How to properly build walls from tongue-and-groove blocks. Installation of partitions made of tongue-and-groove slabs. Technology for installing partitions with doorways

Tongue-and-groove slabs- these are rectangular gypsum parallelepipeds intended for the installation of internal load-bearing partitions in rooms with varying degrees of humidity. There are hollow and solid versions of their execution.

KNAUF tongue-and-groove slabs

One of the most famous manufacturers gypsum board is produced by the German concern KNAUF. The brand's products are available in three sizes: 667x500x80, 667x500x100 and 900x300x80.

Material of tongue-and-groove slabs

The basis for the production of KNAUF tongue-and-groove slabs is gypsum binder of two grades: G-4 or G-5. The material does not support combustion and does not contain toxic components, which allows its use in hospitals and kindergartens. He doesn't spend electricity and is resistant to sudden changes in temperature. High degree vapor permeability is characteristic of all gypsum products. The material lends itself perfectly machining and has no specific odor.

installation of partitions from tongue-and-groove slabs. Photo

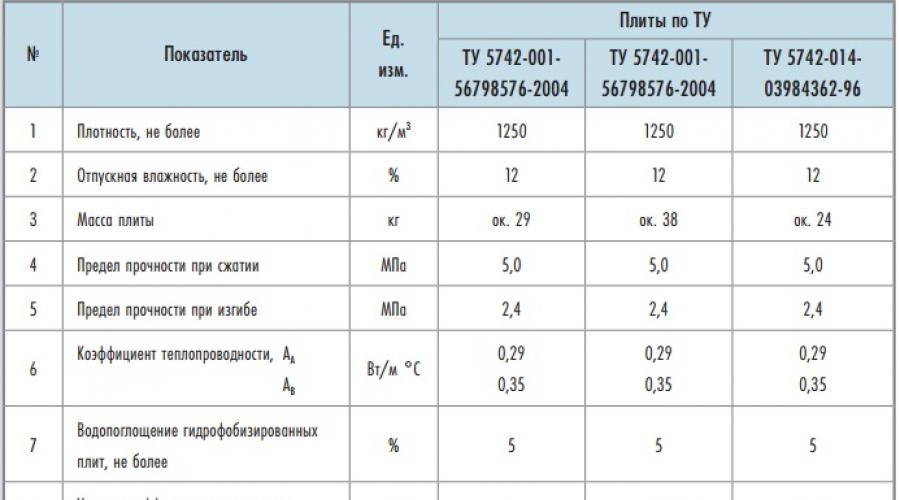

Technical description of KNAUF boards

The KNAUF tongue-and-groove plate has the form of a rectangular parallelepiped, the design of which provides for a special high-precision tongue-and-groove connection. Ready product has the following specifications for all sizes:

Installation of partitions using KNAUF slabs

Do-it-yourself partition made of tongue-and-groove slabs. Video instruction

Partitions made from KNAUF tongue-and-groove slabs are constructed using the designer method, by precisely connecting a groove on the supporting side and a tongue on the joining side, with gluing of the joining surfaces. The adhesive mixture can be used as glue for gluing drywall " Pearlfix", produced by the KNAUF concern. Installation of tongue-and-groove slabs is carried out with precise adherence to rows in vertical as well as horizontal planes.

Work on the construction of partitions should be carried out after completion of production load-bearing elements premises, but before laying the finished floors. This period coincides with finishing work indoors, mainly during the cold season. Temperature indoors should not be below +5 °C. Humidity should correspond to dry or normal conditions. Before use, the slabs must undergo acclimatization, that is, adapt to indoor conditions. To do this, they must lie inside for at least 4 hours.

The permissible length of the partition is 6 m, and the height is 3.6 m. If it is necessary to erect a longer or higher partition, it is made up of separate fragments, each of which has a separate attachment to the supporting structures using a special frame.

Volma tongue-and-groove slabs (solid)

Volma solid slabs - have the shape rectangular parallelepipeds with a tongue-and-groove system, manufactured according to injection molding technology. The main purpose is the construction of internal partitions in rooms with three types of humidity according to SNiP II-3-79. Moisture-resistant boards contain hydrophobic additives and special plasticizers. The moisture-resistant version has a characteristic green color.

