How to properly install soffits under a roof. Hemming of roof overhangs: subtleties of the process. Additional elements for installation

Read also

The procedure for arranging a roof is not only the manufacture of the rafter structure, direct installation roof covering material and installation of gutters, but also the process of filing its cornice. To do this, the overhangs of the gables and cornices are lined with wooden lining, planed boards, vinyl or metal siding. But today there are more on sale comfortable material for roofing under the name of roof soffits.

The need for roofing

A properly built house requires that its roof extend from the wall at a distance of at least 50-70 centimeters to ensure protection of the façade walls from rainwater. In this case, an overhang is formed in the roofing plane, which is covered with roofing material on top and hemmed underneath. Hemming the roof will not only help give the house a finished aesthetic appearance, but also solve the issue of roof ventilation in the space under the roof or between the insulation and the roofing material. This is especially true when installing the roof of an attic floor.

In suburban housing construction, currently, the majority of roofs are built of two types - mansard and attic. Thermal insulation in the case of a cold attic roof is placed in the attic of the house, in an insulated attic - between the rafters. Since the house is able to “breathe,” moisture vapor from the premises will pass through the insulation, although it should not be retained in the thermal insulation layer. In this case, condensation forms and the properties of the insulation deteriorate.

In addition to reducing the quality of the material, the elements of the subsystem will also suffer from moisture - wooden beams begin to rot, metal parts begin to corrode. Various waterproofing films, but it is important not to neglect the creation of ventilated roof overhangs and the provision of draft for ventilation from the eaves to the ridge.

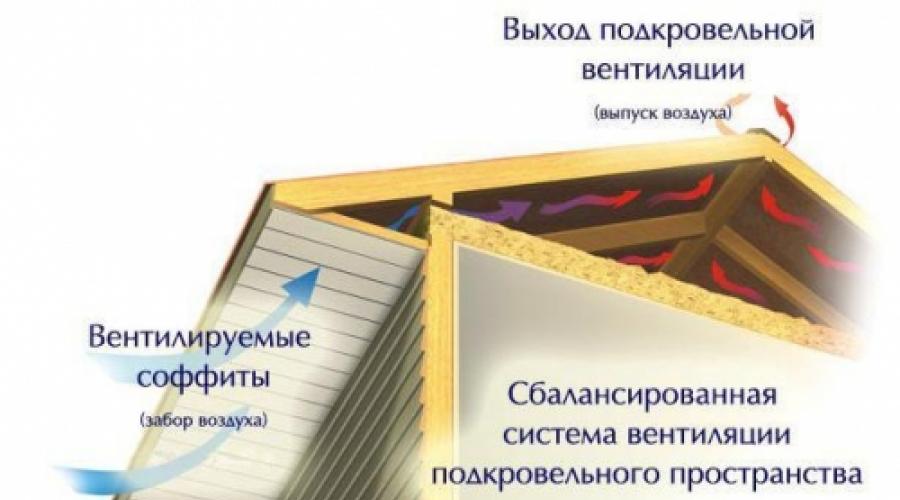

When lining the roof, the soffits are installed with a gap of approximately 10 - 15 millimeters. This will create traction air flow, which enters from the lower eaves into the space under the roof, heats up gradually and rises to the ridge, after which it exits through the ventilation holes. This ensures continuous air circulation and effective removal of moisture, which allows the roof to remain dry. Good ventilation can extend the life of the roof, preventing the appearance of fungus and mold.

It is customary to hem overhangs not only for practical reasons to ensure good traction in the under-roof space. This is also necessary for protection roofing pie from the settlement of insects, birds and rodents, because no one would want to observe such a picture.

Traditionally, roof lining was done using wooden lining. However, you should think about the disadvantages of wood - it needs to be periodically treated with a special solution against rotting and fungus, and tinted. In addition, the lining can absorb moisture and turn black over time, so it is not the best option for lining the roof.

Vinyl siding, which is intended for facade walls, looks unattractive after hemming the roof, and its appearance will only worsen when holes are made for ventilation, which were not provided initially. Galvanized metal siding It is not protected from corrosion, and since it is placed on the eaves overhang, where condensation often accumulates, it has a fairly short service life. Brown rust spots appear on this material very quickly, which is especially noticeable if the color of the roof lining is white or quite light.

