Making a miracle stove for heating with your own hands: features of the stove from a cylinder. How to make a miracle stove with your own hands - Buleryan stove Soviet miracle wood-burning stove for a summer residence

Read also

With elements from car rims

It is not always possible to install a heating system in country house, garage or outbuildings, which would work from natural gas. There may be several reasons for this - the lack of a centralized gas supply, the high cost of connecting to the gas main, etc. Therefore, many “homemade masters” decide to build a miracle stove with their own hands, which can be heated with any kind of fire. solid fuel. And such fuel outside the city limits is usually in abundance.

What types of homemade stoves exist?

The skillful hands of a craftsman, in the presence of accurate and understandable drawings, can make different types heating structures, which fully provide heat small room, even without constructing a pipeline system and installing radiators.

Such devices include:

- Traditional potbelly stoves.

- Buleryan stoves.

- Furnaces under development.

Potbelly stove

Wood-burning stoves have been providing heat to residential houses, garages, greenhouses, sheds and other premises where the creation of a warm microclimate is required for decades. Such stoves are a simple metal barrel, as a rule, used, which has fairly thick walls. First of all, it is necessary to make drawings, in accordance with which all work should be carried out.

The volume of the barrel must be at least 100 liters. The whole job is to share inner space barrels into two compartments, one of which will serve as a combustion chamber, the second as an ash pit. To do this, a horizontal metal partition with a thickness of at least 5 mm is made in the barrel, in which holes are cut to remove ash.

Potbelly stove diagram

The lower compartment, which is an ash pan, is equipped with a retractable metal box, where fuel combustion products are collected. On the front wall, a hole for the combustion chamber measuring approximately 40x40 cm is cut out with a chisel or by welding, and an opening for the ash pan, the size of which is 10–15 cm smaller than the combustion chamber. The combustion hole must be equipped with a door and a valve.

The top of the barrel is closed with a lid, in which a hole should be made for the chimney pipe. The lid itself is scalded around the perimeter by welding. In the future, the barrel must be placed on legs or brick foundation to prevent the floor underneath from catching fire. Naturally, such a structure has many disadvantages. This includes low efficiency, since most of the heat is lost through the chimney pipe, rapid cooling, and the need to constantly add firewood to the firebox. But this is the most economical model, which you can make with your own hands in just a few hours.

Buleryan stove

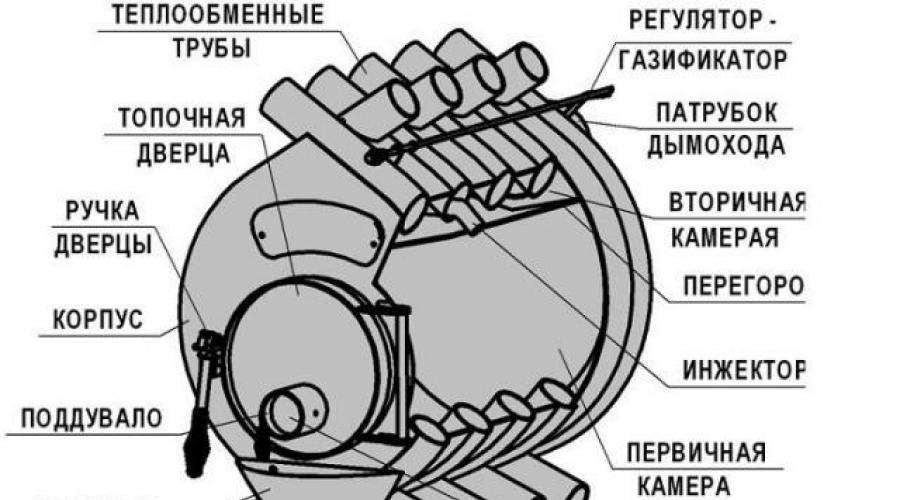

Buleryan device

Buleryan device This type of wood-burning stove is much more expensive at cost than a simple potbelly stove. Do similar design You can also do it yourself, although you will need more professional skills of a welder and mechanic, as well as detailed drawings. Unlike a potbelly stove, in such a stove you can regulate the duration of fuel combustion, which can reach 10–12 hours with one load of firewood.

