Igor Kuznetsov is a stove maker. The best stove heating in your home: Kuznetsov’s bell-type stove. Do-it-yourself Kuznetsov sauna stove

Read also

I.V. Kuznetsov is a man who devoted his entire life to designing stoves. He invented a huge number of new designs and also improved them. His activities in this area began in 1962. At the beginning of his work, he needed virtually no advertising. Fame came thanks to positive customer reviews. Today Kuznetsov has his own website and a team of like-minded people. The site presents numerous designs developed personally by I.V. Kuznetsov using his special technology. Let's take a closer look at this technology, because it is excellent for constructing stoves in modern homes, since it provides both high-quality decoration of the room and adds some zest to its appearance.

The main indicator that I.V. Kuznetsov strived for in his developments is increasing furnace efficiency. Depending on the purpose of thermal devices, they were equipped with improved capabilities. Some have increased heat-saving, others have changed the firebox or added equipment. The quality of these structures is proven by fame and many years of operation. Many, in order to save money, but knowing about the positive reviews of Kuznetsov’s stoves, undertake to make them with their own hands. This is possible if you strictly follow the procedures and use the right materials.

Features of Kuznetsov furnaces

As previously stated, the main thing in Kuznetsov’s developments is efficiency and productivity. Speaking scientific language this is a high efficiency value. The difference between these ovens is fundamentally new and advanced development. Internal system the movement of gases is thought out most competently. Hot air lingers longer in the stove and stores heat, while cold air quickly flies into the chimney through a special recess. These ovens are called " bell-shaped" This name was formed because, according to the design, a “hood” is made inside it - a combination of the hearth and the lower part of the stove. It acts as a gas separator into hot and cold. Hot ones rise into the bell and linger there, concentrating heat. The combustion temperature in such a hood is much higher, resulting in 95% efficiency. For simple comparison It should be noted that the traditional Russian stove has a value of 25−40%. Used in furnaces by I.V. Kuznetsov “free gas movement” system, is more natural, limits the formation of soot, and optimizes uniform heating and operation of the stove.

Other advantages follow from this:

- uniform heating and heat transfer;

- more places to install steel heating element;

- combustion without soot and smoke;

- the need for cleaning is reduced tenfold;

- low level heat loss;

- efficiency;

- resistance to cracks;

- the opportunity to experiment with the shape and design of the stove.

Depending on their main purpose, household stoves are different.

- Cooking ovens designed for cooking.

- Heating used primarily for heating living spaces.

- Bath stoves accordingly installed in the bathhouse.

- Street There are both complexes and simple barbecues.

- Bread. They are often combined with cooking and others.

- Purpose fireplace stoves primarily aesthetic.

And this is not the entire list of the variety of different stoves special purpose, the projects of which were developed by Kuznetsov. In addition, there is a convenient opportunity to create mixed species using several functions. And even the creation of entire multifunctional complexes. For example, heating and cooking stoves are very popular in everyday life.

How to build a Kuznetsov stove yourself

Before implementing the idea of making a Kuznetsov stove with your own hands, you need to decide what function should it perform?. Kuznetsov has developed more than 150 drawings of heating devices, so it will not be difficult to decide and choose the option that suits you. We will consider the option simple heating stove .

Study the floor plan of the room in which you are going to install it. If the house has not yet been built, plan the placement so that every room was equally heated. It is not advisable to install heating into a finished house, but it is possible if necessary. In this case, you need to take into account the location of the beams and load-bearing structures when organizing a place for the chimney.

Then think about foundation preparation. It is made of concrete, 10 cm wider than the planned size of the stove. If possible, it is better to plan the foundation for the stove in advance during the process of building a house. Foundation laying operation labor intensive. Therefore, if you are not confident in your abilities, invite a specialist to this stage.

Basic rules you need to know

- The refractory shell inside the furnace should be as if hang in the air, to be free from all sides. This is necessary because the brick expands when heated.

- It is not always visible on the drawings, but the internal fireproof masonry must be done on edge. This applies to fireclay bricks. Clay bricks on posts and internal walls placed at the discretion of the master.

- Every two rows of bricks you need strengthen the ligament laying the wire.

- Metal elements, doors and other devices must be installed leaving room for possible expansion. Between brick and metal element put a special gasket.

- Preferably process brick upon completion of construction with a fire-resistant composition.

- The first kindling begins with minimum temperature and with further gradual heating.

Order

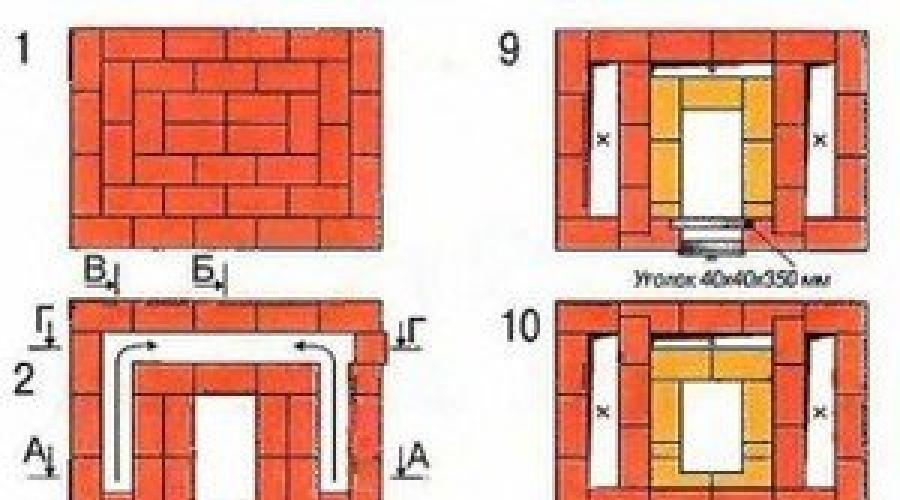

Laying out the stove yourself is a feasible task for a person with hands. Anyone can understand the operating principle of a stove; it’s not difficult. But to create a high-quality stove, you should still unquestioningly use drawings and procedures. The ordering is a set of drawings depicting the step-by-step layout of the furnace, for each row of bricks separately. It is not recommended to change anything in the drawings arbitrarily. And even more so, you shouldn’t do this if you are taking on such work for the first time. Kuznetsov spent many years of hard work and painstaking work to create hundreds of perfect and proven drawings. All you have to do is choose and get down to business.