Fortunately, progress has not stood still for a long time, and now there are more practical material for roofing - roof soffits, which have good visual compatibility with the roof, facade materials And drainage system, and are also characterized by an affordable price. In addition, the price of roof soffits is affordable.

The concept of soffit for roof lining

IN construction industry Soffits are panels designed to cover various horizontal surfaces that face downwards. Soffits are the same siding or lining, but with a special structure that allows air to pass through and does not interfere with its free circulation, which helps protect the roof from dampness, mildew and mold. It is the presence of perforation that is the main difference between the soffits that are used on outdoors, from other decorative panels.

These panels are attached to the box along the edge of the roof. The panels are joined together with a locking connection, which makes it possible to hide their fastenings. The length of the spotlights is most often 3 - 3.6 meters, and the width is 22 - 30.5 centimeters. Specific roof soffit sizes vary by manufacturer. American and Canadian manufacturers often make a triple profile with a width of 30 centimeters and a length of 3.6 linear meters, which is considered the most suitable for lining the roof. optimal size. Soffits from domestic manufacturers may vary in size.

Before you hem the roof, you need to choose one of three types of soffits:

- Solid. This material is perfect for covering the ceiling of your open veranda, porch or garden gazebo. Thanks to constant access to everyone internal surfaces air roofs, everything open structures will not require repairs within long period and keep a great look.

- Fully perforated, which are recommended for use on roofs that are covered with non-profiled materials, for example, seam or bitumen shingles. Perforated soffits are indispensable for lining protruding parts of the roof: overhangs, cornices, ridges, gables and canopies.

- With perforation in the center, which provides efficient ventilation spaces under the roof. In this case, a composition is formed on the overhang of the cornice with alternating two solid strips and one perforated strip. Regardless of the presence or absence of perforation, the cost of the soffit is the same.

Advantages of soffits for roofing

The undeniable advantages of spotlights over traditional materials their following properties appear:

- Mechanical strength - resistance to damage, shock and precipitation. This ensures constant appearance at home throughout the entire period of use. They do not change their color and do not fade when exposed to sun rays And high humidity and also do not rot.

- Versatility. Soffits can be used to cover indoor ceilings and under-roof space. The wide range of colors of the product allows them to be combined with various types finishing and roofing materials, as in the photo of roof soffits.

- Easy to care for. Soffits do not require updating or painting throughout the entire period of operation. To recreate appearance, they should be washed periodically with water and detergents.

- Impeccable appearance. Soffits can easily hide wiring and various communications, and the locking connection allows you to hide panel fastening joints and facade components.

- Resistance to biological factors. Soffits, unlike facing materials made of wood, are not affected by fungus and do not become moldy.

- Ease and convenience of installation. Installation work Thanks to the use of spotlights, it can be carried out at any time and over a wide temperature range. The products do not crack or corrode at temperatures from minus 60 to plus 120 degrees Celsius.

- Environmental and fire safety. All spotlights are made from non-toxic and non-flammable materials, which allows them to be used in special construction with increased requirements for fire safety and resistance to aggressive influences.

Types of soffits for roof lining

Let's look at what types of soffits exist for roof lining today.

Plastic soffits

The most common type of soffit is plastic, as its price is low. Vinyl soffits have good characteristics- they are wear-resistant, elastic, do not fade, are resistant to sudden temperature changes, are easy to install, finishing the roof with plastic soffit is done with almost no waste. Such products come in white, brown and colored. White soffit is an elegant, calm vinyl material that costs less than colored and brown soffit.

Brown soffits emphasize the character and individuality of the house, because they often match the color of the roof and are highly resistant to ultraviolet rays, since the sun has a stronger effect on dark surfaces. Colored vinyl soffits rank by cost golden mean between white and brown goods. It is often customary to use soffits in combination with siding so that the cornice lining does not stand out against the background of the facade.

Steel soffits

Metal soffits are the most stable material used for overhanging and have a huge selection of colors. They can withstand mechanical loads very well and are often supplied complete with roofing, as they are made from polymers together with metal tiles. The guarantee of such a product, of course, surpasses all its competitors.

These soffits can be perforated or without perforation; lining with metal soffit guarantees your home long years high-quality anti-corrosion protection. White, colored or brown products can be used on open verandas and gazebos in the country. The cost of a metal roof soffit is reasonable for a material of this quality.

