Making a vice for a drilling machine with your own hands. Vices: we do it ourselves - options and varieties, diagrams, implementation How to make homemade vices for plumbing at home

Read also

The vice seems to be an important tool that helps in organizing plumbing work. They allow you to correctly organize any operation related to precise adherence to dimensions that require concentration and composure of the master. Any part can be firmly fixed in the desired position, thereby allowing its owner to concentrate on work.

A bench vise is designed to clamp a product during work.

Vices are used especially actively in any workshop, because it is impossible to imagine processing wood or electrical devices without the use of holding devices. You can make homemade bench vise yourself. How to do this correctly? To answer this question, you should study the varieties of this clamping mechanism, the components and elements of the device.

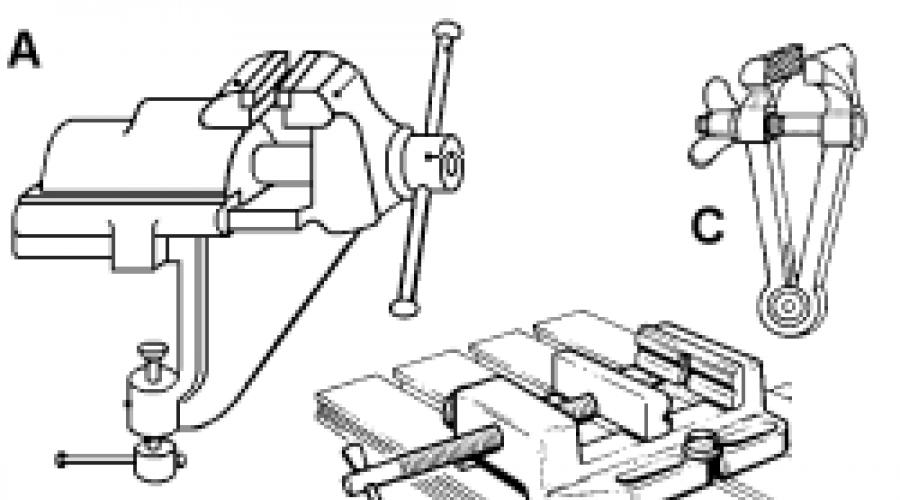

Types of vices: A – metalworking; B – machine tools; C – manual.

Machine vices are used for rough fastening of parts, the processing of which involves the following activities:

- drilling recesses;

- sanding the base;

- finishing the coating with a file;

- gluing elements;

- milling the outer layer.

Machine vices allow you to strengthen the workpiece with the support of the listed elements:

- screw with holder;

- wedge constipation;

- diaphragm;

- pneumatic mechanism;

- eccentric.

An example of elementary devices would be the first point, which allows you to create one of the primitive structures.

Read also:

What is needed and why.

On one's own.

To strengthen the part in the desired position, it is attached to the workplace. In the house, an ordinary table serves as such a covering. Traditionally, machine vices are represented by such elements as:

- supporting body;

- main lead screw;

- handle and nuts;

- a device that allows you to attach the vice to the desired point;

- a set of heads including flattened jaws that secure rounded parts.

Such homemade products most often have two slats, one of which has a movable base. Its movement is associated with the operation of the main lead screw. The second part is motionless; it allows you to fix the base of the device on the table. The holder helps move the clamping structure.

Return to contents

Tools and accessories

To make a bench vice you will need: a hacksaw, drill, hammer, tape measure, etc.

To cope with the assigned task, namely the independent production of metalwork structures, you need to be able to handle basic tools:

- A metal rod with a cross section of 20 mm.

- Iron pins for making handles and pins.

- Wood from pine and birch.

- Steel plates.

- Hacksaw.

- Electric drill.

- Rotary.

- Bolts.

- Hammer or small sledgehammer, file.

- Tape measure or ruler with a metal base.

Return to contents

Self-production of bench vices

You can make a machine vice yourself by making a lead screw or purchasing ready-made samples. Its length corresponds to 140 mm, and the thread is M20. Similar elements are found on sports-purpose structures. To make it yourself, you need to buy a strong steel rod, its diameter is 19-20 mm. The thread is cut by hand or made in a special workshop on a lathe. In this case, you can count on more accurate dimensions.

In accordance with the specified thread dimensions, the distance between the jaw holders is 75-80 mm. These dimensions are suitable for personal production devices. A cut needs to be made at the top of the screw to secure the holder. When using this element from a sports projectile, such a hole is ready-made; you just need to enlarge it a little with a rounded file. The use of a self-made bolt gives rise to the construction of such an opening with a drill with a calibration corresponding to 8-9 mm. The handle can be an iron pin 10 cm long. To securely fix it, you need to make 5 mm openings along the edge, cut in the threads and screw in M5 screws, their length is 3.5-4 cm.

