Imitation of valuable wood. Processing wood to resemble valuable species Imitation of valuable pine wood

Read also

Imitation (painting with transparent paints) of wood simple breeds under more valuable plays a big role in color design furniture. The color and texture of wood depend primarily on its species, however, if necessary, the color of wood can be changed with special dyes. The quality of the imitation depends not only on the dyes, but also on the wood being processed.

Birch, linden, beech, alder are well imitated as walnut; spruce is satisfactory; good for mahogany - pear, alder, cherry, ash, elm, beech; satisfactory - spruce, birch, cedar; under pink tree- good maple, satisfactory - alder, pear; under ebony- good birch, oak, maple, pear, apple, plum, hornbeam, satisfactory - aspen, poplar, beech To imitate wood, various dyes are used (preparing solutions from them), which easily penetrate the wood.

For coloring wood, nut stains (humic dyes) are widely used, as well as all kinds of mordants (copper or iron sulfate), potassium chromate or dichromate, potassium permanganate, ferric chloride (copper chloride), which are used to first etch the wood and then paint it with non-mordant dyes.

Wood species containing tannins (oak, chestnut, walnut, etc.) can be painted without pre-treatment.

To prepare coloring solutions, softened water is used. soda ash(about 0.1%) or ammonia (5%).

Heat the water to 60-80°C, add the required amount of dye (according to the recipe), stir until completely dissolved and let it sit for 48 hours. The settled solution is poured into another container. If part of the sediment gets in, the solution is settled a second time and filtered. Undissolved sediment leaves spots and streaks on the surface of the wood.

For more uniform coloring, the surface of the wood must first be moistened with water using a swab or rag.

The prepared coloring solution is applied to the surface of the wood only along the fibers with a brush, a spray bottle, a greasy sponge, or a clean cotton rag. After painting, the surface of the wood is wiped with a clean rag, removing greasy stains that leave stains and streaks.

In order for the coloring solution to penetrate more deeply into the pores of the wood, it is heated to 50-60°C. Painted products must be dried for at least 1.5-3 hours at a temperature not lower than +18°C, but more is possible long time before completely dry paints.

Various dyes are used for direct dyeing of wood. For example, for dyeing in reddish- Brown color birch, beech, oak, take 10 g of walnut stain per 1 liter of water. To dye birch trees reddish-brown, take 20 tons of walnut stain or 2 g of Ruby dye, etc., per 1 liter of water.

In addition to direct dyeing, mordant dyeing is used, in which the surface is first treated with a solution of salts of certain metals, and then, after 10-15 minutes, painted with a solution that reacts with the mordant, forming a water-insoluble compound. Depending on the stain used and its concentration, the color of the wood may vary.

The waiting time between applying the etching solution and the dyeing solution is 10 minutes.

For example, pine and larch wood is painted brown as follows: first, it is etched with a solution of resorcinol (20 g per 1 liter of water), then coated with a solution of chromium (10-30 g per 1 liter of water). The waiting time between etching and dyeing is 1 - 2 hours. Walnut birch is painted as follows: pickled with brown fur dye (2-5 g per 1 liter of water), painted with acid orange and potassium chromate (2-5 g per 1 liter of water).

In the practice of dyeing wood, many people use conventional dyes intended for dyeing cotton fabrics and fur. The strength of the solution depends on the intensity of the coloring; it is better to use stain.

After dyeing, the transparent finishing begins.

Ingredients for imitation "walnut" (in parts by weight): Glauber's salt - 3,

potassium permanganate - 3, hot water (60-80*C) - 100.

This composition is applied with a brush to the wood 1-2 times.

To obtain veins, first apply the solution to the entire surface and, after giving

dry, apply again in some places in the form of veins.

Composition for imitation "mahogany" (in parts by weight):

aniline cherry paint - 3, hot water (60-80*C) -150.

The composition is applied to wood, which acquires a cherry-red color.

Compositions for imitation birch and maple “walnut” (per 1 liter of water):

Epsom salt - 30, potassium permanganate - 30.

This composition is applied in the same way as the first.

After painting, the wood is coated with filler as indicated

above, then varnished and polished.