The material of the stove does not support combustion and does not contain substances harmful to the human body. They have high sound insulation and do not have a specific odor.

installation of walls made of Volma tongue-and-groove slabs. Photo

Technical characteristics of Volma slabs

The surface of the slab and the geometric accuracy of the design exclude plastering work when decorating a room. The solid slab is produced in one standard size - 667x500x80. The weight of one plate is 28 kg.

Volma tongue-and-groove slabs (hollow)

For the construction of partitions that require reducing the load on the base of the floor, Volma hollow gypsum slabs are provided. Their main application is the installation of interior structures in modern panel houses. This is due maximum load which floor slabs can withstand. Like their solid counterparts, the slabs can be standard and moisture-resistant. The standard size remains the same: 667X500X80 mm. Often a hollow slab is used for cladding the outside of a room. The weight of a standard hollow slab is 20 kg, moisture resistant - 22 kg. The material properties of hollow slabs are similar to their solid counterparts.

Installation of partitions from Volma slabs

Installation of a partition made of Volma tongue-and-groove slabs is carried out by precise alignment of grooves and ridges on parallelepipeds, followed by gluing them. Any adhesive for gluing drywall, including that recommended by the manufacturer, can be used as an adhesive mixture for Volma tongue-and-groove slabs. Volma-montage" Installation of the partition structure is carried out in the following order:

Partition made of Volma tongue-and-groove slabs. Video instruction

Electrical installation in tongue-and-groove slabs

Electrical wiring in tongue-and-groove slabs is carried out by laying wires in pre-made grooves. The depth of laying the grooves has a limitation: it should not exceed 40 mm for a slab thickness of 80 mm, and 50 mm for a slab width of 100 mm. The wires are secured using alabaster or drywall glue. Planting nests for undercutters should also not exceed the specified depth. Their arrangement is possible in a mirror image on both sides of the partition into a through hole. But in this way the noise-absorbing properties of the structure are lost. For additional insulation of electrical wiring in tongue-and-groove slabs, corrugated tubes are used.

technology for installing tongue-and-groove slabs. Photo

Finishing walls from tongue-and-groove slabs

Like any other building surface, partitions made of tongue-and-groove slabs provide for all types of construction finishing works. The advantage of such a partition is the absence of additional putty manipulations preceding decorative work. The finishing of a tongue-and-groove partition includes: painting the surface, laying ceramic tiles And natural stone and wallpapering.

Laying ceramic tiles on tongue-and-groove walls

The process of laying ceramic tiles on plasterboard is similar to gluing tiles to drywall:

Due to the moisture-absorbing properties of gypsum, finished surface should not be disturbed for three days.

Wallpapering walls made of tongue-and-groove slabs

Before gluing the wallpaper to the tongue-and-groove partition, you should make small finishing Painting works . This may be a thin layer application finished plaster, For example, " Rotband" Or covering the surface with a layer of finishing fine-grained putty. Before applying putty, the surface is treated with a primer deep penetration. After the putty has dried, the surface is ready for wallpapering. It is not necessary to treat the base with soil. Wallpaper is glued to partitions made of tongue-and-groove slabs using standard procedure, with the application of glue both to the wallpaper and to the base of the surface to be glued.

Painting walls made of tongue-and-groove slabs

The tongue-and-groove slab is also painted after finishing surfaces fine-grained putty. After the finishing layer has dried, it is carefully rubbed with a fine sanding mesh under the light of a construction lamp. This is necessary to avoid irregularities and roughness invisible to the eye. The surface to be painted should be treated with a primer and given time to dry. After this, you can apply one or more layers of paint as needed.

Before any type of finishing of the tongue-and-groove partition, it must be thoroughly cleaned and treated with a primer.

Do-it-yourself installation of tongue-and-groove slabs. Video

Interior wall partitions, in most cases, are not load-bearing structures in the house. They must have sufficient strength and good sound insulation properties. The design of the partition should easily withstand internal communications and hanging furniture.