After this, the machine vice must be equipped with 2 pins. In this case, fastening elements are taken from the scooter mirrors. Most often they have a slightly curved shape, which can be corrected with a hammer or small sledgehammer. The pins will allow you to move the movable sponge. They can be made independently from a steel bar with a transverse position of 8-10 mm. Small elements are cut off from this iron pin using a hacksaw. The edges should be finished with a file.

Sponges are used to hold machine parts in the devices under consideration. They can be made from wood, provided that the examples of fixing parts are items that do not contain any of the metals. Such material can be pine boards; their height is 40-50 mm. They will be needed to make a stationary sponge; it is immediately fixed to the table surface. Of course, this is done if the structure will not be moved to another location. To build a movable element, take a birch board 50 cm long and 18-22 cm high.

Then the recesses are drilled with a feather drill for the bolt, the studs allow the use of an ordinary drill, the diameter of the tip is 10 mm. Then the design is put together: the studs and lead screw are fixed in the openings made, washers and nuts are placed in the right places. The assembled mechanism can be fully operated.

If you decide to equip your own workshop, workbench or workbench, then you may definitely need a homemade vice. This is a relatively simple task, and the completed workbench or workshop will serve you for a long time. You should study in more detail the question of how to make a bench vice with your own hands and what nuances accompany this process.

Double screw joiner

If you are looking for a carpenter's bench vise that is truly powerful, then this is your best bet. two-screw modification of the specified device. M20 towbar bolts provide a force of several tons, which is an excellent option for such a vice. The assembly procedure for such a device is as follows:

- We prepare all the necessary tools;

- We make the appropriate slots and holes;

- Insert bolts and turns;

- We check the vice for strength and performance.

Step-by-step and detailed instructions on assembling and making your own vices for the workshop and workbench are available on specialized resources and forums in the form of photographs and recommendations.

Very convenient for ready-made desktops make a mini Moxon vice. To get started you will need the following materials and tools:

After the workpiece has been cut, it is necessary to sand the edges with sandpaper. We round the edges of the wheels with a drill and the same sandpaper. To make screws, you need to purchase a long threaded rod and cut metal blanks into two parts.

After this, you need to insert the nuts into the holes. Glue the skin onto the clips and remove all excess. Surface protection is provided by tung oil. It, unlike other wood impregnation agents, polymerizes inside and outside the tree with rapid penetration into the lower layers. After the oil has dried, all that remains is to connect all the resulting parts together - and the vice will be ready for use.

They are also easy to make yourself. First you need to cut the plywood to size. Weld two nuts to the flat panel for the threaded guide and attach them under the table with screws, as this will add stability to the structure in question. It is very important to align everything correctly, otherwise it will not work.

They are also easy to make yourself. First you need to cut the plywood to size. Weld two nuts to the flat panel for the threaded guide and attach them under the table with screws, as this will add stability to the structure in question. It is very important to align everything correctly, otherwise it will not work.

After this, you need to use a chisel to make a recess for the nut. On the outer lock, drill a hole 3 cm deep. Therefore, the thickness of the plywood should be 3 cm.

It is a copy of a regular vice, only made of wood. Of the metal parts, only a screw 45 cm long and 8 cm thick should be used here. Massive pine plywood, well dried, is suitable.

It is a copy of a regular vice, only made of wood. Of the metal parts, only a screw 45 cm long and 8 cm thick should be used here. Massive pine plywood, well dried, is suitable.

The vise jaws are made from separate blocks, which are subsequently glued together. To give them their final shape, sand their edges with sandpaper. In this case, for one block it is worth choosing a thicker tree. This compensates for the space between the moving and fixed parts. The handle should fit through the head into the hole freely, then add the knob and anvil. When finished, remove the mounting screws, coat the vise elements with two coats of oil-based polyurethane and leave to dry overnight. Bolt the vise to the workbench.

Oak vice

The design of this structure is based on ancient drawings, the body is made of oak sleepers. The jaws can be cut by hand or with a saw. Grooves are punched down on both sides of the base. The brackets add strength to the rear jaw and secure it well to the base.

The top of the tee is on top of the clamping bolt. You will also need a large bolt and a square head that fits into the housing groove at the base of the vise. A steel strip should be added to each side of the base at the bottom to protect the side brackets from wear.