What materials will you need

- Bricks for interior masonry. Fire-resistant fireclay bricks are used. Required quantity It is best to calculate it yourself using the drawing. For a simple design, not so much is needed. Some, due to limited financial resources, do not use fireclay bricks. This is acceptable.

- Exterior bricks. That is, ordinary clay brick, acceptable brand- M150. It is better not to use lower quality bricks for the construction of heating appliances.

- Clay (100−130 kg). It is advisable to purchase it good quality, especially in stores now a wide range of decent material. Choice low-quality materials may have a negative impact during the first firing finished oven. Such a solution will easily crack.

- Cleaned sand. Usually they take twice as much sand as clay. You can buy ready-made clay-sand mortar in the store. This way you won’t go wrong with the proportion. A mixture of clay and sand for 500 bricks needs about 0.2 cubic meters. m.

- Metal fittings. This is a valve, combustion and blower doors, a grate, 5 meters of wire and two steel angles.

Here is a variant of the order Kuznetsov's bell furnace. It can be used to independently lay out a household heating stove at home without special preparation. Each row of bricks must be laid out in accordance with the images in a numbered order. At the same time, do not forget about previously described rules. This stove is one of the simplest to use and is universal for daily home use.

There are few specific features for building this particular project. Here the channel between the first and second tier is made into a quarter of a brick to lengthen the firebox. And on the 21st row you need to leave two narrow passages on the sides of the inner walls. They are needed to light the stove. That's all a novice master needs to know. And having done your first job, you will understand that it is simple and clear. The main thing is not to be afraid to start, and things will go by themselves.

Then you can make a more complex design yourself. Kuznetsov developed such a quantity various interesting options that you will definitely want to implement more than one of them.

The so-called “Kuznetsovki” appeared back in 1962. Igor Kuznetsov is the inventor of these furnaces, and has been developing and improving them to this day. Currently, there are about 50 inventions that cover almost the entire range household stoves. Let's take a closer look at what Kuznetsov furnaces are. Orders are still popular today, so the topic is extremely relevant.

Why is Kuznetsovki better than others?

Consumers always ask themselves: why is it worth buying this particular product and not the one next to it? A completely natural and logical question. We always look at the strengths and weak sides products, and only then we draw appropriate conclusions. As for Kuznetsov furnaces, they are famous for their high efficiency. Usually, we're talking about about figures such as 80% or more. For example, a standard 4 kW unit can heat a house with an area of 100 square meters. At the same time, Western branded fireboxes must have a power of at least 10-12 kW. By the way, orders for Kuznetsovka from the USA, Sweden, Canada and a number of other countries are not uncommon. It is impossible not to mention that Kuznetsov stoves (orders) are “omnivorous”, that is, low-grade combustible materials, for example, sawdust, can be used as fuel. There is also the possibility of providing domestic hot water. Wherein performance characteristics are not getting worse.

Foundation comes first

It was Kuznetsov who first used automatic distribution of thrust across channels. This method is good because waste is eliminated, so the view can be kept open. The system of such chimneys is distinguished not only by its uniqueness, but also by its simplicity. If stoves with a complex chimney configuration usually have an efficiency of about 60%, then Kuznetsovki - 80% and higher. In addition, this implies the principle of free passage of gases. This is why the order is often compared to The fact is that the energy of gases, unlike a gas view, does not spin into a vortex, but immediately saturates the oven. Naturally, the generated heat is used either to heat the room or to the hot water supply, depending on the needs.

Kuznetsov two-bell furnaces: order and its features

The principle of constructing furnaces in which it is possible to implement the law of free movement of gases has been known for a relatively long time. The most common and well-known option is a two-melt furnace.

The principle of its operation is that air from the environment enters through the ashtray into the firebox. At the first stage of combustion, when the lightest fractions of the fuel burn, the process is somewhat reminiscent of pyrolysis. This mode is the most effective. But before Kuznetsov, few people took advantage of these advantages. But the orders have a design that allows them to work in pyrolysis mode. As a result, pyrolysis gases burn under the dome of the third bell. The process itself is interesting. Its features are that combustion is self-regulating. If the flame spreads too much, the draft worsens and the combustion process slows down; if the heat is not enough, the draft increases and the combustion process intensifies. Kuznetsov's double-bell furnaces (order) have a second dome so that the combustion process is not disturbed. The temperature in the second bell with an efficiency of approximately 80% reaches 300-400 degrees, and this is quite enough to transfer heat to the coolant.

Multi-bell furnaces

Often a regular one is made multi-stage. Each cascade consists of two caps with an opening at the top. The presence of three cascades allows us to call this furnace a classic one, since there is a free flow of gases. In almost any combustion mode, such equipment has a very high efficiency, reaching 97%. In this case, the fuel used practically does not matter. It could be fuel oil, coal or anything else.

Typically, an even number of caps allows 90% efficiency to be achieved. In this case, much depends on the combustion mode and the fuel used. However, the main disadvantage of this method is that the ovens are quite difficult to maintain. Problems often arise when cleaning carbon caps. In addition, the first cap (with even number) is very small, the temperature under it will be about 1500 degrees, as a result of which the metal will not withstand it, and the lining when suspended is unreliable.