Aluminum soffits

Aluminum soffit today occupies a leading position in sales and hemming of eaves overhangs, as it has established itself as a high-tech and practical material at a reasonable price. Soffit panels of this type are used in private construction and original architectural projects.

The light weight of aluminum soffits is a big advantage, which means they are easy to install, allowing you to even hem high-rise buildings. If you have started renovations or decided to give the facade its original appearance and hide defects, then perforated brown aluminum soffits are best suited for this. In addition, aluminum soffit panels do not have the ability to expand at temperature, like plastic.

Copper soffits

A roof covering, the backing of which is made of copper, will last longer than other materials due to the auto-attenuation of copper sheet corrosion and exemplary resistance to aggressive environments - more than 100 years. Such soffits are connected to each other with a lock that hides the fastening points. Perforated copper soffits cover horizontal spaces on the street, and without perforation they are usually installed indoors.

Copper soffits quickly become covered in air with an oxide film, which gives them a characteristic yellowish-red tint. During use, they gradually become brown, and then become covered with a patina due to weathering and acquire a malachite-green hue. Therefore, true connoisseurs of antiquities buy only copper.

The procedure for lining a roof with soffits

Before lining the roof with soffits, it is necessary to insulate the outside walls of the house. This is most relevant for the most common boxes, which are sewn not directly along the rafters, but in a horizontal direction. The key to successful lining of roof overhangs and eaves with soffits is correct measurements, therefore, before you start filing the roof with soffits, make a high-quality drawing that will help you navigate general information and the sequence of actions.

The procedure for installing spotlights itself is considered quite simple, but remember that they must necessarily fit into the overall appearance of the house. The design of the box itself can be individual, depending on the specific roof structure, but there are two most popular options, which include common elements binders:

- Hemming along the rafters, when an angle is selected for hemming that coincides with the angle of the slope. This technique designed mainly for roofs that have small angle tilt, the installation of soffits is carried out on the rafters parallel to the plane of the walls. If the bottom plane of the rafters is not level, it must be leveled to ensure high-quality roofing. To do this, you can screw on the sides of the rafters with screws cutting boards with a thickness of at least 4 centimeters and a length of at least 10 centimeters. First, screw the first and last boards, between which the threads are pulled and the remaining boards are fastened. In areas where the slopes converge on all sides of the corner rafters, boards are fastened.

- The most common solution is when a horizontal box is installed up to the wall from the edge of the rafters; the frame for lining the roof with soffits is made of boards. One edge is attached to the bottom of the rafters, the second - to an additional board, which must be lowered and attached at the point where the rafters and the wall touch. The board at the corners of the convergence of the slopes should be laid flat, because in this place there will be a joint at which the ends of the boards are fastened. Such a joint must extend to the angle of convergence of the walls from the angle of convergence of the slopes, resulting in the formation of a rigid structure independent of the wall. It is recommended to pay due attention to the reliability of the created fastening; it can be done using screws, but it is better to use metal plates and corners.

The installation of soffit panels is carried out on such a sheathing. To secure the spotlight parts to it, you should use self-tapping screws that are equipped with a press washer. To install the first soffit strip, you need to determine the starting point of installation, step back about 77 centimeters from it and horizontally mark a line along the entire perimeter of your house.

The starting strip should be installed directly below it. To do corner elements and arrange the edging, installation of external and internal elements of the soffit is required. Make sure the bottom end is below the edge of the starting strip. It is recommended to fasten corner parts to a self-tapping screw with the upper groove, other self-tapping screws should be installed in the middle part of the grooves. In this case, the openings should be surrounded by edging or platband.

The parts should be joined at right angles. The soffits are installed to the top of the original strip. Soffit parts need to be joined into a lock. Before installation last panel install the finishing strip. Trim wall panel until the desired length is reached and, holding the cut end in the last strip, mount the wall panel. All that remains is to hem the eaves and roof overhangs.

For high-quality installation roof soffits, you need to use nails: start hammering them from the middle part of the soffit panels towards the edges, but not all the way to avoid gaps. Finally, trim the panels using circular saw. The action is carried out in low temperature conditions. For trimming small parts Special metal scissors are most suitable.

