How to properly cut wood with a hacksaw. How to properly cut a log on a band sawmill. Features of cutting round and oval elements

Read also

If you are going to do any construction or carpentry work, then at some stage you may need to cut something out of plywood. However, plywood sheets are usually quite large and quite difficult to saw, especially in the absence of special tools. But if you remember a few basic rules, you can easily cut plywood with a simple hand or circular saw, also called a circular saw. The main thing is that the blade of your saw is sharp, and plywood sheet maintained a stable position.

Steps

Cutting plywood with a hand-held circular saw

- Working with a circular saw is dangerous. Be sure to wear safety glasses and keep your fingers away from the blade.

- Follow power cord from the saw when you work with it. Keep work area clean.

-

Cut the plywood. Support the sheet securely and make sure it is pressed well against the guide edge of your table saw. Use both hands to feed the sheet onto the running saw blade.

Select correct type blades. To achieve an even cut on plywood, for circular saw the correct type of blade must be used. Look for a carbide blade with big amount teeth

Set the saw to the correct depth of cut. Before cutting the plywood, adjust the depth of cut on the saw. If the depth of the cut is too large, the saw blade will be pulled through the cut point once again. If the cutting depth is too small, then you risk not cutting the plywood to the end.

Provide support for the plywood sheet. When cutting plywood, it is very important to support the plywood sheet on both sides of the cut line.

Saw the plywood face down. To cut plywood with a hand-held circular saw, it must be laid face down. In this case, the saw teeth will enter the base of the plywood from the front side and exit from the back side. When the saw teeth emerge from the plywood, they can tear the edge of the cut a little. Therefore, laying plywood face down will ensure a neat cut line on the face of the sheet.

Pre-mark the cutting line. Use a large ruler to mark your cutting line. Place your marks carefully and make sure to draw a line at right angles to the edges of the plywood sheet.

Use a guide when cutting. Find a piece of plywood that still has a straight factory edge and lay it over whole sheet plywood parallel to the cut line and secure with a vice.

Cut the plywood. Place the saw against the guide and double-check that the blade is aligned exactly with the cutting line. Turn on the saw and guide it with the shoe along the guide. Try to make the cut as straight as possible.

Creating a slot on a sheet of plywood using a hand-held circular saw

Provide the plywood sheet with reliable support. Place a sheet of plywood on top of several 5x10cm beams supported by a pair of sawhorses. The entire sheet of plywood must receive reliable support.

Set the correct cutting depth. Lower the saw blade until the depth of cut is only 5 mm greater than the thickness of the plywood being cut. This way the saw blade will only barely penetrate the thickness of the wood from the bottom side.

Stand to the side of the direction of the saw. When making a cut in plywood, there is a high risk of kickback in which manual Circular Saw is thrown sharply forward in the direction of rotation of the blade. Never stand directly in front of the saw while making a cut.

Set up the saw to make the desired cut. Place the front side of the saw shoe against a piece of plywood. Carefully lift protective cover saw and align the blade exactly along the intended cutting line.

Make sure the underside of the sheet is clean. When you cut, you won't be able to see what's underneath the leaf. Therefore, it is wise to make sure that there is nothing superfluous below before starting work.

Place the running saw into the plywood. Turn on the saw and slowly lower the blade into the wood. Hold the tool firmly to prevent kickback.

For the manufacture of various elements the design of the bathhouse will be useful not only in the ability to properly cut a log, to be able to cut it or build it up, but also to cut various wooden parts- boards, bars.

Depending on the situation, sawing can be done along the wood fibers or across them. To ensure a fairly even cut, it is advisable to securely secure the material in a clamp.

The cutting line is preliminarily marked by marking and only after that the cutting begins.

If the material being cut is securely fixed in a horizontal position, then saw while holding the saw with both hands. If the material is not secured too securely or is located vertically, then saw right hand, and hold the material with the left.

The marked marking line should always be to the left of the cut.

