How to update an old bathtub with your own hands. Enameling a cast iron bathtub - how to easily restore the enamel. Why does enamel usually wear out?

Read also

Any thing or object in the world around us tends to age, both morally and physically. Over time, the bathtub gradually turns from a sparkling, smooth, pleasant-to-touch attribute of a sanitary facility into a dull, rough, spotted and even cracked surface. It is physically unpleasant to be in it, and the visual perception is clearly far from the best. So the question arises of what to do in this case - just send the bathtub to a landfill or maybe try to restore it.

There are only two possible options:

1. radical - installation of a new bathroom;

2. budgetary - restoration of its internal surface.

The second option, naturally, is less expensive, because purchasing a new bathtub, delivering it to the required floor, dismantling and removing the old bathtub, as well as installing a new bathtub requires significant expenses and considerable physical effort. It should be noted that you will have to remove and then restore the tiles laid on the walls. The siphon will inevitably need to be replaced, which most likely will not fit into the new bathroom. However, if there are continuous cracks and holes, large deformations or chips of the bathtub enamel, then it cannot be repaired.

Restoration of any old bathtub can be done in one of the following ways:

acrylic liner;

enameling;

pouring bath method.

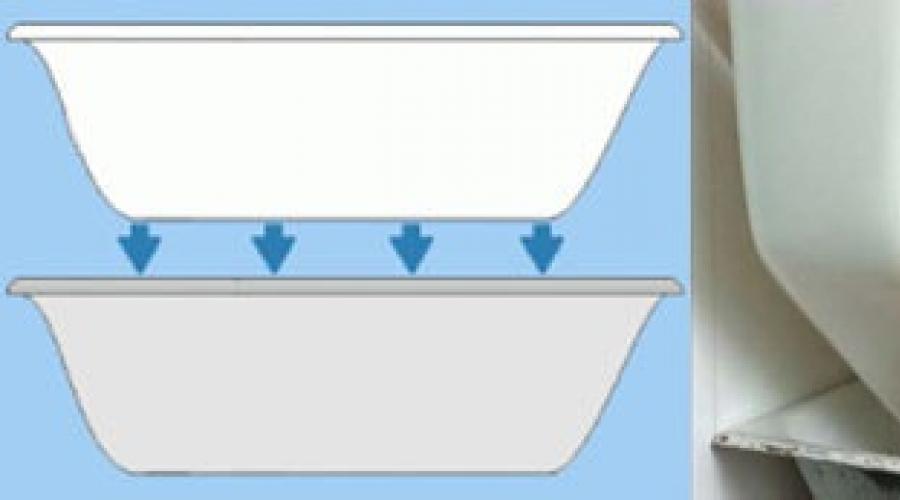

Acrylic liner

An acrylic liner is the easiest solution to the problem. A finished product is placed inside the old bathtub, thoroughly replicating the surface of the inner bowl of the bathtub. The liner has excellent technical parameters - it does not rust or turn yellow. Can be of any color that harmonizes with the interior of the bathroom. It should be noted that the thickness of the acrylic liner is only 4 mm; of course, the volume of the useful area of the bath will decrease somewhat, but not so much as to cause discomfort.

An acrylic liner is the easiest solution to the problem. A finished product is placed inside the old bathtub, thoroughly replicating the surface of the inner bowl of the bathtub. The liner has excellent technical parameters - it does not rust or turn yellow. Can be of any color that harmonizes with the interior of the bathroom. It should be noted that the thickness of the acrylic liner is only 4 mm; of course, the volume of the useful area of the bath will decrease somewhat, but not so much as to cause discomfort.

A significant disadvantage of the acrylic liner is the use of polyurethane sealant when installing it - over time, it subsides, as a result of which cracks appear on the surface of the liner. As a rule, the service life of the liner does not exceed 2-3 years.

Applying new enamel

In the case where the purchase of an acrylic liner creates a financial problem for you associated with the mandatory repair of the entire plumbing room, you should restore the surface using special materials - such a material is. Any hardware store or market offers a wide variety of enamels produced by both domestic and foreign manufacturers. They come in two types - aerosol and in cans. For good atomization, the aerosol package contains a significant part of the solvent, which reduces the service life of the enamel layer, so it is not suitable for bathtub restoration.