In this article we will talk about tongue-and-groove gypsum (plasterboard) slabs (GGP). This material is used to create interior and apartment partitions. With a competent approach to construction, partitions made of tongue-and-groove gypsum boards (GGP) will meet the requirements listed above. But you need to focus on ensuring that the installation of tongue-and-groove slabs is competent!

If you neglect to comply construction technology, then the installation of tongue-and-groove partitions will end in the fact that instead of a durable monolith, the builder will end up with a shaky and uneven wall, ready to collapse at any moment.

Kruchenkov User FORUMHOUSE, Moscow.

I have a bathroom partition at home made of tongue-and-groove slabs. Apparently, when a hole was made in it for sewer pipe, Something went wrong. Now, if you shake this structure by the edge with your hand, you can hear the blocks hitting each other.

You can find a lot of similar examples on FORUMHOUSE. And if the partition was originally folded contrary existing technology, then the defects can be corrected only by completely destroying the structure.

But don’t be afraid, because the technology for constructing wall partitions from PGP is quite simple. And if you treat it with due attention, the impression of the work done will be very positive.

AlexDo User FORUMHOUSE

I worked at a construction site. The buildings of the old foundation were reconstructed. So, all the partitions were made from gypsum tongue-and-groove slabs, the work was a pleasure. Just right as a partition. Easy and quick to install. The walls are smooth. After puttying, they are ready for painting or wallpaper. The fasteners in the slab hold well. Sound insulation is also normal. But if anything, you can make a lath, lay mineral wool and finish it with clapboard or panels.

A little about the practicality of GPP

Manufacturers of gypsum boards guarantee that this material provides reliable fastening standard elements modern interior. This means that gypsum plasterboard partitions can withstand loads comparable to those on walls made of other standard materials. Wall cabinets, Appliances, stretch ceiling– all this can be easily mounted on a tongue-and-groove gypsum partition. Expand functionality wall partition from PGP it is possible by installing metal-plastic water pipes(with a diameter of no more than 16 mm) and electrical wiring elements.

Grachev68 User FORUMHOUSE

You can also install doors in the tongue-and-groove without additional fittings, install electrics without any problems, and hang shelves and TV more reliably.

Tongue-and-groove slabs - what are they?

Standard PGPs come in two types: solid and hollow. The construction of solid slabs is more durable, but this material is significantly heavier than its hollow counterpart. For this reason it is not recommended

used as part of partitions mounted on the floor with

wooden joists.

Hollow PGPs provide high sound insulation (43 dB) without overloading the floor structure. Some people believe that in internal space Hollow slabs can allow all kinds of insect pests to live and multiply intensively. But such an opinion has not yet found serious confirmation.

Conventional (solid and hollow) tongue-and-groove slabs are used to construct partitions or wall cladding in rooms with dry and normal humidity levels. If the partition is planned to be installed in a room with high level humidity, then preference should be given moisture resistant boards, having a peculiar greenish tint. Keep in mind that such PGPs are slightly heavier than regular solid products.

Preparatory work

List of tools for working with tongue-and-groove slabs:

- Marking cord:

- Hacksaw with a wide blade and large teeth;

- Roulette;

- Putty knife;

- Drill with a nozzle for stirring mixtures;

- Bucket;

- Building level and plumb line;

- Rubber mallet;

- Square;

- Screwdriver.

In accordance with the manufacturers' recommendations, the length of the wall partition made of PGP should not exceed 6 m. Maximum height design is 3.5 m. It is possible to increase these parameters, but the maximum strength of the partition is ensured only if the specified dimensions are observed.

The base for the wall made of tongue-and-groove slabs must be level, stable and completely free of dust. If the floor is concrete and there are differences in it exceeding 3 mm, then before starting installation work it needs to be leveled; create a leveling layer. Suitable for this building mixture based on sand and cement (mortar grade - not lower than M50).

Alignment of the wall from PGP.

Alignment of the wall from PGP.

The solution is applied to a clean, damp floor. To obtain an ideal surface, you can create some kind of formwork and fill it with mortar precisely at a horizontal level. After completely dry the base must be coated with a concrete primer.