In addition to the fact that the heat comes from the stove itself, the room quickly warms up due to the hot air coming out of the pipes, which are present in the design of the Buleryan stove and are its distinctive feature.

Furnace in production

Ideal for the garage

Ideal for the garage It is undesirable to use such a design for heating a living space, since burning oil emits unpleasant odors There are also some carcinogenic substances that are extremely harmful to breathe. Such stoves are most often used by car enthusiasts to heat the garage, given the availability of fuel, which you don’t even need to buy. Having primitive drawings in hand, any car owner can build such a miracle stove.

All of these stoves, despite the rapid heating of the room, have a number of disadvantages, which include low productivity, the need for constant control over the process of burning wood and the addition of fuel.

In the ovens long burning these shortcomings do not manifest themselves to the same extent.

How to make a long-burning stove with your own hands

The operating principle of such a unit is based on the fact that firewood does not burn, but smolders. This makes it possible to make one stack of firewood, which lasts for 12–15 hours.

To make a stove, you need any metal container with a wall thickness of at least 5 mm and, of course, detailed drawings. Shape of the future heating device does not play significant role. For example, let's take the old one iron barrel. The top (lid) is cut off using an autogen, welding or a chisel and all burrs are cleaned off.

Long burning

Long burning After this, it is necessary to cut a circle smaller than the cross-section of the barrel, to which a pipe with a diameter of 100 mm is welded. The pipe should protrude 15–20 cm above the upper edge of the barrel, counting from the bottom of the combustion chamber. From below, several more plates need to be welded onto this circle, located perpendicular to the plane of the circle. This part will serve to supply air to the furnace and at the same time pressurize fuel. It is important to make the lower blades rounded clockwise so that the smoke before leaving combustion chamber gave all his heat to the walls of the oven.

A hole is cut out in the front for loading firewood and equipped with a door. A hole is cut out at the back to remove smoke, into which a pipe with a diameter of 150–20 mm is welded. At a level of 20 cm from the bottom, grates are installed inside the barrel, and a hole is cut in front of this part to remove ash and slag. The entire structure is closed from above with a previously cut lid with a hole for the pipe. The lid should be equipped with handles for convenient use.

Needs to be done under the stove solid foundation made of red brick or concrete. The chimney pipe is vented outside. Such a miracle stove must be located at some distance from the walls for fire safety purposes.

Conclusion

Naturally, heating a large country house with such stoves is problematic, but such a task is not set for them. But keeping warm in the cold at the dacha or in the garage is quite possible. Or, by installing such a miracle oven in a greenhouse, grow more early vegetables. Any man who is comfortable with tools and welding and can read blueprints can make such a heating unit.

Not every owner of a country house or country house has the opportunity to install a heating system running on natural gas on its property. This problem may arise due to high cost connection to the main line or lack of a centralized supply. The solution to this problem can be a miracle wood-burning stove. It can be heated with any solid fuel, such as wood or coal.

The miracle stove can be heated with any solid fuel, this is convenient if there is no access to natural gas or electricity

Types of devices

The traditional Russian stove does not fit into the design modern buildings, it takes up too much space, and its heating capabilities leave much to be desired. Nowadays, it is not advisable to install a bulky stove, because you can build a more compact and efficient device if you find suitable drawings. Assembling a miracle oven with your own hands is not as difficult as it might seem at first glance. Such a device can make a room warm and cozy even on the coldest days. Miracle wood-burning stoves come in the following types:

- potbelly stoves;

- devices under testing;

- buleryans or bullers.

If the owner of the house knows how to work with his hands, then with the help of schematic descriptions and video master classes he will be able to create the device he likes. This will help him acquire a heating system without constructing a pipeline and installing radiators.

You can see an example of a wood-burning miracle stove in this video:

Metal potbelly stove

Such installations are usually used in small spaces, for example, in garages, sheds, greenhouses and country houses with a small area. They are great for creating a warm microclimate and are an ordinary barrel with thick metal walls. Before its manufacture, a drawing is developed, according to which the unit is subsequently assembled.

We assume the structure of the Buleryan stove self-assembly

The body must have a volume of at least 100 liters; its internal space is divided into two parts by placing a metal partition 5-10 millimeters thick there. A hole is made in it to be able to clean the device from combustion products. The first compartment plays the role of a combustion chamber, and the second is designed to collect ash.