In the case where the purchase of an acrylic liner creates a financial problem for you associated with the mandatory repair of the entire plumbing room, you should restore the surface using special materials - such a material is. Any hardware store or market offers a wide variety of enamels produced by both domestic and foreign manufacturers. They come in two types - aerosol and in cans. For good atomization, the aerosol package contains a significant part of the solvent, which reduces the service life of the enamel layer, so it is not suitable for bathtub restoration.

The packaging itself contains a detailed description of the coating restoration process, however, there are certain nuances. So, you need to decide that restoring a bathtub with alkyd, oil or nitro paints is absolutely useless. There is no point in using automotive enamels. It is necessary to make a clear choice in favor of two-component epoxy paint to restore the enamel of the bathtub. You will need to remove the siphon - the drain and overflow holes must be free of pipe connections.

The process of restoring enamel is described quite well by the manufacturer on the packaging container and consists of several stages. This labor-intensive process will require you to remove the old enamel, prepare the surface, and only then apply a new coating.

A layer of cleaning powder that does not contain bleach should be applied to the surface of the old enamel. We remove the existing enamel mechanically using an abrasive stone attached to a drill or waterproof sandpaper. It is necessary to carefully remove old enamel in places of chips and rust. We clean the rest of the bath until the surface becomes matte. This procedure depends only on you; the better the cleaning is done, the longer the service life of the new coating. After this, we wash off the resulting mush of water and old paint, and to complete the cleaning process, fill the bath with hot water, and after 8-10 minutes drain it. If the quality of the treated surface satisfies us, degrease it with a solvent and wait for it to dry completely.

If rust defects or poor cleaning are detected, the cleaning procedure must be repeated. The result should be a smooth, matte, uniform, even and dry bath. If there are deep chips, they must be restored using epoxy compositions.

If rust defects or poor cleaning are detected, the cleaning procedure must be repeated. The result should be a smooth, matte, uniform, even and dry bath. If there are deep chips, they must be restored using epoxy compositions.

The next stage of primer application should be approached according to the enamel manufacturer's recommendations. In the case of using aerosol primers, there is no problem at all, it is applied easily. If you prime with a mixture of enamel and hardener, you should not allow bubbles to appear on the finished surface, because then the enamel will peel off in these places. Once you have finished applying the primer throughout the bathtub, give it time to dry.

Before proceeding to the final stage of applying enamel, the bathtub must be coated with a primer. It is advisable to carry out the enameling procedure with a mohair roller - it is better to avoid a brush, since its fibers may fall off and remain on the surface of the bath. In addition, the roller applies the enamel more evenly. To ensure high-quality fixation of enamel on the walls of the bathtub, the first layer of coating must be literally rubbed into the surface. At least three layers of new enamel should be applied, and so that each of the applied layers dries for at least 25-30 minutes.

Over the next day, the enamel will become hard. But this does not mean that it is completely dry. To do this, you should wait up to seven days, while the temperature in the bathroom should be kept within 20°C. At the same time, it is necessary to exclude any access of foreign objects and liquids to the new surface. Only after this, a brand new, snow-white, shiny bathtub, inviting you to take a swim, is ready to embrace you.

Over the next day, the enamel will become hard. But this does not mean that it is completely dry. To do this, you should wait up to seven days, while the temperature in the bathroom should be kept within 20°C. At the same time, it is necessary to exclude any access of foreign objects and liquids to the new surface. Only after this, a brand new, snow-white, shiny bathtub, inviting you to take a swim, is ready to embrace you.

Filling bath

Self-leveling bathtub is the latest development in creating a new surface over an existing cast iron or steel bathtub. A pour-in bath is the application of liquid, impact-resistant plastic based on cast acrylic, to which a ceramic hardener has been added. The bath is prepared in the same way as when applying new enamel.

Self-leveling bathtub is the latest development in creating a new surface over an existing cast iron or steel bathtub. A pour-in bath is the application of liquid, impact-resistant plastic based on cast acrylic, to which a ceramic hardener has been added. The bath is prepared in the same way as when applying new enamel.