If it is possible to do without a leveling layer, then the base under the future partition, as well as the junction of the partition with the enclosing walls, are covered with 2 layers of primer.

If the partition is mounted on a wooden floor, then the base must be reinforced with a strong, even beam.

Kirill147 User FORUMHOUSE

According to the technology of gypsum tongue-and-groove panels, it is required level base– screed or separate non-sagging beam under the partition.

When the base is ready, you can mark the locations of the partitions and doorways. This is done using lacing, a plumb line and a level.

Installation of the PGP can be carried out at temperatures from -10 to +30°C. Construction material Be sure to bring it into the room in advance. This will help him “get used” to the right temperature conditions and will insure the partition from deformation (when the temperature changes, the slabs may slightly change their volume).

Installation of elastic gasket

To ensure that temperature changes and deformation of the load-bearing elements of the building do not lead to the destruction of the partition over time, the structure made of PGP should be isolated from the base and adjacent walls with a special elastic (damper) tape. Damper tape for PGP protects the wall from mechanical damage and increases the soundproofing qualities of the partition. Elastic tape is a special cork backing(at least 75 mm wide), which we will glue to the base and walls in accordance with the markings made. The boards and tape are fixed with the same mounting adhesive.

Consumables intended for installation work ( building mixtures, gaskets, dowels, hangers, etc.) should be selected based on the recommendations of the GGP manufacturer. At negative temperatures installation of the PGP is carried out using a frost-resistant adhesive gypsum mixture.

Glue with a spatula thin layer applied to the prepared surface. The tape is rolled out from above and pressed lightly with your hands. The glue sets within one hour. After this period, you can begin building the partition.

Installation of PGP

The damper gasket under the tongue-and-groove slabs is covered with a layer of assembly adhesive, onto which the lower, first row of the PGP is laid. The plate can be positioned with the groove up or the groove down - it doesn’t matter. But if the groove is at the bottom, then the ridge will not have to be sawed off to make the slab level. It is allowed to install the top row of slabs vertically (if this becomes necessary due to material savings).

When laying the first row, the vertical groove of the tongue-and-groove slab and the base of the floor are coated with glue. Special attention Care should be taken to maintain vertical and horizontal levels. The slabs should be set using a mallet.

The thickness of vertical and horizontal seams should not exceed 2 mm. After installing the next slab in its place, use a spatula to remove excess glue at its joints.

Additional elements for filling gaps between solid slabs, walls and openings are easily cut from PGP using a hacksaw.

The relative displacement of vertical joints in the PGT masonry must be at least 10 cm. This is a prerequisite for ensuring the strength of the structure.

At the intersection of two partitions made of gypsum tongue-and-groove slabs, as well as in the corners, the slabs are laid in such a way that their joints overlap each other. Tongue-and-groove elements that interfere with proper dressing should be cut off with a hacksaw.

After the partition is ready, its outer corners must be reinforced with perforated metal profile and putty.

People often ask whether it is necessary to glue with serpyanka tongue-and-groove partitions. Yes, the inner corners are glued with serpyanka and coated with putty.

Fastening the partition to the wall

The strength of the connection of the tongue-and-groove partition to the walls and base is ensured by the installation additional elements: mounting angles, fittings or hangers. It is more convenient to use mounting angles or hangers. After all, they are attached to the slab using ordinary self-tapping screws, and to the walls using dowels. The slabs of the 1st, 3rd, and 5th rows are attached to the side walls. It is possible more often, but there must be several (at least three) fastenings. A strong base connection is created for every second slab.

During installation, direct hangers can be installed directly into the groove of the slab, having previously cut them to the required dimensions.

Between the top row of masonry and the ceiling of the room you will need a technological gap of at least 1.5 cm. It must be left and foamed polyurethane foam. After drying, excess foam must be cut off and the seam must be puttied. Between the top row and the ceiling, additional fasteners are installed at the same frequency as below.

Creating Doorways

For installing door or window openings, the width of which does not exceed 90 cm, you can make masonry without additional reinforcement. In this case, it is mounted above the opening auxiliary structure from wooden beam, which is removed after the slabs of the top row are laid, and assembly adhesive will grab.

