ensures the most uniform arrangement of the pile throughout the entire volume.

According to various step-by-step instructions for making gabions with your own hands, you can use the following types stones:

- simple cobblestones;

- pebbles of different sizes;

- crushed stone;

- granite and basalt;

- quarry stone (the most affordable);

- about;

- diorite;

- quartzite.

Different design options use both torn stones (with sharp, uneven stones) and rounded stones (river pebbles). As a rule, in designs with large meshes it is appropriate to use last option– large uneven cobblestones do not look so attractive.

Although in cases with fences and massive fences, it is large stones that well stylize the wall as a stone one, giving it an ancient, rich look.

You can see the different design texture options in more detail here.

Types of gabion structures

If exclusively rectangular gabions are used to protect the river bed and coast from erosion, then you can use different types, which can mainly be reduced to 3 groups:

Separately, there are welded and mesh structures, which differ in production technology: mesh structures are made by winding and fixing onto a frame, and welded ones are made by welding different parts metal mesh.

Finally, there is a separate category - the so-called Jumbo gabions (from the English jumbo - huge). These are rectangular, box-shaped products, which are particularly large in size:

- length from 3 to 6 meters;

- width 2 meters (standard);

- height 0.5 meters.

The use of large structures allows, on the one hand, to significantly reduce the cost of production technology, and on the other, to use them for construction purposes:

- strengthening supports;

- additional support for foundations under buildings;

- barriers to avalanches and landslides.

Jumbo is also used to create underwater supports. In this case, the service life becomes almost unlimited due to the fact that silt constantly gets into the space between the stones, which is compressed over time, due to which the entire structure acquires additional strength. Even if the metal mesh completely disintegrates due to corrosion, the gabion itself continues to stand as a single unit.

DIY gabions: step-by-step instructions and video

The materials needed to create a gabion are as follows:

- metal mesh;

- fastening staples;

- steel pins for the frame;

- metal spirals;

- pliers;

- hammer;

- wire stapler;

- digging tools;

- geotextiles - drainage (needed for additional preservation of stones from destruction by water);

- actual stones or other filler.

Installation of boxes

Here are step-by-step instructions for installing a gabion with your own hands using the example of the most common box-shaped structure:

NOTE. If gabions are installed in 2 or more rows, but they are placed closely with their front parts or “backs”. The “face-to-back” arrangement reduces the strength of the entire structure.

The whole process can be seen more clearly here.

Installation of cylindrical structures

Cylindrical gabions have their own specifics - in this case step-by-step instruction for assembling the structure with your own hands will be different:

Installation of mattress gabions

In this case, the installation technology is as follows:

Gabions in landscape design: photo gallery with description

Along with the fact that gabions can be created with your own hands according to the step-by-step instructions provided, they can be used not only as fences, but also as full-fledged decorations on the site. The undoubted advantage of such structures is a combination of practicality (fencing, soil protection from erosion), durability and aesthetic appeal.

The use of these products in garden design is limited only by the user’s imagination, since there are options a large number of- from traditional to unusual. Here are some ideas and photos for inspiration.

Gabion fences

A fence made from such structures is classic designs, which reliably protect the house and area from dust and noise. Such fences are created both from gabions themselves and in combination with wood materials.

Gabion fencing

From similar designs You can make small fences that organize the space inside the site. They will give the entire area a neater, more attractive look.

You can start with the fact that gabions are great for decoration. entrance area or terraces. If the house is located on a high enough hill, then the entire area next to the stairs can also be designed in the form of steps.

Gabions can thus be used not only as fencing, but also as a basis for wooden fence. Moreover, if the height is quite high (from half a meter), then it is better to further strengthen the structures with concrete columns and finish the top with wood or slabs.

Classic options are creating internal borders along the path. If you put basalt tiles or plywood on top, you get a full-fledged bench.

Gabion benches

Finally, such structures can be made into full-fledged seats as shown in the photo.

If you stylize the entire recreation area as a walking platform and add lighting, you get a rather interesting option.

Lights and wiring are laid directly into the stones during construction.

Benches are also created using wooden slabs.

It is interesting that such products even penetrate into the design of premises - if you want to diversify the furniture and interior of your apartment, you can try starting an experiment with gabions.

Gabion flower beds

Gabions, unlike tires and other materials, will serve excellent option for floral and decorative flower beds, since the soil lying among the stones is not subject to any erosion (destruction) - neither from moisture nor from the wind. For flower beds it is best to use stones more light shades, against which the greenery and flowers themselves will contrast especially well and decorate the garden plot.

The labyrinth design deserves special attention. It's really beautiful flower bed, which can enliven a space. As a rule, they are located in the center or in the corners of the garden, maintaining symmetry.

Interesting option - portable structures, which will serve as full-fledged flowerpots. Thanks to their originality, they will serve as a kind of business card. garden plot– directly above the stones you can place a layer of soil in which to plant flowers or ornamental plants.

To make these types of gabions with your own hands, you can use the technology given above in the step-by-step instructions, and take, for example, this drawing as a basis.