The top of the tee is on top of the clamping bolt. You will also need a large bolt and a square head that fits into the housing groove at the base of the vise. A steel strip should be added to each side of the base at the bottom to protect the side brackets from wear.

Make a homemade vice, as we see, it turns out, is not so difficult. There are many sites and articles on the Internet that talk in detail about the manufacture of devices for various workbenches and desktops. Making oak vices is very interesting, since solid pine plywood is ideal for them. A steel strip is a good addition as it prevents wear and tear on the brackets and vice in general. Happy work and making homemade workbenches!

Many plumbing jobs require a special vice. Their purpose is to rigidly fix the workpiece being processed. There are quite a large number of different versions of locksmith's machines on sale, all of them are united by a rather high cost. For a private workshop, you can make a bench vice with your own hands. The created structure will cost much less and is ideal for installation in a private workshop.

Features of the vice

You can make a strong vice with your own hands at home from a profile pipe. The resulting structure will have compact dimensions and can be rigidly attached to the base. Such a vice is used to work with various workpieces, since the device can exert different pressure on the jaws.

Step-by-step instruction

The job requires a relatively small number of tools. The entire manufacturing process can be divided into several main stages:

After the structure has been assembled, it is painted. As a rule, the angle used is made using ordinary steel, which becomes corroded during long-term use. The created vice can be attached to the base using bolts.

Universal design for household use

Homemade vices for a drilling machine or workbench do not require complex calculations. As a rule, a steel pipe is used as a base in most cases.

When considering how to make a homemade vice, you should pay attention to the design features:

Such a design can withstand significant impact and last for a long period.

Doing the work yourself

To work with metal you will need a grinder and a welding machine. Machine milling vices of this type are manufactured as follows:

The created vice design is characterized by high reliability and long service life. At the same time, it is easy to repair and inexpensive. That is why it is quite popular among home craftsmen.

Making carpentry vices

To process wooden workpieces, a carpenter's vice is required. They are used both in the manufacture of new parts and in the repair of existing ones. Working with wood using a bench vice is inconvenient. That is why many people decide to also make carpentry, which have a number of their own characteristics.

The simplest design is represented by a combination of the following elements:

Manufacturing features include the following:

In a similar way, you can make very practical carpenter's vices. They are inexpensive and can be used for most carpentry work.

Homemade structures are in no way inferior to industrial ones. They can also be designed to withstand heavy loads. The created vices can have a variety of qualities, as they are created by the craftsman depending on the needs.

In the vastness of the RuNet you can find statements like: “A real master makes a vice only on his own.” It’s not hard to imagine what a real master will say about this. Whether he is an amateur or a professional who lives by his own labor, he knows perfectly well which tools and equipment are best to buy and what is worth making from it himself. However, there are times when it makes sense to make a vice yourself. For example, for a dacha (bought ones sit idle there over the winter in vain, and they can be stolen), when working on the road and/or on occasion (I came to visit relatives, they asked for help, but they are not artisans at all). Unfortunately, given the current situation with the tool, there is also a circumstance that makes you think: shouldn’t you still make a vice yourself?

Cast iron and steel

The parts of the frame and the clamp of a bench vice should be made of structural cast iron - it rusts very poorly, is hard and tough, has a low TEC (thermal expansion coefficient), but most importantly, it is practically not subject to metal fatigue. Cast iron vices last not decades but centuries. Since “the strength of the entire chain is determined by its weakest link,” the jaws of the vice and the lead screw-nut pair are made from tool steel of various grades. A simple structural one is too plastic, it has a strong tendency during welding, and it rusts easily. Therefore, leave homemade vices like those in Fig. below, it is not recommended to spend the winter at the dacha - they can become completely unusable over the winter.

But this is not the essence of the problem. The problem is that now the jaws of vices purchased at a reasonable price often break during the first clamping; At best, with regular use, the vice will last six months to a year. When examining the fracture, it turns out that they are made of simple gray cast iron. The legs do not break, this is how the running pair wears out - the thread there is the usual triangular profile (see below), and the steel, it seems, is no better than St44. And the prices for certified vices with full specifications and a guarantee... let’s not talk about sad things, let’s rather remember something good from the past. As a result, the question arises: isn’t it worth making a vice yourself at home? Not to mention the case when you need to clamp a workpiece, but there are no vices within reach. They won't turn out better, but at least they'll cost less. Or for free, if there are suitable scraps of metal profiles in the trash, see, for example, the plot:

Video: homemade vice in half a day from scrap metal

Primitive from a block of wood

Most material processing operations require securing the workpiece, and your own hands and feet are by no means the most suitable device for this. Therefore, let's start with a vice made of a wooden block. To make them you will need 4+ hundred square nails or 150-200 mm and an ax. A rip saw wouldn't hurt either, if you have one. The sight of such a device will cause either laughter or horror in a modern person, but the ancestors of the Stone Age would have shed a tear of tenderness over it - a vice made from a block of wood quite reliably holds irregularly shaped workpieces made of almost any material.

