Drywall - material properties, advantages and disadvantages, areas of application. Main characteristics of plasterboard sheets of all types Plasterboard sheets GKL Knauf technical characteristics

Read also

There are plasterboard sheets of different parameters on the market. It is necessary to know their properties, which play a decisive role in the choice. For example, by using ordinary drywall when decorating a warehouse for flammable substances, we risk, after the first fire, receiving significant damage inside the room. And all because we did not know what characteristics drywall has. Read our article on how to recognize fire-resistant drywall and much more.

What is this article about?

A few words about gypsum board

Drywall is one of the most popular materials for interior decoration. Arches, columns, ceilings and other things are made from it. It is highly in demand on the market due to its low cost, ease of processing, harmlessness and sound insulation properties.

Plus, it’s very dense, durable, and lightweight, which makes it easy to transport and install, despite its size. After work there is a minimum of waste left.

Ease of use

To work with drywall, you can get by with the tools that are in every home. The special properties of drywall are that when wet, it bends according to the builder’s wishes, and will remain that way after drying.

It is convenient to make partitions from drywall of any size - it takes much less time than if we did it from foam blocks or bricks. In addition, drywall hypoallergenic.

Flaws

The material is thin, not waterproof, and plasterboard, unlike gypsum fiber, has low strength - if you hang something heavy, you can collapse the entire wall.

Device

Inside there is plaster with additives, outside there is a cardboard lining attached with a special glue. Depending on the properties of the drywall, dimensions may differ from standard ones.

Drywall weightand mass. Have you ever wondered - “how much does a sheet of drywall weigh”? The weight of drywall is no more than 1 s (kilograms per square meter). Fire-resistant plasterboard sheets - not< 0,8 и не < 1,06 s.

Thickness. The size of the plasterboard sheet is not so important; in the end, it can be cut the way you want, the main thing is the thickness. It comes in different profiles - 6, 9, 12 mm, it does not depend on the place where we buy gypsum boards - on the market or in a specialized store. GKL 6 mm is used for bending sheets using the “wet method” - creating products with curves (designer fantasies, niches, arches). GKL 9 mm is usually used for ceilings, and is also used for bending sheets using the “dry method”. They make beautiful ceilings to reduce the weight of the structure. The thickest ones are used by builders to create partitions and wall cladding. They also create racks and columns, the height of which will indicate the status of the owner. There is little demand for other sizes; non-standard gypsum boards are rarely of interest to buyers.

Classification by area of application

Depending on the area of application and properties, there are:

Drywall for walls

The size of the plasterboard sheet has a length of 2.3 or 2.5 m. Width - 1.2 m. Plasterboard thickness - 12.5 mm, gray cladding. Blue markings.

Plasterboard for ceiling

It is used for covering ceilings, creating arches, niches, and two-level ceilings. The size of the plasterboard sheet differs from the previous one only in the thickness of the plasterboard - it is 9.5 mm (which is why it is cheaper than the previous type).

Don't try to use drywall on walls on ceilings. It will sag under its own weight and everything will have to be redone.

Moisture resistant drywall

Used for finishing rooms with high humidity. It has standard dimensions of a plasterboard sheet, the thickness of the plasterboard is standard, the marking is blue, but the color of the sheet is different - it is green. If you cover it with waterproofing material, the service life of drywall will increase. The dimensions of the drywall guides depend on the area of application.

Fireproof plasterboard

This gypsum fiber material is used with high fire safety requirements and increased flammability. The size of drywall is almost standard, only it differs in length - up to 2, 3, 2.5 m. The color is gray, the markings are red. The property of non-flammability, as with all products like gypsum board, is present due to the gypsum fiber composition of additional additives. This effect is achieved by adding gypsum fiber material, which is difficult for fire to reach.

By the way, cardboard of any gypsum board and drywall, regardless of size, does not burn, but only chars. But only this type of core remains in the same shape after a fire.

Flexible arched plasterboard

The size of the plasterboard is 3 m long, standard width, the highlight is the thickness - only 6.5 mm. Gray sheets. This type of gypsum board is used to create flexible forms; it has the smallest thickness among all types of gypsum plasterboard, so it can bend to smaller radii. The greatest bending is achieved by piercing the surface with a needle roller and further wetting the surface. With this treatment, water penetrates into the sheet, the wetted gypsum becomes soaked and bends perfectly.