By modifying the shape, you can achieve designs of various types.

PAY ATTENTION Gabion beds are especially suitable for flowers that do not like excess moisture - the liquid will flow over the stones, as a result of which the soil will not receive excess moisture.

Gabion structures are a new direction in landscape design. They combine practicality, reliability and visual appeal. In addition, such products are cheaper than conventional fences due to the fact that all components (stones and mesh) are inexpensive. That is why gabions are becoming increasingly popular among owners of country houses.

And finally, a video selection of additional options for using gabions on the site.

But also the surrounding area. Its arrangement - important question, standing in front of the owners. The solution to this problem will be environmentally friendly, affordable and relatively inexpensive way design of the site - gabions, made by hand from available materials. Due to the fact that these designs are easy to implement and can solve many problems that arise for a private homeowner, they are very popular.

We make gabions with our own hands. A simple solution for arranging the local area

Garden and personal plots are, first of all, green spaces. Trees, bushes and flower beds placed in a certain order. There are special rules for their location. Modern garden is unthinkable without special structures - gabions, which, together with green spaces, form a single whole.

All kinds of fences, small fancy shapes, benches, as well as small ponds - this is far from full list structures being built on personal plots, based on mesh baskets.

What is a gabion?

The main condition for construction on sites is the ease of performing the work and the availability of materials. Making gabions with your own hands is a process that satisfies these requirements. And the ability to solve many landscaping problems with their help makes them universal.

A gabion is a large metal cage made of twisted wire. This design easy to manufacture and install anywhere on the site. And, most importantly, such a mesh “basket” will be cheap and reliable in operation. Its long-term use does not require additional special care.

We make gabions with our own hands. Necessary materials

Before purchasing blanks for a structure, its functions are determined. Depending on the operating conditions of the form being created, they plan the choice of material intended for its construction. You should also accurately determine the size and location future design, which will make it easier to purchase the necessary supplies. Massive structures such as retaining walls or terraces will require more durable materials than simple and easy decorative forms.

Do-it-yourself gabions are made from metal mesh. Various designs They are made in the form of boxes equipped with an opening lid on top. Interior metal container is filled with massive and heavy filler. The mesh for gabions should have strength and anti-corrosion properties. It is quite difficult to make it with your own hands. Therefore, most often they purchase galvanized chain-link mesh with anti-corrosion coating. In addition, a three-millimeter galvanized flexible wire is required for fastening. The rigidity of the box ribs is provided by eight-millimeter reinforcing bars. The structures are filled with stones of all shapes and sizes. Most often crushed stone or broken brick is used.

Features of box installation

Gabions are easy to assemble with your own hands. The manufacture of the structure begins with the assembly of the box. Depending on the type of gabion, a frame is formed. All existing irregularities on the workpiece are carefully leveled and a box is formed. Using wire, connect the side parts of the structure. The area intended for installation of the box should be leveled. A gabion does not require a special foundation.

The form placed on the site is secured with metal fastening rods, which are installed at the corners of the structure. Next, it is filled with stone in several stages. It must have the necessary strength, frost and water resistance. First fill one third of the box. Perform horizontal fixation with wire. Next, fill the rest of the gabion. This way the entire metal container is filled. At the same time, we should not forget that the filler should be laid in fairly dense layers. Secure the box lid first at the corners, and then along the entire length of the container. The structure is ready.

Variety of shapes

Quite often on household plots and summer cottages install gabions with your own hands. The most common and quite popular are box-shaped structures, distinctive feature of which there will be a wide range of sizes. The ratio of the length and width of the mesh metal container is strictly observed, which is one to two. Rectangular containers serve as the foundation for small structures. They are also often used as such a box. This box is considered the basis for other variations of gabions.

Low boxes with a diaphragm are distinguished by reliable fastening. This type of mesh container is divided into small sections inside. This design reliably fixes the filler inside the container, which allows it to be used as a foundation for all kinds of household structures.

Cylindrical gabions look quite impressive. Light structures with small size Column-shaped cells are filled with finer filler.

On gentle slopes, gabions-mattresses are used to fix the soil. Resistance of this variety metal structure ensured by a low height and the use of more durable materials.

Application of gabions

In areas adjacent to private households, there is always a need to construct all kinds of structures and shapes. Before making gabions with your own hands, plan all necessary facilities Location on. They are different in purpose. First of all, they start by fencing the areas. A fence made of gabions, built with your own hands, is an excellent solution. It will be an excellent alternative to conventional fencing designs. This option is not only high noise protection and original design, but also accessibility and ease of installation. An addition to the fence will be mesh boxes used as gates or garden gates. The construction of fences and zonal fences is excellent.

Magnificent decorative forms will decorate the garden. You cannot do without gabions when creating an artificial reservoir or swimming pool. Making terraces and retaining walls, steps, small foundations for lamps and garden flowerpots is not a complete list of the uses of metal containers with filler. The advantage of such structures is the possibility of using them in combination with engineering systems. This will allow you to build a fountain or outdoor shower on the site.