How to make a vice from a wooden block is shown in the figure:

A piece of log/log made of good straight-grained wood is split (sawed) as shown on the left in the figure; a crooked chip can be roughly trimmed onto a plane. The fixed jaw and thrust heel are attached to the “frame” with nails; the ancients secured them with sharp slivers of hard wood. The nails are driven in obliquely so that the clamping force pulls them rather than bends them.

The movable jaw slides freely along the bed. Clamp – wedge; a wedge can be hemmed at the end of a branch or a pair of them. Some skill is required to trim the wedge(s) correctly: too sharp will tip the movable jaw onto the workpiece, and too dull will push it (the jaw) upward. But the clamped workpiece, due to the elasticity and viscosity of the wood, holds quite securely. So secure that you have to knock out a wedge to release the workpiece.

Note: Long workpieces can be fixed with a pair or more of the same vice.

What to expect from homemade

The described device, of course, is temporary - all its parts get wet quite quickly, even if the tree is crushing the tree. Therefore, let’s first address the question: what homemade vices should be made?

An innumerable variety of clamping devices of various kinds are used in technology; patents for them number in the thousands and tens of thousands. It makes sense to make a vice yourself, firstly, the most commonly used ones. Secondly, they do not require special materials, production equipment or complex technologies for production.

An ordinary bench vice (item 1 in the figure) will have to be made non-rotating. Otherwise, you will have to look for either a ready-made neck-skirt pair (see below), which can also be taken away during assembly by welding, or the opportunity to use a shaping machine (simply - shaping). Of which there are very few left in operation, labor- and energy-intensive shaping processing is increasingly being replaced by precision casting, stamping and robots.

Note: in a shaping machine, the workpiece is clamped motionless, and the cutter, rotating, moves along the longitudinal and transverse axes. In screw-cutting lathes and rotary lathes, the workpiece is clamped in a rotating spindle (on a rotary table in a rotary machine) and the cutter moves in the longitudinal-transverse (in a lathe) or in the vertical-transverse plane. It never occurred to you to think about how the flanges/necks of curved cast pipes, casings of centrifugal “snail” pumps, etc. are turned. parts of complex configuration? On shaping.

Adjustable (mobile) mini-vises, pos. 2 seem to be simpler, but their production requires particularly high-quality and, accordingly, difficult-to-process materials. The fact is that the clamping force of a hand vice is determined by the muscular strength of the worker. And the cross-section of the vice parts decreases according to a quadratic law as their sizes decrease, i.e. fast. The paws most often break off just at the mini-vise. However, it is not difficult to expand their functionality on your own, see below.

Conventional carpenter's vice, pos. 3, are part of the carpentry workbench and are inoperative without it. But next we will look at how to make a Moxon vise for woodworking, which turns any workbench (including even a desk) into an almost full-fledged carpentry workbench.

What a home craftsman should really do on his own is a single-axis machine vice (a simple fixed table) for a drilling machine, pos. 4. They can also be used independently (separately from the machine) for a wide variety of jobs. The material for machine tools is the usual one that is widely available; Literally nothing is required to produce a machine vice that is not inferior to a branded one.

Jewelry vices, manual (item 5) and tabletop (item 6) are the most convenient things for small precision work. But alas, their production requires special materials and equipment, which is available at every general machine-building plant. At home, you can make good substitutes for “frog” vices, pos. 7, which, by the way, are often included in the set of desktop jewelry vices, pos. 8.

But with an angular vice (item 9) for clamping parts connected at an angle, the matter, as they say, is deaf. It is possible to make something similar with your own hands (item 10), but, firstly, it turns out that it is very difficult to ensure clamping at a fixed angle of exactly 90 degrees, and if you succeed, then the angle then quickly “floats”. It’s not worth talking about a homemade corner vise with an adjustable clamping angle. The same applies to 2-3 coordinate manual machine vices (pos. 11-14) and, for example, devices for tying fishing flies (pos. 15), which are no longer a vice, but a highly specialized machine.