A wax layer, i.e. painted wood, can serve as a filler

wax with cooled wax, which is applied to the surface with a hard brush

and short stubble.

The coating should be uniform, without gaps.

The applied wax layer is dried for 24 hours at a temperature of 18-20*C,

after which it is rubbed with a cloth until the surface becomes clean,

with an even shine.

To secure the finish, the wood is coated with varnish diluted with polish.

in a 1:1 ratio.

Wax finishing is used primarily on porous wood.

species (walnut, oak).

Composition of wax mastics (in parts by weight):

1) wax - 30, stearin - 10, soap - 10, turpentine 40, rosin - 10;

2) wax - 25, soap - 12, ocher - 5, potash solution - 18, rosin

or oil varnish - 40.

To prepare mastics, wax, stearin, rosin are melted by heating

up to a temperature of 80-90*C.

To the molten mixture, continuously heating, successively add

while stirring an aqueous solution of potash, oil varnish and soap shavings,

mix again and add ocher (to the second mixture).

Heating and stirring continue until

until the mastic becomes homogeneous.

Cooled mastic of composition N-1 is diluted with turpentine before use.

The technology for finishing painted wood with varnishes is the same as for transparent wood.

If wax mastics are used as a filler,

the surface is not primed.

If it is necessary to eliminate small defects on the surface of furniture

(loss of gloss, tarnishing varnished surface, stains, scratches,

traces of moisture) use the following compositions (in parts by weight):

1) turpentine - 25, denatured alcohol - 15, shellac - 4, drying oil - 5,

soap solution (10%) - 1, water - 45.

First, mix turpentine, alcohol and soap solution, and then

while stirring, add drying oil and pre-molten shellac

and diluted with water.

The composition is applied cold, thoroughly rubbing with flannel until

until the surface regains its former shine;

2) stearic acid - 2, turpentine - 3, dye (to the required color).

Surface treatment should be carried out in compliance with technological

operations as already described above.

In case of significant damage to the polished surface of the furniture, it is necessary to

remove the entire finishing layer, for which it is washed with SK-36 solvent

or one of the following compositions: aqueous 10% solution ammonia, a mixture of ammonia and turpentine (2:1) or a 10% solution oxalic acid, solvents: acetone, ethyl acetate.

The wash must be cooled when working.

First, the entire surface is moistened with a solvent, then they begin to thoroughly wash away individual areas and again wipe the entire surface with the solvent.

After this, the surface is wiped with gasoline, turpentine or warm water,

to remove traces of solvent.

The stains and traces of finishing remaining after drying the surface are removed by scraping. After this, the entire surface is sanded with fine sandpaper and tinted dark.

color using the methods described above.

If the surface has been stained or etched, after removing the finishing varnish layer, the paint layer is also removed, for which the surface is washed

10% - oxalic acid solution or bleach.

Next, apply the finishing layer again in the same sequence,

which is described above.

Imitation of valuable wood species.

Imitation of valuable wood species is usually carried out by impregnating the surface with an aqueous or alcoholic solution of various stains, aqueous solutions of aniline dyes or special chemical compounds aqueous solutions various substances. To process wood to look like mahogany, you can also use a mixture of black and red ink (the required proportion should be selected empirically). Imitation of walnut wood can be done with a 2% alcohol solution of iodine.

Finish:

“mahogany” lends itself well to alder, elm, ash, beech, cedar, birch, cherry and pear,

“ebony” birch, oak, maple, hornbeam, apple, plum and cherry,

“walnut” alder, birch, linden and beech.