Thus, after erecting the roof frame, it is necessary to cover it with soffits. Since this area of the roof is exposed to rain, snow, cold, wind, insects, birds and rodents, it is recommended to choose the covering material very carefully. Thanks to the emergence of such material as soffits, roof lining allows you not only to protect yourself from bad weather and its harmful effects, but also to solve the problem high-quality ventilation in the space between the insulation and the roof.

When the main stages of installation of the floor are completed, you can proceed to not so large-scale, but very important work. One of them is lining the roof eaves. Purpose this stage construction work is to create the final appearance of both the roof and the house as a whole.

Simultaneously with the sheathing of the eaves overhangs, the installation of drains, as well as ventilation systems for the under-roof space, is carried out.

Roof overhang

The roof performs several functions, the main one of which, undoubtedly, is protecting the building from the adverse effects of winds and moisture. It is necessary to protect from precipitation not only inner part house, but also its walls.

To prevent rain from destroying the upper part of the walls and the wind from penetrating inside, the roof is created with an extension protruding above the walls. When used with imagination, overhangs add a unique twist to the design of a building and make it much more attractive.

Overhangs are planned and calculated simultaneously with the design of the roof itself. On the one hand, they increase the amount of load on the walls, and on the other hand, they become integral part and continuation.

When selecting both the shape and appearance of overhangs, pay attention to several circumstances:

- peculiarities climatic conditions region;

- geometric shape of the roof and its angle of inclination;

- size of the foundation blind area;

- roof materials and lining for its overhangs.

The use of certain materials for the roof dictates the choice of a specific type of lining, and this makes some changes in the weight of the entire structure and in the calculation of fastening.

The roof can have two types of overhangs:

- pediment;

- cornice

Gable overhang- these are the edges of the roof that protrude beyond the border of the front side of the building.

He might be like balcony canopy, and an insulated canopy or small overhang located above the entrance or window - this depends on the size of the designed protrusion.

The eaves overhang is installed on the sides of the building on pitched roof. Devices for drainage are attached to it. In this case, often the rafters do not extend beyond the boundaries of the walls, but are attached to the mauerlat.

Very great importance has a water outflow system, since when it gets under wooden beam moisture causes irreparable damage.

Options for drainage designs with weepers or drips, using special gutters or film, protect the roof from rainwater or moisture formed when icicles melt. Windows for ventilation protect wooden parts from rotting and mold.

Overhangs may only be absent on flat roofs equipped with parapets.

Features of the roof lining design

Work on filing the overhangs begins after the installation of the rafters is completed, when it is necessary to lay sheathing along the border of the roof covering.

Before hemming the overhangs, the ends of the rafters should be sawed off clearly along a straight line. At the same time, it is necessary to ensure that this line was parallel to the adjacent wall of the building.

Usually the cornice is hemmed with boards. To achieve aesthetically attractive looking, for different sections of the wall it is necessary to use boards of the same width. The ends of the rafters are cut vertically. The end part is sewn up with hemming in the same way.

Having completed the work of sawing along one line of rafters, it is necessary to nail the first dock of the sheathing on top. It will become a kind of guideline for the next stages of work.

External walls can be insulated only when the work on lining the roof overhangs has been completed. If this sequence of work is violated while working with the cornice, the insulation may be damaged.

Sheathing materials

A wide variety of materials are used for hemming cornices. They all have various properties and appearance, but must certainly meet specific requirements:

- reliably protect the eaves of the roof from frost and moisture;

- provide insulation;

- protect from precipitation;

- allow ventilation of the under-roof space.

In addition to the listed qualities, it is necessary that the material retains all its properties for as long a period of time as possible.

Corrugated sheeting– This is galvanized steel coated with a layer of polymer material. Today the market is overcrowded polymer materials different colors.

This material is quite rigid and resistant to mechanical stress, wind and other loads, and sudden temperature fluctuations.

Ventilation of the corrugated sheeting is carried out through a gap equal in size to the height of the wave. You can also make the panels yourself, but be guided by their width.

This will significantly reduce the amount of time spent on installation and the cost of filing.

Soffits are special designs created to facilitate the work of filing cornices. They consist of a plank and a finished frame.

Soffits are special designs created to facilitate the work of filing cornices. They consist of a plank and a finished frame.

These plastic panels They are most often used for hemming overhangs. Externally, the soffit is similar to siding. The difference is the presence of a thicker layer of plastic in the soffits and special perforation, the purpose of which is to allow air circulation under the roof.