Resistance to external influences

Flexural strength. The maximum load (in kg) that drywall cannot withstand determines its strength. If the size of a plasterboard sheet is 10 mm thick, then the sheet should withstand 15 kg, if the standard size of plasterboard with a thickness of 11 - 18 mm is 18 kg.

Flammabilitydrywall. Drywall is not flammable and resists fire for a long time. But if the flame reaches the core, it crumbles (with the exception of fire-resistant sheets).

Regarding GOSTs, they are:

- flammability - G1;

- flammability – B2;

- ability to generate smoke – D1;

- toxicity - T1.

Frost resistance. Low temperature does not affect the gypsum plasterboard, and does not cause much damage to it. But the material is created for interior work, so room temperature is the ideal environment!

Water absorption and softening coefficient. Moisture-resistant gypsum boards can absorb no more than 10% of liquid. The softening coefficient (Kp) is calculated by dividing the tensile strength in a water-saturated state (Rн) by the tensile strength in a dry state (Rс). The strength of sheets of conventional gypsum board when interacting with moisture is significantly reduced. Their softening coefficient is approximately 0.45. This indicates the low strength of the materials after getting wet and a short service life after that. For waterproof materials the coefficient is 0.8.

Interesting video “Crash test of drywall”:

Thermal conductivity. The size of the sheet is plasterboard, which perfectly retains heat, making it frost-resistant. The thermal conductivity coefficient of plasterboard is from 0.22 to 0.35 W/ (m×K). This means that gypsum board is excellent for improving thermal insulation. It's fast, inexpensive and, most importantly, effective. By the way, make a gap of 3-10 mm, you will create another air layer that will retain heat.

One option for improving thermal conductivity is to add insulation to the cavity between the wall that we are insulating and the plasterboard sheet. Such insulation can be mineral wool or polystyrene foam. The thickness of the thermal insulation layer is always a compromise - the thicker it is, the warmer it is, but the smaller the living area of the rooms.

GKL. Do you want to hang a shelf on a plasterboard wall? The load should not exceed 30 kg per square meter, including the shelf, otherwise you will simply destroy the gypsum board wall. You need to screw it on with screws, forget about nails!Varieties of edges

Marking

To find out the characteristics and groups of thin drywall that interest us, you need to know and be able to decipher the conditions indicated on the sheet.

- Designation by letter of sheet type (A or B);

- information about the group to which the plasterboard sheet belongs;

- longitudinal edge information;

- dimensions of drywall sheets in millimeters;

- manufacturing standard - GOST 6266-97.

Here, for example, is the size of KNAUF drywall “A”. Its length is 2500 mm, the width is standard, the edge is semicircular, the thickness of the plasterboard is 9 mm. These are the dimensions of Knauf gypsum boards. As you can see, the plasterboard standard sheet size applies to KNAUF.

What the marking looks like:

Drywall- This is one of the most popular modern finishing materials.