Table: Aqueous solutions for simulating valuable wood:

Solution number: 1 Potassium dichromate

2 Potassium permanganate

Concentration, g/l: 1: 25

2: 25

Imitation: “Walnut”

Technology: Apply the second solution 10 minutes after the first

Solution number: 1 Copper sulfate

2 Yellow blood salt

Concentration, g/l: 1: 10-50

2: 100

Imitation: “Mahogany”

Technology: Apply the second solution after the first has dried

Solution number: 1 Aniline chloride

2 Copper chloride

3 Potassium dichromate

Concentration, g/l: 1: 50

2: 50

3: 25

Imitation: “Ebony”

Technology: First apply a mixture of the first two solutions, and after 10 minutes the third solution

The solution is applied to a carefully sanded surface with a swab of gauze folded in several rows, a rough brush, or a spray bottle. You can immerse parts in the solution. In order for the composition to lay down in an even layer, the surface of the product should be pre-moistened. If 15-20 minutes after the first coating the color of the desired tone is not obtained, the treatment should be repeated (possibly more than once), but try not to over-moisten the wood, so as not to cause it warping and cracking.

It is better to check the color and tone of the dye first on paper, and finally on a piece of wood of the same species, prepared in a similar way. Raw, treated wood gives an almost correct idea of the future brightness of color and tone under varnish. The dried smear coated with varnish matches the final color and tone of the future coating.

Paint adheres better to wood if you add a little (up to 3%) wood glue to the solution. When processing wood coniferous species It is recommended to first clean it of resin deposits, and then wash it with a 10% solution of caustic soda, gasoline, turpentine, alcohol or a 10% solution table salt. Metal cases can also be finished with plywood veneer.

Here is one of the technological methods:

A smooth, flawless sheet of organic glass with a thickness of about 3 mm and other dimensions, 30-50 mm larger than the largest wall of the case, is thoroughly washed from dust and dirt, dried, greased one side with Vaseline and wiped dry. In this case, Vaseline remains in the micropores of the glass. Then the sheet is placed on a flat horizontal surface with the greased side up and a certain amount of prepared epoxy glue is poured onto it. The glue is carefully spread over the glass in a layer of 1-1.5 mm and a sheet of veneer cut with some allowance is placed on it with the front side.

All air bubbles from the adhesive layer are carefully removed by squeezing them to the edges. Bubbles can be easily detected by viewing the bag from the glass side. The veneer is then covered thin layer epoxy glue and place a case on top of one of its sides. Before this operation, the case must be thoroughly cleaned of dust and degreased. After 6-7 hours organic glass removed. To do this, a sheet of glass is carefully bent at one edge, and it gradually moves away from the layer of hardened glue.

The surface is smooth, with a mirror shine. Any glue leaks along the edges are filed off immediately, without allowing it to completely harden (after a few days it will become brittle and will chip during processing). After this, the next side of the case is processed.

The structure of pine, birch, maple, aspen and linden wood is very similar to the structure of mahogany, walnut, oak, and beech. For many years now, this observation has allowed cabinetmakers to create true masterpieces from inexpensive wood, which is always at hand, by modifying available material in a noble and respectable way with a tassel. The main thing for imitation is to choose the right dye.

Hard nut to crack

Walnut wood attracts with its richness of shades and wavy patterns. To imitate the pattern of walnut fibers, you need to have several basic shades of stain: rich taupe, light brown (“café au lait”) and yellow-brown.

Walnut wood has a dark brown core with gray undertones. This color fades through light brown and dark to yellow-brown sapwood.

It often happens that the fibers intertwine and dark stains form in the light layers. All three shades are applied without drying, with one brush, alternating and intertwining with each other. You should not go through the same places several times.