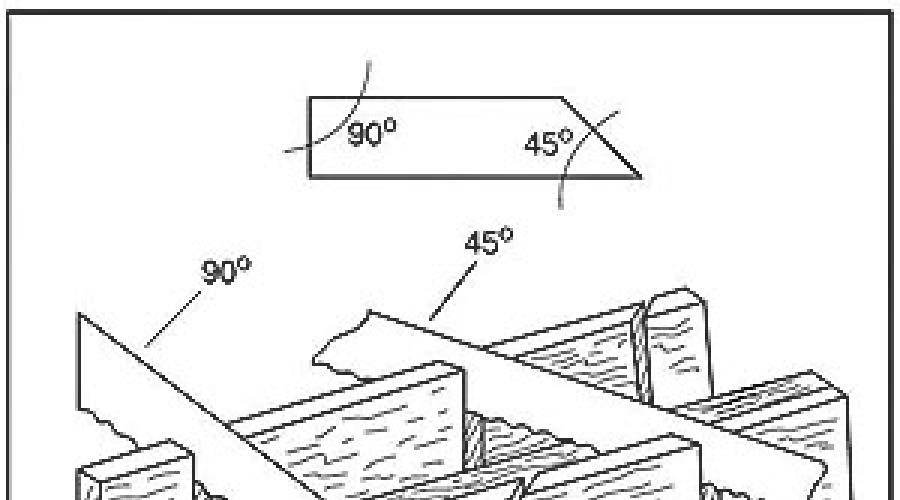

If you need to cut a board or block at an angle, it is convenient to use special device in the form of a box with guide grooves in the walls. This device is called a miter box.

You can make a miter box yourself. To do this, it is enough to connect three strong boards so that one serves as the base, and the other two act as side walls with cuts made in them, as shown in the figure below.

Miter box various types today they offer the most various manufacturers construction tools. The photo below shows the Stayer miter box.

Depending on the thickness of the material being cut, the angle of inclination of the saw blade to the plane of the material is selected. The more thin material- especially sharp corner the cutting edge should form hacksaw blade to the plane of the material being cut and vice versa.

For cutting along a curved line, special circular saws are used. A circular saw is distinguished by a narrow blade and such sharpening of the teeth that it allows cutting along complex curved lines, which is almost impossible to do with a conventional hacksaw.

For cutting along a curved line, special circular saws are used. A circular saw is distinguished by a narrow blade and such sharpening of the teeth that it allows cutting along complex curved lines, which is almost impossible to do with a conventional hacksaw.

For sawing large quantity It is more convenient to use modern hand-held electric and chainsaws for cutting boards. This saw does not require significant physical effort and allows you to quickly make an even cut.

You can see how to use a chainsaw in the video below:

Now you know, how to cut boards and bars correctly. In the following articles we will learn how to plan boards correctly and how to make a groove.

Latest publications:

Even laid out correctly brick oven, repairs are required over time. High temperatures, traction disorder, mechanical damage masonry - all this leads to the appearance of defects that require elimination. After all, good traction and the absence of cracks in the walls are... Read...

The general theory of sawing with a hacksaw looks something like this:

Looking at this picture, you may suddenly feel sad, so further presentation of the material will be based on solving the problems that arose during the recent accident practical application(V economic theory this is called learning-by-doing) this ancient instrument and appropriate metal cutting technology.

So, let's start with the fact that you need to cut metal with a hacksaw horizontally, grasping the instrument with both hands. Why it would be good to use a hacksaw with a well-defined handle for gripping with the second hand.

In this video, the entire story about how to saw is presented, but now a postscript will present a number of additions and amendments (plus brief retelling video content).

Sawing horizontally is inconvenient because it requires the workpiece to be secured at chest level, and sawing while standing. However, workbenches, as a rule, are tables at which you need to sit, and if you cut, then stand up and from top to bottom. Therefore, hacksaws are often made one-handed and sawed with them. at an angle of 45°.

To adjust the pressure on the saw(the harder the metal, the more you need to load the blade, put pressure on it so that the teeth bite into the flesh; and vice versa - if the teeth cut too much, for example, into aluminum, then you need to reduce the pressure) you can: a) change the angle of inclination when sawing, b) put your hand on top to increase the weight, c) turn the blade with its teeth back.

Drank often gets stuck in the cut when reaching end of the canvas. This is due to the fact that the blade has a wavy set of teeth (so that the cut is wider than the blade and it does not get stuck in the cut), but over time, the amplitude of this wave decreases in the center of the blade, and almost none at the ends.