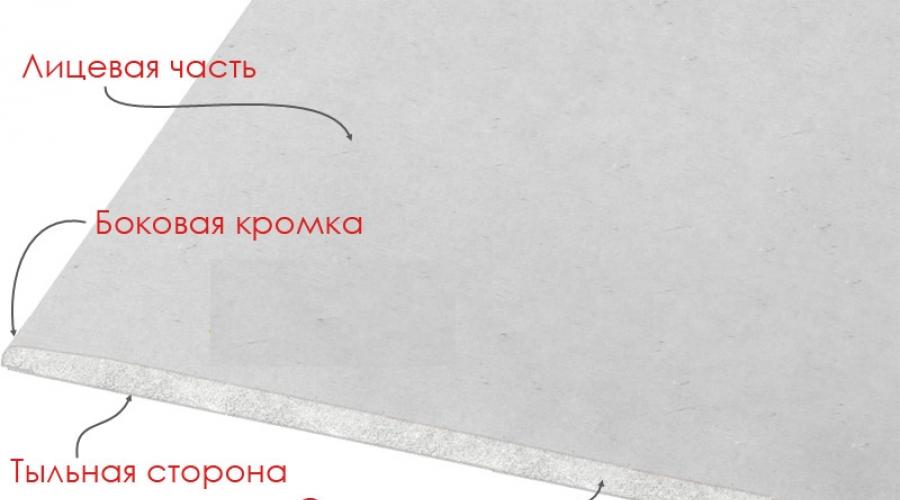

Drywall consists of three layers: two outer layers of reinforced cardboard and an inner layer of gypsum, photo 1. Various additives are added to the composition of gypsum, which make it possible to obtain different types of drywall with special properties.

Using plasterboard, you can level the surface of walls and ceilings, create an original design design for walls and ceilings of varying complexity, photo 2. Using drywall you can hide communication passages, electrical wiring, etc.

Classification of drywall: main types, sizes and characteristics

Plasterboard sheets are produced in the following main sizes:

- 1200 × 2000 mm;

- 1200 × 2500 mm;

- 1200 × 3000 mm.

Depending on the thickness of the sheet and its purpose, plasterboard has the following name:

- arched – 6.5 mm;

- ceiling - 9.5 mm;

- wall – 12.5 mm.

IN table 1 The main types of drywall and their sizes (thickness of drywall) are presented.

Table 1

Dimensions of drywall sheets

|

Sheet size, mm |

Weight of 1 m 2 sheets, kg |

|

|

1200×2500…4000×9.5 |

||

|

1200×2500…4000×12.5 |

||

|

1200×2500…4000×15 |

||

|

600×2000…3500×9.5 |

||

|

1200×2500…4000×9.5 |

||

|

1200×2500…4000×12.5 |

||

|

1200×2500…4000×15 |

||

|

1200×2500…4000×12.5 |

||

|

1200×2500…4000×15 |

||

|

1200×2500…4000×12.5 |

||

|

1200×2500…4000×15 |

Let's look at the main types of drywall

- plasterboard sheet (GKL) or ordinary plasterboard, sheets are produced in gray color. Marked in blue ink. Designed for installation of walls and ceilings in dry rooms with low humidity.

- fire-resistant plasterboard sheet (GKLO. GKLO gypsum contains special additives that increase its fire resistance. Designed for rooms with high temperatures or with an increased level of fire hazard (attics, walls near fireplaces). Such drywall can withstand up to 20 minutes of exposure to an open flame. The color of the drywall is gray or beige, marked in red ink.

- moisture-resistant plasterboard sheet (GKLV) designed for rooms with high humidity (kitchen, bath, toilet, swimming pool) and can withstand constant exposure for 10 hours to air with a relative humidity of 82...85%. Such drywall is resistant to a humid environment, provided that the front side is treated with waterproofing and waterproof materials (ceramic tiles, primer, protective coatings). Water absorption of GKLV is no more than 10%. The moisture-resistant drywall contains silicone granules that reduce the hygroscopicity of gypsum, and can also contain antifungal and hydrophobic additives. The plasterboard is green, the markings are made in blue ink.

- moisture-resistant and fire-resistant plasterboard sheet (GKLVO)– such drywall combines the properties of gypsum board and gypsum board. Green plasterboard, marked in red ink.

- gypsum fiber sheet (GVL). The main difference between such drywall and plasterboard is the addition of cellulose to the gypsum composition, which significantly increases the strength characteristics. For example, a nail hammered into drywall (GVL) can withstand a weight of 30 kg or more.

- façade plasterboard sheet (GKLF) Designed for facade cladding of buildings, capable of withstanding atmospheric influences. GKLF brand plasterboard is produced in yellow color.

Brief information about the types of gypsum board is given in Table 2.