Well, we have already figured out what Kuznetsov bell furnaces are. Order is often built at home. Let's see how to do this and what to pay attention to.

Kuznetsova: ordering with your own hands

Before starting work, you need to decide on the main function of the stove. Let's look at the usual heating equipment the simplest design. I would like to note that it is advisable to immediately build Kuznetsov stoves with your own hands along with the house. The order can also be erected if the building is already standing - this, of course, is undesirable, but possible.

At the first stage, it is necessary to prepare the foundation. It should be made of concrete and have a width 10-15 cm larger than the size of the stove. This is one of the most time-consuming jobs you will have to do, so in some cases it makes sense to call a specialist. The foundation should not be connected to the base of the house, do not forget about this. Its absence is also unacceptable, since the floors will not withstand high loads. Next, it is extremely important to properly arrange the chimney on the roof of the house. To carry out these works, it is advisable to take advantage of the laughter and advice of professionals. Let's see how Kuznetsov's stoves are built. Orders in their simplest form are made quite simply and quickly.

Required material

It is extremely important to choose high-quality material, in particular, it must withstand high temperatures. So, for internal masonry they use Its quantity is determined according to the drawing. Often there are structures made of ordinary brick, which is done in order to save money. This is acceptable, but the durability of the masonry is reduced. For external masonry, M150 - clay brick - is suitable.

You can’t do without 100-130 kilograms of clay. It's better to spend a little more money and pay for quality material. In this case, when crimping, the clay will not crack and will serve for quite a long time. You will need sand twice as much as clay. For approximately 500 bricks, it is necessary to make a mixture of clay and sand in a volume of 0.2 cubic meters.

All that remains is the metal fittings. This includes a valve, steel angles, a grate and two doors. Well, now we will look at how the Kuznetsov order is made.

Laying and checking

If you have already had experience in laying stoves, then you will not have any problems. The only thing worth paying attention to is the quality of the bundle. To improve this characteristic, it is necessary to lay a wire on every 2nd row of brick. To lay a channel from the first tier, it is better to lay ¼ bricks. This will allow you to slightly increase the length of the firebox. Wherein top floor between tiers is organized on the 17-18 tier.

After finishing the masonry, you need to wait some time until the solution hardens. Then you can install doors and other metal products. Only after this do they begin the first kindling. This step checks how well the oven is working. They look at the draft, the tightness of the valves, doors, etc. In principle, this is all that can be said about how Kuznetsov stoves are laid out. Do-it-yourself orders can have different powers.

Something else about masonry

Kuznetsov stoves for bathhouses are often made. The order of such a purpose is very rarely erected with one’s own hand. This is due to its rather complex design. But you should understand that a well-made sauna stove performs a huge number of tasks. For example, it provides heating for several rooms: steam room, dressing room, washing room. In addition, it prepares steam, provides ventilation and heats water.

Oddly enough, only one Kuznetsov sauna stove can cope with all this. The ordering has virtually no fundamental differences, but manufacturing accuracy is important.

Conclusion

So we looked at Kuznetsov’s two-bell and bell-type furnaces. Do-it-yourself orders are not as common as we would like. Often such stoves can be seen in dachas and villages. Sometimes they are purely decorative, as they are made in the form of a fireplace.

Nevertheless, such heating equipment should not be ignored. Considering its high efficiency compared to some other stoves that have more high cost, This The best decision For country house. Moreover, it is possible, and sometimes even necessary, to build such a stove yourself. This way you can not only effectively heat your home, but also gain valuable experience.

This is all that can be said about what Kuznetsov’s stoves are famous for and how they are installed. The routines are good and, no doubt, will be popular for a long time.

Ideas for creating ultra-economical stoves by I.V. Kuznetsov are borrowed all over the world, including the USA and Europe. With a responsible approach, you can make one of the stoves according to the Kuznetsov model with your own hands.

Application of the Kuznetsov furnace

Over many years of inventive activity, I.V. Kuznetsov has developed about 150 models of furnaces, designed for use in all areas of human activity without exception where heat generation is required. According to the type of specialization, “blacksmithing” is:

- heating;

- cooking;

- heating and cooking;

- baths

- outdoor, intended for smoking food, barbecuing and grilling;

- fireplaces with an open firebox, allowing you to admire the flames.

Examples of the Kuznetsov furnace

Advantages and disadvantages

The wide popularity of Kuznetsov stoves and the deep respect that people knowledgeable in the stove business have for them are due to a number of advantages:

- The efficiency of “blacksmiths” exceeds 80%, and for some models it can reach 95%.

- Furnaces operate at high temperatures, but at the same time they do without materials and technologies available only in factory conditions.

- The high-temperature mode allows you to heat the stove even with the most waste and low-quality fuel.

- Again, due to the high combustion temperature, the fuel is oxidized almost completely, so soot is formed in minimal quantities. The oven may not require cleaning for several years.

- The design of the furnace ensures very uniform heat transfer between the fireboxes, while less material is used than in construction using traditional technology.

- In furnaces equipped with a heat exchanger, heat for heating water is taken from flue gases, and not from the firebox, so the “blacksmith” can easily perform the function of a boiler without deteriorating performance.

- The operating principle of the stove provides good draft, so there is no need to build a high chimney.

- “Kuznetsovka” is very plastic both in terms of design and design. That is, it can easily be adjusted to any room without compromising performance and efficiency.

- The stove is designed in such a way that after firing, its chimney does not need to be blocked with a view. Carbon monoxide poisoning is completely excluded.

- The design assumes uniform heat distribution in the furnace body, so cracks do not develop in the masonry due to local deformations.