An iron box is placed in the ash pan, in which all the garbage will accumulate. A hole for the combustion chamber is cut out in the front wall; its size is usually 40x40 centimeters. The ash pan also needs an opening, but it is smaller than the first by about 10-15 centimeters. It must be equipped with a valve and a door.

The barrel itself is closed with a lid through which a chimney pipe is inserted into the stove. All parts of the furnace are connected together using a welding machine. Ready design placed on legs or a brick stand so that when hot it does not damage or set fire to the floor. It is worth noting, What are the disadvantages of such a device:

- cools down quickly;

- you need to regularly add firewood to it;

- low efficiency.

However, the potbelly stove has a low cost and is very easy to assemble. Typically, craftsmen spend no more than 3 hours on making a structure. It is capable of heating small rooms, which is why such devices are often placed in bathhouses.

Buleryan or buller

Powerful air heater suitable for warming up various areas, is buleryan (otherwise known as buller). The price of such a stove is several times higher than that of a potbelly stove; in addition, not every owner can cope with its assembly. The device has a more complex design, and its manufacture requires detailed drawings, as well as the ability to perform plumbing and welding work.

Complex structure wood stove requires detailed drawings

A distinctive feature of such stoves is the ability to regulate the burning time of wood. One load of fuel can provide an average room with heat for 10-12 hours. In addition, the heat comes not only from the device itself, but also from the pipes. They must be included in the design of such a furnace.

It is not necessary to use iron to make a buller. The structure can be made of brick. A large body will increase the power of the stove, and the chimney is easily made from cement pipes.

However, such a device has a serious disadvantage - uneven heating of the air. The temperature of the floor is much lower than that of the ceiling. This disadvantage can be compensated for by connecting water heating pipes to the device. In this case, the stove will not only warm up the entire room completely, but will also provide the household with hot water.

It is worth noting that while the buleryan is operating, the room warms up not only due to the heat generated by the body, but also from the hot air coming out of the stove. The process looks like this:

- The firewood gradually burns out.

- The heated air flow passes into a special chamber.

- There it gives off some of the heat to the walls and then goes outside.

The advantage of such an installation is its ability to burn the gases released by the fuel during combustion. This significantly increases efficiency and the amount of heat generated. It is for these purposes that the stove is divided into two compartments: in the first, wood burns, and in the second, gas. This happens using a special arrangement of nozzles. This feature allows you to save fuel and also eliminates the formation of ash and soot, which makes cleaning the stove more convenient and quick.

Thanks to the special design, the amount of fuel is reduced and heat transfer is increased

It is important to place the chimney closer to the floor. To better understand the design and mechanism of operation of the buleryan, it is recommended to watch several videos on this topic. Information is never superfluous, and the master will be able to obtain more accurate and visual information that will help him create a detailed and accurate drawing of his own device.

Stoves under development

It is better not to use such devices for heating. residential buildings, since burning oil smells unpleasant and also releases carcinogenic substances into the air that are hazardous to health. Car enthusiasts should pay attention to such devices, because they can be placed in garages. They have a rather simple and primitive design, so these stoves are easy to make yourself.

Exhausting devices warm up the air quickly, but have a number of disadvantages: they require constant monitoring, systematic addition of firewood, and are characterized by low productivity.

DIY assembly

Miracle stoves have gained popularity among many consumers. Sometimes there is a need to be able to quickly and efficiently heat a small room without significant material and time costs. In this case, knowledge about manufacturing will come in handy heating devices on wood with your own hands. For this you only need available materials, tools, desire and ingenuity.

A simple unit from a can

Most simple design has a stove-stove. To heat a small workshop or garage, you can build a device from an old can. Of course, such a device cannot boast of durability or strength, but it is quickly assembled and easy to install. All the work consists only of arranging the pipe, connecting the parts and building a brick stand or legs. To do this you need to prepare:

- iron can;

- chimney;

- wire;

- some tools;

- welding machine.

Work begins with the horizontal placement of the can and markings. First of all, they designate the place where the vent will be. Usually it is placed under a lid and given the shape of a sickle or rectangle. After this, they begin to create the stove according to the following algorithm:

A simple potbelly stove is ready. The design can be modified by attaching a reflector to the outer wall of the housing, which will prevent heat from evaporating. If you attach handles to the device, it becomes portable. The advantages of homemade stoves of this type include:

But along with the advantages, potbelly stoves also have a number of disadvantages. So, if the case has thin walls, then over time they will become leaky and the device will fail. In addition, damp and tarry firewood can fill the smoke exit pipe with a thick layer of soot.