Brief information about the types of gypsum board is given in Table 2.

table 2

Types and markings of plasterboard sheets

|

Type of drywall (brand) |

Application area |

Leaf color |

Marking color |

|

Regular (gypsum plasterboard) |

Finishing walls and ceilings; construction of non-load-bearing partitions |

||

|

Moisture resistant (GKLV) |

Finishing walls and ceilings of kitchens, bathrooms; construction of partitions in rooms with high humidity |

||

|

Fire resistant (GKLO) |

Finishing of air ducts and communication shafts; finishing of metal structures in civil buildings |

||

|

Moisture-resistant (GKLVO) |

Finishing of structures to achieve the required degree of fire resistance in wet rooms (kitchens, bathrooms, bathrooms, baths, saunas, etc.) |

There is also a classification of drywall according to the type of edge

- Straight edge (PC or SK). With this edge there is no need to seal seams.

- Refined edge (UK or AK). The joints of such drywall are additionally reinforced with special tape and then puttied.

- Semicircular edge on the front side (PLC or HRK). HRK joints are only puttied.

- Semicircular and thinned edge on the front side (PLUK or HRAK). The joints of such drywall are additionally reinforced with special tape and then puttied.

- Rounded edge (ZK or RK). Drywall joints with a rounded edge are only puttied.

Classification of drywall by purpose

Let's consider the classification of drywall according to its purpose.

Plasterboard ceiling intended for finishing (cladding) ceilings, installing suspended ceilings in dry rooms with relative humidity up to 70%. Basic properties:

- non-toxic material;

- no smell;

- not electrostatic;

- hygroscopic material - capable of absorbing excess moisture and releasing it when there is a lack of it in the room.

Wall plasterboard. Designed for cladding walls of premises, installing interior partitions and other construction work on furnishing premises.

Advantages of using drywall:

- The labor intensity of work is significantly reduced.

- The lightweight design reduces the overall load on the foundation.

- Environmentally friendly material.

Arched plasterboard. Designed for arched design solutions of any complexity, since 6.5 mm thick plasterboard can bend well. So, for example, from such plasterboard, you can easily make an arched doorway, wave-shaped partitions, etc. I would like to note that plasterboard bends better when it is pre-moistened. Here are some data on the possibility of bending drywall of various thicknesses:

- thickness 6.5 mm: moistened sheet - bending radius of at least 300 mm, dry sheet - bending radius of at least 1000 mm;

- thickness 9.5 mm: dry sheet – bending radius of at least 2000 mm;

- thickness 12.5 mm: dry sheet – bending radius of at least 3000 mm.

The disadvantages of drywall are as follows:

- The strength of the material is relatively low; with significant mechanical damage, dents and even breakdowns are formed.

- Drywall doesn't breathe.

- It is not possible to hang heavy cabinets and shelves on a plasterboard wall.

- Plasterboard sheathing takes up a lot of usable space in the room.

- Rodents can live between the plasterboard sheathing and the wall.

Useful information about drywall

- In table Figure 3 shows the weight and area of different sheets of drywall.

Table 3

Weight characteristics of plasterboard sheets

|

Drywall sheet size (sheet area) |

Weight of plasterboard sheet, kg with its thickness |

||

|

6.5 mm |

9.5 mm |

12.5 mm |

|

|

1200x2000 mm (2.4 m2) |

|||

|

1200x2500 mm (3 m2) |

|||

|

1200x3000 mm (3.6 m2) |

|||

- Symbols in the marking of plasterboard sheets. Marking is done on the back (rear) side. For example, consider the symbol for drywall:

GKLV-A-ZK-2500×1200×12.5 DIN 190 - 81

Explanation of sheet markings:

- GKLV– moisture-resistant plasterboard sheet;

- A– drywall group according to dimensional accuracy. They produce two groups A and B (A – high accuracy of geometric size);

- ZK— edge type;

- 2500 × 1200 × 12,5 – sheet dimensions (length × width × thickness, mm);

- DIN 190— 81 – normative document, standard.

Near the main marking there is also information about the manufacturer and production date.

- Bending strength of plasterboard sheets depending on thickness:

Table of flexural strength of plasterboard depending on its thickness

Publication prepared by an expert

Konev Alexander Anatolievich

Drywall, also known as gypsum board, gypsum building boards (GSP according to GOST 32614-2012) or gypsum board, is a combined material. Between two layers of special cardboard there is a gypsum core with various additives depending on the properties of the sheet. The main area of use of plasterboard is residential and non-residential premises for various functional purposes. Construction of partitions, wall cladding and suspended ceilings, in a word, using technologies that do not involve wet processes and, as a result, require quick readiness for finishing.