What can you say about the disadvantages? Technically there are none, but there are still some things to consider. The Kuznetsov furnace cannot have massive walls - this would negate many of its advantages. But at the same time it is subject to fairly high thermal loads. Therefore, this unit must be carefully calculated and verified at the development stage and built just as carefully, with scrupulous compliance with all technology requirements. At the slightest deviation from technical regulations“blacksmithing” will turn out to be very short-lived.

You can even build a Russian stove with your own hands if you follow detailed instructions. You will find them in our next article: .

Design and principle of operation

The inventor I.V. Kuznetsov used a bell-type furnace, known for its efficiency, as a basis.

This is what a bell furnace looks like - a prototype of Kuznetsov’s model

The high efficiency of such furnaces is due to the nature of the movement of flue gases. If in channel stoves they are drawn out into the chimney, often without having time to give off heat to the brick mass, then in bell-type stoves they swirl under the roof of the bell for a long time until they cool down. Only then do they fall down to the outlet, from where they then enter the chimney. The gas-filled cap simultaneously plays the role of a view: cold air from a chimney cannot penetrate into it, just as water cannot fill an inverted diving bell. This effect is called gas view.

The inventor worked with a complicated version of such a furnace, which had two hoods.

Diagram of a two-bell model

As you can see, the hoods are connected in series, that is, heat from the flue gases is removed according to two-stage scheme. Previously, the construction of stoves with such a design was not undertaken very willingly - not only because of the complexity, but also because of some undesirable features. So, for example, the draft in the second bell can easily break the gas plug in the first, negating the effect of the “gas view”.

The master dealt with this drawback in the following way. The furnace was equipped with so-called downstream channels, laid to bypass the heat-accumulating parts of the array. While the flame is burning in the firebox, the convective flow it creates ensures that the draft operates as usual. When the fuel is used up and convection stops, the thrust will redistribute itself in such a way that the cold air flow will follow through the downstream channels, and not through the heated body of the furnace.

This solution not only compensated for the instability of the gas coil, but also turned out to be more reliable: a plug formed by gases can be pulled out by a strong gust of wind, whereas in the Kuznetsov furnace, the draft is redirected away from the hot mass under any conditions. In addition, thanks to the presence of downstream channels, there is no need to arrange room ventilation.

How does it work

This is the sequence in which the processes occur in the Kuznetsov furnace:

- Due to the air entering through the blower (item 1), the fuel burns in the firebox (item 2), and the resulting mixture of flue and pyrolysis gases rises into the lower hood (item 3). Under its roof (position 4), the pyrolysis gas finally breaks down into flammable components, which burn here. This design provides a self-regulation effect: when the flame burns strongly, the gas plug increases and blocks the draft; due to the weakening of the draft, the combustion in the furnace also weakens, the gas plug, cooling, decreases and the draft resumes.

- Conditionally cold gases from the lower bell enter the upper one (position 5). If the oven is round (this is perfect shape for a two-bell scheme), then the role of the upper cap is played by its body. In its upper part (position 6), carbon monoxide and nitrogen oxide are oxidized, so that the exhaust entering the chimney (position 7) mainly consists of carbon dioxide and water vapor. The gases entering the second bell are no longer super-hot - temperatures from 200 to 400 degrees - and chemically aggressive, so a water heat exchanger made of ordinary structural steel can be installed here. The extraction of heat from water does not change the operating mode of the furnace in any way, since the high-temperature part - the firebox + the lower hood - is insulated with a brick wall.

Due to the high combustion temperature, the fireclay firebox in Kuznetsov furnaces should be made isolated from the main mass or, as they also say, floating. None of its elements should be embedded in the ceramic brickwork, otherwise the latter, even if there are expansion joints, will break during firing - the difference in the thermal expansion coefficients of these materials will affect it.

The firebox must be surrounded by a so-called dry seam. This is a seam between fireclay and ceramic bricks, which, instead of clay mortar, is filled with a gasket made of asbestos or basalt cardboard.

There is an annular gap (L1) between the firebox and the lower hood, and another one (L2) between the hoods. If the width of L2 is made greater than that of L1, the gas view will be more stable.

Calculation of the Kuznetsov furnace

“Kuznetsovka” is a very complex heating device and attempts to calculate and design it yourself will not lead to anything good. You just need to choose from all the available options the most suitable one for yourself - the author does not make a secret of his developments. If the characteristics of the model you like do not indicate the heat transfer power, it can be calculated approximately: a stove that is heated twice a day, every sq. m of its surface gives off approximately 500 W of heat.

The OVIK-9 furnace, the manufacturing procedure of which we will consider, with dimensions of 1015x630x2100 mm, has a heat transfer power of 3.6 kW.

Model OVIK-9: general view

Preparatory work

First of all, you need to choose a place to build a furnace. The easiest way to do this is before building a house - then both the stove and the building are designed together so that three or at least two rooms are heated. Since already ready home the situation is more complicated. In this case, they tend to build the oven into interior partition, since its implementation in load-bearing wall requires complex calculations and dangerous labor-intensive work (part of the wall will have to be dismantled, keeping the load from being blocked by a system of lintels and columns).

You can, of course, limit yourself to a simple wall-mounted arrangement, but then only one room will be heated.

You need to build at the chosen location reinforced concrete foundation. Its dimensions must exceed the dimensions of the oven by at least 100 mm on each side. It is not allowed to combine the foundation of the furnace with the foundation of the building - both structures give different settlements and one of the foundations will pull the other along with it, causing it to skew.

A reinforced concrete foundation must be installed under the furnace.

The depth of the foundation depends on bearing capacity soil, the depth of its freezing, the method of operation of the building (periodically/continuously). Usually in buildings with year-round accommodation for people located on stable ground, the foundation is deepened by 400–600 mm. Crushed stone should be poured onto the bottom of the excavation as a reinforcing layer, and a sand cushion should be placed on top of it.