An obvious advantage of spotlights is the presence of special substances in this material - UV stabilizers, thanks to which they are reliably protected from the adverse effects of sunlight.

Soffits are manufactured according to the customer’s taste from materials such as copper, aluminum, galvanized steel with polymer coating, polyvinyl chloride (or PVC plastic).

Each type of spotlight has special advantages.

Copper soffits very attractive in appearance. Over time they become even more presentable as a result of a natural patina.

Copper soffits are fire resistant and have high level strength. In addition, they do not require maintenance and have a long service life.

Minus of this material is relatively expensive, since copper soffits are made of steel using a special technology for applying a layer of copper - patination, coating with an oxide film, tinning with tin.

Aluminum soffits very light, elastic, fire-resistant, retain their shape during temperature fluctuations, and do not lose their saturation after prolonged exposure to the sun Brown, they are easy to repair. Available only in brown and white.

Galvanized soffits have a high level of moisture and fire resistance, do not require maintenance or processing, and do not change shape under the influence of high temperature, very durable, withstands temperature changes well, does not lose color (has a wood-like color). The disadvantage of this type of spotlight is its significant weight.

Vinyl soffits inexpensive, very light and comfortable, highly resistant to corrosion. However, they are impractical because they expand when heated, are a fire hazard, are not very durable, and also emit when heated. toxic substances. Available in different colors.

All spotlights are very convenient and easy to install. Even beginners can assemble a binder from them. However, some aspects of work require professional advice: when it is necessary to adjust right size, choose a complex configuration or lay out an intricate angle.

Soffit panels are cut along the length of the roof overhang, and they are installed perpendicular to the wall, and not along it.

Regular lining made of wood is used outdoors, as a result of which it is exposed to extreme climatic conditions. Therefore, the choice of wood must be taken very seriously.

When purchasing lining, you need to pay attention to the thickness: you should not purchase material that is too thin.

Another significant point is humidity. The wood should be of medium moisture content: very dry or wet material is not suitable.

The optimal choice is lining that has been stored for at least a month in the open air, the humidity of which is equal to the humidity of the external environment.

Edged and planed boards 1.5-2 cm thick enable uniform and high-quality air ventilation throughout the entire under-roof space.

When stuffing this material, maintain a gap of 1 to 1.5 cm.

Important point: when used wooden filing you need to take care of the ventilation system yourself, while the soffits are produced perforated, moreover, to varying degrees - partial, full or in the center.

The device of the filing and its features, the frame for filing

There are two types of overhang lining.

In the first version, the firmware is performed directly along the rafters. Choosing this option is advisable when there is a not very steep slope or when it is necessary to increase the height of the building.

For this method binders are needed to Bottom part all rafters were located in the same plane. When the rafters are in different planes, alignment is carried out using additional boards.

They overlap on the rafters. After this, the first and last plank, between which threads are pulled, which later serve as a level.

Then all other planks are installed required material. With two-way convergence roof slopes Installation of rafter boards is carried out on both sides. Typically the length of overhangs is 600 mm.

The second method is more popular. All rafters used are cut horizontally and vertically. A board is fixed at the bottom of the rafters, and a beam is attached to the wall.

It is located 1 cm above the frontal board in order to allow moisture to drain away.

When the width of the overhang is more than 450 mm, it becomes necessary to install an additional board in the middle. When the roof slopes converge in one place, the board is nailed from the corner of the house to the corner of the roof.

In both cases, the roof overhang box is installed in the same way: along the wall along the gable, the board is nailed onto the sheathing, then a distance is separated from it that corresponds to the width of the overhang, after which the board is nailed parallel to the gable wall.

Installation of corrugated sheeting

Roof overhangs are hemmed with corrugated sheeting in the following way. The material is screwed to the frame along the eaves line (parallel to the wall) using screws.

At the junction points of the corrugated sheet and the wall, a frontal strip and an internal corner are installed. The plank is screwed to the front board, and the inner corner is screwed to the corrugated sheet.

The outer corner is secured along the external joints of the material. Corrugated sheeting along the pediment is installed along the walls, along the outer edge of the overhang.

Then the end strip and corners are fixed. For ease of installation and ventilation, the width of the corrugated sheet should be 2 cm less than the width of the overhang.

A J-bar is used to install the soffit to the base. It is secured along the cornice and wall with screws.