If the opening width exceeds 90 cm, then a wooden or metal lintel should be installed above it. The ends of the lintel should protrude 50 cm beyond the opening on each side. This will ensure even distribution of the load on the partition.

The door (window) frame is attached to the partition using frame dowels and mounting foam.

Inter-apartment partitions made of PGP

Apartment partitions made of PGP, unlike interior partitions, are made double. A technological gap of 4 cm is left between the plates. First, one partition is erected, then the second. In order to enhance sound insulation, the space between the slabs is filled soundproofing material, mineral wool, etc..

Installation of communications

The design of partitions made of PGP allows the installation of hidden electrical wiring. Gypsum boards are strong enough to allow vertical grooves to be made into them and are thick enough to install distribution boxes. Technological cavities inside hollow PGP can be used as horizontal grooves.

If the channel chosen for laying the wire is expanded with a crown with a diameter of 45 mm, then the cable will pass through it without difficulty. The main thing is not to clog it with glue during installation work. side hole slabs

To make it more convenient to pass the wire through horizontal channels, blind mounting holes can be made in the side surface of the partition.

Some doubt the safety of vertical gating of plaster walls. But, according to manufacturers (and the builders themselves), there is nothing to be afraid of.

Partitions made from PGP are used for redevelopment of premises or delimitation of apartments in new buildings. They differ flat surface, ease of installation and low cost. The blocks are connected using a tongue-and-groove system; the seams on the finished structure are minimal. This makes it possible not to putty, but to immediately coat the wall with a primer and decorate it.

Tongue-and-groove slabs for partitions are rectangular elements with longitudinal grooves and protrusions (ridges) at the joints, necessary for a strong and seamless bond. Their standard sizes- 667x500x80 mm, thickness can be 100 mm.

There are tongue-and-groove slabs for partitions large sizes, height from floor to ceiling.

Their installation occurs very quickly, but you cannot cope with it yourself - due to heavy weight A whole team is involved in the installation of building elements.

Types of tongue-and-groove blocks for interior partitions depending on the material of manufacture:

| View | Preparation method | Positive traits |

| Gypsum boards | Made from gypsum with plasticizing additives. Gypsum blocks for partitions are divided into moisture-resistant (green) and those whose moisture permeability is high. | Allowed for installation in children's rooms. Another advantage of gypsum blocks is their ease of processing. Gypsum blocks can be sawn at any angle - gypsum elements can be used to create structures of various shapes and configurations. |

| Silicate blocks | From quicklime and water with added quartz sand using an autoclave. | They have significant sound insulation qualities. Compared to gypsum, they are resistant to moisture and have greater strength and durability. |

PGP partitions can be solid or hollow. The latter weigh less (22 kg compared to 28 for monolithic ones), but cannot withstand hanging massive household items.

Advantages of GGP partitions

The general advantages of partitions made of gypsum or silicone tongue-and-groove plates are:

The use of hollow slabs reduces the load on the supporting base.

The main advantage of such building elements: installation of tongue-and-groove partitions is not difficult. Finished design does not require special finishing work. There is no need to plaster the wall, just cover it with a primer and decorate it.

Installation of partitions from PGP

The installation of partition elements made of gypsum or silicate in the apartment begins after the construction of load-bearing parts, but before laying the subfloor and starting painting and plastering work.

Installation of a partition made of standard-sized tongue-and-groove slabs takes only two to three days. This is due to the convenient tongue-and-groove system and the absence of the need for additional reinforcement.

When docking, any deviations along the planes are eliminated, which allows you to assemble in a short time flat wall without even a millimeter error.

If you need to hide communications, special grooves are made in solid blocks. In hollow ones, wires and pipes can be laid in the internal cavity. If the construction of partitions from PGP does not involve gating, use the method double walls. But they “eat up” twice as much space.

Materials and tools

To build a partition from tongue-and-groove slabs you will need the following set of tools:

- roulette;

- electric drill;

- mallet;

- construction level;

- putty knife;

- hand saw;

- ruler, pencil;

- screwdriver;

- mixer for mixing glue.