To restore a bathtub in this way, 4 kg of liquid plastic is enough - it is poured directly onto the bathtub. The thickness of the new acrylic coating reaches 6mm on the walls and up to 10mm on the bottom of the bathtub. If small drips or defects appear during pouring, they can be easily removed with a spatula. Drying takes place at room temperature for up to four days. After this time, the bathtub looks like new, the surface is perfectly glossy, resistant to damage, bacteria and, most importantly, safe and non-slippery.

Did you find this article helpful? Subscribe to site updates to receive the latest articles about renovation and interior design before anyone else!

Dear visitor, in this article we talk about existing methods of restoring bathtubs, compare technologies, advantages and disadvantages of methods.

If you have already decided on the choice of bath restoration method and you are interested in prices, then you can find them on the page "Bathtub restoration price"

We will not describe the reasons why your bathtub has lost its whiteness and shine, be it due to bad water or aggressive detergents, or the enamel has worn off or become cracked.

Let’s just confront ourselves with the fact that the bathtub in this state doesn’t suit you and “you need to do something about it” :).

Restore the bathtub or buy a new one?

And, it would seem. Here is a bathtub that has been in the house for 30-40 years. Why not save some money and buy a new one just like it. You look at it for another ten years and it will stand...

This is usually the very first idea that comes to people's minds when faced with this situation.

And when we are asked about this over the phone, we usually explain why this seemingly good option is not suitable for most people.

And the point here is not at all the price of a new bathtub (it is usually more expensive than the restoration of a bathtub, see “prices”), but the fact that such bathtubs were made using the same technologies and those in the country of the “USSR”. You won't find it in any store. They haven't been released for about 10 years now. They haven't been released at all.

And the durability of enamel in modern bathtubs is so questionable that you often wonder whether it’s worth paying extra. We are asked to restore bathtubs that were purchased less than 4 years ago, the enamel of which has already been “eaten through” to the cast iron frame.

Well, if we talk about the price. It is worth considering that when purchasing a new bathtub, in addition to the hassle of installation and dismantling, you only get a renewed white layer of enamel in its pure form.

Well, since it’s only a matter of the enamel layer, maybe it’s worth “changing” only that?

As we wrote earlier, in this article we will consider restoration methods where the enamel coating is directly renewed, while preserving the old bathtub body, be it cast iron or iron.

We will also consider only those methods that can be done at home.

So, to restore a bathtub, iron or cast iron, first let’s list all the methods: - (when the enamel is applied with a brush, roller, spray gun.) - (aka the “Bathtub in a Bathtub” method) - (aka: filling the bathtub with liquid acrylic, stacrylic, poured enamel. “Pour-in bath”) - (The method is extremely specific and not particularly practical, but worth mentioning)

Let's look at the methods in more detail, compare prices and draw some conclusions for ourselves:

A method for restoring a bathtub using enamel.

Bathtub enamel or classic enamel is the oldest restoration method. In those Soviet times, when new bathtubs were “impossible to get” and you didn’t want to bathe in a rough bathtub, the first thing that came to mind for those savvy people was “why don’t we just paint the old bathtub???”. And so they did. Of course, paint differs from paint to paint, and not every paint is suitable for enameling a bathtub, but in principle the process technology is similar to the banal painting of any surface. Depending on the quality and manufacturer of the bath enamel, a bath restored in this way will last from 1 to 5 years on average.

Bathtub enamel or classic enamel is the oldest restoration method. In those Soviet times, when new bathtubs were “impossible to get” and you didn’t want to bathe in a rough bathtub, the first thing that came to mind for those savvy people was “why don’t we just paint the old bathtub???”. And so they did. Of course, paint differs from paint to paint, and not every paint is suitable for enameling a bathtub, but in principle the process technology is similar to the banal painting of any surface. Depending on the quality and manufacturer of the bath enamel, a bath restored in this way will last from 1 to 5 years on average.

Disadvantages of enameling

- Turns yellow - Epoxy enamels tend to turn yellow over time

- The appearance of cracks - "Hard" enamel - is very sensitive to impacts, and chips are possible over time.

- Long drying time - (You can use the bathtub only after 5-7 days)

- Copies factory casting - The enamel does not hide the factory unevenness of the bathtub, any bulges or depressions can stand out

The cost of this method usually depends on the enamel used to cover this bath and usually ranges from 3000 (the cheapest paints) to 4900 (good, foreign ones).