Locksmith

The design of a hand bench vice is shown in Fig. The shaped screw nut is fixedly fixed in the frame tunnel; it also includes the shank of the clamp, called the slider. The sections of the tunnel and the slide are also shaped (of complex configuration) and correspond to each other.

As has already been said, you will have to abandon the rotation of the vice in the horizontal plane: for this you need to machine a neck on the base plate, and a skirt on the bottom of the bed. This does not require ultra-precision, but special equipment is required, see above.

The second problem is paws with sponges. The paws must be very rigid so that the clamped part does not react, and at the same time viscous so that they do not break. Therefore, the cheapest material for the jaws of a good vice, together with the clamp and frame, is structural cast iron, but it is poorly processed, and the clamp and frame are cast. You can’t set a cupola furnace or electric furnace at 1700-1800 degrees at home, so we forget about casting ferrous metals.

However, cast iron is also very hard and quite fragile, and therefore paws without jaws can either damage the part or crumble on it themselves. Jaws made of hard, wear-resistant and at the same time very elastic special steel solve the problem. It would be possible to make all the vices from it, but their price then... You haven’t come across a tabletop vice at a price of... $1 for also 1 mm of jaw width? These are all-steel ones, but we need to think about how to make a frame and a vice clamp, suitable for at least occasional use, from ordinary structural steel.

Running pair

But what problems arise with that seem insurmountable is with the running pair of vices. It seems nothing complicated: a screw with a nut or a threaded hole in the frame. There is a groove machined in the neck of the screw; It seems that you can select it with a file by clamping a screw wrapped in thin aluminum by the thread into the chuck of a drilling machine or a drill mounted on a table. In the clamp (or in the slider of a vice assembled from individual parts), the screw is fixed with a fork grip, see fig. on right.

The thing is that all these parts have to take on huge workloads. If you lean on the knob with a force of approx. 20 kgf (nonsense for a normal adult man), then the thread with the neck of the screw and the counter parts will require more than 120-130 kgf/sq.m. mm. In total, so that the vice does not wear out very quickly, the screw, nut and fork must be made of steel with a yield strength of more than 150 kgf/sq. mm; for a conventional structural thread it is less than 100. And a regular metric thread of a triangular profile will quickly wrinkle or stick together.

Drawings of the lead screw of a bench vice with a jaw width of up to 180 mm are given in the figure:

One critical point is bypassed here: instead of a groove on the neck, there are a pair of bushings made of ordinary steel. In this case, the fork grip can also be made from it. The screw retainer parts will have to be changed periodically, but that's all right. But how to cut a D20 trapezoidal thread? Looking for a running pair from an old vice? So, with a 99.0% probability, it is the “stroke” that is worn out in them, and the cast-iron frame, clamp and plate are still quite suitable for use.

It's not all bad

A lead screw and a nut for it for irregularly used vices with a jaw width of up to 150 mm can be found in almost any hardware, tool or construction store or at an iron market. New, the fly was not sitting. Where? From fastening units designed for a load of at least 450-460 kgf. These units are very important, and the steel used for them is just right, even better - a running pair of vices, which are not used intensively, will be quite durable and have a regular metric thread.

The cheapest option is a ring anchor for hanging heavy chandeliers or multifunctional exercise equipment from the ceiling and walls, shown above in Fig. below. Just make sure that the screw is either cast or the joint between the ring and the neck is welded (shown by the red arrow). Anchor rings are available up to M22 with a length of up to 450 mm - make the vice you want. The anchor ring M12x150 holds a load of 480 kgf, and M16x220 for a 150 mm vice is also suitable with a reserve.

The second option, “the class of the fly did not sit” will cost more, but perhaps at the price of scrap metal - if it is broken. This is a hook-ring lanyard, shown below in Fig. Of course, the ring part comes into play (shown by the green arrow). The advantage is that you will immediately have an excellent wear-resistant nut. The disadvantage is the shorter length and, accordingly, the stroke of the vice jaws: the lanyard screws for 200 have a length of threaded parts that is slightly more than 100 mm.

Note: some disadvantages of both - the vice knob will have to be turned for a long time each time, because standard metric thread pitch approx. three times smaller than a special trapezoidal one. The running pair will need to be periodically lubricated with grease or other grease - a “dry” vice with such a running pair rotates tightly, but does not press well.

Sponges

How a bench vice, well known to readers of the RuNet, works is shown in Fig. below. There is, however, a mistake - the locking nuts are also M16. The rear one, along the screw, is screwed on first and welded to the stud. Then the pin with the rear washer on is inserted into the clamp, which in this case is also the slider (“moving part” in the figure); the front washer is put on, the M16 front nut is screwed on and welded, and the eye for the knob is welded; this is already an M18 nut. Bed (“moving part”) – square corrugated pipe 120x120x4; the slider is also a square corrugated pipe 100x100x3.