Between the slats are soffit sheets. They are cut to a length that is equal to the distance between the J-shaped planks minus 6 mm (designed for thermal expansion).

In this case, if the overhang size is more than 900 mm, 6 mm should be subtracted from both sides. The frontal plate must be covered with a frontal strip.

So

- The function of roof overhangs is to protect against the effects of adverse factors and give the house a more attractive appearance.

- The choice of sheathing depends on climatic conditions and roofing material.

- Overhangs can be pediment or cornice.

- Before starting work on hemming the overhangs, the rafters must be cut.

- Many materials are used for hemming, but the most good choice are the soffits.

- Overhangs are hemmed in two ways.

- When installing corrugated sheeting, a certain sequence of actions must be followed.

Video instructions for installing spotlights:

The roof of a house is a complex, multi-layer structure, the reliability and thoughtfulness of which determine the comfort of living and the durability of the structure. It protects from cold, precipitation and wind. The process of constructing a roof today is very different from the same process some 50-70 years ago, since construction market During this time, I increased the range of salted tools and materials, which significantly simplified the work. Such inventions that help in the difficult task of erecting a roof include soffits and panels used for lining cornices. In this article we will tell you how to install spotlights yourself.

Soffits are panels used for lining cornices, ebbs, overhangs, with partial or complete perforation. In appearance, they resemble regular siding, but have a width of up to 80 cm, which speeds up and simplifies the DIY installation process. Soffits are made from many materials: plastic, galvanized steel, aluminum. By appearance they distinguish the following types products for roof lining:

Important! When choosing soffits, first of all pay attention to the width of the panels. IN construction stores There are models with a size of 30-80 cm. Please note that the wider the soffit, the faster and easier it is to do the filing yourself. It will be more convenient for an inexperienced craftsman to work with vinyl panels, since they are easier to cut and also have less weight.

Installation methods

Installing spotlights is enough simple work, which even a novice builder can handle with his own hands. For installation you will need full set fastening profiles, hacksaw or sharp knife, self-tapping screws, a screwdriver, a marker, a ruler, and also a ladder, since the work is done at height. There are two common methods:

Note! A three-meter soffit in retail stores costs 250-600 rubles, this amount is affected by the material, width and country of origin of the product. In addition, for filing you will need a set of guide strips, which can double the announced amount. The average cost of soffit installation services is 300-350 rubles per linear meter, so by doing the work yourself, you can save a significant amount.

Installation technology

Attaching soffit panels to a gable or eaves overhang is simple technological operation, which is executed after completion roofing works, but in front of the gutters, as they make access to the installation site difficult. Instructions for filing roof structural elements from the inside are as follows:

Important! Vinyl soffit undergoes a linear fluctuation in size with temperature changes environment. When it rises, they expand slightly, and when it gets colder, they contract. Although these fluctuations are quite insignificant and do not exceed 1-2 mm, experienced craftsmen It is recommended to avoid rigid fastenings during installation. When tightening the screw, you need to stop and leave a gap of 1-2 cm so that the soffits do not deform when changing the size.

When choosing a material for lining overhangs, you need to remember that soffits are lightweight, easy to install and provide ventilation rafter frame roofing structure. The ability to freely pass air, but prevent the penetration of moisture, is the main advantage that distinguishes this type of panels, which literally prolongs life wooden rafters and thermal insulation material, preventing the spread of fungus, mold and rot.

Video instruction

12362 0 1

Competent filing of the roof eaves - choice of 3 options and step by step guide

The facade of the house will never look finished and neat if the roof overhangs are not trimmed. Now there are different variants development of this sector. Based on the extensive experience of the practitioner, I have chosen the 3 most popular types of cornice cladding and then you will find out why most owners prefer them, and at the same time we will step by step analyze the installation process with our own hands.

Why hem the cornice?

The aesthetic component of the cladding is, of course, important, but in addition to it, eaves overhangs also perform an important practical function:

- In the vast majority of roofs, it is now customary to insulate, and if the roofing cake is not covered along the edge with a frontal strip, then it will remain defenseless against the vagaries of nature and will begin to actively deteriorate, especially for insulation;

- The frontal board, which covers the frontal strip and is also considered part of the cornice structure, is the basis for the ebb system; in most cases, the ebbs are attached directly to it, it’s easier;

- Ventilation of the under-roof space proceeds from the bottom up; accordingly, in sloping roofs, the air enters through the eaves overhang and exits in the area of the ridge. A well-designed eaves overhang plays the role of a kind of filter, preventing debris and excess moisture from entering under the roof;

- And finally, birds, insects and other living creatures often build their homes under the roof, and by covering the overhangs, you extend the life of your roof.