The cost of this method usually depends on the enamel used to cover this bath and usually ranges from 3000 (the cheapest paints) to 4900 (good, foreign ones).

Since the main criterion of this method is “cheap”, usually no more additional payments are provided, the only thing is that if you have previously enameled your bathtub, then the craftsmen charge an additional payment for this, for stripping the old layer (400 - 500 rubles ).

What you should pay attention to:

- It is important to use enamel designed specifically for baths. Only they are safe for humans. Almost all others, when in contact with hot water, release toxic enzymes.

- The bathtub should be covered with at least 2 layers, ideally 4.

- It is worth taking your time and maintaining the full drying period established by the enamel manufacturer.

Acrylic insert, "Bath in bath", Acrylic insert - many names, displays one meaning. This is a restoration process when a new plastic trough is inserted into the inner surface of the bathtub, repeating its shape. This trough is glued to a special foam to your bathtub and, according to the manufacturers and craftsmen, the installer should last about 15 years.

Advantages:

- Acrylic, unlike enamel, is a much more plastic substance and is not as susceptible to chipping as enamel.

- Always white - Plastic does not turn yellow over time.

- Perfectly flat surface.

- The voids between the liner and the cast iron bathtub, into which water can enter and begin to rot.

- It is prohibited to install in steel baths.

- Mandatory dismantling of the old drain siphon.

- The liner is held in the bath on a special adhesive foam. And over time it tends to peel off.

- Clearances between the wall and the bathtub are required (minimum 3cm).

At first glance, the cost of installing an acrylic liner does not seem high. Typically, installer companies announce a price in the range of 4,000 - 4,700 rubles. But it is worth paying attention that often these prices are indicated only for delivery, lifting and installation of the liner. You should be prepared for additional expenses, such as “the arrival of a surveyor-consultant” - (usually 500 rubles). You may also have to pay extra for dismantling the old drain siphon and installing a new one (from 600 to 1,200 rubles). Well, if the bathtub is embedded in tiles, then you will also have to pay extra for its dismantling (usually 300 - 600 rubles per wall).

At first glance, the cost of installing an acrylic liner does not seem high. Typically, installer companies announce a price in the range of 4,000 - 4,700 rubles. But it is worth paying attention that often these prices are indicated only for delivery, lifting and installation of the liner. You should be prepared for additional expenses, such as “the arrival of a surveyor-consultant” - (usually 500 rubles). You may also have to pay extra for dismantling the old drain siphon and installing a new one (from 600 to 1,200 rubles). Well, if the bathtub is embedded in tiles, then you will also have to pay extra for its dismantling (usually 300 - 600 rubles per wall).

There are rumors on specialized forums that some unscrupulous installers dismantle the drain siphon, deliberately damaging the sewer pipe. Thereby increasing the cost of work significantly.

You can spend a long time describing the positive properties of acrylic (as a material), and in principle, the idea of installing a liner in the bathtub is not a bad one. But as time has shown, there is a drawback in this method that reduces the service life of such a bathtub to 3-5 years. This is the glue that is used to attach the liner to the bathtub and the not perfectly smooth surface of the bathtub.

What is this shortcoming? The moment you step on the bottom of the bathtub in which the liner is installed, its surface microbends; when you leave the bathtub, it bends in the opposite direction. In those places where the bathtub comes into contact with the liner, these bends are minimal; in the same places where there is factory unevenness, the amplitude of the deflection is greater.

Polyurethane foam, which is applied to the inner surface, is designed to hold the liner inside and successfully copes with this in the first or second year. But time passes and from constant “stomping” on the bottom of the bathtub, it begins to peel off and voids appear in the cavities, into which water begins to enter. What happens next, I think there is no point in telling, the water in the voids rots over time, and the smell is incredible.

Such problems with liners appear regularly, and manufacturers and inventors, having thought twice, decided to somehow get rid of the weak connecting link, the glue. This is how a new method of restoring bathtubs with liquid acrylic was invented. About the method below...

Restoration method: Liquid acrylic.

This restoration method is also called acrylic enamel. And knowing how the classical method is done, you can understand this one too.

In a nutshell, this is approximately the same material from which acrylic liners are made, it is very similar to plastic, but it is produced in a liquid state. In "raw"; looks like "condensed milk". Well, it is applied to the bathtub using the “pouring” method, if you look at the pink picture on the left, it roughly reflects this procedure.