Then everything is done using traditional technology - they install the formwork, fix the reinforcement frame and fill it with concrete. You should proceed to the construction of the furnace only after the concrete has fully matured and gained sufficient strength - this usually takes about a month.

Before laying the 1st row, waterproofing of two layers of roofing material or roofing felt must be laid on top of the foundation. The contours of the future furnace are drawn on it with chalk - this will make it easier to navigate.

Materials and tools

To work you will need:

- trowel;

- level;

- mallet and other construction tools.

To divide bricks you will need a pick hammer and a grinder with a diamond wheel.

This set of tools will be needed for work

The furnace will be built from two types of bricks: conventional solid ceramic with a grade of M150 (250x120x65 mm) and fireclay grade ShB-8 (250x123x65 mm) or Sh-5 (230x114x40 mm). The firebox walls will be lined with fireclay bricks.

When purchasing fireclay bricks, you should be very careful. Unscrupulous sellers They may pass it off as acid-resistant brick, which is similar in appearance but cannot withstand high temperatures. So it won’t hurt to ask to see a certificate.

Brick for laying the furnace

It is often recommended to choose fireclay bricks by color - the darker the better. But this rule does not always apply. If clay taken from different deposits was used, then the characteristics of light brick may well be higher than that of dark brick. It is more correct to evaluate the quality of fireclay bricks according to the following criteria:

- the structure must be uniform and fine-grained - without visible naked eye pores and inclusions;

- when tapping metal object(light hammer or wrench) the brick should produce a clear, abrupt and ringing sound;

- when dropped, it should break into large pieces (low-quality ones crumble into small fragments down to sand).

For a structure with dimensions of 1015x630x2100 mm, you will need 430 ceramic bricks (excluding the chimney) and 22 fireclay bricks.

How to prepare the solution

The solution used is clay. The clay and sand used for its preparation should not contain organic impurities that can lead to cracking of the seams. In clay, the presence of these impurities can be recognized by a clearly audible smell (it can even be pleasant) - normally clay has almost no smell.

Sand should be used either from mountain sand or made by grinding broken bricks - in these varieties the content of organic impurities is minimal, or they are completely absent. Brick sand usually costs less than mountain sand, but is not inferior in quality. Just pay attention to the following circumstance: for the solution ceramic masonry you need sand from ceramic bricks, and for fireclay bricks - accordingly, from fireclay bricks.

Pay attention to the grade of clay. The mortar for fireclay masonry should be prepared on the basis of white kaolin or fireclay marl. Any clay with fire-resistant properties is suitable for ceramic masonry, for example, gray or blue Cambrian, gray kaolin.

Clay of the same grade, but from different deposits, can differ greatly in viscosity, fat content and adhesive properties. Therefore, the solution recipe, namely optimal ratio sand and clay in it should be selected experimentally. In the case of using brick sand, this is done as follows:

- A 1 kg portion of clay should be filled to the top with water and left for a day.

- After this, the soggy clay is kneaded with the addition of water until it looks like plasticine or thick dough and stops sticking to your hands.

- first - 10% of the volume of clay;

- in the 2nd - 25%;

- in the 3rd - 50%;

- in the 4th - 75%;

- in the 5th - 100%.

Each portion must be thoroughly stirred until smooth and dried for 4 hours. Don't forget to mark how much sand is contained where.

After this, each portion of the solution must be rolled out into the shape of a cylinder 30 cm long and 1–1.5 cm in diameter. All of them are wrapped around a round blank with a diameter of about 5 cm. Now the test samples must be dried for two weeks under conditions room temperature and lack of drafts.

After this, it remains to evaluate each of the options:

- If there are no cracks on the cylinder at all or they are very fine mesh, such a solution can be used for any part of the oven.

- If the depth of the cracks reaches 1–2 mm, the solution can withstand temperatures up to 300 degrees. This mixture can be used for masonry country fireplace or barbecue.

- If there are deep cracks or breaks, the solution is considered unsuitable for use - the proportion of sand in it is excessive.

Typically, about 0.2 cubic meters are consumed for a laying of 500 bricks. m mixture of clay and sand.

Note! If they don't bother you additional expenses, can be purchased at a specialty store ready mixture for preparing oven solution.

Having thus determined the optimal combination of clay and sand, we begin to prepare the solution:

- the required amount of clay (approximately 40 kg per 100 bricks) is again soaked for 24 hours, kneaded until the consistency of dough, but then rubbed through a sieve with a mesh size of 3x3 mm;

- then sand is added according to the experimentally selected recipe;

- gradually adding water, stir the solution until creamy;

- evaluate how the solution wets the trowel and, if necessary, adjust its composition by adding a small amount of clay or sand.

What else do you need?

- A fire door, for example, brand DT-3, with opening dimensions of 250x210 mm.

- Blower door, for example, DPK brand, with an opening of 250x140 mm.

- Grate size 250x252 mm.

- Cast iron hob with two burners, size - 586x336 mm.

- Doors measuring 510x340 mm, 2 pcs. – for the cooking chamber.

- Gate valves with a flow area of 130x130 mm, 2 pcs. – for the cooking chamber and for switching between summer and winter modes work.

- Valve with a clearance of 250x130 mm - for a chimney.

- Equal angle pieces 36x4, 600 mm long (4 pcs.).

- A piece of steel strip 40x4 mm, 600 mm long.

- Steel sheet 3 mm thick, size 600x550 mm.

- 3 mm thick steel sheet measuring 500x700 mm to protect the floor in front of the firebox.

Replace steel with any other fireproof flooring, for example, ceramic tiles.

Have you always dreamed of having a magical fireplace in your home? You can fold it yourself. And the following guide will help with this: .