So far so good, but the sponges are also made from professional pipe. Their working surfaces are smooth, but they need corrugated ones, but that’s not so bad. But the trouble is that even with just a little pressure, the lips will irreversibly separate (added to the picture). The jibs inside or outside will not help - the metal itself is unsuitable. The reader may have already guessed - since the problem is described, there is a way out. Even two, see below and next. chapter.

Note: The advantage of a bench vise made from sections of corrugated pipes is their low cost. Suitable pieces will probably be found in any scrap metal pile, see for example. video below:

Video: homemade vice from pipe scraps

The first one is also from RuNet: paws and jaws from the shanks of metal turning tools. On the paws there are thicker incisors; for sponges - less. But this, in general, is not a solution. Tool steel is very difficult to process. Almost all that can be done with it in a home workshop is to saw off the shanks with a grinder, weld jaws to the legs and weld the whole thing to the frame and clamp. Tool steel has almost no resistance to welding. But it is also poorly cooked: the finished legs with jaws, when welded to the corrugated pipes, will have to be heated so that the frame/clamp will move unacceptably. And the times are not the same now when worn-out cutters could be collected from a factory dump, and defective ones could be bought for pennies in the Young Technician store. With the spread of electric arc melting of metals in the world, tool steel has become a valuable secondary raw material, and at enterprises, used turning tools are counted individually. Therefore, we move on to the second exit.

Machine tools

As stated above, it is most profitable to make a machine vice with your own hands. They greatly simplify drilling work, and the material for the machine vice is suitable for almost any available material: from a channel, see video:

Video: simple channel vise

to plywood, see story:

Video: plywood carpentry vice for a drilling machine

And again sponges

The strength and stability of the jaws for a machine vice is even more important than for a bench vice: if a drill (cone, cutter) turns a part out of them, this can lead to serious injury. And so, we return to the question above: what are the vice jaws made of? From a corner from 40x40x4. In this case, the entire sponge will work not for shear, but for bending, to which the metal resists much more strongly. This is the case when less iron turns out to be stronger.

But not every corner of the same size is suitable. A drawn and cold-rolled corner (pos. A and B in the figure below) is unsuitable - the metal is rather weak. The jaws of both homemade and metalworking and machine vices must be made from hot-rolled angle (pos. B). Firstly, it is much stronger. Secondly, the range of its standard sizes is wider: if the thickness of the flange of a cold-rolled general-purpose angle is up to 0.1 of the width of the smaller one, then for a hot-rolled angle it is up to 0.2b. That is, you can find a hot-rolled angle, say, 60x60x12 - the vise jaws from it will be quite reliable.

A hot-rolled angle is easy to recognize by the type of cut: the entire edge of the outer corner is always sharp (shown by the arrow on the left in the next figure), and inside it there is a fillet larger than that of a cold-rolled angle. If the vice is assembled by welding, both equal and unequal angles will do. If you assemble them with bolts, it is better to use an unequal shelf with a shelf width ratio of (1.5-2)/1 (a/b = 1.5...2/1). In this case, the large shelf is laid horizontally!

The design diagram of a homemade machine vice from a corner with bolts is given in the center in Fig. on the right are drawings of their general appearance. The slider and bracket for the clamping screw are bent from a steel strip with a thickness of 1.5 mm. The screw in it can be fixed with a groove, because its fixation works only when the movable jaw is retracted and is loaded negligibly. On the clamp, the tail of the screw rests directly on the sponge; the screw itself is M16-M20. For more information about homemade machine vices from a corner, see the video:

Video: simple vice for a drilling machine

Improving the mini

Modern mini-vises cannot be improved much, but if you come across or already have old Soviet ones (for example, pos. A in the figure on the right):

Their functionality can be significantly expanded as follows:

- Drill out (carefully, not all the way!) the flared shank of the set screw, which holds the set clamp plate. You need to drill with a drill with short “poke” diagonally from different sides.

- The plate is removed and the mounting clamp screw is unscrewed (do not lose either it or the plate).

- A hole is drilled in a section of the channel for a bolt with the same thread as on the clamp screw.

- The vice is mounted on the resulting stand and secured with a lock nut (pos. B).

- In the clamp screw, through the remainder of the shank, a blind axial hole is drilled for the M2-M3 thread. This is not difficult to do, because... There is a conical depression left in the peg from the shank.