Advantages:

- Drying time - Can usually be used after 36 hours

- There is no layer of glue between the bathtub and the acrylic. This makes the coating stronger.

- Liquid acrylic inherits the good qualities of the acrylic liner; it also does not turn yellow over time, retains heat in the bath just as well and is resistant to acidic detergents.

- Both cast iron and iron bathtubs can be restored.

Flaws

- It is advisable to remove the drain siphon.

- Self-leveling acrylic completely copies the curves of the bathtub and if there are factory unevenness on the bathtub, they can be noticeable.

The cost of the method of restoring bathtubs with liquid, self-leveling acrylic (self-leveling bath method) is usually 3,500 - 4,100 rubles. Depends on the size of the bathtub and the acrylic used. Usually the prices for this type of restoration are predictable, the only thing is that, as with enameling, if you have previously enameled a bathtub, you will need an additional payment (400 - 500 rubles) and if you need to dismantle the old drain siphon, then the craftsmen also charge an additional payment for this work (400 - 700 rubles )

Liquid acrylic is a relatively new material. Manufacturers often change their compositions, as they say “to improve quality,” but in reality this is not always the case. Unfortunately, you need to regularly monitor the quality of liquid acrylic. It has already been noticed several times that after a renowned manufacturer updates the composition of its acrylics, their quality drops. Moreover, the manufacturer himself will never admit such a jamb. So our advice to craftsmen, in order not to listen to bad words from customers, check each batch of material you buy.

Over time, any bathtub loses its former novelty: the color fades, an unpleasant roughness appears, the enamel cracks... If your bathtub has lost its beauty, you don’t necessarily have to spend money on a new one. Restoring an old bathtub is not difficult, especially since you can choose the most suitable method.

Before you begin restoring a bathtub, you need to make sure that it is being renovated and not disposed of.

The bath can be updated if:

- the enamel has become rough;

- there are shallow cracks, scratches and chips of the enamel;

- the color faded and became a dirty yellow.

If the body of your bathtub is deformed, or deep cracks have formed in it, no restoration will help.

Enamelling

Cast iron bathtubs are found in almost all apartments in the post-Soviet space. These are reliable non-lifting structures that are easier to repair than to replace, which is what we will do today.

The enamel on such bathrooms wears out for several reasons. Firstly, the service life is too long. As a rule, enamel lasts about 10-15 years if used correctly. If the apartment, for example, was built back in Soviet times, then the “natural death” of the enamel should have occurred a long time ago. Therefore, if you get such a “treasure”, you need to immediately restore the cast-iron bathtub. Secondly, during operation, household chemicals are used to clean the surface, sometimes very aggressive ones. Slowly but surely they destroy the enamel and speed up the repair time.

Restoring a smooth enamel coating at home is quite simple. You just need to purchase the necessary tools and materials and get to work.

Tools and materials:

- drill with grinding attachment;

- abrasive powder;

- rust solvent (you can buy a special product in the store or get rid of rust with a “folk” remedy - Coca-Cola);

- sandpaper;

- degreasing agent;

- lint-free rags;

- flute brush made of natural bristles (flat);

- gloves;

- respirator;

- two-component enamel.

Progress:

Congratulations, you have refinished your bathtub! However, do not rush to swim - it is better to wait about a week before use so that the enamel hardens properly. This coating will last for 6-10 years, depending on the quality of the enamel used.

Liquid acrylic

This is a relatively “young” method, which, however, has already gained popularity around the world due to its speed, convenience and durability. You just need to call a specialist, and in just an hour you can enjoy the view of a snow-white, renovated bathroom! But we are here because it is not in our rules to spend money on the services of masters. Restoring a bathtub with your own hands using acrylic is as easy as shelling pears.

First, a few words about this very acrylic. This is a special high-strength composition called stacrylic. Stacrylic is a two-component acrylic (acrylic and fixer), which is created specifically for bathtubs. That is, when buying glass, you simply cannot go wrong, while enamel can be used for cars, for water pipes, and for painting wood. Glass acrylic forms a dense film 4-6 mm thick, which does not allow water to pass through and has excellent performance characteristics.