A homemade potbelly stove is an effective heater for work spaces and garages. Its assembly will not cause any trouble even for novice craftsmen, and also does not require material investments.

Rectangular heating device

When determining the shape and size of the stove, each master must proceed from his own preferences and the area of the heated room. A person with the necessary skills can always stop at a drawing of the simplest installation and then improve it by making the desired changes. A simple and multifunctional oven can be made from the following materials:

- sheet metal;

- steel corners 4-5 millimeters thick;

- pipes 180 mm;

- iron tubes with a diameter of 25-30 mm.

The rectangular body is made from steel sheets, welded to each other. You will need 5 main parts: bottom, 2 side walls, up and back. A door for the furnace and ash pan is cut out on the front wall.

Bake rectangular shape even easier to make with your own hands than a round one

First, the side sheets are attached to the bottom; the joints should form right angles. Their location can be determined using a square or building level. Then the back wall is welded to the structure.

The internal space of the body is divided into three compartments: the ash pan, the firebox and the smoke circulation. The first two are separated using a grate, on which firewood will later be laid. It is done as follows:

- At a height of 10-15 centimeters, corners are welded inside the oven.

- The grate is made from iron blanks 25-30 millimeters wide; their length should correspond to the width of the stove. Such parts can be made from pipes or strips of thick sheet steel.

- Prepared rods are welded to two metal tubes with a diameter of 12-20 mm. The distance between them should be about 4-5 centimeters.

The finished part is simply placed on the inner corners; there is no need to weld it. The convenience of the removable grill is that it will be quite easy to get out for cleaning or replacement.

The side parts of the furnace do not need to be welded, making them replaceable

Then a reflector is placed in the furnace, which is an iron sheet designed to separate the firebox and smoke circulation. It is also made removable. To do this, two metal rods are welded on top, on which the part is placed so that a channel is formed in front of it. It is through this that the smoke will pass. It is worth considering that this place will become very hot, so it needs to be made of very thick material.

The potbelly stove should be made of very thick material

At this stage heating system almost ready, it's time for finishing work. First, a lid with a hole for the chimney is welded to the stove. Then the door, latches and curtains are attached. The latter should be made of a steel tube and thick rod.

The structure is placed on legs or a stand made of bricks, after which a smoke pipe is installed. It should come out through a hole in the wall of the room. This element is placed at an angle of 45 degrees; there should be no horizontal sections. The device is ready, now it can be used for its intended purpose.

Even novice craftsmen can make a miracle oven with their own hands, if they know how to read diagrams and handle welding machine. You don’t have to start making it right away complex structures, you can practice by assembling a simple potbelly stove for your garage or workshop.

When a person plans to live in a private home, be it country house, a cottage in the city or a house somewhere isolated, the question always arises quality heating building.

Possibility to enter the house central heating is available only within the city limits, and even then not always; in less civilized places, a system running on natural gas can come to the rescue. Sometimes it happens that in the place chosen for construction there is no gas pipeline, or connecting to it is too expensive, and delivery of gas in cylinders for some reason is not an acceptable option. In this case, the only suitable solution is to build a heating unit such as a miracle stove using wood or other solid fuel, which is usually sufficient in any place outside the city, and you don’t even need to pay for it. You can design it yourself if you have everything necessary tools and materials, as well as good drawings.

Variety of stoves and their manufacture

This stove looks like an engine internal combustion in the steampunk style and has a significantly higher cost than . A homemade miracle oven of this type will require sophisticated skills hot welding and plumbing skills, and, of course, you definitely need detailed drawings, you can’t go anywhere without them. This stove differs from a potbelly stove in that it has the ability to adjust the burning time of solid fuel, be it wood or coal.

This stove looks like an engine internal combustion in the steampunk style and has a significantly higher cost than . A homemade miracle oven of this type will require sophisticated skills hot welding and plumbing skills, and, of course, you definitely need detailed drawings, you can’t go anywhere without them. This stove differs from a potbelly stove in that it has the ability to adjust the burning time of solid fuel, be it wood or coal.