What is the difference between a gable overhang and a cornice overhang?

Such structures are divided into pediment and cornice. Each of these overhangs performs its own function:

- Cornice called horizontal overhangs, which originate from the lower section of the roof. Their arrangement is considered the most important, since this is where the air comes in to provide under-roof ventilation;

- Gable overhang- this is the lower inclined sector of the roofing pie, bordering the gable of the house. It does not take part in ventilation and the sheathing is needed here only for beauty and to protect the insulation from living creatures.

Pediment overhangs can only be in those roofing structures, where there is an inclined cut of the roof plane, for example, gable roofs. Hip, hip and other closed rafter systems have only eaves overhangs.

Three options for finishing materials

In reality, there are many more such options; we took only the most popular ones, plus even in popular directions there are differences in models and types.

Option No. 1: wooden overhangs

Until recently, wood was the most common material. beauty natural wood is indisputable and the sheathing is installed quite easily. The only downside is the need for good wood impregnation. The line includes lining, as well as hemmed and edged boards.

| Illustrations | Recommendations |

|

Lining.

The main advantage of such planks is the convenient tongue-and-groove connection. There is a tenon on one end and a groove on the other. Thus, the cornice finished wooden clapboard, there will be no cracks or gaps. |

|

Hemming board.

This board has a peculiar shape, its ends are beveled at an angle, which allows you to equip the surface without visible cracks.

|

|

Edged board.

This is the simplest option. Edged board can be stuffed flat with small ventilation gaps between the slats, but it won't be very nice. Or sew up the cornice with a herringbone pattern, as in the photo on the left, although in this option you will have to leave special gaps for ventilation. |

Option No. 2: soffits or siding for eaves

Covering eaves with siding is now breaking all records of popularity. To be precise, eaves siding is usually called soffits. Such planks differ from conventional siding by the presence of ventilation meshes or grilles. Otherwise, both the material and the installation of soffits are similar to the arrangement of siding.

| Illustrations | Recommendations |

|

Copper soffit.

Copper soffit with correct installation will last longer than the roof itself. Copper does not need to be painted or impregnated with anything, it is good as is. The only problem is that copper soffits are very expensive. |

|

Aluminum.

Aluminum soffits are just as durable as copper ones. Plus, these planks are powder painted, which means the color can be matched to any façade. True, the price of aluminum soffits is not much lower than copper ones. |

|

Cink Steel.

The price here is average, plus galvanized soffits are also painted and if they are not scratched, they will last a long time. |

|

Plastic.

Vinyl soffits can be called the best option. They are light, not afraid of moisture and the most affordable. The main thing is not to buy cheap models, as they change color over time. |

Option No. 3: profiled sheet

Finishing with corrugated sheets is not much different from covering eaves with soffits; they are even visually similar. Moreover, the corrugated sheet is made from the same galvanized and painted metal as steel soffits. Only the dimensions of these sheets are much larger and there are no ventilation meshes on them. They will have to be arranged separately.

Overhang installation technique

Installation of overhangs is carried out after the roofing pie is completely arranged. It is desirable that the wall decoration is also finished, but this requirement is not necessary.

Types of structures

Sheathing of overhangs can be carried out in 3 options:

- Under the rafters;

- Using hanging fillies;

- Tied to the wall.

| Illustrations | Recommendations |

|

Sheathing parallel to the roof.

Roofs with a small angle of inclination, usually up to 30º, are covered under the rafters. Fewer calculations and measurements will be required here, but it is important that all rafter legs are of the same thickness and located on the same plane. |

|

Hanging fillies.

Box designs are more common. According to the rules, it is necessary to equip the fillies as in the diagram on the left and attach the lining to them. |

|

Snap to the wall.