Advantages of glass:

- viscosity;

- fluidity (the composition quickly envelops and spreads over the surface);

- slow polymerization (low rates of hardening help to carry out restoration efficiently and without haste);

- protection from mechanical damage (in its frozen form there is no fear that the composition will break off from an accidental blow).

Progress:

- Prepare the surface of the bath in the same way as in the case of enameling.

- Disconnect the siphon and place a plastic container under the drain (you can use a cut-off five-liter bottle). The acrylic will flow there.

- Prepare the acrylic mixture according to the instructions on the package and begin pouring it in a thin stream over the edge of the bathtub. As soon as the mixture flows down to the middle height of the sides, begin to slowly move along the perimeter. When you return to the starting point, repeat the procedure again, starting from the middle of the bath.

- Acrylic must be poured continuously, so you must immediately ensure that the container is of the appropriate size. It is better not to save money in this matter, since redoing mistakes after improper handling of glass is much more difficult than restoring an ordinary enamel bathtub.

Polymerization takes from two to four days, depending on the type of composition. It is best to take your time and choose acrylic with a long curing time (the longer the better). In this case, it will be much stronger and will last much longer than quick-drying compounds. The service life of acrylic coating is about 20 years.

Video on how to restore a bathtub using acrylic:

Insert or “bath in bath”

The most basic, but at the same time the most expensive way to restore a bathtub. Its essence is as follows: the surface of the bathtub is smeared with glue and a thin “cast” of identical dimensions is inserted into it. Everything seems simple, but you can only get such a liner at the factory where the baths are made. If you live near one of these businesses or have managed to purchase one, the following instructions are written especially for you!

Progress:

Now you know how to restore a bathtub yourself. As a good parting word, we can only advise you not to limit yourself to the standard white color, but to choose the shade of enamel in accordance with the interior or your own fantasies. So, black bathtubs look very impressive, but you should be warned that this is a “capricious” color that requires constant care. Blue and green colors will allow you to relax and unwind, and orange will instantly lift your spirits!

The main defects in the bathtub coating include cracks, scratches and chips. Damage occurs after careless installation of furniture, plumbing fixtures and heavy objects falling into the bathing bowl. Calling a professional to fix problems won’t be cheap, so it would be nice to learn how to repair a cast iron bathtub yourself, don’t you agree?

We will help you resolve this issue. The article provides detailed instructions for removing chips, small and deep scratches, and also describes effective methods for restoring cracks. By studying the material, you can restore the attractiveness of a cast iron bowl and extend the life of the bathtub.

The use of multi-component cleaning products, cleaning the contaminated surface with a stiff brush, careless handling of metal objects during repairs - all this leads to the formation of shallow scratches.

Such scratches must be eliminated immediately, since the penetration of moisture and caustic chemicals into the resulting gap leads to the formation of rust, the proliferation of moisture-loving microorganisms and an increase in the size of the scratch. Which will lead to further destruction of the bathtub surface.

Shallow scratches include damage that does not expose metal. These minor damages can be repaired even without priming the surface.

Methods for restoring cracks

Cast iron bathing bowls have become popular due to their high wear resistance and durability. But even such durable products experience defects in the form of enamel chips, corrosion or cracks.

The occurrence of a crack as a result of plumbing work or natural changes in water and air temperature becomes one of the reasons for replacing the bathtub. In some cases, it is possible to repair the defect.

Methods for eliminating a crack in a cast iron bathtub base: using cold welding, applying epoxy resin, soldering with lead-tin solder.

Option #1 - cold welding

At the first stage, the bath is degreased and cleaned with Pemolux or soda. If there is rust around the edges and inside the crack, it is necessary to use a harsh abrasive such as Sanox or Chistin Sanitary.

The anti-corrosion agent is applied to the surface of the crack in a thick layer, wetted and left on the damage for 20 minutes. After washing off the cleaning agent, locking micro-holes with a diameter of 3 mm are drilled along the visible edges of the crack on one or both sides, depending on the location.

After degreasing, the surface is sanded with a grinder, electric drill with a grinding wheel or abrasive. Not only the crack is cleaned, but also the enamel around it, 1.5-2 cm wide.

A grinding wheel removes the coating right down to the metal. At the site of the crack, a hollow is ground out along the entire length of the fault.

