Herman Service Center. Hermann gas boiler error codes - malfunctions and recommendations for troubleshooting. We offer boiler repair

Read also

GORCERIS service center is an official partner in the repair, maintenance of Ariston Biasi Bosch Chaffoteaux & Maury De Detrich Electrolux Ferroli Gazlux Haier Immergas Pro equipment ...

Additionally: on-site repair of a heating boiler at home or in the office, replacement Supplies, heating boiler installation (connection, setting)

Benzo and diesel power plants. Air compressors from 1.1 to 400 kW. Heat guns. Water washing installations. Embedded Appliances, split systems, refrigerators, automatic washing …

Additionally: delivery of a heating boiler to / from a service center, on-site repair of a heating boiler at home or in an office, replacement of consumables, installation of a heating boiler (connection, configuration)

Lipetskgazservice will develop a project heating system any room. A complete set of boiler houses of any capacity will be made. When installing the water supply system, we use modern ma…

Pages: 1Additional services of service centers for the repair of heating boilers

How much will a boiler repair cost?

Do you prefer to deal with maintenance or repair yourself? It's not as difficult as it seems. Take advantage useful tips from the section.To install or configure the purchased equipment, you can use the services of specialists from authorized organizations (authorized service center), who will carry out all necessary work for further exploitation heating boiler. If the specified address service center missing or located at a different address, please let us know.

Hermann was founded in 1970 and has specialized in the production of wall mounted gas boilers for over 35 years.

In 1986, a boiler with a built-in boiler was put into mass production, in 1998 - the most compact boiler with a height of only 700 mm, and in 2000 - the first condensing boiler.

In 2005, a unique hot water temperature control system (WSS Water Stability System) was patented.

Hermann today is a specialized company covering 40,000 m2, more than half of which is in the production area. The production cycle is fully automated and is carried out on seven conveyor lines. The company employs more than 200 people. In Italy, Hermann has one of the widest networks after-sales service with more than 500 service centers. The company's products are exported to 21 countries around the world.

The company has grown by 150% over the past five years. Today, the company's factories produce their products from Sanieur Duval, Renova, Romstal, AEG, Vaillant, Baltur. In 2005, Hermann produced 160,000 wall mounted gas boilers.

The company has its own technical department, research laboratories, pilot production. Every year more than 4,500,000 euros are invested in innovative developments, product research and development. All Hermann novelties are designed in a modern design center with the involvement of specialists from French design bureaus.

The Hermann gas wall-mounted boiler is a serious product, stuffed with electronics that controls all the main parameters. But we encountered a breakdown that did not "fit" into the instruction manual.

Signs of a malfunction of the Hermann boiler

- When switching modes to the "Summer" mode, the boiler does not switch to hot water. In the "Winter" mode, the boiler "does not see" a request for hot water (opening a tap) and does not start a shutdown circulation pump for heating.

- In the "Winter" mode, when the DHW tap is opened, the heating circuit is not turned off and the system "takes" hot water from the heat exchanger of the heating system.

At the same time, the electronics "does not see" a malfunction. Light indicators show the working status.

A set of symptoms of a malfunction indicates the place where the mode switching occurs - the flow sensor. At the inlet pipe cold water in the heat exchanger, the only element associated with electricity is installed - a reed switch, the control element of which is a float valve with a magnet (setting element). There is nothing to break in this sensor.

It turned out that this is not the case at all. The reed switch of the sensor is triggered when a magnet approaches it, but, for unknown reasons (weak magnet, low sensitivity of the reed switch or something else), the reed switch stops responding to the approach of the valve magnet when hot water is requested.

You can buy a flow sensor separately, but the reason may be in the valve magnet and not everyone has a service center nearby.