- A thread is cut in the axial hole.

- The plate is put back in place and is kept from falling out by a screw with a conical head (shown by an arrow in position B).

- The clamp screw is stored in the stash, sorry, stash.

Thus, we get, neither more nor less, a rotary table for small drilling work. True, without an angular divider, but instead of it, a protractor can be attached to the channel base, and a pointer arrow can be attached to the vice bracket. The resulting accuracy of 1 degree is sufficient for amateur home work. And if you remove the vice from the base and return the clamping screw to its place, they can be used for their original purpose.

Making a frog

Jewelry vices in amateur work, as mentioned above, in most cases are replaceable with a frog vice; They can also be clamped in a regular vice. The best homemade option is if your pliers or other pliers have a broken handle, at the top in Fig. To drill the jaws of the pliers, you need to purchase a carbide twist drill - a regular one for metal will not take them.

Homemade “frog” vice (locksmith’s clamps with fixation)

A simple replacement, if the pliers still don’t break, a frog vice made of oak or beech bars, a steel bracket, overhead jaws made of steel angle and fasteners, bottom left in Fig. A stronger option is a frog from a door or small barn hinge, bottom right. But you will have to work on it using a regular vice. The workpiece may need to be tempered by heating until red hot and then cooling slowly.

Carpentry

The Moxon Carpenter's Vise is designed for the traveling joiner and carpenter. In Europe, the USA and Canada, this is a rather in-demand specialty: given the prices for lumber there, many customers demand that the master work with them locally and leave the slightest scraps, even sawdust and shavings, to the owner. A pair of Moxon vices, which makes it possible to work with long materials, can be carried in the trunk of a car, on a bicycle, on a scooter or in a bag. The find was immediately appreciated by amateurs - Moxon's vice allows you to quickly and reversibly turn any more or less durable table into a carpentry workbench.

The appearance and method of fastening the Moxon mobile carpenter's vice are shown on the left and in the center in Fig. On the right is a device for their amateur version for fastening tightly to the table.

The Moxon vice has spawned many modifications. Drawings of one of them, a very simple and convenient carpenter's vice made of just 3 boards and a pair of clamps, are shown in Fig. Further. True, you will actually need 2 more short clamps to attach the vice to the table. An extra 4 clamps (also not a very cheap pleasure these days) can be expensive for an amateur. But for an individual carpenter who works on call, such a vice is a godsend; disassembled, you can carry it with you in a regular duffel bag.

There is hardly a more necessary device in a home workshop than a bench vise. Even if you mostly work with wood, sometimes you won't be able to do without a vice. And if you don’t have a workshop, a garage or a corner in your apartment where you can repair simple household utensils, having a small benchtop bench vise can be a great help in many situations, turning a kitchen table or even a stool into a mini-workshop.

First of all, about the purpose. The purpose of a vice is to securely fasten and hold a part or workpiece when processing it with various tools. Depending on what objects primarily need to be secured in a vice and what tools will be used to work with them, the design parameters of the vice vary. But the most universal and most common look like this:

The basis of any vice is a screw pair. In most cases, the screw is fixed in the movable part of the vice body, and the nut is fixed in the stationary part, which is either directly or through a rotating mechanism attached to a bench or a special stand that ensures the immobility of the vice during any operations with the part fixed in it.

Types of bench vices

In addition to reliable support, you must clearly understand what types of work you will be doing and relate the choice of bench vise to them. First of all, this concerns the material of the case. In the post-Soviet space, it is often cast iron.

This material is hard, wear-resistant, but quite fragile. Therefore, if you are not going to bend thick steel workpieces with a sledgehammer without seriously preheating them, then feel free to take such a vice, and if you do, then it’s better to look for a steel one.

If you need to regularly fasten cylindrical workpieces in such a table vise, then it is advisable to make a jaw cover with a triangular cutout. And if such operations are quite frequent, then we advise you to consider options for the design of a bench vice that are somewhat different from the standard ones.

In general, if we talk about the functionality of a bench vice, then first of all you should think about the size. If you know for sure that you will not have to work with large parts, then do not pay for extra metal, and perhaps even consider a compact machine vice.

Or vice versa - it is possible to work with large-sized parts, but without much effort when processing them. Then you can consider the option of a vice with the ability to pre-expand the jaws without using a lead screw.

If you do not have a workbench, and the list of works also includes more operations that do not require the application of brute physical force to the parts being processed, then the option with a table vice, secured with various clamps, is yours.