The stove can operate for half a day on one supply of logs, which will ensure high-quality and uninterrupted heating of the room.

In addition to the heat emitted by the stove body itself, heating also comes from the heated air leaving the Burelyan stove, which are characteristic feature this unit.

The operating process of this furnace looks like this:

- The fuel burns in the firebox.

- The heated air passes through the air ducts into a special large-volume heating chamber.

- Hot air gives off most of the heat metal walls ovens.

Read also: Brick heating panel

The chimney should be as close to the floor surface as possible. To better understand the structure and mechanism of operation of the stove, it is worth watching a video on this topic, this will help to draw up accurate and detailed drawings of the device.

The basic principle of operation of such a furnace is that it burns not only the fuel itself, but also the released gases, which significantly increases the efficiency and, accordingly, the amount of thermal energy released. To do this, the furnace has two compartments, in one of which the fuel itself burns, and in the second the gas is burned using nozzles of a special configuration. The advantages include much lower fuel consumption than with conventional combustion. Moreover, When the miracle stove operates, almost no soot and ash are formed, which minimizes the need for cleaning and maintenance.

This stove has such a disadvantage as serious unevenness of the ambient air temperature - it is noticeably higher at the ceiling than at the floor. This disadvantage can be compensated for by connecting water heating pipes to the stove. In addition, in this case, the stove will not only heat the air in the house, but will also provide the owners with a sufficient amount of hot water.

Interesting fact: it is not at all necessary to use metal when constructing the Burelyan; you can make the stove entirely from brick. The increased housing size due to this will ensure an increase in furnace power. Can be used as a chimney cement pipe, laid next to the baseboards so that less heat is wasted.

Manufacturing method

Detailed drawings will be required for construction., any suitable metal canister of sufficient volume with a wall thickness of at least 5 mm. It doesn’t matter what shape the device will be, you can give free rein to your imagination. In the very simple example an ordinary one is taken old barrel volume of 200 liters, as in the case of a potbelly stove. Using a welding machine, the top surface of the barrel is cut off and all metal defects are carefully removed.

Detailed drawings will be required for construction., any suitable metal canister of sufficient volume with a wall thickness of at least 5 mm. It doesn’t matter what shape the device will be, you can give free rein to your imagination. In the very simple example an ordinary one is taken old barrel volume of 200 liters, as in the case of a potbelly stove. Using a welding machine, the top surface of the barrel is cut off and all metal defects are carefully removed.

After this, a circle is cut out, which should be smaller than the container itself - this will be a press that presses the firewood to the bottom of the combustion chamber. A metal tube about 10 cm wide is welded to the bottom. It should be so long that it is a couple of tens of centimeters above the container, counting from the bottom of the fuel combustion chamber. Rectangular plates are welded to this circle from below, located at an angle of 90 degrees to each other. This structural element is designed to supply air to the furnace chamber and at the same time to ensure the supply of oxygen for the combustion reaction. It is important to remember and be sure to put it on the drawings: the lower blades must be twisted from left to right so that the furnace body has time to take all thermal energy from smoke before it leaves the combustion chamber.

With elements from car rims

It is not always possible to install a heating system in a country house, garage or outbuildings that would run on natural gas. There may be several reasons for this - the lack of a centralized gas supply, the high cost of connecting to the gas main, etc. Therefore, many “homemade masters” decide to build a miracle stove with their own hands, which can be heated with any type of solid fuel. And such fuel outside the city limits is usually in abundance.

What types of homemade stoves exist?

The skillful hands of a craftsman, in the presence of accurate and understandable drawings, can make different types of heating structures that fully provide heat to a small room, even without constructing a piping system and installing radiators.

Such devices include:

Potbelly stove

Wood-burning stoves have been providing heat to residential houses, garages, greenhouses, sheds and other premises where the creation of a warm microclimate is required for decades. Such stoves are a simple metal barrel, usually second-hand, with fairly thick walls. First of all, it is necessary to make drawings, in accordance with which all work should be carried out.

The volume of the barrel must be at least 100 liters. All the work consists of dividing the internal space of the barrel into two compartments, one of which will serve as a combustion chamber, the second as an ash pan. To do this, a horizontal metal partition with a thickness of at least 5 mm is made in the barrel, in which holes are cut to remove ash.