This distortion arose due to sawing with this blade not of its entire length. It is no longer possible to correct this (increase the spread in the center or decrease it at the ends), due to the fact that the teeth are hardened. So morality: From the very beginning of using a new blade, you should always saw along its entire length.

This distortion arose due to sawing with this blade not of its entire length. It is no longer possible to correct this (increase the spread in the center or decrease it at the ends), due to the fact that the teeth are hardened. So morality: From the very beginning of using a new blade, you should always saw along its entire length.

Next problem: if you cut thin sheet metal, whose thickness is less than the distance between the teeth, saw gets stuck:

If the metal is hard (iron), you can barely move it, but if it is soft (aluminum), a huge piece of metal is torn out, torn edges are formed, and the edge bends.

If the metal is hard (iron), you can barely move it, but if it is soft (aluminum), a huge piece of metal is torn out, torn edges are formed, and the edge bends.

Saw at an angle to form a cut of such length that at least two teeth lie on it at the same time (cut length ≥ two distances between teeth).

Saw at an angle to form a cut of such length that at least two teeth lie on it at the same time (cut length ≥ two distances between teeth).

Next topic: sawing thin-walled aluminum pipe:

We install the blade with the teeth backwards, twist the pipe in the direction of the teeth (otherwise the blade will get stuck on the near edge of the cut, and if force is used, it will tear).

We install the blade with the teeth backwards, twist the pipe in the direction of the teeth (otherwise the blade will get stuck on the near edge of the cut, and if force is used, it will tear).

Well, and even before the heap... the blade of a hacksaw for metal can be restored, sharpen teeth, for example, like this:

Initially, this diamond disk was larger in diameter and this drill with this disk, being pressed in this way to the blade, was positioned strictly parallel to the line of the teeth of the blade, and the disk, accordingly, was perpendicular. And this was correct - the front edges of the teeth on the new hacksaw are orthogonal to the blade. Now a small negative angle is formed... - a little less better, but still normal.

Initially, this diamond disk was larger in diameter and this drill with this disk, being pressed in this way to the blade, was positioned strictly parallel to the line of the teeth of the blade, and the disk, accordingly, was perpendicular. And this was correct - the front edges of the teeth on the new hacksaw are orthogonal to the blade. Now a small negative angle is formed... - a little less better, but still normal.

How to properly saw with a hacksaw for metal

5 (100%) 20You should always cut with outside cutting, close to marking line. This applies to both rough cuts with a hacksaw and precise cuts with a fine-toothed saw. Next, it is very important that the workpiece being cut has a stable support in the form of a workbench table top or a regular work table. For large-sized workpieces, it is better to use sawhorses. During the sawing process, the part must be held firmly with your hand at all times (for large-sized workpieces, also with your knee) - in other words, only the saw should move.

Sawing begins with the first short movements at an angle of 30 to 45 degrees. Only after the saw blade has entered the wood and is fixed in it, you can start working with the saw along the entire length of the blade.

At the edge of the cut, cut only in short, sharp strokes. This will avoid breakages on the underside of the workpiece.

Cutting along the wood fibers is always a “critical” situation, especially if the wood has a large grain. Saw naturally wants to follow the path of least resistance, and if it is not restrained, it will begin to “walk.” That is, in such cases you have to press the saw harder than usual, which, in turn, requires the most stable position of the workpiece.

When making large cross cuts, a regular hacksaw can jam. In such cases, it is better to use a rip saw with widely spaced teeth. You just need to take into account that the cut strip will be much thicker than the saw blade.

How to protect your saw from damage.

Any saw (especially its teeth) should not come into contact with other tools during storage. Such proximity can quickly cause it to fail.

If the saw does not have a cover, then a simple method will help protect its teeth from damage. A slot of the required length is made in a piece of hose, after which the hose is placed on the saw blade. A rigid hose covered with fabric on the inside is best suited for this purpose. It holds tightly to the saw blade even after repeated use.

Tsulaga.

When sawing small workpieces, the tsulaga shown in the pictures below can be of great help.