True, the latter are mini-tise, it is better to have them on the farm as additional ones. You can’t clamp large parts in them, and you can’t put any serious effort into the workpiece being processed - there’s not enough pressure on the clamp to hold the vise itself, but making a lock key based on a sample is just the thing.

In addition, such vices are sometimes indispensable if you need to unscrew a stuck nut, when you can use them as a hand tool. Despite their miniature size, their jaw pressure is very good.

It is also worth mentioning a small vice on a ball joint, which serves for the convenience of processing very small parts of complex configurations, allowing you to process various surfaces of the part with one fastening.

It is clear that the clamping force of the ball joint is not enough for serious physical loads, so such a vice is suitable for quite specific types of work. The same, in our opinion not very serious, will be vices with fastening using a suction cup.

To secure them more or less securely, you need either a well-polished surface or glass. It is unlikely that they will be securely attached to other surfaces. And their functionality is also limited.

For all types of bench vices, you will obviously need additional pads to secure parts made from soft materials.

Some table vices have a pneumatic drive, which greatly facilitates the process of securing the workpiece.

But if you don’t have a mini plumbing workshop at home, then you are unlikely to need such a vice.

What else is important to know when choosing a bench vise? There are quite a lot of complaints from users about Chinese vices with cast iron bodies, equipped with clamps for fastening - they often break off, so if you want a cheap vice from the Middle Kingdom, it is better to choose one made of steel.

Choose a vice that has the least amount of play between the body parts when the jaws are set as far apart as possible. Also, if you do not need a rotating mechanism at the base of the vice for work, choose a model without it: you will save money and the structure is more rigid.

How to make a bench vise with your own hands

The question arises: why, with such an abundance of sizes, shapes and configurations of bench vices offered by the retail chain, bother making them yourself? When making a bench vice with your own hands, you can save up to 10 times in cost, and also make a device with the specified parameters.

And this is absolutely real, because almost everything that can be useful for making a table vice can be found at scrap metal collection points for mere pennies.

This is especially noticeable in the photograph, in which parts of a plumbing pipe valve with a flywheel are used as a screw pair.

You can also take a screw pair from an old vertical jack. Even if part of the thread has already worn slightly, then, as a rule, this is a small area from the edge of the screw, which will still need to be trimmed to shorten it. The lead screws of old lathes, screw presses, etc. are also very durable.

At worst, for very little money you can order a turner at the nearest vocational school such a pair with a wide nut, with a regular metric thread. Just make the diameter larger and the nut wider. In this case, the clamping force will be redistributed over a sufficiently large area due to the diameter of the screw and the number of turns.

As a last resort, just buy a stud with a larger diameter from a store that sells hardware, and a tall nut for it, or 3 regular ones, which you then weld in series, screwed onto the stud.

The classic version of a homemade bench vise

The photograph clearly shows the steel parts, which can almost always be picked up without much difficulty at the nearest metal shop:

- steel plate 200 x 200, thickness 3 – 6 mm (thicker is possible);

- 2 channels (120 mm - external, 100 mm - internal) with a length of 160 mm and 300 mm, respectively; in your case, the dimensions may be different depending on the length of the lead screw;

- steel ears from some large container;

- 2 worn turning tools;

- rod for the wrench, in this case a piece of reinforcement;

- a screw or pin corresponding to the diameter of the rod, and 2 nuts;

- 2 washers, with a diameter corresponding to the diameter of the lead screw;

- screw pair - any of those described (in this case - ordered by a turner), 335 mm long;

- powerful plate for fastening the lead screw.

The lead screw on both sides of the plate is separated by washers, one of which, on the side of the threaded part, is welded to it, although with this diameter it can be secured with a cotter pin or retaining ring. Then this unit will be completely dismountable, which is clearly better for reasons of maintainability.

The handle on one side is sealed with a welded nut, and on the other side it is made collapsible after welding the thread from a screw of the appropriate diameter to it.

The nut from the screw pair is welded to the base plate flush with the 120 channel.

For normal fit of the inner channel with the lead screw attached to it, its ribs need to be lightly processed with a file.

The ears with jaws welded to them, made from cut turning tools, must be positioned with the lead screw screwed in. This way they will take the exact place. You can even twist the jaws together with soft wire, ensuring their ideal position.

You can also first apply a notch to them using an angle grinder with a metal cutting disc.

Due to this type of fastening of the jaws, namely the shape of the hooks and the distance between them, non-standard parts that are widened towards the bottom can be fastened in such a vice.

And the maximum thickness of workpieces processed in these vices is quite impressive. And there is no need to talk about the maintainability of such equipment - you can see for yourself.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you;)