Masonry: ordering and step-by-step instructions

The sequence of work looks like this:

Lay out the 1st row of 20 bricks, which should be an ideal rectangle with a strictly horizontal surface.

First row diagram

“Rectangularity” is checked by measuring the diagonals - they must be equal. In the absence of experience, the row must first be laid out without mortar and only then, when everything has been adjusted and checked, the mortar must be applied. The thickness of the seams should be 5 mm.

Advice. To make the stove look more attractive, install rounded bricks in the corners. You don’t have to cut them yourself - such blocks are sold ready-made.

In the 2nd row, the first (lower) hood and the blower chamber originate. The two halves of the brick are laid without mortar and slightly pushed out. When the masonry is completed, these bricks will need to be removed, which will make it possible to clean the base of the cap from splashes of mortar and brick fragments. After cleaning, the halves are finally placed on the solution.

Second row diagram

When the 2nd row is laid out (14 bricks are required), install the blower door on it, supporting it with several bricks. The door frame must be wrapped with asbestos cord, which will act simultaneously as a seal and expansion joint. It is fixed in brickwork by means of wire, which is placed in the seams.

Having laid out the 3rd row according to the diagram (the bricks included in it should tightly fix the blower door), proceed to laying the 4th. Here, in addition to ceramic bricks, fireclay bricks are used - we begin to lay out the side and rear walls of the firebox.

Third row diagram

The blower door is covered with hewn ceramic bricks looking outwards, and hewn fireclay bricks looking inwards. They must be separated by a thermal gap of 5 mm. It can be arranged in the following way: a spacer of corrugated cardboard is placed between the bricks - it has just the required thickness; When kindled, the cardboard will burn out and a gap will form on its own. Temperature gaps must be provided wherever fireclay bricks are adjacent to ceramic bricks.

Fourth row diagram

In row No. 5, the fireclay bricks forming the side walls of the firebox are slightly shifted so that the bricks of the 4th row located underneath them form a shelf 10–15 mm wide for the grate. The bricks should be moved apart so that there is a gap of 5 mm between them and the grating, which is necessary for the free expansion of the heated metal.

Fifth row diagram

The brick forming the front wall should be cut at an angle.

In the same row, the formation of a vertical channel connecting both caps begins.

When the row is laid out, you should install the grate in its place, filling the gap between it and the bricks with sand.

Installation of grate bars

In parallel with laying the 6th row, you need to install and fix the fire door. Direct contact of its frame with the brick is not allowed - it is necessary to lay an asbestos cord as a gasket. The door frame can be fixed from below with wire, but a more reliable element is required from above - the wire will quickly burn out. Instead, a steel strip is used.

Sixth row: installation of the combustion door

When laying row No. 7 on the side of the brick forming back wall fireboxes, leave a gap 20–30 mm wide. This is the beginning of a dry weld.

Seventh row diagram

Having laid out row No. 8 according to the diagram, proceed to laying the 9th row. At this stage, a channel is formed connecting the firebox with the lower hood. Lilac color indicates bricks in the side walls of the firebox, the upper edges of which should be 10 mm below the plane of the row. An asbestos strip 10 mm thick will need to be laid on the left wall so that it is flush with the plane of the row.

Eighth row diagram

Pay attention to how it is blocked combustion door: the bricks are cut at an angle to create a “lock-on” masonry.

Ninth row diagram

When laying out the 10th row, you should remember that ceramic bricks must be laid without mortar on the asbestos lining (it covers the fireclay bricks in the firebox wall).

Tenth row of order

It is necessary to make a cutout for the hob in the ceramic bricks surrounding the firebox. Its dimensions should be such that there is a temperature gap of 5 mm around the slab, that is, the bricks will need to be trimmed by about 10 mm. And in the contact zone hob with fireclay bricks, a gap of 10 mm must be left. These bricks, cut at an angle, are located in the front and to the right (indicated in orange).

If the slab is equipped with stiffening ribs at the bottom, additional grooves must be cut in the brick for them so that the slab is supported on the brick along the entire edge. It is installed immediately after laying the row - on an asbestos cord soaked in clay solution. The gaps between the slab and bricks are filled with sand.

Near No. 11 the walls of the cooking chamber begin. A door for it is also installed here, the frame of which must be wrapped with asbestos cord. For fixation, you can again use wire.

Eleventh row diagram

Rows 12, 13 and 14 do not need comments - we simply lay them out according to.

After laying the bricks of the 15th row, the cooking chamber is closed steel sheet 3 mm thick and 600x550 mm in size with a cutout for the exhaust duct. The top of the sheet is reinforced with 4 pieces of angle and a steel strip. The steel ceiling prevents the ingress of various small debris into the food that could fall into it from the brickwork.

Installing the hob

In the bricks of the 16th row, framing the exhaust and front vertical ducts, cutouts are made for valves, taking into account a 5 mm temperature gap.

Scheme of the 16th row

When the row is laid out, the valves are installed in place.

Installation of valves

After the 17th row, the formation of the upper cap begins (18th row). Here, too, it is necessary to leave the slightly extended halves without mortar; by removing them, it will be possible to clean the base of the cap from the mortar and various debris that fell during the laying process. After cleaning, the removed bricks are coated with mortar and finally installed in their place.

The eighteenth row of the order is the beginning of the formation of the cap

Rows 19 to 27 are laid out in order.

In the 28th row the main chimney damper is installed. Under it, cutouts 10 mm deep should be made in the bricks (marked lilac color) and such a width that there is a temperature gap of 5 mm around the valve body.

Scheme of the 28th row

The valve must be installed immediately after laying out the row, and it is laid on the solution.

Installation of a chimney damper

In rows No. 29 and 30 the furnace is closed, and in row No. 31 a mounted pipe begins with a smoke exhaust channel into the brick (270x140 mm).