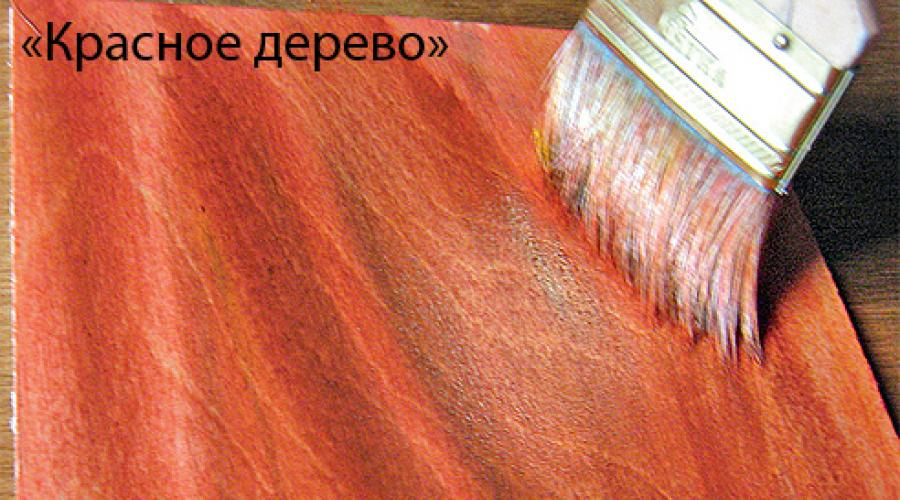

Red tree

Mahogany comes in a wide range of shades, from pale pink to purplish or walnut red. It is not difficult to imitate this breed. The texture of mahogany is simple and, as a rule, fairly evenly colored, with smooth transitions of tones. But there are exceptions: some types of mahogany have a special texture, with strictly alternating bright paths, which is difficult to confuse with others.

To imitate, you need to divide the stain color into two solutions so that one is brighter than the other. First, a light tone is applied to the wood, then a second, more saturated shade is applied with a brush over the raw surface. It should be applied in parallel stripes at short intervals. If the workpiece has been well sanded, the layers of texture will shimmer and look real under the varnish.

On that oak tree

Oak wood can be imitated using a tangential cut of pine (the plane of such a cut runs tangentially to the annual layer), where the texture is more twisted and there are no straight layers that give away the species.

First, you need to process the workpiece along the fibers with a hand-held metal brush with a sparse pile. On soft layers a tubular microstructure is formed, like oak wood. The right shade imparts solution iron sulfate or industrial stains in the desired shades.

Work on wood and glass Korshever Natalya Gavrilovna

Imitation of valuable wood

The color and texture of wood depend primarily on its species. However, the color can be changed if necessary using special dyes. The quality of the imitation depends not only on the dyes, but also on the wood that has been processed.

To imitate valuable wood, various dye solutions are used that easily penetrate the wood. The most famous of them are walnut stain, stain No. 10. For painting various tree species V different colors, and also to imitate valuable wood species, you can use the following compositions.

To color pine, spruce, birch and beech wood brown tint, you need to take 3 g of acid chrome-brown dye, 3 g of vinegar essence and 10 g of aluminum alum per 1 liter of water.

To color birch and beech wood under mahogany, prepare two solutions: 50 g copper sulfate per 1 liter of water and 100 g of yellow blood salt per 1 liter of water; Initially, the surface is treated with a solution of copper sulfate, then left for 10 minutes and a solution of yellow blood salt is applied.

You can stain birch wood to look like walnut using 20 g of walnut stain and 2 g of stain No. 10 per 1 liter of water.

For coloring under an old oak you need 16 g of potash, 20 g of brown aniline dry paint. 20 g of dry blue paint are dissolved in 0.5 liters of water, the mixture is boiled for 20–30 minutes, after which 1 teaspoon of vinegar is added; the surface is covered with a hot solution using a brush.

If they are painted to look like gray oak, then the treated surface of the oak wood is first coated with black alcohol varnish, and when the varnish dries, silver powder (aluminum powder) is poured onto the surface. Then, using a clean swab, rub the powder into the pores of the oak. The remaining silver powder is removed from the surface with a clean swab after about 1 hour.

The powder remaining in the pores of the wood is slightly glued with varnish, and gray hair appears on the oak. The dried painted surface is wiped along the fibers with a lump of horsehair or wood shavings, then coated with a colorless alcohol or oil varnish.

To imitate valuable wood species, you can use the following industrial water-soluble wood dyes.

Dye No. 1: reddish brown, used for coloring beech to look like mahogany.

Dyes No. 5, 6 and 7: light brown, used for coloring beech and ash under light walnut, for coloring walnut, birch and ash.

Dye No. 10: yellowish-brown, used for coloring birch and ash to look like walnut.

Dyes No. 11, 12, 13, 14: walnut brown, used for coloring birch, ash and beech in medium and dark walnut tones.

Dye No. 17: light brown, used for coloring birch and beech with a medium walnut tone.

Dye No. 122: orange-brown, used for coloring birch and ash to look like walnut.