Potbelly stove diagram

The lower compartment, which is an ash pan, is equipped with a retractable metal box where fuel combustion products are collected. On the front wall, a hole for the combustion chamber measuring approximately 40x40 cm is cut out with a chisel or by welding, and an opening for the ash pan, the size of which is 10–15 cm smaller than the combustion chamber. The combustion hole must be equipped with a door and a valve.

The top of the barrel is closed with a lid, in which a hole should be made for the chimney pipe. The lid itself is scalded around the perimeter by welding. In the future, the barrel must be placed on legs or a brick foundation to prevent the floor underneath from catching fire. Naturally, such a structure has many disadvantages. This includes low efficiency, since most of the heat is lost through the chimney pipe, rapid cooling, and the need to constantly add firewood to the firebox. But this is the most economical model, which you can make with your own hands in just a few hours.

Buleryan stove

Buleryan device

This type of wood-burning stove is much more expensive at cost than a simple potbelly stove. You can also make a similar design with your own hands, although you will need more professional skills of a welder and mechanic, as well as detailed drawings. Unlike a potbelly stove, in such a stove you can regulate the duration of fuel combustion, which can reach 10–12 hours with one load of firewood.

In addition to the fact that the heat comes from the stove itself, the room quickly warms up due to the hot air coming out of the pipes, which are present in the design of the buleryan stove and are its distinctive feature.

Furnace in production

Ideal for the garage

It is undesirable to use such a design for heating a living space, since burning oil, in addition to unpleasant odors, also emits some carcinogenic substances, which are extremely harmful to breathe. Such stoves are most often used by car enthusiasts to heat the garage, given the availability of fuel, which you don’t even need to buy. Having primitive drawings in hand, any car owner can build such a miracle stove.

All of these stoves, despite the rapid heating of the room, have a number of disadvantages, which include low productivity, the need for constant control over the process of burning wood and the addition of fuel.

In long-burning furnaces, these shortcomings do not manifest themselves to the same extent.

How to make a long-burning stove with your own hands

The operating principle of such a unit is based on the fact that firewood does not burn, but smolders. This makes it possible to make one stack of firewood, which lasts for 12–15 hours.

To make a stove, you need any metal container with a wall thickness of at least 5 mm and, of course, detailed drawings. The shape of the future heating device does not play a significant role. For example, take an old iron barrel. The top (lid) is cut off using an autogen, welding or a chisel and all burrs are cleaned off.

Long burning

After this, it is necessary to cut a circle smaller than the cross-section of the barrel, to which a pipe with a diameter of 100 mm is welded. The pipe should protrude 15–20 cm above the upper edge of the barrel, counting from the bottom of the combustion chamber. From below, several more plates need to be welded onto this circle, located perpendicular to the plane of the circle. This part will serve to supply air to the furnace and at the same time pressurize fuel. It is important to make the lower blades rounded clockwise so that the smoke transfers all its heat to the walls of the furnace before leaving the combustion chamber.

When it comes to autonomous heating, then you will probably remember such a device called a buleryan. In other words, such a unit contains a firebox, to which several bent pipes OK. The design allows you to burn different types of solid fuel, including firewood, with high efficiency.

Is it worth making

Such wonderful wood-burning stoves industrial production They have an impressive cost; for one model you will have to pay more than $200, but the price increases depending on the size of the firebox. Despite the fact that the design of the stove is somewhat more complicated compared to a conventional potbelly stove, many craftsmen undertake the manufacture

Design features of the miracle oven

In order for the manufacture of the described stove design to be successful, you must study the diagram of the miracle wood-burning stove, as well as its structure. The unit is an all-metal structure, which includes a firebox and bent metal tubes adjacent to it. There should be a door on the front panel through which you will load fuel. In addition, there is a device for adjusting power. With it you can change combustion modes. In the firebox there must be a secondary combustion chamber and a pipe, the outlet for which will be used by the chimney. Wonderful wood-burning stoves will work more efficiently if you properly insulate the chimney. Experts advise using for this mineral wool, the thickness of which should not be less than 3 millimeters. You will also need a vent; air will flow through it into the firebox; it is necessary for the combustion of fuel. The craftsman can also work on creating an oversized ash pit, but during the slow burning process virtually no waste will be generated. The rear wall should be double; it makes the unit even more efficient. Some models are equipped with a double housing for this purpose.