Formation of the casing pipe

The finished oven must be thoroughly dried. To do this, it is kept for some time with the doors and valves fully open. Things will go faster if you hang a light bulb with a power of 200–400 W in the firebox. It will provide not only heat, but also a stable convective flow, which will remove all moisture in a short time.

The first fire should be carried out with a small portion of fuel - the fire must first harden the walls of the firebox.

You should not start finishing the stove before it has completed its first season - decorative coating may be damaged during shrinkage processes.

Operation in various modes

IN summer mode Kuznetsov's stove turns from a heating and cooking stove into a cooking stove. To do this, it is enough to open a special valve (it is called the summer valve), after which flue gases will enter the chimney directly, bypassing the caps. Accordingly, only the hob will be subject to heating.

The temperature inside the cooking chamber can be regulated by a valve installed on the outlet from it. exhaust duct. By closing the valve and the chamber door, it can easily be turned into an oven. For ease of use, shelves for baking sheets can be fixed in the walls.

If you need to quickly warm up the room or dry out, open the door of the cooking chamber. At the same time, the temperature on the burners remains high enough for cooking.

Video: building a two-bell oven with your own hands - part 1

Video: part 2

Kuznetsov's furnace has the highest technical characteristics, but at the same time it is quite accessible for a master in a beginner’s class. But experienced stove makers should be careful - they often overestimate their knowledge and do something in their own way, neglecting the recommendations of the inventor. Such deviations are not allowed - as was said, the Kuznetsov furnace with high accuracy calculated and must be constructed just as accurately. Follow the instructions in the article and you will be protected from errors.

1.

2.

3.

4.

5.

6.

7.

Stove makers who do their business professionally believe that Kuznetsov’s heating stoves, the drawings of which we will consider in this article, have deservedly received recognition. Their creator I.V. Kuznetsov spent all his time labor activity, which began in 1962, he devoted himself to his favorite pastime, namely designing new structures and improving them.

Fame came to the designer as a result of numerous positive feedback clients and customers. Now Kuznetsov has a team of like-minded people and his own website, which presents various options design solutions developed by him personally using special technology.

You can install a Kuznetsov stove with your own hands in modern residential buildings. Its design solutions make it possible not only to heat rooms efficiently, but also to appearance give the interior something special and unique, as you can see by looking at the photo provided.

While developing new heating units, Kuznetsov sought to improve the main indicator of their performance - efficient heating. Depending on the purpose of the structures, certain indicators improved for them. In some models the firebox was modernized, in others heat saving was increased, and in others equipment was added, as evidenced by the drawings on the Kuznetsov furnace.

Proof High Quality designs is the popularity of heating units, their demand and long-term operation.

This work can be done with your own hands, but on condition that the owner of the house uses and uses only recommended quality materials.

Features of the Kuznetsov furnace

Since the main goal of Kuznetsov’s developments was efficiency and productivity (he worked to increase the efficiency value), this required a fundamentally new and improved approach.If you look at the drawings of Kuznetsov’s furnaces, every professional sees that he has thought out the system of internal gas movement most competently. As a result, thanks to the design solution hot air it stays in the unit for a longer time and retains heat, and the cooled air masses quickly fly away into the chimney through a special recess.

Such furnaces are called “bell-shaped” furnaces. Inside they are united by a hearth and bottom part, creating a semblance of a cap. His functional purpose consists of separating gases into cold and hot. The last of them rise into the bell and, lingering in it, concentrate the heat. The combustion temperature in such units is higher, and their efficiency is 95%. How much more efficient the functioning of the structures developed by Kuznetsov is is evidenced by the fact that for a traditional Russian stove this figure is 25-40%. Read also: "".

From the above, the conclusion follows: the system of free movement of gases created by this master is more natural, it optimizes the operation of the device and uniform heating. In addition, soot formation is minimized.

In addition to these advantages, Kuznetsov furnaces have other positive aspects:

- combustion occurs without soot and smoke;

- heating is more uniform;

- better heat transfer;

- the need for cleaning is ten times less;

- efficiency;

- available more space for placing a steel heating element;

- low level of heat loss;

- resistance to cracks;

- the ability to change the shape and design of the structure.

Kuznetsov furnaces: drawings and their variety

Over the course of decades, Kuznetsov has developed many designs for furnaces himself. for various purposes. You can build some of them yourself. To do this, you will need drawings and orders of Kuznetsov furnaces.

- cooking structures for cooking;

- heating units for heating residential premises;

- devices for baths (read also: " ");

- street complexes and simple barbecues;

- bread ovens, which are often combined with cooking structures -;

- fireplaces that serve more of an aesthetic function.

Construction of a Kuznetsov furnace with your own hands

Before making one of the heating devices, you need to decide on its purpose. Kuznetsov created more than 150 drawings of household units (read also: " "). Making a choice among the variety of models will not be difficult. When Kuznetsov furnaces are created, order is necessary. IN in this case As an example, a simple version of a heating unit is given.The sequence of actions is as follows:

- First, study the floor plan where installation is planned. heating device. In the case when the house is not built, it is necessary to ensure uniform heating of all rooms. It is not advisable to install a heating unit into a finished building, but it is possible if necessary. But at the same time, you should take into account the location of the supporting structures and beams when arranging the chimney.

- Then prepare the foundation for heating device. It is made of concrete, and the width should be 10 centimeters greater than the size of the device. It is advisable to design the foundation for the stove at the house planning stage.

Basic rules for creating a heating stove

- To make Kuznetsov stoves, the ordering (masonry diagrams) should be printed in advance.

- The refractory shell located inside the furnace must be free on all sides, since the brick expands during the heating process.

- Internal refractory masonry when using fireclay bricks is always done on edge. If the bricks are made of clay, on the inner walls and on the posts, they are laid at the discretion of the stove-maker.