Dye No. 124: red, used for coloring birch, oak and beech to look like mahogany.

Water-soluble dyes are prepared as follows: weigh out required amount dye, dissolve it in a small volume of hot water (at least 95 °C) and stir thoroughly. The resulting mass is poured into hot water and mix.

The dye solution is left to settle for 48 hours, then filtered through two layers of gauze and applied to the product with a swab, brush or spray. The dye solution can have different concentrations depending on the desired color tone.

From the book Wood and Glass Works author Korshever Natalya GavrilovnaWood structure By making only a cross section, you can clearly see the structure of the wood. Each block of unhewn wood has bark - this is the skin of the tree, which is not used in work; it must be removed. Beneath the bark is the tree's growth zone, which

From the book Creating an Android Robot with Your Own Hands by Lovin JohnDefects of wood External examination is enough to identify defects of wood: knots, cross-grain, rot, wormhole. Wood defects can be different. Some of them can completely eliminate wood from use, others only limit the possibilities for

From the book Materials Science: Lecture Notes author Alekseev Viktor SergeevichDrying wood Various wood defects during work can be avoided by placing the drawing on the workpiece in one way or another. But in any case, you need to take only well-dried wood for work, otherwise there is a chance that after long and hard work, all the work

From book Information Security. Lecture course author Artemov A.V.Wood planing Used only for processing logs, plates and quarters. The main tool of work is an axe. Before starting to hew the log, it is freed from the bark, laid on a scaffold and the hew lines are marked with a cord. On the side of the log that

From the author's bookWood sawing A type of sawing that requires the use of special equipment We will not touch upon woodworking enterprises. Depending on how thick the solid wood is chosen, one or another saw is used. And from fixing on

From the author's bookWood planing This wood processing technique involves leveling the surface after sawing. Depending on the stages of planing, they use different types planes. The part prepared for finishing is placed on a workbench and secured. Start with

From the author's bookDrilling wood This technique is used to make various holes. The holes can be through and blind, deep and shallow, wide and narrow. Drilling is used to select round holes and sockets for tenons, screws, and bolts; Besides,

From the author's bookWood chiselling Chiselling is used when it is necessary to obtain through and blind sockets for tenon joints. This work is done with a chisel and chisels. If the tool is well sharpened, then, as a rule, there are no difficulties in performing it.Before

From the author's bookBleaching wood Paint cannot always cover up uneven color of wood. Even healthy wood can have multi-colored spots - this is a sign of uneven distribution of natural pigment. What can we say about wood that has been stored for years and has darkened?

From the author's bookImitation of valuable wood The color and texture of wood depend primarily on its species. However, the color can be changed if necessary using special dyes. The quality of the imitation depends not only on the dyes, but also on the wood that has been processed. For

From the author's bookImitation of life Perfect walking robots imitate the movements of insects, crustaceans, and sometimes humans. Bipedal robot designs are rare because they require complex engineering solutions. I am planning to consider a bipedal robot project in my

From the author's book1. Types of tree species and parts of a tree Growing trees have the following components: roots, trunk, branches, leaves. Root system trees act as a supplier of moisture and nutrients from the soil along the trunk and branches to the leaves. In addition, the roots hold

From the author's book3. Microscopic structure of coniferous and deciduous wood Coniferous wood has a certain microstructure, which can be established using microscopes, as well as chemical and physical methods research Coniferous wood differs from

From the author's book1. Determinant of tree species Based on the “Handbook of Wood” by A. M. Borovikov and B. N. Ugolev, a guide to species was compiled. 1. Groups of tree species: 1) annual layers are clearly visible in all sections of wood. The medullary rays are not visible. There are no vessels. Wood

From the author's book3. Density of wood. Thermal properties of wood Wood density is the mass per unit volume of material, expressed in g/cm3 or kg/m3. There are several indicators of wood density that depend on humidity. The density of wood matter is the mass

From the author's bookQuestion 3. Protection of programs and valuable databases from unauthorized copying and distribution. According to experts, in the first decade of the 21st century, in the United States alone, the total cost of illegally replicated software amounted to about 3 billion annually