The popularity and widespread use of the material is due to the unique combination of affordable cost, ease of application technology and excellent performance characteristics. The latter include low weight, the ability to select sheets of different sizes and properties, comfort and practicality of operation, etc. An important bonus is the convenience of placing utility lines, as well as heat and sound insulation materials under the gypsum board layer.

Advantages

HISTORY OF GYPSUM CARDBOARD

-

1881-1910

The first analogue of modern plasterboard was invented by the American engineer August Sackett, who invented and produced a 5 mm thick material consisting of 10 layers of cardboard glued together with gypsum mortar. The patent for the new technology was issued at the end of the century before last - in 1881.

Drywall acquired a more familiar appearance to modern people at the beginning of the 20th century through the efforts of Stefan Kelly and Clares Utzmann. The first patented a material consisting of two layers of cardboard with hardened gypsum between them, and the second came up with a folded edge of the sheet, which made the use of plasterboard more convenient.

The first factory engaged in the mass production of plasterboard was opened in 1917 in England. However, for several more years the material was used in construction only to an extremely limited extent.

-

1932-1958

A key role in the rapid growth of the popularity of drywall was played by the creation in Germany in 1932 of a new company for the production of various building materials and structures. Since two Knauf brothers, Alfons and Karl, took part in this, the company quite expectedly began to be called Knauf.

The merit of the KNAUF company lies not only in the fact that thanks to the active implementation of new production technologies, the volume of plasterboard produced and the quality of the material were significantly increased. The company's specialists constantly worked to improve the design of gypsum board sheets in order to further improve performance properties while reducing manufacturing costs.

As a result, in 1958, with the direct participation of Alfons Knauf, the technology for the production of plasterboard was introduced in the form in which it is still produced. Naturally, later changes were also made, for example, to the composition of the gypsum mortar or the density and thickness of the cardboard used, however, they were of a cosmetic nature. In fact, the material that is called plasterboard today appeared precisely in 1958 at the KNAUF factory.

-

1958-1970

After this, the material conquered construction markets throughout the developed world within one to two decades. The Soviet Union was no exception, acquiring several Knauf technological lines under Lend-Lease terms.

However, in the USSR in those years there was no serious production culture, which became the reason for the production of extremely low quality products. Ultimately, the current situation ceased to suit both the Soviet leadership and the German manufacturer, who sought to expand their own sales markets.

-

1970-1991

As a result, in the 70s of the 20th century, KNAUF bought several factories from the Soviet Union and began producing drywall and other materials in the USSR, but with a European level of quality. The material almost immediately began to be in high demand on the market, which confirmed the correctness of the policy pursued by KNAUF. This practice was expanded after the collapse of the Union and the creation of the Russian Federation.

-

Nowadays

Currently, 14 KNAUF enterprises are productively operating in Russia. Another 11 factories are located in other CIS countries. This allows the company to maintain a leading position in the building materials market, constantly increasing production volumes.

It is important to note that today different types of plasterboard are used not only for cladding partitions and ceilings, but also as a structural material in a wide variety of KNAUF systems. A large range of such solutions, including ready-made systems of partitions, ceilings, cladding of building structures and structures, facades and even floors, is listed on the official website of the manufacturer.

Product catalog

SURFACE QUALITY STANDARDS

Complete systems

Specifications,

Comparison of KNAUF plasterboard sheets

| Type of drywall | Sheet length and width (m) | Thickness (mm) | GKL area (m2) | Weight, kg) | Characteristics |

|---|---|---|---|---|---|

| Knauf-sheet Sapphire (GSP) | 2.5x1.2 | 12,5 | 3 | 37,5 | Cardboard color blue-gray, marking color black, edge PLUK |

| KNAUF moisture-resistant sheet (GSP-N2) | 2.0x1.2 2.5x1.2 2.5x1.2 3.0x1.2 |

12,5 12,5 9,5 12,5 6,5 |

2,4 3 3 3,24 3 |

20,5 25 22 28 18 | Green cardboard, black markings, hydrophobic additives in the core, PLUK edge |