- To strengthen the bond, a wire is laid every two brick rows.

- When the Kuznetsov furnace is created, it provides that various elements(for example, doors) are installed in such a way that there is room for expansion. A special gasket is placed between the brick and the metal element.

- After completing the construction of a brick structure, it should be treated with a fire-resistant compound.

- The first kindling begins at a minimum temperature and is then gradually increased.

Ordering the Kuznetsov furnace

Post heating structure The problem can be solved on your own, but it will require some ordering sauna stove Kuznetsov or another type of heating unit. The operating principle of the heating device is not so complicated that it is impossible to understand (read also: " ").

To create a high-quality heating unit, regardless of the bell-type version or the Kuznetsov stove for a bath, ordering will be required, as well as general drawing. What is order? This is a set of drawings that schematically depict step-by-step, in detail for each row of bricks. No changes should be made to them.

Materials for building a brick kiln

- Fireclay brick for interior masonry. You can calculate its quantity according to the order. For a simple design you will need a little of it.

- Clay brick for external masonry, when they are created, including Kuznetsov bell furnaces - the order will help you find out its quantity. It is advisable to purchase products of the M150 brand.

- Clay in the amount of 100-150 kilograms. It must be of good quality. Otherwise, at the first firing finished design the solution will crack.

- Cleaned sand. It will require 2 times more than clay. Ready-made clay-sand mixtures are available for sale. They are needed for 500 bricks, approximately 0.2 m³.

- Metal fittings– grate, combustion and blower doors, 2 steel angles, 5 meters of wire.

Order samples

This article discusses the Kuznetsov bell-type furnace, and more specifically, one of its variants. Each row should be laid out in a numbered order in full accordance with the images. This oven is simple in design and is universal solution for household use.

Similarly, when there is an order on the Kuznetsov stove for a bath, you can do the laying yourself (read also: " "). After the work on creating a heating unit is completed for the first time, it becomes clear to each performer that this is not difficult and quite doable.

Next time we will be able to do more without any problems complex design. It could even be a two-bell Kuznetsov stove - the order of one of the creation options of which is available as an example on the website. Perhaps in the future there will be a desire to bring into reality one of the many projects of the great master.

Video phased construction Kuznetsov furnaces according to drawings:

Among all the diversity existing species stoves model I.V. Kuznetsov stand out especially. This option for stove heating for a bathhouse, a private house, or arranging a barbecue area deserves your attention thanks to undeniable advantages. Let's talk about the features of “blacksmiths” in more detail.

We briefly touched on the features of Kuznetsov stoves when we wrote about the types of fireplaces, Russian stoves and open hearths. Now let’s pay more attention to this version of stoves, because “blacksmiths” are heated by many Russian houses and arouse genuine interest. Igor Viktorovich himself indicated that he had developed the fundamentals correct design household stoves, which were developed by I. S. Podgorodnikov on the basis of the works of Professor V. E. Grum-Grzhimailo, a Russian metallurgist.

How do conventional duct ovens work? The movement of gases in them occurs under the forced action of draft. The gas gives off its heat to the brickwork, heating it from the inside, passing through the narrow furnace channels. You have to build a high, narrow chimney, the stove heats up unevenly, and the brickwork can crack. Bell furnaces Kuznetsov work differently - on the principle of natural, free movement of gases.

These ovens received the name “bell-shaped” for a reason: inside they have large cavities, hogs, inverted bells, which can be located both horizontally and vertically, one above the other.

As a result, the heated smoke rises, hits the hood, dome, lingers there, and then gradually cools and falls. Thus, heat is retained inside the furnace and the time of contact of hot gas with the brickwork increases noticeably.

This principle of operation can be explained using the example of a rubber glove, which is completely filled with gases in all cavities. In a cap, which in general may have different shape, convection occurs, the convective movement of gases naturally, according to the laws of nature.

The most common are two-bell blacksmiths. At the bottom of the furnace there is a chamber in which the heat, ensuring the completion of the combustion reaction of gases that are divided into warm and cold. In this case, hot gases are retained in the furnace, and cold gases are gradually discharged into the pipe, without cooling the heat exchanger itself.

Advantages of Kuznetsov furnaces:

- Efficiency reaches 93%. For comparison, for traditional Russian stoves this figure does not exceed 70-80%;

- soot in “blacksmiths” burns, so the stove and chimney can not be cleaned for years, which makes caring for them much easier;

- the caps inside the furnace are voids, this allows you to save on brickwork, which would have to be done by equipping conventional draft channels;

- the stove can be placed anywhere - in a corner, in the center of the room, against the wall. Often, “blacksmiths” heat several floors of a house, working on one firebox;

- any type of fuel can be used in Kuznetsov furnaces;

- the chimney can be made short, which also leads to savings in materials;

- uniform heat transfer, the temperature in a house heated by a “kuznetsovka” fluctuates noticeably less;

- the oven can be easily combined with hob, fireplace, couch - yes a large number of modifications;

- it is possible to integrate a supply circuit hot water and water heating;

- high efficiency the pyrolysis that occurs allows you to save on the fuel used;

- masonry lasts longer, there is less risk of cracks;

- closing the valve at the wrong time will have virtually no effect on the cooling of the furnace, because the hood is always filled with hot air, and cold air is pressed to the bottom.

Kuznetsov stoves have few disadvantages. Firstly, it is still difficult to find a craftsman willing to take on such a project; the work of a stove maker will cost a lot, and there are specific features and construction rules. Secondly, the “blacksmiths” are quite large in size, they are quite massive. However, Russian stoves cannot be called compact either.

During his career, Kuznetsov developed many versions of furnaces operating on the principle of free movement of gases. There are bathhouses, for heating a house, outdoors (with barbecue), fireplaces, bread ovens, cooking ovens, and mixed types.