The materials you will need are the blocks themselves, a cork or felt seal, edge tape, rope, glue, and primer. Fastening elements are also needed: screws, dowel-nails, fixing brackets - straight hangers or corners.

Preparatory work

The construction of a partition created from tongue-and-groove blocks requires certain preparation. First of all, you need to check the compliance of the floor and ceiling horizontal levels, and make sure that the tongue-and-groove slabs are closely adjacent to them: smooth out prominent irregularities, fill cracked areas and depressions with a mortar of cement and sand.

The blocks are brought into the room no later than 24 hours before installation so that the material “adapts”, that is, has the necessary humidity and temperature.

Used to build a wall acrylic glue based on gypsum.

But it is very expensive, so many people replace it with regular tile adhesive or a solution of cement and sand in a ratio of 1:3 with the addition of polyvinyl acetate glue. If everything is thoroughly mixed, the result is a fairly plastic and finely dispersed mixture that can be easily applied with a spatula. It is easier to make masonry with mortar, since its setting time is longer than that of gypsum glue.

Before constructing interior partitions, all surface areas in contact with them are primed and marked according to the previously created drawing.

Laying tongue-and-groove blocks

It is not difficult to assemble a partition from tongue-and-groove slabs with your own hands. The main thing is not to violate the technology when constructing a bulkhead from PGP.

Installation guide for partitions made of tongue-and-groove slabs - step-by-step instructions:

If the structure of a false wall requires an opening for a door, it is necessary to fix the blocks located on top. When installing one row of blocks over an opening up to 0.8 m wide, it is permissible to install them on a door frame or a non-permanent wooden lintel.

If the width is more than 0.8 m or it is necessary to lay several rows, you will need to install a lintel for tongue-and-groove slabs made of wooden blocks or a metal channel.

It is mounted with glue in specially made cuts approximately 5 cm deep in corner blocks. After the solution has dried, the upper rows of slabs are installed.

After finishing the work, the tongue-and-groove partitions need to be primed. Especially if tongue-and-groove gypsum boards. The primer ensures adhesion of the decorative layer and will avoid the appearance of surface defects.

Any type of wallpaper and painting are suitable for finishing. It is better to finish the kitchen and bathroom tiles or plastic panels. For the living room, children's room, and bedroom, wallpaper or decorative plaster is often chosen.

Remodeling an apartment is a common thing; all that remains is to decide on the material and technology for constructing new walls and partitions. We suggest paying attention to tongue-and-groove gypsum boards - a practical, affordable and versatile material.

Tongue-and-groove slabs and their scope of application

Tongue-and-groove slabs (GGP) are rectangular blocks of gypsum fiber 80 or 100 mm thick. The size of the slabs is standard - height 500 mm, width 667 mm. To strengthen the connection between the plates, their edges are made in the form of grooves and ridges. The technology allows the construction of up to 4 m 2 of partitions per hour.

Standard slabs are used in rooms with normal humidity conditions; moisture-resistant GGPs are used for bathrooms and baths. The plate can be either solid or hollow with horizontal through holes with a diameter of 40 mm. Hollow slab It is distinguished not only by its reduced lightness and thermal conductivity, but when laying slabs in one row, the cross-sectional alignment of the holes is guaranteed to be at least 90%, which allows the cavities to be used as technical channels for laying electrical wiring or pipes.

Preparing the installation site

PGP is universal in use and can be installed in almost any construction conditions. Due to their low weight, they do not require a foundation and can be installed directly on a screed or even on a solid wooden floor.

The only requirement for the location of the partition is that the base should not have a horizontal height difference of more than 2 mm per 1 meter. If the floor in the room does not meet these requirements, then a leveling screed 20-25 cm wide is made.

The surface of both the screed and the floor must be coated several times with a deeply penetrating primer, then dried and cleaned. It is optimal to install the PGP before plastering the load-bearing walls, so finishing coating it will turn out more complete.

Damper pad device

To compensate for thermal expansion and settlement of the building, a tape of elastic material is laid at the junction of the partitions with the floor and walls. It could be rubber Cork tree or silicone tape.

The base is covered with a thin layer of GGP glue and the tape is laid. It takes 6-8 hours to harden, after which you can begin constructing the partition.