| KNAUF-list (GSP-A) | 2.0×1.2 2.5×1.2 2.5×1.2 3.0×1.2 2.5×1.2 |

12,5 12,5 9,5 12,5 6,5 |

2,4 3 3 3,24 3 |

20,5 25 22 28 18 | Gray cardboard, black markings, PLUK edge |

Drywall, gypsum board, is a rectangular sheet with a gypsum core, lined on both sides with cardboard, which, in addition to a smooth surface, gives a reinforcement effect, which makes the sheet more durable. The most common sizes are width 1200-2500 mm and thickness from 0.8 mm. A very convenient modern material for leveling walls and ceilings, as well as building false walls, partitions, arches and other intricate structures.

Structure of a plasterboard sheet: 1 - gypsum, 2 - cardboard.

Drywall is a material with unique properties

The physical and hygienic properties of plasterboard make it an ideal material for finishing residential premises.

Gypsum does not contain any toxic substances, so its use is also applicable to the renovation of children's rooms. It perfectly absorbs water from the air when the room is humid, and perfectly releases moisture in a dry room, maintaining approximately the same level of humidity. For this feature it is called breathable material. In addition, gypsum plasterboard also has soundproofing properties, and if you line sewer system pipes with it, then in combination with additional materials you can achieve complete silence and absolutely not hear the “happy waterfall” through these very pipes. This way you can hide all such communications, various heating pipes, electrical wiring and alarms, air ducts and ventilation corrugations and much more.

Work associated with gypsum plasterboards is mostly dry, which eliminates the leaving of mountains of debris and dirt. Based on its technical characteristics, we can add that the material is quite light and pliable, and this, along with similar universal cladding materials, gives plasterboard its undeniable leadership. The sheets can be given absolutely any shape, limited only by the designer’s thoughts. GCR bends easily, is sawed with a regular hacksaw, and straight lines can be cut using a regular stationery knife.

A smooth cardboard surface is an ideal field for wallpapering. Virtually no additional surface treatment is required. The only thing is that you should coat the screw heads with an anti-corrosion compound to avoid rusty spots on the wallpaper in the future. GCR can be simply whitened or painted with ordinary oil and nitro enamels in the same way as plastered surfaces.

A simple and easy form of constructing a frame from profiles and a large working surface area of the material can significantly reduce the time required to complete the work. For example, leveling walls will take 2-3 times less time than plastering and puttying. Gypsum has lower thermal conductivity than plaster, and makes it possible to insulate walls from the inside, which again means heat saving and reduced energy consumption due to the fact that less energy will be required to heat the room. This is quite relevant for our harsh climate. And vice versa, plaster, while retaining the heat of the summer heat, will not let it into the room.

Return to contents

Relative disadvantages of drywall

Why relative disadvantages? It's simple! Any obvious shortcomings can easily be compensated for by simple design modifications or various modern “bells and whistles”, the use of which greatly facilitates the work process. But any material has both pros and cons. The use of gypsum boards in rooms with air humidity above 90% is undesirable. Drywall, like a sponge, absorbs moisture, and over time, due to constant dampness, the sheets will begin to swell, warp and may gradually crumble at the attachment points. In such cases, moisture-resistant brands are used, but the humidity should not exceed 80% and no more than 10 hours a day.

Manufacturers use various additives that give strength to the material, but this does not completely eliminate drywall from its natural fragility. In different rooms, it is necessary to take into account the nature of future mechanical impacts and simple human factors. People may lean their elbows or something heavy against the wall, or simply hit it. The sheets split easily, may crack or break through. Repairing holes and chips is quite problematic; you have to replace the entire screwed sheet.

However, as experts note, this fragility of the material greatly facilitates the process of installing plasterboard structures. Plaster does not need to be sawed, like plywood, boards or chipboard, it breaks off perfectly on its own, you just need to make an incision with a knife. Still, this is not the material to withstand enormous loads, so it is not recommended to level floors with it. For these purposes, a similar material is used - gypsum fiber sheets.