To make it, you will need a piece of wood slab measuring approximately 20 x 30 cm and a thickness of 2 mm, as well as two planed strips, which must be fixed to the slab as shown in the figure. To prevent the slab from bending and breaking, the planks must be positioned transverse to the direction of its core layer.

The lower bar of the tsulaga rests against the edge of the tabletop and thus sets the correct direction for the cut; the shortened upper bar ensures good centering of the saw.

If you have to saw long boards or planks, then a second tsulaga will not hurt, which will serve as a stop for the other end of the workpiece.

Choice of residence, Big city or the countryside, also means a choice of lifestyle. And if a city dweller can only complain about old trees threatening to fall from any wind, then a resident of the suburbs or rural areas Most likely, you will have to learn how to cut trees with a chainsaw and, of course, control this tool.

With a chainsaw you can easily and quickly not only cut down trees, but also saw them into boards or logs.

On modern market The range of saws is quite wide, but in order to make the right choice, you should decide on the amount of work that will have to be done and its regularity. If the purchase is made by a non-professional lumberjack, then the need to purchase a professional segment tool does not make sense. Besides the fact that its price is quite high, for the most part it will simply sit idle, being used a maximum of one to three times a year. A professional tool designed for continuous operation during normal work shift, that is, 6-8 hours. Perhaps, only in one case will the costs of purchasing a professional chainsaw be justified, when it is necessary to clear the area for construction from trees.

Of course, on suburban area sometimes it becomes necessary to get rid of several old and dry trees and for this you can invite specialists, but if the owner of the site prefers to do this on his own, then the most optimal choice- semi-professional instrument. According to their own functionality it is comparable to the corresponding professional models, but a semi-professional chainsaw cannot be used long time without interruption, the engine may overheat.

The so-called “household” models of chainsaws that do not have high power and resource and intended for simple work. With their help, it is easy to prepare firewood for the fireplace and sauna or trim branches in the garden. Among the advantages is ease of use due to light weight, simple controls and service.

Operating rules and safety precautions

But before you start working, you should not only learn how to cut trees correctly, but also master the rules safe operation chainsaws. There are no trifles when working with this tool: both its technical condition and the level of skill of the lumberjack are important.

The first thing you should do is carefully study the operating instructions and safety rules. You should definitely buy personal protective equipment. You will need comfortable shoes with non-slip soles, thick protective clothing, preferably overalls, goggles, and gloves. You should also think about ear protection. Special headphones are designed for this, but ordinary earplugs can also save the situation.

When working, the chainsaw should be held firmly with both hands, while being at the side of it, but not behind it. The legs should be approximately shoulder-width apart: this makes it easier to maintain body balance; one should not forget about the back, it should be straight, but without tension. If you need to relocate during work, then the chainsaw must be put on the brake - such a precaution will avoid injury. It is forbidden to cut down trees in windy weather: in this case, the calculated and actual directions of the tree's fall may not coincide, which is fraught not only with operational problems, but also life-threatening.

Return to contents

Checking the technical condition of the chainsaw before starting work

Before starting work, it is mandatory to check technical condition tool. Special attention You need to pay attention to the chain: it must have the necessary tension and be properly sharpened. The fact that the chain is correctly tensioned can be judged by the following sign: when pulling it away from the upper bar, the guide teeth lie exactly in the groove. In this case, the chain should stretch easily; if necessary, adjust the tension. This action is recommended to be carried out regularly, and when replacing or adding oil, it is mandatory.

It is also necessary to check the condition of the inertial brake; in its normal position, its handle does not touch the handle. If the brake moves, the chain may fall out. It is also important to remember this rule: you should always start sawing wood or wood only with the edge of the tire.

Tree cutting is not only complex look work, but also very dangerous.

A falling tree can become a threat to both people and objects located along the line of its fall. Naturally, there should be no people or animals where the work is being done. The only exception is the participants of the work. It should be borne in mind that it is almost impossible to cope with such work alone, so the help of at least one person will be required.

All work zone should be loose enough to be able to get out of it quickly and without hindrance. It is important to ensure that a falling tree does not hit others, especially to avoid getting stuck in branches.

Ideally, the tree should fall in such a way that it can be easily removed later: cut off branches and twigs, saw the trunk, and, if necessary, provide access for transport to remove it from the site.