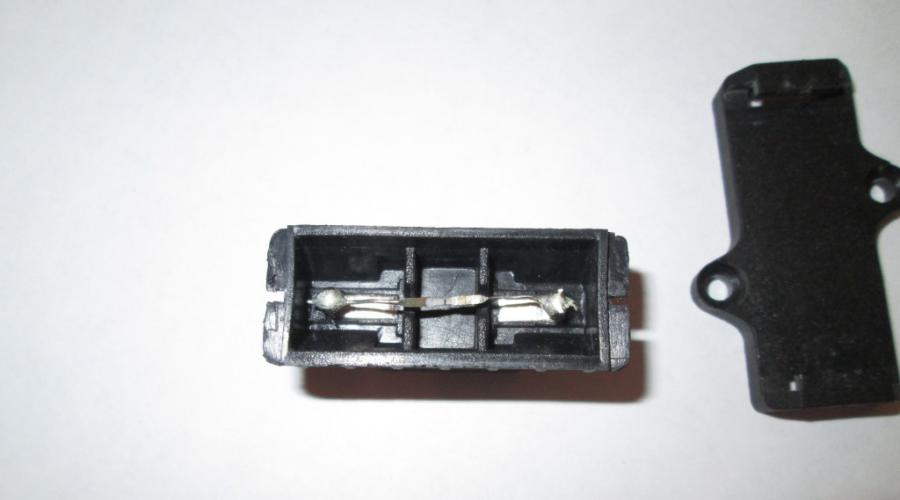

Big life experience our specialists came up with the idea to use a reed switch from an alarm sensor IO 102-14. According to their characteristics (sensing distances: closed - 12 mm, open - 45 mm and operating voltage- 1…72 V) and overall dimensions it is not much different from the "native".

We disconnect the connector from the sensor, remove it from the valve (2 screws) and disassemble the sensor. All we need from him is a foundation.

We fix the sensor from IO 102-14 (with wires) to the base. The mounting method does not matter (we glued it to eliminate the possibility of the valve “sticking” on the metal fastener), but it is desirable to align the center lines of the new reed switch with the position of the old one.

Because we don’t know if the reed switch will work from the “native” magnet, then we carefully change it to a magnet from the broadcaster. The weight of the magnet does not matter, because. the valve is lifted by the pressure of the water.

RosTeploEnergia provides services for the repair of modern boiler equipment. Italian boilers Hermann are in great demand in Russia due to excellent performance characteristics and high energy efficiency. However, over time, even the most reliable equipment needs to be repaired.

The most common causes of breakdowns are associated with the features of operation and do not depend on the quality of the equipment. These include:

- unprofessional installation of the boiler;

- wrong setting modes of heating and water heating;

- frequent power outages;

- use of hard water, etc.

If a malfunction or malfunction is detected, it is important to contact specialists as soon as possible. The sooner this is done, the cheaper the repair will cost and the longer the equipment will last. Contemporary boiler equipment is a complex automated systems which should only be operated by experienced personnel.

Contact "RosTeploEnergia"

RosTeploEnergia is one of the leaders in the sale of spare parts and repair of Hermann boilers. Our specialists have a great practical experience maintenance of boiler equipment of any type. Modern equipment and software allow for accurate diagnosis and repair of any complexity. You can learn more about the repair of Hermann heating equipment from the company's employees.

The cost of repairing Hermann heating boilers

|

Name of works |

Note |

Price, rub.) |

|

|---|---|---|---|

|

Replacing the ignition and control unit |

|||

|

Replacing the built-in boiler in boilers |

|||

|

Fan Replacement |

|||

|

Replacement, adjustment of the ignition and ionization electrode |

|||

|

Pump replacement |

|||

|

Expansion tank replacement |

2 800 | ||

| Replacing the boiler heat exchanger | 3 500 | ||

| Replacement of combined gas fittings | 4 900 | ||

| 1 300 | |||

| Cleaning soot in the boiler | 3 000 | ||

| EMK (complex) | 1 750 | ||

| Prevention wall boiler(non-condensing) | 4 000 | ||

| Prevention of floor boiler | 30 to 60 kW | 5 000 | |

| Prevention instantaneous water heater | PCS. | 3 000 | |

| Boiler burner cleaning and flushing | 2 200 | ||

| Cleaning the tankless water heater burner | 1 200 | ||

| Igniter cleaning | 1 150 | ||

| Thermocouple cleaning | 1 500 | ||

| Cleaning the thermogenerator | |||

|

Cleaning the ignition and ionization electrodes |

|||

|

Cleaning the flow sensor |

|||

|

Cleaning the igniter nozzle |

|||

|

Cleaning the water filter |

|||

|

Pumping pressure in expansion tank |

|||

|

Reconfiguring the boiler for natural / liquefied gas |