After sanding, the tank coating is cleared of saw cuts and dirt. When the bathroom is dry, the crack area must be degreased with solvent, alcohol or cologne.

Hot water is poured into the bowl for half an hour, after it is drained, the surface is dried with a hairdryer. Now the treated coating defect can be covered by cold welding.

You can use the bath no earlier than after 24 hours. To even out the tone of the coating, the crack area can be painted with two-component acrylic or epoxy enamel.

Option #2 – epoxy resin

The process of preparing a surface for applying epoxy resin is practically no different from the technology for preparing a bath for applying cold welding.

Scheme of work:

- cleansing and degreasing;

- grinding and turning of grooves;

- additional degreasing.

After completing the preparatory work, it is necessary to prepare epoxy resin or epoxy-based putty. A layer of epoxy resin is applied to the crack site, fiberglass cloth is applied on top, and adhesive mounting material is applied again.

After the structure has dried, it is necessary to repeat the procedure: epoxy - fiberglass - epoxy. The result should be a patch above the enamel level; if not, then the procedure is repeated a third time.

Epoxy resin is the best solution for repairing cracks in a bathtub. The liquid texture of the material allows it to penetrate into every microcrack, providing increased adhesion and protection of the metal.

Option #3 – soldering the crack

If you have soldering skills, you can solder a small crack in a cast iron bathtub. This requires thorough cleaning and freeing of the metal from the enamel.

Soldering is done with a 100-200-watt soldering iron using lead-tin solder and a special flux for steel and aluminum.

This method of solving a problem takes time and skill. The seam will not last long, but it will be suitable for temporarily fixing the problem.

To extend the attractiveness and life of a renovated bathtub, it is necessary to properly. To clean the surface, do not use hard brushes, which can damage the smooth enamel.

Conclusions and useful video on the topic

For reliable adhesion of materials and durability of the coating, it is necessary to follow a clear sequence of preparatory and restoration work:

High-quality repair of a cast-iron bathtub means careful restoration of the most important plumbing fixture in the apartment.

Restoration of a damaged surface is possible as a result of the “jewelry” work of a master. The result of painstaking work and many hours of waiting will be a bath without visible chips, scratches and cracks, which will last for another ten years.

Share with readers your experience of restoring damaged enamel of a cast-iron bathtub and carrying out restoration work. Please leave comments, ask questions about the topic of the article and participate in discussions - the feedback form is located below.

Like any coating, enamel becomes thinner over time, rust spots, stains, and chips appear on it. When the most effective chemical cleaners containing abrasives fail to correct the problem, most owners decide to change equipment.

But after assessing the complexity of installation work and material costs, they begin to look for alternative options related to updating an old cast-iron bathtub. Despite its aesthetically unsightly appearance, the design, which is quite suitable for performing the main function in accordance with all operational characteristics, will last for another half a century. It's all about the enamel coating. This means that something new is required, and thanks to new technologies, this manipulation is carried out in the shortest possible time.

Restoring or replacing a cast iron bathtub?

A radical method is to replace the sanitary tank. First of all, you need to calculate how much this procedure will cost. Let’s sum up the cost of an ordinary classic bathtub with the cost of its delivery, including transportation and loading, taking into account the desired floor. Dismantling of old equipment and installation of new equipment is carried out in accordance with the company’s price list. According to the most conservative estimates, you will need at least 13,000 rubles. This does not take into account damage to wall and floor coverings, which is inevitable with any type of installation work. Partial replacement of cracked fragments and cosmetic repairs will be required. Conclusion - getting rid of the old one and installing a new bathroom is quite troublesome and expensive.

Isn't it better to think about restoration, if the functionality of the old bathtub with thinned or washed away white surfaces is good? Moreover, a large amount does not guarantee an excellent result, since the purchase of the least budget capacity was initially intended. When choosing a higher quality convenient or design project, costs can increase significantly. If this method is not suitable for owners, they think about affordable and effective restoration options. It is important to approach this issue wisely, choosing the optimal solution.

Restoring the old surface layer by “pouring” acrylic is the most popular method. Most consumers appreciate the know-how technology due to its simplicity and low cost. With this method, a liquid synthetic mass is poured onto the inner lining of the bathroom.