Preparation before starting work

Before you start making a miracle wood-burning stove, you should stock up metal pipes, outside diameter which should vary from 50 to 60 millimeters. You will also need sheet metal. Since the oven will operate at high temperature burning, should be used metal sheets, their thickness can vary from 4 to 6 millimeters. You should stock up standard set tools and a welding machine, in addition, you will need a pipe bender.

In the process of making a miracle wood-burning stove, you will have to cut out sections of pipes that need to be bent. At the next stage, a device is manufactured that will be used to assemble and remove smoke. The master will have to make dampers for the outlet and blower. We must not forget about the need to make a door that will cover the combustion chamber. A miracle wood-burning stove, the price of which can reach 20,000 rubles, must have a frame that will consist of bent pipes. These elements are welded together, and then a partition is installed inside. You will need to install a sheet of metal in the hollow space between the pipes. The door must have a lock, and the next step will be its installation. In order for the structure to stand firmly during operation, it will be necessary to manufacture and then weld metal legs.

Methodology of work

When it is made from a pipe it will need to be cut individual elements, of which there should be 8 in the design. The length of each of them should be 1.2 meters. A pipe bender will help bend these workpieces, giving them a radius of 225 millimeters. These components of the furnace will need to be arranged in a checkerboard pattern. To remove smoke and accumulated moisture, T-shaped devices should be made, through which the smoke will rush up into the pipe; as for moisture, it will flow down. To eliminate moisture, a special tap is installed to remove water; it must be opened only for these purposes, and then closed again. This is the only way you can prevent deterioration in traction.

What should you pay attention to when making a stove?

When making a homemade miracle wood-burning stove, you will need to make a special damper; it is necessary to remove smoke from the device. With the help of this component you can adjust the intensity of traction. For the blower, which is located on the front door, the master must make a blind damper. In order to ensure its reliable and correct fit, you need to use a spring. The most complex component of a homemade Buleryan is the front door. It should close almost hermetically. The better it adheres to the surface of the furnace, the more efficiently the entire structure will work. The miracle wood-burning stove, which has the most positive reviews, should be made using the technology described in the article. This is the only way you will be able to get a device that will work efficiently and be durable.

Using a pipe of impressive diameter, you should make two rings that should fit almost tightly into one another. To do this, you need to cut pieces of 40 millimeters in the amount of 2 pieces from a pipe that has a diameter of 350 millimeters. One of the segments needs to be cut and then unfolded. Then the front side of the structure is made, using a ring of a smaller diameter. The second ring should be used when installing the door and should be welded to the sheet metal circle. Then another ring is welded onto the door, which is slightly smaller than the diameter of the ring located on the front side of the device. In the gap formed by the door rings, you need to lay an asbestos sealing cord, and then a damper.

Nuances of the work

The design of a miracle wood-burning stove was described above; your product must comply with a generally accepted design. In the next step you will need to return to bent tubes. In the first two you need to make holes by welding injection tubes to them. This metal elements, the diameter of which is 15 millimeters. Whereas the length should be equivalent to 150 millimeters. They are needed to ensure the connection of the firebox with the convection elements.

Using pipes, you should weld the frame with the partition. For the last element, 6 mm sheet steel should be used. The gaps between the pipes are closed with strips of metal, and then welded back wall, which will allow you to form the furnace body. To accurately fit the partition elements, metal strips and walls, you must first make cardboard blanks. It is recommended to make a special lock for the door, which is an eccentric that strengthens metal loop. It is located on the wall of the structure. This device will ensure the tightest possible fit between the oven and the door. The miracle wood-burning stove, the greenhouse version of which is presented in the article, must have a door and hinges, the latter are made and hung on final stage. This also applies to the legs of the stove, which should be as strong as possible.

Conclusion

The production of buleryan is difficult to name simple process, a traditional potbelly stove will be much easier to make. However, the high coefficient useful action and ease of use justify the time and effort spent. Initially, however, you will have to prepare drawings of a miracle wood-burning stove; they will allow you to carry out the entire process without errors, which will be the key to the success of the work done.