Installation of the first row

Installation of PGP is carried out strictly in rows, starting from the bottom. The first row is basic and must be correctly oriented in space, vertically and horizontally. Most common mistake during installation - “waviness” of the partition, which occurs due to a slight displacement in the grooves. To eliminate this phenomenon, when laying each slab, you need to use a rule strip and check against it common plane partitions.

The first row should be laid from the corner. The area where the slab touches the floor and wall is covered with GGP glue, then the block is installed with the ridge up and its position is leveled. Convenient to use for moving slabs rubber mallet. Be sure to fasten the first block to the wall and floor using L-shaped plates, the role of which is successfully performed by direct hangers. To use them, you need to cut off the toothed comb from the edges and bring the thickness of the plate to the width of the comb. The plates are first attached to the base using dowels quick installation from 80 mm long, then to the plate with black self-tapping screws no less than 60 mm long.

Subsequently, the slabs are attached through one side: on one side to the floor, on the other - to the previous slab, with a preliminary coating of the joint with a thin layer of glue and strong pressing. To control the placement of slabs according to the project, it is convenient to use lacing or laser level. It would also be a good idea to mark the partition on the floor and walls indicating the locations for the doorways.

Construction of a partition and adjoining to load-bearing walls

The second and subsequent rows are laid with a seam offset of at least 150 mm. The slab is located strictly in the plane of the partition thanks to the tongue-and-groove connection. It is enough to control the horizontal installation level and lateral tilt. The end plates are attached to load-bearing walls L-shaped plates or reinforcement bars 8 mm thick.

To move the joints and remove the edge of the partition, you will need to trim the additional elements to the exact size. It is best to use a regular wood hacksaw with a thick blade and set teeth. If the partition is not adjacent to another wall, its end can be made perfectly flat by increasing the thickness of the glue in the vertical seam from 2 to 6-8 mm.

Construction of doorways

The vertical edges of the openings do not require additional reinforcement. To lay slabs over an opening with a width of less than 90 cm, it is necessary to build a supporting U-shaped strip, which can be removed after the glue has dried.

Openings 90 cm wide or more require laying on top of a series of support beam slabs - 40 mm boards or 70 mm reinforced CD profile. To reach one level, it is recommended to trim the slabs laid on top of the crossbar. The jumper is placed into the partition at least 50 cm on each side.

Corners and intersections of partitions

At the corners and junctions of partitions, it is necessary to strengthen the masonry. To do this, the slabs are laid across a row, alternately covering the joints. In places where the relaying occurs, it is necessary to remove the ridges; they are cut with a hacksaw into sections of 4-5 cm and chipped with a chisel.

The connection can be further strengthened with sections of straight hangers or welded T-shaped elements made of smooth reinforcement. In any case, additional trimming of the ridge to the required distance will be required.

Top row bookmark

When laying the top row, a greatest number waste due to cutting to the desired height. They can be glued together and placed in voids, since this row of partitions does not experience a strong functional load.

Electrical wiring is usually laid in the voids of the top row, so it is important to prevent glue from getting into the holes. To facilitate cable pulling, you can additionally drill holes or make transverse holes with a diameter of 45 mm.

When laying the top row, it is necessary to maintain a gap from the ceiling of at least 15 mm to compensate for the deflection of the ceiling during settlement. The top row also needs to be attached to the floor of every second slab. Upon completion of installation, the remaining space is filled with polyurethane foam.

Interior finishing options

With the right installation of PGP the curvature of the surface is no more than 4-5 mm per meter of plane. This is an acceptable indicator for wallpapering walls. External corners partitions must be protected with a perforated corner profile mounted on starting putty. Internal corners they are also puttied, strengthening them with serpyanka. The joints between the plates are cleaned with an 80 grit abrasive mesh, then the entire surface is coated twice with a high-adhesion primer.

Leveling walls made of PGP can be done with any finishing putty, but the coating will need to be reinforced with fiberglass mesh. Often, puttying partitions is used only to hide seams; as a rule, the layer does not exceed 2-4 mm. The tiles can be laid directly on the surface of the PGP with preliminary priming.