Advantages of self-leveling acrylic:

- long-term wear resistance. When applied correctly, the service life is designed for a period of 8-15 years;

- Thanks to the density and plasticity of synthetics, an even, smooth surface structure is formed;

- The flowing mass smooths out all kinds of defects and scratches;

- Acrylic is applied at high speed, simple application technology allows you to increase the volumetric surface layer to 6 mm;

- The filling is characterized by the absence of a specific odor, so allergy sufferers, children and the elderly will not need other housing during the renovation.

Significant disadvantages of self-leveling acrylic are:

- long drying time of the composition - 3 days;

- Coating sensitivity. It is unacceptable for dust to get on the drying surface, otherwise it will deteriorate;

- The apparent simplicity of the technological operation is extremely deceptive. In fact, pouring acrylic requires certain skills in working with liquid mass;

- Relatively high material costs compared to enameling. But the cost pays off given the increased service life and high quality.

Painting is often considered the oldest method of restoration, when special enamel is applied to a worn-out coating. The owner must think about how to refresh old equipment? There are two types of enamels: for professional use and for domestic purposes. The structure of the former is very thin; at least 3-5 layers will be required. This is a labor-intensive procedure. The latter are characterized by a thicker structure and, accordingly, two-layer styling is easier to apply. The liquid coating is applied with a roller or brush, trying to distribute evenly over the cleaned canvas.

Advantages of the enameling method:

- is the most economical restoration option;

- there will be no need to dismantle the drain and the overflow will not require reconstruction;

- This method is intended not only for cast iron products, but also for steel containers.

Enameling has the following disadvantages:

- short service life, less than 5 years;

- Drying time is about a week;

- the resulting coating is non-glossy, uneven, sensitive to deformation;

- a thin layer of enamel is not able to mask dents and chips that may appear over time;

- the appearance of a yellow tint during operation, since the original factory epoxy coating is radically different in composition;

Cold enameling is considered the cheapest and simplest method of restoration. It can be compared to painting a canvas with a special composition. To extend the service life of enamel, you must listen to the following recommendations:

- To wash a renewed cast iron coating, you do not need abrasive cleaning agents that violate the integrity of the coating, but a solution of washing powder or soap;

- the new container must be protected from impacts; sharp objects can scratch the acrylic sheet;

- enamel does not tolerate boiling water, it may crack. When filling the bathtub, before opening the hot water tap, let the cold water in first, and not vice versa.

Acrylic liner

For option 3, additional equipment will be required - an acrylic liner, which is mounted using the “bath in bath” method. This two-layer construction will last about 15 years. At the same time, a new acrylic liner is installed inside the old structure, which perfectly follows its outline. The stability of the additional element is ensured by technical adhesive foam.

This method has advantages:

- acrylic is a more durable material than enamel;

- thanks to perfect alignment, all defects and deformations of the cast iron sheet are smoothed out;

- the inert material does not turn yellow until the end of its service life;

- The two-layer design successfully combines all the advantages of acrylic and cast iron.

Disadvantages of acrylic liner:

- the drain siphon will need to be dismantled;

- the acrylic structure must not be applied to areas made of lightweight or thin cast iron, otherwise the bath will sag and the adhesive layer will move away from the fastening liner;

- with the “bath to bath” method, the materials must meet the standards. Low-quality inserts or a composition not intended for gluing metal will negate all efforts;

- careful measurement of the insert is required, down to the millimeter. The slightest discrepancies with the parameters of the main design are unacceptable.

All 3 restoration methods are simple and effective; they require preliminary degreasing and removal of dirt and limescale. You can get rid of greasy marks using oxalic acid or baking soda. Then they begin thorough cleaning, removing plaque and deformed fragments until a smooth plane is obtained. The next stage is grinding, the purpose of which is to obtain a rough surface. Irregularities in the fabric upon contact with the adhesive will ensure the maximum degree of adhesion.

To restore or not - objective conclusions

After weighing all the pros and cons, the owner must decide whether to dismantle or restore the much-needed plumbing equipment. But with competent and qualified restoration work using high-quality materials, the updated bathtub will look like new. If possible, you should trust experienced craftsmen who have proven themselves to be good. Then an excellent result for relatively little money is guaranteed.

Restoration of a cast iron bathtub video