Often you need to mount something on the walls: paintings, lamps, shelves, and so on. An ordinary self-tapping screw or screw will not hold in plaster, and the thickness of the sheet itself is unsuitable for this type of fastener. But even here a simple innovative solution comes to the rescue - the use of special butterfly bolts. These bolts themselves are fixed on the back side of the sheet after they are inserted into the wall, and are tightened from the outside with a nut. One such fastener is designed for 15 kg of payload.

In conclusion, I would like to say that plasterboard sheets are the undisputed leader in the field of installation of various types of structures and leveling of walls and ceilings. Today, no renovation can be done without this unique material. With all its merits, it will not go out of fashion soon and will certainly only improve over time.

Introduction

The Giprok company, in its main range of plasterboard sheets, produces flexible Giprok plasterboard, used for constructing arches, figured ceilings and cladding other curved surfaces. Flexible plasterboard Giprok has a thickness of about 6 mm, and its production technology allows it to be bent without using the wet method of bending plasterboard.

- Elastic gypsum sheet Glasroc F Reflex.

- Giprok GKLD.

- Glasrock GFL.

The main flexible gypsum sheet is, undoubtedly, the Glasroc F Reflex elastic gypsum sheet. Let's start with it.

Ease of use

To work with drywall, you can get by with the tools that are in every home. The special properties of drywall are that when wet, it bends according to the builder’s wishes, and will remain that way after drying.

It is convenient to make partitions from drywall of any size - it takes much less time than if we did it from foam blocks or bricks. In addition, plasterboard is hypoallergenic.

Elastic, super flexible gypsum board - Glasroc F Reflex

Gyprok plasterboard sheet is a product of one of the divisions of the Saint-Gobain concern. Sheets are made from gypsum binder, cardboard and additives. Gyprok sheets have a rectangular shape.

The ends of the sheets are cut evenly from the short edges and lined with cardboard from the long edges of the sheet. Long edges can be straight or tapered.

In this article we will look at the types and characteristics of Giprok plasterboard sheet.

I will list the main names of gypsum board sheets:

- Giprok gypsum board - Standard plasterboard sheet Giprok

For installation of interior partitions, wall cladding and suspended ceilings. For dry and normally damp rooms.

- Giprok GKLV - Moisture-resistant plasterboard sheet Giprok

For installation of interior partitions, wall cladding and suspended ceilings, in damp rooms, not excluding dry and normally damp rooms.

- Giprok GKLU - Reinforced plasterboard sheet Giprok

For installation of interior partitions, wall cladding and suspended ceilings. For work in dry and normally damp rooms and with increased noise protection and performance characteristics, for example, suspended equipment, heavy lamps.

- Giprok GKLVU - Moisture-resistant reinforced plasterboard sheet Giprok

For installation of interior partitions, cladding of walls and suspended ceilings in rooms with dry, normal and high humidity with increased performance characteristics.

- Giprok GKLO - Fire Resistant Plasterboard Sheet Gyprok

For installation of interior partitions, cladding of suspended walls and ceilings in dry and normal humidity conditions for increased fire resistance of structures.

- Giprok GKLZ - Windproof plasterboard sheet Giprok

For windproof cladding of external walls.

- Giprok GKLD - Designer plasterboard sheet Giprok

Unique plasterboard sheet Giprok for curved surfaces and volumetric interior elements. It bends easily and does not require special bending devices.

| Edge type | Designation | Length, meter | Sheet width, meter | Thickness, mm |

| PC | GKL Giprok | 1,2 | 9,5;12,5 | |

| PC | GKLV Giprok | 2,5; 2,55; 2,6; 2,7; 2,75; 3,0; 3,3; 3,6 | 1,2 | 12,5 |

| PC | GKLU Giprok | 2,55; 2,6; 2,7; 2,75; 3,0; 3,3 | 1,2 | 12,5 |

| UK | GKLVU Giprok | 2,0; 2,52; 2,6; 2,7; 2,75; 3,0 | 1,2 | 12,5 |

| UK | GKLO Giprok | 2,75; 3,0 | 1,2 | 15,4 |

| PC | GKLZ Giprok | 2,75; 3,0 | 1,2 | 9,5 |

| UK | GKLD Giprok | 2,75; 3,0 | 0,9 | 6,5 |