This installation is much simpler than the previous one, but it is impossible to sheathe overhangs using this scheme wooden houses, since during shrinkage they may warp or even collapse. |

Installation of end and front boards

- Installation should begin with trimming to level rafter legs and under-roof sheathing strips. To do this, stretch the cord between extreme points and everything is trimmed according to it;

- The end board is nailed along the sloping edge of the roof. It will become a limiter for installing a gable overhang;

- Under the front board, the edges of the rafter legs must be cut strictly vertically, but before installing it, first a strapping or hemming board is nailed and only then the front board is attached to it;

- The dimensions of the hem board should be about 20x150 mm. The end and front boards are taken thicker, from 30 mm.

Arrangement of spotlights

It doesn’t matter what material the soffits are made of, their installation technology is the same. From the material we will need a J-chamfer, a J-profile, a finishing profile and the soffits themselves.

There are 3 schemes for arranging a cornice with soffits, we will take 1, since it is cheaper.

| Illustrations | Recommendations |

|

J-profile.

We measure the J-profile. Outer and inner corner in gable roof are the same, in other roof structures they need to be measured separately. |

|

cutting.

Soffits and profiles are easier to cut with a grinder. |

Construction of a roof is a labor-intensive, lengthy process that is not completed after installation of the roofing material, but only enters its finishing phase. After completion of the main work, follow Finishing work, bringing the appearance of the house to perfect condition, these include finishing cornices and filing overhangs.

Previously, these operations were carried out using clapboard, siding or cutting boards, materials not intended for this, which complicated the task for builders. However, since roof soffits appeared in stores, it has become possible to hem overhangs efficiently and quickly.

Advantages of spotlights

Before the advent of soffit panels, overhangs were hemmed using other non-specialized materials; usually, everything that was left over from construction was used: cutting boards, lining or siding. However, finishing with soffits has huge advantages:

Previously, craftsmen who understood the need for perforation in the overhang lining material tried to do it with their own hands by drilling holes in the siding panels, however, such finishing looked sloppy and “artisanal”.

The need for perforation in finishing overhangs

An overhang is a section of the roof slope that protrudes 50-80 cm beyond the perimeter of the structure; it serves to protect the surface of the walls from moisture. Outer part the overhang is covered by roofing material, protecting it from getting wet, and the lower part without lining the soffits remains vulnerable. However, it is impossible to seal the overhang tightly, as this will violate natural circulation air flows inside the roof space. This is especially true for thermally insulated heated attics, in which it is not possible to install dormer windows.

Air circulation in the attic occurs according to the laws of convection, that is, more warm air rises to the top, freeing up space for cold air. Without normal ventilation, condensation accumulates in the thickness of the roofing pie, leading to rotting, mold and destruction rafter system. To avoid such problems, the overhang is hemmed using perforated soffits, through which fresh air enters the attic. atmospheric air, and aerators are installed on the roof.

Soffit perforation

Roof soffits consist of panels of varying degrees of perforation with a lock used for fastening. Standard length such products are about 3 m, and the width varies depending on the manufacturer within 20-30 cm. The following types of soffit models are produced:

To choose the right soffits, you need to consult an experienced roofer, so only professional master can calculate correct degree perforation of panels corresponding to specific ventilation system, which will provide air flow through the overhang into the attic or attic.

Materials

The plastic type of soffit is a panel made of polyvinyl chloride, equipped with a lock and perforation. This is the most cheap material, which can be found to hem an overhang. Variously colored models are matched to the color of the facades or roofing material. In order not to disturb the integrity of the appearance, siding of the same shade for finishing the pediment is purchased along with the soffits for lining the overhang and cornice. The most popular is the cinnamon-colored plastic soffit, which harmoniously combines with the dark shades traditional in Russia.

The panels are made of steel, aluminum and copper. However, a common problem more affordable steel and aluminum panels is that they are susceptible to corrosion to varying degrees. If galvanized steel enters into oxidative reactions only when damaged outer covering, then it is possible to protect aluminum from water only with the help of a special composition. Oxidized copper soffits do not have problems with corrosion, however, not everyone can afford the installation of such expensive fittings.

Installation methods

Sheathing of overhangs begins after the completion of the main roof installation work, when the slopes and walls of the attic have already been insulated. It is more convenient to install the soffits before so that nothing interferes. There is nothing complicated in this process, so you can slowly get to work with your own hands. Hemming of overhangs is carried out in two different ways:

Filing is a painstaking process, the main thing in which is accuracy and precision of measurements. High-quality soffits will protect the overhang from moisture, mold, insects and birds, without restricting access fresh air into the under-roof room.

Video instruction